Sophivorus (talk | contribs) m (Text replacement - "{{#widget:YouTube\|id=([^}]+)}}" to "{{Video|$1}}") |

Sophivorus (talk | contribs) m (Text replacement - "| affiliations = " to "| organizations = ") |

||

| (77 intermediate revisions by 13 users not shown) | |||

| Line 1: | Line 1: | ||

[[File:Recyclebotrep.png|thumb|[[RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament]]]] | |||

{{Project data | |||

| status = Designed, Modelled, Prototyped, Verified | |||

| verified-by = MOST | |||

| cost = USD 700 | |||

| location = Michigan, USA | |||

}} | |||

{{Device data}} | |||

{{FAST notice}} | |||

{{MOST}} | {{MOST}} | ||

{{ | |||

{{Recyclebot menu}} | |||

A '''RecycleBot''' is a [[waste plastic extruder]] that creates [[3-D printer]] filament from waste plastic and natural polymers. | A '''RecycleBot''' is a [[waste plastic extruder]] that creates [[3-D printer]] filament from waste plastic and natural polymers. | ||

Notice: Check out the new [https://arxiv.org/ftp/arxiv/papers/2012/2012.00191.pdf camera based diameter sensor] | |||

Why it is needed [https://www.filamentive.com/the-3d-printing-waste-problem/ Filamentive survey] | |||

{{ | == RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament == | ||

{{Main|RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament}} | |||

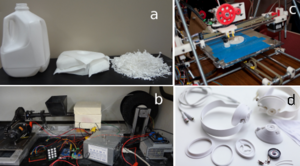

In order to assist researchers explore the full potential of distributed recycling of post-consumer polymer waste, this article describes a recyclebot, which is a waste plastic extruder capable of making commercial quality 3-D printing filament. The device design takes advantage of both the open source hardware methodology and the paradigm developed by the open source self-replicating rapid prototyper (RepRap) 3-D printer community. Specifically, this paper describes the design, fabrication and operation of a RepRapable Recyclebot, which refers to the Recyclebot's ability to provide the filament needed to largely replicate the parts for the Recyclebot on any type of RepRap 3-D printer. The device costs less than $700 in mate rials and can be fabricated in about 24 h. Filament is produced at 0.4 kg/h using 0.24 kWh/kg with a diameter ±4.6%. Thus, filament can be manufactured from commercial pellets for <22% of commercial filament costs. In addition, it can fabricate recycled waste plastic into filament for 2.5 cents/kg, which is <1000X commercial filament costs. The system can fabricate filament from polymers with extrusion temperatures <250 °C and is thus capable of manufacturing custom filament over a wide range of thermopolymers and composites for material science studies of new materials and recyclability studies, as well as research on novel applications of fused filament based 3-D printing. | |||

=== Source === | |||

Aubrey L. Woern, Joseph R. McCaslin, Adam M. Pringle, and Joshua M. Pearce. RepRapable Recyclebot: Open Source 3-D Printable Extruder for Converting Plastic to 3-D Printing Filament. HardwareX 4C (2018) e00026 doi: https://doi.org/10.1016/j.ohx.2018.e00026 [https://www.academia.edu/36721604/RepRapable_Recyclebot_Open_source_3-D_printable_extruder_for_converting_plastic_to_3-D_printing_filament open access] | |||

* Just the code: [https://osf.io/9hsmb/ OSF] | * Just the code: [https://osf.io/9hsmb/ OSF] | ||

== Distributed Recycling of Waste Polymer into RepRap Feedstock == | |||

[[File:Recyclebot-process.png|thumb]] | |||

=== Abstract === | |||

== | ==== Purpose ==== | ||

A low-cost, open source, self-replicating rapid prototyper ([[RepRap]]) has been developed, which greatly expands the potential user base of [[rapid prototyper]]s. The operating cost of the RepRap can be further reduced using waste polymers as feedstock. Centralized [[recycling]] of polymers is often uneconomic and energy intensive due to transportation [[embodied energy]]. This paper provides a proof of concept for high-value recycling of waste [[polymers]] at distributed creation sites. | |||

==== Design/methodology/approach ==== | |||

Previous designs of waste plastic extruders (also known as RecycleBots) were evaluated using a weighted evaluation matrix. An updated design was completed and the description and analysis of the design is presented including component summary, testing procedures, a basic [[life cycle analysis]] and extrusion results. The filament was tested for consistency of density and diameter while quantifying electricity consumption. | |||

==== Findings ==== | |||

Filament was successfully extruded at an average rate of 90 mm/min and used to print parts. The filament averaged 2.805±0.003mm diameter with 87% of samples between 2.540± 0.003mm and 3.081± 0.003mm. The average mass was 0.564 ± 0.001 g/100mm length. Energy use was 0.06 kWh/m. | |||

{{Video|3Xpsv3IRk_Q|3DPI.tv on Recycling with Recyclebot}} | |||

==== Practical implications ==== | |||

The success of the Recyclebot further reduces RepRap operating costs, which enables distributed in-home, value added, plastic recycling. This has implications for municipal waste management programs as in-home recycling could reduce cost and greenhouse gas emissions associated with waste collection and transportation as well as the environmental impact of manufacturing custom plastic parts. | |||

==== Originality/value ==== | |||

This paper reports on the first technical evaluation of a feedstock filament for the RepRap from waste plastic material made in a distributed recycling device. | |||

=== Source === | |||

''''' | Christian Baechler, Matthew DeVuono, and Joshua M. Pearce, "[https://dx.doi.org/10.1108/13552541311302978 Distributed Recycling of Waste Polymer into RepRap Feedstock]" ''Rapid Prototyping Journal,'' '''19'''(2), pp. 118-125 (2013). [https://www.academia.edu/2643418/Distributed_Recycling_of_Waste_Polymer_into_RepRap_Feedstock open access] | ||

==Recyclebot evolution== | == Recyclebot evolution == | ||

Full technical information, BOMs and build instructions found at the links below. Also when designing consider [[Improving recyclebot concepts]] | Full technical information, BOMs and build instructions found at the links below. Also when designing consider [[Improving recyclebot concepts]] | ||

===[[ | === [[Waste plastic extruder|Recyclebot version 2.0 and 2.1]] === | ||

=== [[Recyclebot v2.2|Recyclebot version 2.2]] === | |||

=== [[Recyclebot v2.3|Recyclebot version 2.3]] === | |||

* 3-D printable Chain guard for the RecycleBot | |||

=== [[Recyclebot v3.0|Recyclebot version 3.0]] === | |||

* Nick's [[Filament Extruder]] | * Nick's [[Filament Extruder]] | ||

===[[Recyclebot v4.0ac]]=== | |||

=== [[Recyclebot v4.0ac]] === | |||

* Under final development now | * Under final development now | ||

===[[Recyclebot v4.0dc]]=== | === [[Recyclebot v4.0dc]] === | ||

* Under final development now | * Under final development now | ||

===[[Recyclebot v4.1]]=== | === [[Recyclebot v4.1]] === | ||

=== [[Recyclebot v5.0]] === | |||

* Under development now (NOT FULLY FUNCTIONAL) - please use [[RepRapable Recyclebot]] | * Under development now (NOT FULLY FUNCTIONAL) - please use [[RepRapable Recyclebot]] | ||

===[[RepRapable Recyclebot]]=== | === [[RepRapable Recyclebot]] === | ||

* Functional -- Recyclebot v6 | |||

=== [[RepRapable Recyclebot 6.1]] === | |||

=== RepRapable Recyclebot 6.2 === | |||

Igor Cudnik of Poznan University of Technology resolved i2c (right now working on adding it as a preproccesor instruction, and move all config to config.h file). He made also a whole new electric scheme, to make it easier for electrical newbies. Eventually he is working on CAD models to make them fully parametric and accessible from FreeCAD. | |||

All of his changes can be found on my codeberg repo: | |||

https://codeberg.org/309631/recyclebotV6.2 | |||

== Other types of RecycleBots == | == Other types of RecycleBots == | ||

* [[Fused Particle Fabrication 3-D Printing: Recycled | |||

* [[Fused Particle Fabrication 3-D Printing: Recycled Materials' Optimization and Mechanical Properties]] | |||

* The [[Plastic Bank]] has a nice semi-industrial recyclebot - [[Plastic Bank Extruder v1.0]] | * The [[Plastic Bank]] has a nice semi-industrial recyclebot - [[Plastic Bank Extruder v1.0]] | ||

* There are also several OSH tools being developed by [https://preciousplastic.com/en/machines.html | * There are also several OSH tools being developed by [https://web.archive.org/web/20191121083214/https://preciousplastic.com/en/machines.html Precious Plastic] to reuse plastic waste | ||

* You can buy a commercial open-source recyclebot called the "[http://www.filastruder.com/ filastruder]" kit for $290 and a [http://www.filastruder.com/collections/spare-parts/products/filawinder Filawinder] for $160. | * You can buy a commercial open-source recyclebot called the "[http://www.filastruder.com/ filastruder]" kit for $290 and a [http://www.filastruder.com/collections/spare-parts/products/filawinder Filawinder] for $160. | ||

