This is a retractable cooling mechanism for the Recyclebot. Recyclebot can be a showcase example for OSAT - Open Source Appropriate Technology. It uses waste plastic from water bottles, soda bottles, Milk cans, etc., to turn into filament for 3D printers. This filament is comparable to the commercially available filament. With enough research, in the near future, it could perform equally and even exceed the performance of the commercially available filaments. This cooling mechanism that I designed is an upgrade to the existing design. The Recyclebot by MOST research group at Michigan Tech has modular design which gives flexibility to upgrade, improve or modify individual modules and make them better. This helped me modify the design.

The current mechanism in place does not allow for smooth operation when the Recyclebot is running. It would be tricky/frustrating, as Aubrey described, to draw the filament through and under the cooling section when the fans are attached to the Aluminum bar.

My design will enable to retract the fans backwards, draw the filament and then put them back in their place.

Bill of Materials

- PLA plastic filament

- 1 x 50mm DC Fan ($4.50 per piece in this link) >> [1]

- 3 - M4 x 40 Hex head bolts

- 3 - M4 x 0.7 - Hex nuts

- 6 x 1/2" sheet metal screw

Tools needed

- MOST Delta RepRap or similar RepRap 3-D printer

- Precision Knife - to shave off the support material.

- 4mm Allen Key Wrench

Skills and knowledge needed

- 3D-Printing knowledge

- Ability to use CAD softwares (FreeCAD, OpenSCAD, Blender / others)

- Ability to use a slicer program like Cura.

Technical Specifications and Assembly Instructions

FreeCAD files and printable stl files

- FreeCad File >> File:Both parts.FCStd

- Download the.stl files available on YouMagine. --> [2]

Print Instructions

For all printed components

- Material: PLA

- Layer height: 0.2 mm/s

- Shell thickness: 0.8 mm/s

- Infill Density: 20%

- Print Speed: 50 mm/s

- Printing Temperature: 204 C

- Supports: Everywhere

- Support Density: 15%

- Total Printing Time: 1.5 hours

- Assembly time: Atleast 5 mins.

Assembly Instructions

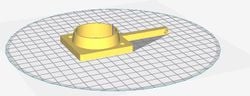

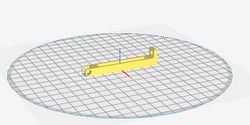

Using the.stl files above, 3-D Print the parts in following orientations.

- After the prints are done and taken off the print bed, use a precision knife to gently shave off the supports in the holes.

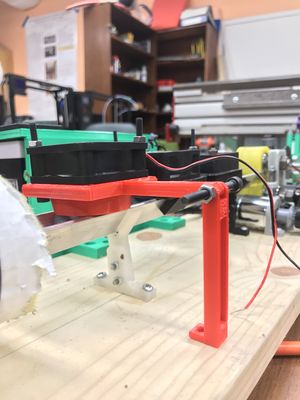

- Mount the 50mm DC fan on the fan mount using two M4X40mm hex head bolts on the diagonal ends and secure them with the nuts. The sticker side of the fan should be facing upwards.

- Assemble the pillar and the fan mount using a M4X40mm hex head bolts and nuts. You can use any other available bolts. But make sure to increase or decrease the screw hole diameter on the parts.

- Using a 6X1/2" sheet metal screw, attach the whole mechanism on the wooden board of the Recyclebot.

<<< Assembled mechanism

Now you have one fan mounted on the mechanism. You will need at-least 3 fans. So, you could repeat all these steps for 3 different times, so that you will have 3 fans in your cooling section.

Common Problems and Solutions

- Do not print the parts vertically. Print them horizontally with their flat sides on the print bed.

- Be careful while removing the support material in the holes. You could damage the holes if not careful

Cost savings

- Cost to build $5.50, $16.50 for 3 such mechanisms.

- Filabot Fan Cooling: $649.00 - https://www.filabot.com/collections/filabot-core/products/filabot-airpath

- Savings of $632.50 or 98%

Benefited Internet Communities

== References ==[1]

- ↑ Elsevier paper: RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament Available: https://www.sciencedirect.com/science/article/pii/S2468067218300208