m (→How to build) |

|||

| Line 57: | Line 57: | ||

<gallery> | <gallery> | ||

Image:Zoom Door Barrel.jpg|Fig | Image:Zoom Door Barrel.jpg|Fig 3: A common 55 gallon drum used by many in the restaurant industry was used for the first stage rotator. | ||

Image:HaspsDoor.jpg|Fig | Image:HaspsDoor.jpg|Fig 4: A door can be made using a cut out section of the barrel. In this case we attached it using weather-resistant hinges and hasps found at the local hardware store. | ||

Image:Hubs.jpg|Fig | Image:Hubs.jpg|Fig 5: The rotator barrel sits on bicycle wheel hubs, which act as efficient rolling mechanisms with small contact area. | ||

Image:Hubs.jpg|Fig | Image:Hubs.jpg|Fig 6: The bicycle hubs are supported by bicycle forks, which are welded to the frame structure below. | ||

Image:Signs_and_hinges.jpg|Fig | Image:Signs_and_hinges.jpg|Fig 7: A second stage, made out of street signs attached to the main structure, sits directly below the 55 gallon barrel. | ||

Image:Door Latch.jpg|Fig | Image:Door Latch.jpg|Fig 8: The front door of the second stage box is attached to the frame with hinges, and secured on its free end with a simple wooden latch that slides into the adjacent sidepiece. | ||

Image:3rd stage crate.jpg|Fig 9: The third stage of the system was constructed from shipping palates. | |||

</gallery> | </gallery> | ||

Revision as of 03:10, 9 December 2016

Abstract

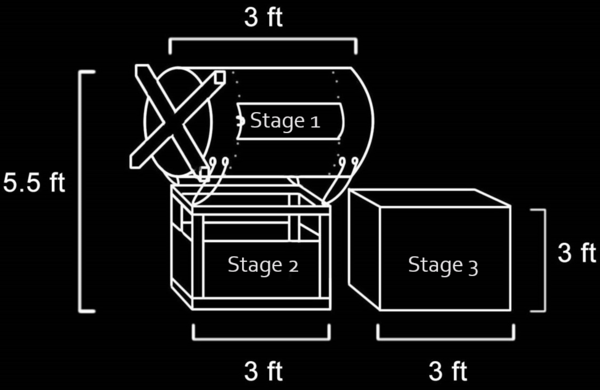

The "Three Stage Rotating System" is the design that was chosen for the improved compost system at the sanctuary. Members of the Sanctuary want an improved compost system that will be more aesthetically pleasing, desirable, and easy to use. The project should also include improvements in rat-proofing and weather resistance. Additional requirements include low embedded energy of materials, preferably reused and re purposed materials.

Background

Team Compost was created in the Fall of 2016 at the Humboldt State University's Engineering 215 class. Our client for the ENGR 215 class was The Sanctuary, a creative space for artists and people from the Humboldt community to use tools, take music classes, participate in community events, or teach a skill. A primary interest of the Sanctuary crew was sustainable living and design, so much of their yard was devoted to gardening, building, or composting. Because their old compost system was a do-it-yourself mash-up of an old metal pipe and some trash cans, the process was fairly inefficient and had the added problem of infestation by rats.

Problem statement and criteria

Team Compost's objective was to improve the Sanctuary's compost system by making the design inviting, accessible and rat-proof. The previous compost system was composed of two metal trash cans that were leaking and wet, and a finishing bin that was an old metal rusty container with a non functional lid. The project aimed to upgrade the Sanctuary's old system into a functional composter that is easy to use, easy to maintain, aesthetically pleasing and easily accessible, for a price not to exceed $400. The final design was dubbed the "Three Stage Rotating System."

Team Compost used a set of weighted criteria to best fit the design process to the Sanctuary's needs. The new compost system had to satisfy all criteria in order to last for multiple years. See below for a table that organizes the weighted criteria.

| Criteria | Importance | Constraints |

|---|---|---|

| Ease of Use | 7 | The system's use is readily apparent and easily done by most people. |

| Durability | 10 | The improved compost system should last at least two years. |

| Ease of Maintenance | 9 | Requires little to no maintenance on the part of the owners. |

| Pest-Resistance | 8 | Must keep away pests and rats. |

| Cost | 5 | Cost must not exceed $400: $100 provided by the client and $75 per team member. |

| Aesthetics | 4 | The system must look inviting enough for people to want to interact with it. |

| Accessibility | 6 | Accessible for people of most heights, ages, and ability levels. |

Description of final project

The final design met the criteria in a lasting, and effective way. Because the Sanctuary's old compost system was prone to rats, succumbing to the weather, and difficult to use, the new system had to be made of more durable materials while existing in a configuration that would repel invasion by pests. In response to these problems, the team formulated the "Three Stage Rotating System" design. The final configuration was comprised of a 55 gallon drum resting on rollers above a metal frame housing a secondary composting bin. A larger storage bin, made of wood palates, was located adjacent to the second stage. The rotating bin design solved two problems at once by elevating the freshest food-waste materials away from access by rats, and by allowing for easy turning and aeration of the compost. The rotating element was extremely important to the team and the client because stirring compost materials frequently can greatly aid in the efficiency of their break-down. Once material in the first stage was broken down enough it could easily be dumped directly into the second stage below, where it would finish decomposition before being transferred to the third stage storage bin.