* There are many other commercial filament extruders now including the [http://www.filafab.co.uk/ FilaFab], [ | * There are many other commercial filament extruders now including the [http://www.filafab.co.uk/ FilaFab], [https://web.archive.org/web/20210225150904/https://www.noztek.com/ Noztek], [http://www.filabot.com/ Filabot], [https://web.archive.org/web/20210228071355/http://www.eweindustries.com/ EWE], [https://web.archive.org/web/20210303233719/http://www.extrusionbot.com/ Extrusionbot], [http://filamaker.eu/ Filamaker] (also has shredder) and the [https://web.archive.org/web/20161016030853/http://omnidynamics.co.uk/shop/Strooder Strooder], [http://felfil.com/ Felfil (OS)], which all could potentially be used for recycling. | ||

* | * Also grinder to go with extruder (vid shows PET but no crystallization) | ||

* See collection: | * See collection: [https://www.thingiverse.com/jpearce/collections/recyclebot-and-friends http://www.thingiverse.com/jpearce/collections/recyclebot-and-friends] | ||

* Also a plastic shredder from [http://filamaker.eu/ Filamaker] used in project [http://www.projectseafood.com/ Seafood] to turn waste ocean HDPE into useful items | * Also a plastic shredder from [http://filamaker.eu/ Filamaker] used in project [http://www.projectseafood.com/ Seafood] to turn waste ocean HDPE into useful items | ||

* Recent list of companies in this space [https://3dprintingindustry.com/news/3d-printer-filament-refil-yogurt-pot-122839/] | * Recent list of companies in this space [https://3dprintingindustry.com/news/3d-printer-filament-refil-yogurt-pot-122839/] | ||

| Line 78: | Line 122: | ||

* Recent list of companies in this space [https://3dprintingindustry.com/news/3d-printer-filament-refil-yogurt-pot-122839/] | * Recent list of companies in this space [https://3dprintingindustry.com/news/3d-printer-filament-refil-yogurt-pot-122839/] | ||

* https://www.greenbatch.com/ | * https://www.greenbatch.com/ | ||

* Shred buddy https://openbuilds.com/builds/shred-buddy3d-upcycler-open-source-multi-material-cutter-pelletizer.4275/ by http://www.venture-bit.com/ | * Shred buddy https://openbuilds.com/builds/shred-buddy3d-upcycler-open-source-multi-material-cutter-pelletizer.4275/ by [https://web.archive.org/web/20180425131019/http://www.venture-bit.com/ http://web.archive.org/web/20180425131019/http://www.venture-bit.com/] | ||

* [https://filamentive.com Filamentive], [https://www.3dfuel.com/shop/landfillament-garbage-filament/ 3d fuel ] - commercialized recycled filament | * [https://web.archive.org/web/20210122220329/https://www.filamentive.com/ Filamentive], [https://www.3dfuel.com/shop/landfillament-garbage-filament/ 3d fuel ], [https://ecoreprap.com Ecoreprap] - commercialized recycled filament | ||

* [https://doi.org/10.1016/j.prostr.2021.10.101Design and Manufacturing of a 3D printer filaments extruder] | |||

* pullstruder https://hackaday.io/project/185196-pullstruder-from-plastic-bottle-to-pet-filament | |||

* mini shredder https://www.youtube.com/watch?v=qoxxyttw3HQ | |||

* Polyformer for PET https://www.reiten.design/polyformer | |||

* https://recyclingfabrik.com/shop/ | |||

<gallery> | |||

File:Recyclebot1_display_large_preview_featured.jpg|[http://www.thingiverse.com/thing:12948 RecycleBot v2.2] | |||

File:Recyclebot-process_preview_featured2.jpg|[http://www.thingiverse.com/thing:54180 RecycleBot v2.3 Controls]|Image:IMG_20140413_165438_preview_featured.jpg|[http://www.thingiverse.com/thing:298429 Filastruder Vertical Plate JIG for version 1.4] | |||

File:Filawinder_laser-sensor_preview_featured.jpg|[http://www.thingiverse.com/thing:288914 Filawinder laser sensor holder - parametric and customizable] | |||

File:3d_preview_featured.jpg|[http://web.archive.org/web/20150217035622/http://www.thingiverse.com:80/thing:285127 Printed housing for mini shredder] | |||

File:2014-03-21_17.27.03_preview_featured.jpg|[http://www.thingiverse.com/thing:277996 Vertical Filastruder Hopper v2] | |||

File:Hopper_2_view_preview_featured.jpg|[http://www.thingiverse.com/thing:272101 Hopper for filaextruder] | |||

File:Extruder_preview_featured.jpg|[http://www.thingiverse.com/thing:267105 PseudoBot Filament Extruder] | |||

File:DSC00956_preview_featured.jpg|[http://www.thingiverse.com/thing:265375 LYMAN FILAMENT EXTRUDER V4.1] | |||

File:2013-05-21_16.47.57_preview_featured2.jpg|[http://www.thingiverse.com/thing:83570 Filament extruder] | |||

File:1_preview_featured.jpg|[http://www.thingiverse.com/thing:262049 DIY filament extruder version 2 ] | |||

File:Bild7_2_Extruder_Fhrungseinheit_preview_featured.jpg|[http://www.thingiverse.com/thing:262361 New Extruder and Shredder concept - Using methods of innovative engineering (TRIZ)] | |||

File:1_preview_featured.jpg|[http://www.thingiverse.com/thing:262732 DIY filament extruder version 2 STL] | |||

File:Filabottlev2_both-s20140121-19506-go4p44-0_preview_featured.jpg|[http://www.thingiverse.com/thing:231292 FilaBottle UPDATED 2x (wider neck)] | |||

File:DSC_0013_preview_featured.jpg|[http://www.thingiverse.com/thing:197184 X3uder - OS 12VDC RepRap Filament extruder] | |||

File:DSCN0461_preview_featured.jpg|[http://web.archive.org/web/20160426072743/http://www.thingiverse.com:80/thing:24583 Filabot Wee Open Source Plans (Update Pending)] | |||

File:IMG_5680_preview_featured.jpg|[http://www.thingiverse.com/thing:174383 FilaWinder] | |||

File:IMG_6149_preview_featured.jpg|[http://www.thingiverse.com/thing:81662 Guided Filament Winder] | |||

File:Img_5928_preview_featured.jpg|[http://www.thingiverse.com/thing:44262 Lyman's Spool Winder Tweaks] | |||

File:20140104_224557_preview_featured.jpg|[http://www.thingiverse.com/thing:219463 Filastruder hopper for vertical mount] | |||

File:Photo_preview_featured.jpg|[http://www.thingiverse.com/thing:212239 Filastruder Guide-bar Washer/Spacer's] | |||

File:Photo_preview_featured2.jpg|[http://www.thingiverse.com/thing:192076 45 Degree stand for Filastruder case.] | |||

File:Wall-hung_preview_featured.jpg|[http://www.thingiverse.com/thing:145960 Filastruder Randolph Wall/Desk mount] | |||

File:IMG_6032_preview_featured.jpg|[http://www.thingiverse.com/thing:92815 Filastruder Laser Cut Case] | |||

File:Photo-18_display_large_preview_featured.jpg|[http://www.thingiverse.com/thing:157575 FilaBottle UPDATED 2x] | |||

File:IMG_8062_preview_featured.jpg|[http://www.thingiverse.com/thing:165190 Filastruder Electronics Enclosure v3 & Hopper Funnel v3 (Based on the original by Tim Elmore)] | |||

File:2013-07-20_11.14.35_preview_featured.jpg|[http://www.thingiverse.com/thing:120570 FilaHopper] | |||

File:Photo_2-14_preview_featured.jpg|[http://www.thingiverse.com/thing:108018 Filastruder cooling bar] | |||

File:IMG_3064_preview_featured.jpg|[http://www.thingiverse.com/thing:110922 Filastruder Fan Base] | |||

File:FilAngle_preview_featured.jpg|[http://www.thingiverse.com/thing:165464 FilAngle] | |||

File:Photo_44_preview_featured.jpg|[http://www.thingiverse.com/thing:109650 Vertical Hopper for Filastruder] | |||

File:IMAG0027_preview_featured.jpg|[http://www.thingiverse.com/thing:102973 Filament Extruder (Filastruder KIT)] | |||

File:IMG_2596_preview_featured.jpg|[http://www.thingiverse.com/thing:134836 Motor spin indicator for the Filastruder] | |||

File:WP_20130525_007_preview_featured.jpg|[http://www.thingiverse.com/thing:94429 Filastruder Electronics Faceplate] | |||

File:preview_featured.jpg|[http://www.thingiverse.com/thing:105877 Official Filastruder Enclosure] | |||

File:Grotetanddel_preview_featured.jpg|[http://www.thingiverse.com/thing:32635 LYMAN FILAMENT EXTRUDER GEAR] | |||

