(→Design) |

(→Design) |

||

| Line 51: | Line 51: | ||

I synthesized the literature into a design consisting of 10 key subsystems: | I synthesized the literature into a design consisting of 10 key subsystems: | ||

== Feed water flow control == | |||

Storage of feed water and controlling the rate at which it is fed to the wicks | Storage of feed water and controlling the rate at which it is fed to the wicks | ||

== Frame/mounting == | |||

The way in which all the components are mounted and housed & the spacing between the plates | The way in which all the components are mounted and housed & the spacing between the plates | ||

== Absorber == | |||

The solar selective surface absorber that absorbs the sun | The solar selective surface absorber that absorbs the sun | ||

== Optical cover == | |||

Sitting in front of the absorber that prevents convective losses | Sitting in front of the absorber that prevents convective losses | ||

== Reflector == | |||

Mirrored surface that reflects the sun onto the absorber | Mirrored surface that reflects the sun onto the absorber | ||

== Wicking Bed == | |||

The way in which the wicks are mounted and fed feed water | The way in which the wicks are mounted and fed feed water | ||

== Insulating Panels == | |||

Side and back panels that prevent heat loss | Side and back panels that prevent heat loss | ||

== Wicks == | |||

The material for wicking the feed water down the device | The material for wicking the feed water down the device | ||

== Condenser plates == | |||

The plates that act as condensers and conductors to create the multi-effect diffusion reaction | The plates that act as condensers and conductors to create the multi-effect diffusion reaction | ||

== Distillate Collection == | |||

The way the distillate flows and is collected | The way the distillate flows and is collected | ||

Revision as of 10:44, 14 June 2017

Around 2 billion people lack access to clean drinking water across the globe and many of those live in arid and remote areas perfect for the implementation of a highly efficient, low cost, small scale solar still. The aim is for it to produce between 5-10 liters of fresh water per day in a sunny climate, enough for a small family’s needs. The design has been optimised to be lightweight, low cost, robust and user friendly. And a scale functional prototype has been built and tested.

Solar Pura is part of my honours thesis in the school of design at RMIT in Melbourne, Australia. It is the culmination of a year of research into creating technology that can empower those caught in the poverty cycle and how by open sourcing designs and solutions we can give people the means to be self sufficient and build resilience for communities in need.

Vertical multiple effect diffusion type solar stills vs basin solar stills

You can learn about the mechanics and history of solar stills here solar stills and here improving basin solar stills and here understanding solar stills. These pages have a lot of great information on how single effect basin solar stills function. This design would have to be the norm for low tech solar distillation.

After many experiments and a lot of research I decided that a single effect basin type solar still could not meet these criteria and looked towards more experimental and complex designs. That is how I came across the work of R.V Dunkle and his 1961 paper on the topic of multiple effect diffusion solar stills[1]. As well as contemporary research groups such as Hiroshi Tanaka et al from Japan[2]. As well as researchers from Taiwan national university also exploring this space [3].

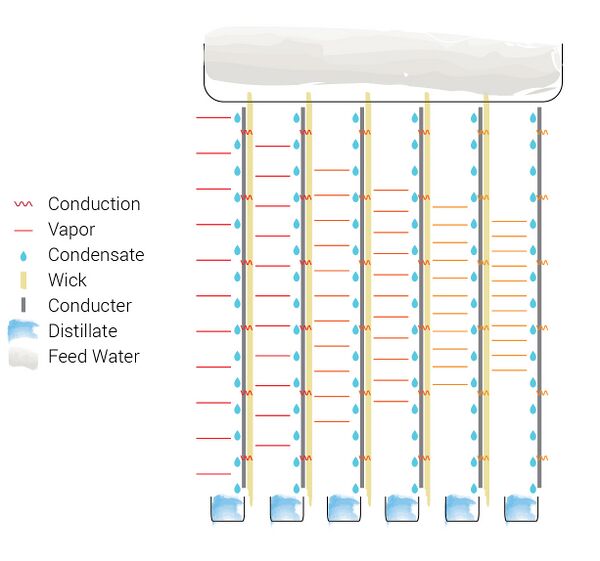

The principle behind the vertical multiple effect diffusion solar still is best described visually:

The multi effect diffusion principle works by stacking plates very close together to create different cells or 'effects' this is so that the latent heat of vaporization can be recycled multiple times before being dissipated into the atmosphere. From the diagram, Heat enters the device from the left while water is fed from above onto absorbent wicks. The wicks are laminated to one side of the conducting plate while the other side acts as the condenser. When the water on the wick is heated via conduction through the plate it vaporizes and then 'looks' for the next coldest surface to condense upon (the next plate) where it then drips down into a collection gutter that routes the distillate into a storage vessel. This process is repeated for as many effects as the device contains.