-

Fig 3: A common 55 gallon drum used by many in the restaurant industry was used for the first stage rotator.

-

Fig 4: A door can be made using a cut out section of the barrel. In this case we attached it using weather-resistant hinges and hasps found at the local hardware store.

-

Fig 5: The rotator barrel sits on bicycle wheel hubs, which act as efficient rolling mechanisms with small contact area.

-

Fig 6: The bicycle hubs are supported by bicycle forks, which are welded to the frame structure below.

-

Fig 7: A second stage, made out of street signs attached to the main structure, sits directly below the 55 gallon barrel.

-

Fig 8: The front door of the second stage box is attached to the frame with hinges, and secured on its free end with a simple wooden latch that slides into the adjacent sidepiece.

-

Fig 9: The third stage of the system was constructed from shipping palates.

Costs

The table below lists materials used on the project and component costs.

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 1 | Scrap metal street post(Telespar) | Donated | 0.00 | 0.00 |

| 1 | 55 Gallon Barrel | Donated | 0.00 | 0.00 |

| 4 | Bicycle Forks | The Bike library | 10.00 | 40.00 |

| 4 | Bicycle Hubs | Donated | 0.00 | 0.00 |

| 5 | Road Signs | Arcata Scrap | 37.00 | 37.00 |

| 5 | Wood Pallets | Donated | 0.00 | 0.00 |

| 84 | Machine Screws | Ace Hardware | 00.30 | 25.20 |

| 60 | Washers | Ace Hardware | 00.25 | 15.00 |

| 2 | Hasp | Ace Hardware | 05.20 | 10.40 |

| 3 | Hinge | Ace Hardware | 07.00 | 21.00 |

| 30 | Nuts | Ace Hardware | 00.30 | 9.00 |

| Total Cost | $157.60 | |||

How to build

In order to build the compost system that was built for the Sanctuary, the steps are as follows.

Maintenance

The ongoing cost of the system on the sanctuary is expected to be relatively low compared to the cost of implementation in hours and monetary cost. Most structural components are designed to minimize maintenance due to weather resistance. Parts that must be replaced due to weather corrosion are designed around materials that the sanctuary frequently acquires for free: bicycle wheel hubs used for rollers under the tumbler must be re-greased periodically, and wire mesh under the bins must be replaced every few years depending upon corrosion of wires. The hinge and hasp on the rotator door must be re-greased frequently, and in the event of rust must be replaced every 1-2 years to ensure structural strength. Tumbler support struts may need replacement as welded joints corrode.

Schedule

The following guidelines should be followed to ensure proper functioning and longevity of the compost system.

- Daily

- Fill rotator barrel with material to be composted

- Rotate compost at least three revolutions.

- Weekly

- Remove the pin to release hasps, and empty contents into next bin.

- Use tool to mix compost in second stage.

- Monthly

- Grease bicycle hubs(rollers) and hinges and hasps to avoid corrosion.

- Yearly

- Replace wire mesh underneath the rotating barrel and second stage.

- Replace rollers

- Every 3 years

- Replace hinges.

- The rotating support may need replacement if welded joints corrode.

Troubleshooting

Consult the following table if issues arise with the system. While non-comprehensive, these steps may help improve functionality.

| Hinges or hasps are making it difficult to open. | Add grease to loosen hinges or hasps. |

| Contents of Stage 1 not emptying properly. | Rotate barrel several times with the door closed, and try emptying again. If it is still binding consider excavating by hand. |

| Rollers binding/ barrel difficult to turn. | Remove wheel hubs and re-grease bearings. |

| Stage 1 or Stage 2 becoming watery and smelly. | Mix contents daily, or as often as possible. |

Testing Results

Soon after completing work on the new system we transferred some of the Sanctuary's existing compost into the first stage tumbler. Initial load tests at 3/4 volume capacity were a resounding success. The door, the only sizeable weak point on the barrel, showed no signs of stress, and the roller supports turned smoothly and easily despite the significant weight in the tumbler. This page will be updated as the second and third stage are filled in the coming weeks.

Discussion and next steps

We expect most of the structural elements of the system to hold up extremely well to the Humboldt weather. However we expect the bamboo rod we used to hold the rotator's hasps closed and as the turning handles on the rotator to weather fairly quickly. Initially, bamboo was used because the client had a sizable stand of it growing in the yard, but in future projects an alternative may be considered for improved longevity. We suggest treatment of the current bamboo with a weather-resistant coating such as a lacquer or sealant.

See Help:Footnotes for more. Template:Reflist