File:IMG_0850_preview_featured.jpg|[http://www.thingiverse.com/thing:94027 Filament extruder based on LYMAN's version] | |||

File:IMG_0916_preview_featured.jpg|[http://www.thingiverse.com/thing:32667 My version of the LYMAN FILAMENT EXTRUDER] | |||

File:2012-08-20_13-18-14_463_preview_featured.jpg|[https://web.archive.org/web/20210625061625/https://www.thingiverse.com/thing:30642 LYMAN FILAMENT EXTRUDER] | |||

File:IMG_1117_preview_featured.jpg|[http://www.thingiverse.com/thing:62544 YALFE - YET ANOTHER LYMAN'S FILAMENT EXTRUDER] | |||

File:IMG_1476_preview_featured.jpg|[http://www.thingiverse.com/thing:212894 YALFE V2 - YET ANOTHER LYMAN'S FILAMENT EXTRUDER V2] | |||

File:Snapshot_2_8-31-2013_9-01_AM_preview_featured.jpg|[http://www.thingiverse.com/thing:145500 LYMAN FILAMENT EXTRUDER V3] | |||

File:IMG_0841_preview_featured2.jpg|[http://www.thingiverse.com/thing:152380 3D printed Filament Extruder based on Lyman Design] | |||

File:DSCF0155_preview_featured.jpg|[https://web.archive.org/web/20210420191802/https://www.thingiverse.com/thing:34653 LYMAN FILAMENT EXTRUDER II] | |||

File:DSCF0105_preview_featured.jpg|[https://web.archive.org/web/20210423042542/https://www.thingiverse.com/thing:30705 LYMAN FILAMENT SPOOL WINDER] | |||

</gallery> | |||

== Quick payback time calculation == | |||

Assumptions: | Assumptions: | ||

* commercial filament currently sells for about $35/kg | * commercial filament currently sells for about $35/kg | ||

* electricity cost from [ | * electricity cost from [https://www.appropedia.org/Life_cycle_analysis_of_distributed_recycling_of_post-consumer_high_density_polyethylene_for_3-D_printing_filament] is $0.10/kg | ||

* plastic if recycled cost $0/kg | * plastic if recycled cost $0/kg | ||

* if you buy pellets sells from $1-$10/kg | * if you buy pellets sells from $1-$10/kg | ||

| Line 147: | Line 195: | ||

Rich case = filastruder+filawinder/(commercial filament cost avoided - recycled plastic) = $450/($35-0.1) = 12.8kg | Rich case = filastruder+filawinder/(commercial filament cost avoided - recycled plastic) = $450/($35-0.1) = 12.8kg | ||

Then you stick the filament in your RepRap and print $1000s of dollars of goods for pennies: see [[Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers]] | Then you stick the filament in your RepRap and print $1000s of dollars of goods for pennies: see [[Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers]] | ||

==Recyclable Polymers == | == Recyclable Polymers == | ||

{| class="wikitable" | {| class="wikitable" | ||

! Image | ! Image | ||

! Made of | ! Made of | ||

| Line 161: | Line 206: | ||

! Melting temperature C | ! Melting temperature C | ||

|- | |- | ||

|[[ | | [[File: Recycling plastic1.jpg|thumb|center|Type1]] | ||

| PETE Polyethylene Terephthalate (PET) | | PETE Polyethylene Terephthalate (PET) | ||

| Soda & water containers, some waterproof packaging. | | Soda & water containers, some waterproof packaging. | ||

| 260°C | | 260°C | ||

|- | |- | ||

|[[ | | [[File: p1.jpg|thumb|center|Type2]] | ||

| HDPE High-Density Polyethylene. | | HDPE High-Density Polyethylene. | ||

| Milk, detergent & oil bottles, Toys and plastic bags. | | Milk, detergent & oil bottles, Toys and plastic bags. | ||

| 130°C | | 130°C | ||

|- | |- | ||

|[[ | | [[File: p2.jpg|thumb|center|Type 3]] | ||

| V Vinyl/Polyvinyl Chloride (PVC). | | V Vinyl/Polyvinyl Chloride (PVC). | ||

| Food wrap, vegetable oil bottles, blister packages. | | Food wrap, vegetable oil bottles, blister packages. | ||

| 160°C | | 160°C | ||

|- | |- | ||

|[[ | | [[File: p3.jpg|thumb|center|Type 4]] | ||

| LDPE Low-Density Polyethylene. | | LDPE Low-Density Polyethylene. | ||

| plastic bags. Shrink wrap, garment bags. | | plastic bags. Shrink wrap, garment bags. | ||

| 120°C | | 120°C | ||

|- | |- | ||

|[[ | | [[File: p4.jpg|thumb|center|Type 5]] | ||

| PP Polypropylene. | | PP Polypropylene. | ||

| Refrigerated containers, some bags, most bottle tops, some carpets, some food wrap. | | Refrigerated containers, some bags, most bottle tops, some carpets, some food wrap. | ||

| 130°C | | 130°C | ||

|- | |- | ||

|[[ | | [[File: p5.jpg|thumb|center|Type 6]] | ||

| PS Polystyrene. | | PS Polystyrene. | ||

| Throwaway utensils, meat packing, protective packing. | | Throwaway utensils, meat packing, protective packing. | ||

| 240°C | | 240°C | ||

|- | |- | ||

|[[ | | [[File: p6.jpg|thumb|center|Type 7]] | ||

| Others. | | Others. | ||

| Layered or mixed plastic. | | Layered or mixed plastic. | ||

| Line 197: | Line 242: | ||

|} | |} | ||

* [https://www.sciencedirect.com/science/article/pii/S2214860419301502 3D printing of high density polyethylene by fused filament fabrication] | * [https://www.sciencedirect.com/science/article/pii/S2214860419301502 3D printing of high density polyethylene by fused filament fabrication] | ||

'''These symbols are meant to indicate the type of [[plastic]], not its recyclability.<br>''' | |||

* Types 1 and 2 are commonly recycled. | * Types 1 and 2 are commonly recycled. | ||

* Type 4 is less commonly recycled. | * Type 4 is less commonly recycled. | ||

| Line 205: | Line 251: | ||

* Common plastics polycarbonate (PC) and acrylonitrile-butadiene-styrene (ABS) do not have recycling numbers. | * Common plastics polycarbonate (PC) and acrylonitrile-butadiene-styrene (ABS) do not have recycling numbers. | ||

* Plastics 3, 6, and 7 probably contain [[BPA]] and should not be used to store anything that will be consumed by humans. | * Plastics 3, 6, and 7 probably contain [[BPA]] and should not be used to store anything that will be consumed by humans. | ||

* The majority of plastic packaging was made with one of six resins there are codes for those six as well as | * The majority of plastic packaging was made with one of six resins there are codes for those six as well as a seventh, 7-OTHER, to be used when the product in question is made with a plastic other than the common six, or is made of more than one plastic used in combination. Currently, 7 plastics can sometimes be recycled into bottles or plastic lumber. However, polycarbonate plastic, one variety coded number 7, is made with the chemical bisphenol A, or BPA. The National Toxicology Program reports that BPA may have adverse effects on the development of the brain and behavior of fetuses, infants and children, and advises consumers to limit BPA exposure by avoiding number 7 plastic containers.[http://homeguides.sfgate.com/recycle-number-mean-plastic-container-79186.html]. '''There is a potential academic project here to call for greater granularity in the plastic codes - if anyone wants to work on this please contact me.''' -- [[User:J.M.Pearce|Joshua]] 17:18, 31 July 2013 (PDT) | ||

==See | == See also == | ||

{| | {| class="wikitable" | ||

!<big><big>Perpetual Plastic Project</big> | ! <big><big>Perpetual Plastic Project</big> | ||

|- | |- | ||

| | | {{Video|sIsGhuZVT7Q}} | ||

|- | |- | ||

| | | | ||

[http://www.perpetualplasticproject.com/Perpetual_Plastic_Project/Project.html Perpetual Plastic Project] - Giant Room Size RecycleBot that takes people through all the steps | [https://web.archive.org/web/20140209103700/http://www.perpetualplasticproject.com:80/Perpetual_Plastic_Project/Project.html Perpetual Plastic Project] - Giant Room Size RecycleBot that takes people through all the steps now joined by Ultimaker | ||

|} | |} | ||

* [[Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing]] | |||

*[[Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing]] | |||

* [[Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System]] | * [[Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System]] | ||

* [[Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament]] | * [[Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament]] | ||

| Line 236: | Line 274: | ||

* [[Plastic bank]] | * [[Plastic bank]] | ||

* [[Polymer recycling codes for distributed manufacturing with 3-D printers]] | * [[Polymer recycling codes for distributed manufacturing with 3-D printers]] | ||

* [[Mechanical testing of polymer components made with the | * [[Mechanical testing of polymer components made with the RepRap 3-D printer]] | ||

* [[Development and feasibility of applications for the RepRap 3-D printer]] | * [[Development and feasibility of applications for the RepRap 3-D printer]] | ||