Researchers mentioned above have found that around 12 effects is optimal before returns are diminished. With 5mm spacing between plates being optimal to create the effect. This has lead to productivity for these devices to be anywhere from 20 to 40 liters per day per square meter. This is a 4 - 8 x increase in productivity compared to a single effect basin type still.

Project goals

For my project I developed 5 key design goals to focus my research around:

- low cost

- high efficiency

- mobility

- robustness

- usability.

I followed a simple iterative methodology with 3 key stages

- Research

- Experiment

- Evaluate

Design

There is very little experimental research that has been done on the construction and optimization of these devices. Most of Tanaka's designs he never built fully functional prototypes, just tested 1 effect and theorized the rest of the work. While the team at Taiwan university did build their prototypes, they were all hooked up to evacuated tube collectors that could supply a steady stream of 100 degree heat to the device. This coupling adds so much cost and complexity that in my eyes moves the technology beyond Appropriate Technology applications.

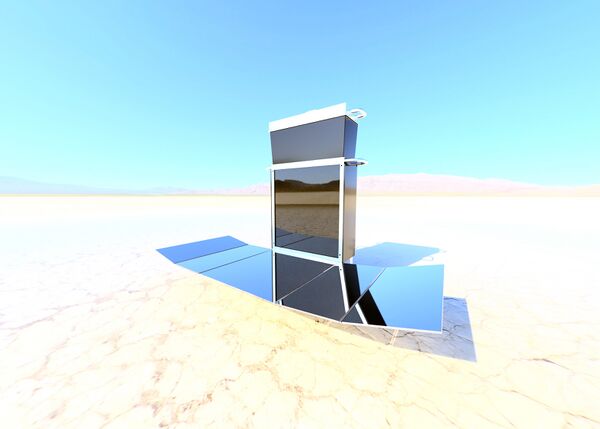

The inspiration for my design came from the Tanaka's paper from 2005 [4] where in he describes a multi effect diffuser that is coupled to a flat plate collector. I was very attracted to this idea because of its integration of the solar collector and the condenser. So from that point to move forward I used 3d CAD tools to flesh out the various systems and went about building my first prototype.

I synthesized the literature into a design consisting of 10 key subsystems:

Feed water flow control

Storage of feed water and controlling the rate at which it is fed to the wicks

Frame/mounting

The way in which all the components are mounted and housed & the spacing between the plates

Absorber

The solar selective surface absorber that absorbs the sun

Optical cover

Sitting in front of the absorber that prevents convective losses

Reflector

Mirrored surface that reflects the sun onto the absorber

Wicking Bed

The way in which the wicks are mounted and fed feed water

Insulating Panels

Side and back panels that prevent heat loss

Wicks

The material for wicking the feed water down the device

Condenser plates

The plates that act as condensers and conductors to create the multi-effect diffusion reaction

Distillate Collection

The way the distillate flows and is collected

- Sample gallery

-

Sample caption text.

-

More sample caption text. This would look better with different images. :)

-

Even more sample caption text.

Next level heading

You may need deeper level headings. Just keep adding equal signs to get that.

Costs

You may describe your costs here.

| header 1 | header 2 | header 3 |

|---|---|---|

| row 1, cell 1 | row 1, cell 2 | row 1, cell 3 |

| row 2, cell 1 | row 2, cell 2 | row 2, cell 3 |

See Help:Tables and Help:Table examples for more.

Discussion

Your discussion.

Next steps

The next steps.

Conclusions

Your conclusions.

References

- ↑ http://trove.nla.gov.au/work/34968478?selectedversion=NBD9189687 Original mutliple effect diffuser paper

- ↑ http://www.cc.kurume-nct.ac.jp/~tanakad/intro-eng.htm Hiroshi Tanaka home page

- ↑ http://www.sciencedirect.com/science/article/pii/S0011916415000983

- ↑ http://www.lenntech.com/abstracts/1421/a-simple-and-highly-productive-solar-still-a-vertical-multiple-effect-diffusion-type.html

Contact details

Get in touch at mflood124875%gmail.com (replace % with @) if you want to know more about the project or chat about solar stills. All plans are freely avaialble by request