* [[Life cycle analysis of distributed polymer recycling]] | * [[Life cycle analysis of distributed polymer recycling]] | ||

* [[Solar powered distributed customized manufacturing]] | * [[Solar powered distributed customized manufacturing]] | ||

| Line 243: | Line 281: | ||

* [[Ethical Filament Foundation]] | * [[Ethical Filament Foundation]] | ||

* [[Expanding the Consumer Bill of Rights for material ingredients]] | * [[Expanding the Consumer Bill of Rights for material ingredients]] | ||

* [http://3dprintingindustry.com/2014/03/19/mobile-eco-3d-printing-station/ LDPE recycling on a bike with a RepRap] from Taipei-based company | * [https://web.archive.org/web/20160424042431/http://3dprintingindustry.com:80/2014/03/19/mobile-eco-3d-printing-station/ LDPE recycling on a bike with a RepRap] from Taipei-based company Fabraft | ||

* UBC recycling of old prints with blender and liquid nitrogen | * UBC recycling of old prints with blender and liquid nitrogen | ||

* | * Filament By Filacycle Is 100% Recycled! - 3D Printing Industry 12-16-2014 | ||

* [http://www.yankodesign.com/2014/12/31/a-beachs-best-friend/ Dr. Recare]- nice concept to have automated plastic beach cleaner/3D printer make recyclebins | * [http://www.yankodesign.com/2014/12/31/a-beachs-best-friend/ Dr. Recare]- nice concept to have automated plastic beach cleaner/3D printer make recyclebins | ||

* Haruna Hamod. 2015.Suitability of recycled HDPE for 3D printing filament. Arcada University of Applied Science. [http://theseus32-kk.lib.helsinki.fi/bitstream/handle/10024/86198/Thesis%20final.pdf?sequence=1 Thesis covering recycling HDPE to filament] | * Haruna Hamod. 2015.Suitability of recycled HDPE for 3D printing filament. Arcada University of Applied Science. [https://web.archive.org/web/20160928103245/http://theseus32-kk.lib.helsinki.fi:80/bitstream/handle/10024/86198/Thesis%20final.pdf?sequence=1 Thesis covering recycling HDPE to filament] | ||

*Tisserat, Brent, Zengshe Liu, Victoria Finkenstadt, Branden Lewandowski, Steven Ott, and Louis Reifschneider. "3D printing biocomposites." [http://www.4spepro.org/pdf/005690/005690.pdf 3D printing biocomposites] | * Tisserat, Brent, Zengshe Liu, Victoria Finkenstadt, Branden Lewandowski, Steven Ott, and Louis Reifschneider. "3D printing biocomposites." [http://www.4spepro.org/pdf/005690/005690.pdf 3D printing biocomposites] | ||

* | * Closing the Sustainability Cycle with InnoCirlce Recycled 3D Printing Filaments - 3D Printing and Industry | ||

* [https://www.terracycle.com/en-US/ Terracycle] | * [https://www.terracycle.com/en-US/ Terracycle] | ||

* [http://reflowfilament.com/index.html Reflow Filament] - commercial recycled PET filament producer | * [https://web.archive.org/web/20190127141655/http://reflowfilament.com:80/index.html Reflow Filament] - commercial recycled PET filament producer | ||

* [https://www.innofil3d.com/product-category/innocircle/ Innofil3D] - Recycled PET 3D Filament Manufacturer | * [https://www.innofil3d.com/product-category/innocircle/ Innofil3D] - Recycled PET 3D Filament Manufacturer | ||

* [https://www.filamentive.com/pet-vs-petg-filament-whats-the-difference/ Filamentive PET vs PETG] | * [https://www.filamentive.com/pet-vs-petg-filament-whats-the-difference/ Filamentive PET vs PETG] | ||

* [[Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing]] | * [[Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing]] | ||

* [[Systems Analysis for PET and Olefin Polymers in a Circular Economy]] | * [[Systems Analysis for PET and Olefin Polymers in a Circular Economy]] | ||

* [https://www.army.mil/article/202398/us_army_lab_finds_plastic_bottles_other_waste_products_have_re_use_potential_for_battlefield US Military's efforts] | * [https://web.archive.org/web/20210125192826/https://www.army.mil/article/202398/us_army_lab_finds_plastic_bottles_other_waste_products_have_re_use_potential_for_battlefield US Military's efforts] | ||

* [https://www.intechopen.com/books/material-recycling-trends-and-perspectives Material Recycling free ebook] | * [https://www.intechopen.com/books/material-recycling-trends-and-perspectives Material Recycling free ebook] | ||

* [https://3dprintingindustry.com/news/transform-ce-mmu-e9-6-million-plans-to-give-plastic-a-new-lease-of-life-with-3d-printing-168754/ Intrusion molding] | * [https://3dprintingindustry.com/news/transform-ce-mmu-e9-6-million-plans-to-give-plastic-a-new-lease-of-life-with-3d-printing-168754/ Intrusion molding] | ||

* [https://printers3dmax.com/how-to-create-a-3d-printer-file/ 3D Printer File Format] | |||

== Peer Reviewed articles covering recyclebot technology == | |||

* Christian Baechler, Matthew DeVuono, and Joshua M. Pearce, "[https://dx.doi.org/10.1108/13552541311302978 Distributed Recycling of Waste Polymer into RepRap Feedstock]" ''Rapid Prototyping Journal '''''19'''(2), pp. 118-125 (2013). [https://www.academia.edu/2643418/Distributed_Recycling_of_Waste_Polymer_into_RepRap_Feedstock open access] | |||

* Christian Baechler, Matthew DeVuono, and Joshua M. Pearce, | * M.A. Kreiger, M.L. Mulder, A.G. Glover, J. M. Pearce, [https://dx.doi.org/10.1016/j.jclepro.2014.02.009 Life Cycle Analysis of Distributed Recycling of Post-consumer High Density Polyethylene for 3-D Printing Filament], ''Journal of Cleaner Production'', 70, pp. 90–96 (2014). [https://www.academia.edu/6188555/Life_cycle_analysis_of_distributed_recycling_of_post-consumer_high_density_polyethylene_for_3-D_printing_filament open access] | ||

* M.A. Kreiger, M.L. Mulder, A.G. Glover, J. M. Pearce, [ | * Megan Kreiger and Joshua M. Pearce (2013). [http://pubs.acs.org/doi/abs/10.1021/sc400093k Environmental Life Cycle Analysis of Distributed 3-D Printing and Conventional Manufacturing of Polymer Products], ''ACS Sustainable Chemistry & Engineering'', ''Engineering'', '''1''' (12), (2013) pp. 1511–1519DOI: 10.1021/sc400093k [https://www.academia.edu/4685670/Environmental_Life_Cycle_Analysis_of_Distributed_3-D_Printing_and_Conventional_Manufacturing_of_Polymer_Products Open access]* | ||

* Megan Kreiger and Joshua M. Pearce (2013). [http://pubs.acs.org/doi/abs/10.1021/sc400093k Environmental Life Cycle Analysis of Distributed 3-D Printing and Conventional Manufacturing of Polymer Products], ''ACS Sustainable Chemistry & Engineering'', ''Engineering'', '''1''' (12), (2013) pp. 1511–1519DOI: 10.1021/sc400093k [ | * Megan Kreiger and Joshua M. Pearce (2013). [https://journals.cambridge.org/action/displayAbstract?fromPage=online&aid=8858311 Environmental Impacts of Distributed Manufacturing from 3-D Printing of Polymer Components and Products]. ''MRS Online Proceedings Library'', 1492, mrsf12-1492-g01-02 [https://www.academia.edu/3057942/Environmental_Impacts_of_Distributed_Manufacturing_from_3-D_Printing_of_Polymer_Components_and_Products open access] | ||

* Megan Kreiger and Joshua M. Pearce (2013). [https://journals.cambridge.org/action/displayAbstract?fromPage=online&aid=8858311 Environmental Impacts of Distributed Manufacturing from 3-D Printing of Polymer Components and Products]. ''MRS Online Proceedings Library'', 1492, mrsf12-1492-g01-02 [ | * M. Kreiger, G. C. Anzalone, M. L. Mulder, A. Glover and J. M Pearce (2013). Distributed Recycling of Post-Consumer Plastic Waste in Rural Areas. ''MRS Online Proceedings Library'', 1492, [https://journals.cambridge.org/action/displayAbstract?fromPage=online&aid=8851128 mrsf12-1492-g04-06] [https://www.academia.edu/2921972/Distributed_Recycling_of_Post-Consumer_Plastic_Waste_in_Rural_Areas open access] | ||

* M. Kreiger, G. C. Anzalone, M. L. Mulder, A. Glover and J. M Pearce (2013). Distributed Recycling of Post-Consumer Plastic Waste in Rural Areas. ''MRS Online Proceedings Library'', 1492, [https://journals.cambridge.org/action/displayAbstract?fromPage=online&aid=8851128 mrsf12-1492-g04-06] [ | * Emily J. Hunt, Chenlong Zhang, Nick Anzalone, Joshua M. Pearce, [https://dx.doi.org/10.1016/j.resconrec.2015.02.004 Polymer recycling codes for distributed manufacturing with 3-D printers], ''Resources, Conservation and Recycling'', '''97''', pp. 24-30 (2015). DOI:10.1016/j.resconrec.2015.02.004 [https://www.academia.edu/11229348/Polymer_recycling_codes_for_distributed_manufacturing_with_3-D_printers open access] | ||

* Emily J. Hunt, Chenlong Zhang, Nick Anzalone, Joshua M. Pearce, [ | * Feeley, S. R., Wijnen, B., & Pearce, J. M. (2014). [http://www.ccsenet.org/journal/index.php/jsd/article/view/32187 Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament]. ''Journal of Sustainable Development'', '''7'''(5), 1-12. DOI: 10.5539/jsd.v7n5p1 [https://www.academia.edu/8406439/Evaluation_of_Potential_Fair_Trade_Standards_for_an_Ethical_3-D_Printing_Filament open access] | ||

* Feeley, S. R., Wijnen, B., & Pearce, J. M. (2014). [http://www.ccsenet.org/journal/index.php/jsd/article/view/32187 Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament]. ''Journal of Sustainable Development'', '''7'''(5), 1-12. DOI: 10.5539/jsd.v7n5p1 | |||

* Hunt, R., 3D Printing Applications for Creating Products Made from Reclaimed Fishing Nets-Rhiannon Hunt, Martin Charter. 2016.[http://www.circularocean.eu/wp-content/uploads/2016/11/S116_Proceedings_papers-R-Hunt.pdf] | * Hunt, R., 3D Printing Applications for Creating Products Made from Reclaimed Fishing Nets-Rhiannon Hunt, Martin Charter. 2016.[http://www.circularocean.eu/wp-content/uploads/2016/11/S116_Proceedings_papers-R-Hunt.pdf] | ||

* Okshtein, Y., 2009. RecycleBot 2.0: An Integrated Recycling Sorting and Separating System (Doctoral dissertation, The Cooper Union). | * Okshtein, Y., 2009. RecycleBot 2.0: An Integrated Recycling Sorting and Separating System (Doctoral dissertation, The Cooper Union). | ||

* Chong, S., Pan, G.T., Khalid, M., Yang, T.C.K., Hung, S.T. and Huang, C.M., Physical Characterization and Pre-assessment of Recycled High-Density Polyethylene as 3D Printing Material. Journal of Polymers and the Environment, pp.1-10. | * Chong, S., Pan, G.T., Khalid, M., Yang, T.C.K., Hung, S.T. and Huang, C.M., Physical Characterization and Pre-assessment of Recycled High-Density Polyethylene as 3D Printing Material. Journal of Polymers and the Environment, pp.1-10. | ||

* Knips, C., Bertling, J., Blömer, J. and Janssen, W., 2014. FabLabs, 3D-printing and degrowth–Democratisation and deceleration of production or a new consumptive boom producing more waste?.https://co-munity.net/system/files/Knip.pdf | * Knips, C., Bertling, J., Blömer, J. and Janssen, W., 2014. FabLabs, 3D-printing and degrowth–Democratisation and deceleration of production or a new consumptive boom producing more waste?.[https://web.archive.org/web/20210308083016/https://co-munity.net/system/files/Knip.pdf http://web.archive.org/web/20210308083016/https://co-munity.net/system/files/Knip.pdf] | ||

* Despeisse, M., Baumers, M., Brown, P., Charnley, F., Ford, S.J., Garmulewicz, A., Knowles, S., Minshall, T.H.W., Mortara, L., Reed-Tsochas, F.P. and Rowley, J., Unlocking value for a circular economy through 3D printing: a research agenda.https://www.researchgate.net/profile/Melanie_Despeisse/publication/303701616_Unlocking_value_for_a_circular_economy_through_3D_printing_a_research_agenda/links/574ea1f808aedd1c180d7ef5.pdf | * Despeisse, M., Baumers, M., Brown, P., Charnley, F., Ford, S.J., Garmulewicz, A., Knowles, S., Minshall, T.H.W., Mortara, L., Reed-Tsochas, F.P. and Rowley, J., Unlocking value for a circular economy through 3D printing: a research agenda.https://www.researchgate.net/profile/Melanie_Despeisse/publication/303701616_Unlocking_value_for_a_circular_economy_through_3D_printing_a_research_agenda/links/574ea1f808aedd1c180d7ef5.pdf | ||

* Ramli, F.R., Jailani, M.I., Unjar, H., Alkahari, M.R. and Abdullah, M.A., 2015. Integrated recycle system concept for low cost 3D-printer sustainability. Proc. Mech. Eng. Res. Day, 1, pp.77-78. | * Ramli, F.R., Jailani, M.I., Unjar, H., Alkahari, M.R. and Abdullah, M.A., 2015. Integrated recycle system concept for low cost 3D-printer sustainability. Proc. Mech. Eng. Res. Day, 1, pp.77-78. | ||

* Pelley, Janet. "[http://onlinelibrary.wiley.com/doi/10.1890/1540-9295-12.9.484/full Fair-trade plastic for 3D printers]." Frontiers in Ecology(2014): 484-484. | * Pelley, Janet. "[http://onlinelibrary.wiley.com/doi/10.1890/1540-9295-12.9.484/full Fair-trade plastic for 3D printers]." Frontiers in Ecology(2014): 484-484. | ||

* Birtchnell, T. and Urry, J., 2013. Fabricating futures and the movement of objects. Mobilities, 8(3), pp.388-405. | * Birtchnell, T. and Urry, J., 2013. Fabricating futures and the movement of objects. Mobilities, 8(3), pp.388-405. | ||

* Hoyle, W., 3D Printing in the Developing World: Learning from | * Hoyle, W., 3D Printing in the Developing World: Learning from Techfortrade's 3D4D Challenge. LOW-COST 3D PRINTING, p.177. | ||

* Pearce, J., 2014. Technology whose time has come. Physics World, 27(01), p.33. | * Pearce, J., 2014. Technology whose time has come. Physics World, 27(01), p.33. | ||

* Fastermann, P., 2014. Nachhaltigkeit–3D-Druck als umweltfreundliche Technologie?. In 3D-Drucken (pp. 103-113). Springer Berlin Heidelberg. | * Fastermann, P., 2014. Nachhaltigkeit–3D-Druck als umweltfreundliche Technologie?. In 3D-Drucken (pp. 103-113). Springer Berlin Heidelberg. | ||

| Line 288: | Line 328: | ||

* Hart, K.R., Frketic, J.B. and Brown, J.R., 2018. Recycling Meal-Ready-To-Eat (MRE) Pouches into Polymer Filament for Material Extrusion Additive Manufacturing. Additive Manufacturing. https://www.sciencedirect.com/science/article/pii/S2214860417305742 | * Hart, K.R., Frketic, J.B. and Brown, J.R., 2018. Recycling Meal-Ready-To-Eat (MRE) Pouches into Polymer Filament for Material Extrusion Additive Manufacturing. Additive Manufacturing. https://www.sciencedirect.com/science/article/pii/S2214860417305742 | ||

* Zander, N.E., Gillan, M. and Lambeth, R.H., 2018. Recycled polyethylene terephthalate as a new FFF feedstock material. Additive Manufacturing, 21, pp.174-182.https://doi.org/10.1016/j.addma.2018.03.007 | * Zander, N.E., Gillan, M. and Lambeth, R.H., 2018. Recycled polyethylene terephthalate as a new FFF feedstock material. Additive Manufacturing, 21, pp.174-182.https://doi.org/10.1016/j.addma.2018.03.007 | ||

* Sherer, S. (2018). Objects that Create Community: Effects of 3D Printing and Distributed manufacturing beyond Circular Economy (Doctoral dissertation, OCAD University). http://openresearch.ocadu.ca/id/eprint/2291/1/Sherer_Samantha_2018_MDes_IAMD_Thesis.pdf | * Sherer, S. (2018). Objects that Create Community: Effects of 3D Printing and Distributed manufacturing beyond Circular Economy (Doctoral dissertation, OCAD University). [https://web.archive.org/web/20210228114857/http://openresearch.ocadu.ca/id/eprint/2291/1/Sherer_Samantha_2018_MDes_IAMD_Thesis.pdf http://web.archive.org/web/20210228114857/http://openresearch.ocadu.ca/id/eprint/2291/1/Sherer_Samantha_2018_MDes_IAMD_Thesis.pdf] | ||

* Lionel Taito-Matamua, , Simon Fraser, , Jeongbin Ok, (2018), Renewing Materials: Implementing 3D Printing and Distributed Recycling in Samoa, in Robert Crocker , Christopher Saint , Guanyi Chen , Yindong Tong (ed.) Unmaking Waste in Production and Consumption: Towards the Circular Economy, pp.191 - 212 | * Lionel Taito-Matamua,, Simon Fraser,, Jeongbin Ok, (2018), Renewing Materials: Implementing 3D Printing and Distributed Recycling in Samoa, in Robert Crocker, Christopher Saint, Guanyi Chen, Yindong Tong (ed.) Unmaking Waste in Production and Consumption: Towards the Circular Economy, pp.191 - 212 | ||

* Mohammed, M.I., Wilson, D., Gomez-Kervin, E., Vidler, C., Rosson, L. and Long, J., The recycling of E-Waste ABS plastics by melt extrusion and 3D printing using solar powered devices as a transformative tool for humanitarian aid.https://www.researchgate.net/profile/Mazher_Mohammed2/publication/329216987_The_recycling_of_E-Waste_ABS_plastics_by_melt_extrusion_and_3D_printing_using_solar_powered_devices_as_a_transformative_tool_for_humanitarian_aid/links/5bfd4a01299bf1c2329d5f5c/The-recycling-of-E-Waste-ABS-plastics-by-melt-extrusion-and-3D-printing-using-solar-powered-devices-as-a-transformative-tool-for-humanitarian-aid.pdf | * Mohammed, M.I., Wilson, D., Gomez-Kervin, E., Vidler, C., Rosson, L. and Long, J., The recycling of E-Waste ABS plastics by melt extrusion and 3D printing using solar powered devices as a transformative tool for humanitarian aid.https://www.researchgate.net/profile/Mazher_Mohammed2/publication/329216987_The_recycling_of_E-Waste_ABS_plastics_by_melt_extrusion_and_3D_printing_using_solar_powered_devices_as_a_transformative_tool_for_humanitarian_aid/links/5bfd4a01299bf1c2329d5f5c/The-recycling-of-E-Waste-ABS-plastics-by-melt-extrusion-and-3D-printing-using-solar-powered-devices-as-a-transformative-tool-for-humanitarian-aid.pdf | ||

* Mohammed, M.I., Wilson, D., Gomez-Kervin, E., Rosson, L. and Long, J., 2018, November. EcoPrinting: Investigation of Solar Powered Plastic Recycling and Additive Manufacturing for Enhanced Waste Management and Sustainable Manufacturing. In 2018 IEEE Conference on Technologies for Sustainability (SusTech) (pp. 1-6). IEEE. https://ieeexplore.ieee.org/abstract/document/8671370 | * Mohammed, M.I., Wilson, D., Gomez-Kervin, E., Rosson, L. and Long, J., 2018, November. EcoPrinting: Investigation of Solar Powered Plastic Recycling and Additive Manufacturing for Enhanced Waste Management and Sustainable Manufacturing. In 2018 IEEE Conference on Technologies for Sustainability (SusTech) (pp. 1-6). IEEE. https://ieeexplore.ieee.org/abstract/document/8671370 | ||

| Line 298: | Line 338: | ||

* Peeters, B., Kiratli, N. and Semeijn, J., 2019. A barrier analysis for distributed recycling of 3D printing waste: Taking the maker movement perspective. ''Journal of Cleaner Production'', p.118313. https://doi.org/10.1016/j.jclepro.2019.118313 | * Peeters, B., Kiratli, N. and Semeijn, J., 2019. A barrier analysis for distributed recycling of 3D printing waste: Taking the maker movement perspective. ''Journal of Cleaner Production'', p.118313. https://doi.org/10.1016/j.jclepro.2019.118313 | ||

* Gudadhe, A.A., Bachhar, N., Kumar, A., Andrade, P. and Kumaraswamy, G., 2019. 3D Printing with Waste High-Density Polyethylene. ACS Applied Polymer Materials. https://pubs.acs.org/doi/abs/10.1021/acsapm.9b00813 (HDPE+LLDPE 10% and 1% DMDBS makes printable) | * Gudadhe, A.A., Bachhar, N., Kumar, A., Andrade, P. and Kumaraswamy, G., 2019. 3D Printing with Waste High-Density Polyethylene. ACS Applied Polymer Materials. https://pubs.acs.org/doi/abs/10.1021/acsapm.9b00813 (HDPE+LLDPE 10% and 1% DMDBS makes printable) | ||

* Recycle plastic into 3D printer filament at home | |||

== Articles about the RecycleBot == | == Articles about the RecycleBot == | ||

* Turning Trash into Cash . . . and Saving Energy -- [ | * Turning Trash into Cash... and Saving Energy -- [https://www.mtu.edu/news/stories/2013/february/story85355.html Michigan Tech News], [http://upmichigan.wdio.com/news/environment/53552-turning-trash-cashand-saving-energy WDIO], [https://nanopatentsandinnovations.blogspot.com/2013/03/turn-trash-into-cash-replace-made-in.html Ideas, Inventions and Innovations], [http://www.thecuttingedgenews.com/index.php?article=79110&pageid=&pagename= The Cutting Edge], [http://www.sciencecodex.com/turn_trash_into_cash_and_save_energy-107791 Science Codex], [https://web.archive.org/web/20150115193013/http://www.albanytribune.com:80/01032013-turning-trash-into-cash-and-saving-energy/ Albany Tribune], [https://web.archive.org/web/20150115093838/http://www.sciencenewsline.com:80/articles/2013030200390008.html Science News Online], [http://www.innovationtoronto.com/2013/03/turning-trash-into-cash-and-saving-energy/ Innovation Toronto], [http://www.examiner.com/article/thingiverse-turn-trash-into-cash-and-design-recycled-gadgets-with-3-d-printing Examiner], [https://web.archive.org/web/20170312091549/https://www.pddnet.com/news/2013/03/turning-trash-cash-and-saving-energy Product Design and Development], [http://www.newswise.com/articles/turning-trash-into-cash-and-saving-energy-additional-information-related-links-joshua-pearce-s-research-group-in-open-sustainability-technology-categories-academics-administration-alumni-athletics-campus-life-entertainment-honors-industry-outreach-philant Newswise], [http://www.energy-daily.com/reports/Turning_Trash_into_Cash_and_Saving_Energy_999.html Energy Daily], [http://www.materialsgate.de/en/mnews/9169/Turning+Trash+into+Cash+and+Saving+Energy.html Materials Gate] | ||

*3D Printed gun moving from sinister joke to sinister business model By Bruce Sterling -- | * 3D Printed gun moving from sinister joke to sinister business model By Bruce Sterling -- Wired - Beyond the Beyond | ||

* 3-D Printing Using Old Milk Jugs - [ | * 3-D Printing Using Old Milk Jugs - [https://www.sciencedaily.com/releases/2013/03/130301153645.htm Science Daily] | ||

* New process transforms old milk jugs into everything from lab equipment to cell phone cases - [ | * New process transforms old milk jugs into everything from lab equipment to cell phone cases - [https://phys.org/news/2013-03-jugs-lab-equipment-cell-cases.html Phys.org] | ||

* Feed Your 3D-Printer With Used Milk Jugs -- [http://www.scienceworldreport.com/articles/5319/20130301/feed-3d-printer-used-milk-jugs.htm Science World Report] | * Feed Your 3D-Printer With Used Milk Jugs -- [http://www.scienceworldreport.com/articles/5319/20130301/feed-3d-printer-used-milk-jugs.htm Science World Report] | ||

{| | {| class="wikitable" | ||

!<big><big>The New Scientist - Ethical Filament Story</big> | ! <big><big>The New Scientist - Ethical Filament Story</big> | ||

|- | |- | ||

| | | {{Video|Ieqqhv_YQOI}} | ||

|- | |- | ||

| | | | ||

|} | |} | ||

* RecycleBot turns old milk jugs into 3D printer feedstock -- [ | * RecycleBot turns old milk jugs into 3D printer feedstock -- [https://www.3ders.org/articles/20130302-recyclebot-turning-old-milk-jugs-into-3d-printer-feedstock.html 3Ders] | ||

* Researchers Develop RecycleBot to Recycle Plastic Using 3D Printers -- [http://www.azom.com/news.aspx?newsID=35907 Azom] | * Researchers Develop RecycleBot to Recycle Plastic Using 3D Printers -- [http://www.azom.com/news.aspx?newsID=35907 Azom] | ||

* 3D Printer Recycles Milk Jugs -- [http://www.laboratoryequipment.com/news/2013/03/3d-printer-recycles-milk-jugs Laboratory Equipment] | * 3D Printer Recycles Milk Jugs -- [http://www.laboratoryequipment.com/news/2013/03/3d-printer-recycles-milk-jugs Laboratory Equipment] | ||

* RecycleBot: An open source recycling plant - [http://www.prsnlz.me/articles/recyclebot-an-open-source-recycling-plant/ Personolize] | * RecycleBot: An open source recycling plant - [http://www.prsnlz.me/articles/recyclebot-an-open-source-recycling-plant/ Personolize] | ||

* How Recycled Milk Jugs Can Make 3D Printing Cheaper and Greener - [http://www.greenoptimistic.com/2013/03/04/3d-printing-milk-jugs-recyclebot/#.UTUMdaXCaSo Green Optimistic] | * How Recycled Milk Jugs Can Make 3D Printing Cheaper and Greener - [http://www.greenoptimistic.com/2013/03/04/3d-printing-milk-jugs-recyclebot/#.UTUMdaXCaSo Green Optimistic] | ||

* Your 3D Printer Could Eat Empty Milk Jugs Instead of Expensive Plastic -- [ | * Your 3D Printer Could Eat Empty Milk Jugs Instead of Expensive Plastic -- [https://gizmodo.com/5988147/your-3d-printer-could-eat-empty-milk-jugs-instead-of-expensive-plastic?post=57940526 Gizmodo],[http://www.i4u.com/2013/03/michigan-technological-university/jugs-could-plastic-instead-3d-expensive-your-milk-empty I4U] | ||

* RecycleBot zet oud plastic om in grondstof voor 3d-prints - [ | * RecycleBot zet oud plastic om in grondstof voor 3d-prints - [https://tweakers.net/nieuws/87629/recyclebot-zet-oud-plastic-om-in-grondstof-voor-3d-prints.html Tweakers (Dutch)], [https://web.archive.org/web/20140821231539/http://www.demorgen.be/dm/nl/5401/Multimedia/article/detail/1590016/2013/03/04/RecycleBot-zet-plastic-om-in-grondstof-voor-3D-printer.dhtml DMorgan] | ||

* La basura puede servir para imprimir en 3D - [http://www.elcorreo.com/innova/investigacion/20130304/impresion-botella-leche-201303041853-rc.html El Correo (Spanish)] | * La basura puede servir para imprimir en 3D - [http://www.elcorreo.com/innova/investigacion/20130304/impresion-botella-leche-201303041853-rc.html El Correo (Spanish)] | ||

{| | {| class="wikitable" | ||

!<big><big>AdaFruit Industries:3D Hangouts with Matt Griffin, Noe & Pedro Ruiz</big> | ! <big><big>AdaFruit Industries:3D Hangouts with Matt Griffin, Noe & Pedro Ruiz</big> | ||

|- | |- | ||

| | | {{Video|6_FNiW4BR2A}} | ||

|- | |- | ||

| | | | ||

| Line 341: | Line 375: | ||

* Designing the Future -- [http://www.3d4dchallenge.org/designing-the-future/ Tech4Trade] | * Designing the Future -- [http://www.3d4dchallenge.org/designing-the-future/ Tech4Trade] | ||

* Trash Technology: 3D Printing With Recycled Material - [http://www.redorbit.com/news/science/1112796887/trash-recycled-used-3d-printing-030513/ Red Orbit] | * Trash Technology: 3D Printing With Recycled Material - [http://www.redorbit.com/news/science/1112796887/trash-recycled-used-3d-printing-030513/ Red Orbit] | ||

* The importance of the Lyman Extruder, Filamaker, Recyclebot and Filabot to 3D printing - | * The importance of the Lyman Extruder, Filamaker, Recyclebot and Filabot to 3D printing - Voxel Fab | ||

* How milk jugs can make 3D printing cheaper - [http://www.smartplanet.com/blog/bulletin/how-milk-jugs-can-make-3d-printing-cheaper/14223 Smart Planet] | * How milk jugs can make 3D printing cheaper - [https://web.archive.org/web/20140318091752/http://www.smartplanet.com/blog/bulletin/how-milk-jugs-can-make-3d-printing-cheaper/14223 Smart Planet] | ||

* Research: 3D Printed Filament from Recycled Milk Jugs - | * Research: 3D Printed Filament from Recycled Milk Jugs - 3D Printing Industry | ||

* Rapid Ready Roundup: OsteoFab, Dreambox, RecycleBot and Trains - [http://www.rapidreadytech.com/2013/03/rapid-ready-roundup-osteofab-dreambox-recyclebot-and-trains/?utm_source=rss&utm_medium=rss&utm_campaign=rapid-ready-roundup-osteofab-dreambox-recyclebot-and-trains Rapid Ready Tech] | * Rapid Ready Roundup: OsteoFab, Dreambox, RecycleBot and Trains - [http://www.rapidreadytech.com/2013/03/rapid-ready-roundup-osteofab-dreambox-recyclebot-and-trains/?utm_source=rss&utm_medium=rss&utm_campaign=rapid-ready-roundup-osteofab-dreambox-recyclebot-and-trains Rapid Ready Tech] | ||

* Turn your milk jugs into… whatever. At home. With 3D printing. - [http://guildofscientifictroubadours.com/2013/03/11/turn-your-milk-jugs-into-whatever-at-home-with-3d-printing/ Guild of Scientifc Troubadours] | * Turn your milk jugs into… whatever. At home. With 3D printing. - [http://guildofscientifictroubadours.com/2013/03/11/turn-your-milk-jugs-into-whatever-at-home-with-3d-printing/ Guild of Scientifc Troubadours] | ||

* How to Turn Trash into Cash- [http://organicconnectmag.com/wp/how-to-turn-trash-into-cash/ | * How to Turn Trash into Cash- [https://web.archive.org/web/20130316020217/http://organicconnectmag.com:80/wp/how-to-turn-trash-into-cash/ Organic Connections] | ||

* Recycled fodder for the 3D printer - [ | * Recycled fodder for the 3D printer - [https://stochasticscientist.blogspot.com/2013/03/recycled-fodder-for-3d-printer.html Stochastic Scientist] | ||

* 3-D Printing Using Old containers - [ | * 3-D Printing Using Old containers - [https://dawoolgar.blogspot.com/2013/04/3-d-printing-using-old-containers.html DA Woolgar Blog] | ||

* [http://noticiasdelaciencia.com/not/6809/imprimir_en_3d_a_bajo_costo_usando_plastico_convencional_reciclado_en_casa/ Print in 3D at low cost using conventional plastic recycling at home (Spanish)] -- Noticias de la Ciencia | * [http://noticiasdelaciencia.com/not/6809/imprimir_en_3d_a_bajo_costo_usando_plastico_convencional_reciclado_en_casa/ Print in 3D at low cost using conventional plastic recycling at home (Spanish)] -- Noticias de la Ciencia | ||

* Health, Wealth & Wisdom on 1470 AM WMGG April 12, 2013 ([http://seniorvoiceamerica.com/2013/04/14/are-you-going-napstered-and-what-exactly-printing/ listen]) | * Health, Wealth & Wisdom on 1470 AM WMGG April 12, 2013 ([http://seniorvoiceamerica.com/2013/04/14/are-you-going-napstered-and-what-exactly-printing/ listen]) | ||

* [http://www.mtu.edu/engineering/media/publications/pdfs/2013.html Turning Trash into Cash and Saving Energy] - MTU Undergraduate Engineering Education 2013 | * [https://web.archive.org/web/20170325045455/http://www.mtu.edu/engineering/media/publications/pdfs/2013.html Turning Trash into Cash and Saving Energy] - MTU Undergraduate Engineering Education 2013 | ||

* [http://theinstitute.ieee.org/people/profiles/less-expensive-and-greener-3d-printing Less Expensive and Greener 3-D Printing]- IEEE Institute | * [http://theinstitute.ieee.org/people/profiles/less-expensive-and-greener-3d-printing Less Expensive and Greener 3-D Printing]- IEEE Institute | ||

* [http://www.tu.no/it/2014/01/15/en-ketsjupflaske-kan-gjenvinnes-til-materiale-for-3d-printere RECYCLEBOT: A ketchup bottle recyclable materials for 3D printers] - TU (Norway) | * [http://www.tu.no/it/2014/01/15/en-ketsjupflaske-kan-gjenvinnes-til-materiale-for-3d-printere RECYCLEBOT: A ketchup bottle recyclable materials for 3D printers] - TU (Norway) | ||

* [ | * [https://www.techrepublic.com/article/how-recycled-plastic-for-3d-printing-will-drive-sustainability-and-raise-the-social-conscious-of-business/ How recycled plastic for 3D printing will drive sustainability and improve social consciousness] - Tech Republic | ||

* [http://www.artandsciencejournal.com/post/92074353235/plastic-bottles-the-new-artistic-medium Plastic Bottles: The New Artistic Medium] - Art and Science Journal | * [http://www.artandsciencejournal.com/post/92074353235/plastic-bottles-the-new-artistic-medium Plastic Bottles: The New Artistic Medium] - Art and Science Journal | ||

* [https://www.adafruit.com/blog/2014/08/21/diy-3d-filament-recyclebot-to-produce-3d-printer-filament-from-waste-polymers-3dthursday-3dprinting/ DIY 3D Filament – Recyclebot to Produce 3D Printer Filament from Waste Polymers #3DThursday #3DPrinting] - Adafruit Industries Blog | * [https://www.adafruit.com/blog/2014/08/21/diy-3d-filament-recyclebot-to-produce-3d-printer-filament-from-waste-polymers-3dthursday-3dprinting/ DIY 3D Filament – Recyclebot to Produce 3D Printer Filament from Waste Polymers #3DThursday #3DPrinting] - Adafruit Industries Blog | ||

* [http://www.crazyengineers.com/threads/domestic-recycling-to-nourish-3d-printers.77348/ Domestic recycling to nourish 3D printers] - Crazy Engineers | * [http://www.crazyengineers.com/threads/domestic-recycling-to-nourish-3d-printers.77348/ Domestic recycling to nourish 3D printers] - Crazy Engineers | ||

* [http://www.pieterbas.nl/3d-printen-met-afval-als-grondstof-video/ 3D-printen met afval als grondstof] - Pieterbas.nl | * [http://www.pieterbas.nl/3d-printen-met-afval-als-grondstof-video/ 3D-printen met afval als grondstof] - Pieterbas.nl | ||

* [http://www.earthisland.org/journal/index.php/elist/eListRead/can_we_3d_print_our_way_to_sustainability Can We 3D Print our Way to Sustainability?] - | * [http://www.earthisland.org/journal/index.php/elist/eListRead/can_we_3d_print_our_way_to_sustainability Can We 3D Print our Way to Sustainability?] - Earth Island Journal | ||

* [http://www.nbcnewyork.com/news/national-international/3-D-Printing-Green-Plastic-Carbon-Footprint-298626001.htmlBeyond Plastic: New Technology Promises Greener 3-D Printing] NBC News New York | * [http://www.nbcnewyork.com/news/national-international/3-D-Printing-Green-Plastic-Carbon-Footprint-298626001.htmlBeyond Plastic: New Technology Promises Greener 3-D Printing] NBC News New York | ||

* [http://green.wiwo.de/recycling-per-3d-druck-ein-zweites-leben-fuer-plastikabfaelle/ Green.Wiwo.de] - (German) | * [http://green.wiwo.de/recycling-per-3d-druck-ein-zweites-leben-fuer-plastikabfaelle/ Green.Wiwo.de] - (German) | ||

* [https://www.mtu.edu/news/stories/2015/november/three-goes-3-d-enterprise-teams-recycling-plan-earns-ford-college-community-challenge-award.html Three C Goes 3-D: Enterprise Team's Recycling Plan Earns Ford College Community Challenge Award], [http://techcentury.com/2015/11/12/michigan-tech-3-d-printer-recycling-effort-wins-ford-grant/ Tech Century], [ | * [https://www.mtu.edu/news/stories/2015/november/three-goes-3-d-enterprise-teams-recycling-plan-earns-ford-college-community-challenge-award.html Three C Goes 3-D: Enterprise Team's Recycling Plan Earns Ford College Community Challenge Award], [http://techcentury.com/2015/11/12/michigan-tech-3-d-printer-recycling-effort-wins-ford-grant/ Tech Century], [https://www.3ders.org/articles/20151113-michigan-tech-3d-printer-recycling-plan-wins-ford-grant.html 3Ders], [https://web.archive.org/web/20160426190650/http://3dprintingindustry.com:80/2015/11/13/michigan-tech-wins-25000-from-ford-for-recycled-filaments/ 3D Printing Industry] | ||

* [http://www.mininggazette.com/page/content.detail/id/550292/Tech-innovation-fills-3-D-printers.html?nav=5006 Tech innovation fills 3-D printers] - Mining Gazette | * [http://www.mininggazette.com/page/content.detail/id/550292/Tech-innovation-fills-3-D-printers.html?nav=5006 Tech innovation fills 3-D printers] - Mining Gazette | ||

* [ | * [https://www.washingtontimes.com/news/2016/jan/18/students-work-to-make-recycled-3-d-printer-filamen/?utm_source=RSS_Feed&utm_medium=RSS Students work to make recycled 3-D printer filament] - Washington Times, [http://www.theolympian.com/news/business/article54542590.html The Olympian], [http://www.charlotteobserver.com/news/science-technology/article54542590.html Charlotte Observer], Arizona Daily Star, [https://www.sacbee.com/news/business/technology/article54542590.html Sacramento Bee], [http://www.wopular.com/students-work-make-recycled-3-d-printer-filament Miami Herald], [http://www.kansascity.com/news/business/technology/article54542590.html Kansas City Star], [http://www.hollandsentinel.com/news/20160118/students-work-to-make-recycled-3-d-printer-filament Holland Sentinel], [http://www.wral.com/students-work-to-make-recycled-3-d-printer-filament/15232144/ WRAL] | ||

* [http://sloanreview.mit.edu/article/the-revolution-will-be-customized-and-recycled-and-solar-powered/ The Revolution Will Be Customized (and Recycled and Solar-Powered)] - MIT-Sloan Management Review | * [http://sloanreview.mit.edu/article/the-revolution-will-be-customized-and-recycled-and-solar-powered/ The Revolution Will Be Customized (and Recycled and Solar-Powered)] - MIT-Sloan Management Review | ||

* [https://3dprint.com/135453/superior-filament-michigan-tech/ Superior Filament at Michigan Tech] -3DPrint.com [http://www.uppermichiganssource.com/content/news/Michigan-Tech-students-pave-the-way-for-plastic-3D-Printing-380308581.html TV6 UP Michigan Source] | * [https://3dprint.com/135453/superior-filament-michigan-tech/ Superior Filament at Michigan Tech] -3DPrint.com [http://www.uppermichiganssource.com/content/news/Michigan-Tech-students-pave-the-way-for-plastic-3D-Printing-380308581.html TV6 UP Michigan Source] | ||

*[ | * [https://www.mtu.edu/news/stories/2016/september/student-entrepreneurs-put-discarded-water-bottles-new-use.html Student Entrepreneurs Put Discarded Water Bottles to New Use] - MTU News | ||

* [http://www.mininggazette.com/news/2017/06/research-enterprise-intense-activity-picking-up-even-more-in-some-fields/ Research Enterprise- Intense activity picking up even more in some fields] -- Mining Gazette | * [https://web.archive.org/web/20170804115851/http://www.mininggazette.com:80/news/2017/06/research-enterprise-intense-activity-picking-up-even-more-in-some-fields/ Research Enterprise- Intense activity picking up even more in some fields] -- Mining Gazette | ||

{{MOST-RepRap}} | |||

{{Page data | |||

| keywords = recyclebot, waste plastic extruder, plastic extruding, 3d printing, filament, waste plastic, plastic, polymers, natural polymers, robot, osat, open source, recycling, upcycling, polymer recycling | |||

| sdg = SDG09 Industry innovation and infrastructure | |||

| authors = User:J.M.Pearce | |||

| published = 2011 | |||

| organizations = MOST, MTU | |||

}} | |||

[[Category:MOST methods]] | [[Category:MOST methods]] | ||

| Line 374: | Line 418: | ||

[[Category:Polymer recycling]] | [[Category:Polymer recycling]] | ||

[[Category:MOST completed projects and publications]] | [[Category:MOST completed projects and publications]] | ||

[[Category:Appropriate technology videos]] | [[Category:Appropriate technology videos]] | ||

[[Category:Engineering videos]] | [[Category:Engineering videos]] | ||

[[Category:3D printing]] | [[Category:3D printing]] | ||

[[Category:Upcycling]] | [[Category:Upcycling]] | ||

[[Category:3d printing]] | |||

[[Category:Plastic]] | |||

[[Category:Polymers]] | |||

[[Category:Open source]] | |||

Latest revision as of 14:31, 28 February 2024

A RecycleBot is a waste plastic extruder that creates 3-D printer filament from waste plastic and natural polymers.

Notice: Check out the new camera based diameter sensor Why it is needed Filamentive survey

RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament[edit | edit source]

In order to assist researchers explore the full potential of distributed recycling of post-consumer polymer waste, this article describes a recyclebot, which is a waste plastic extruder capable of making commercial quality 3-D printing filament. The device design takes advantage of both the open source hardware methodology and the paradigm developed by the open source self-replicating rapid prototyper (RepRap) 3-D printer community. Specifically, this paper describes the design, fabrication and operation of a RepRapable Recyclebot, which refers to the Recyclebot's ability to provide the filament needed to largely replicate the parts for the Recyclebot on any type of RepRap 3-D printer. The device costs less than $700 in mate rials and can be fabricated in about 24 h. Filament is produced at 0.4 kg/h using 0.24 kWh/kg with a diameter ±4.6%. Thus, filament can be manufactured from commercial pellets for <22% of commercial filament costs. In addition, it can fabricate recycled waste plastic into filament for 2.5 cents/kg, which is <1000X commercial filament costs. The system can fabricate filament from polymers with extrusion temperatures <250 °C and is thus capable of manufacturing custom filament over a wide range of thermopolymers and composites for material science studies of new materials and recyclability studies, as well as research on novel applications of fused filament based 3-D printing.

Source[edit | edit source]

Aubrey L. Woern, Joseph R. McCaslin, Adam M. Pringle, and Joshua M. Pearce. RepRapable Recyclebot: Open Source 3-D Printable Extruder for Converting Plastic to 3-D Printing Filament. HardwareX 4C (2018) e00026 doi: https://doi.org/10.1016/j.ohx.2018.e00026 open access

- Just the code: OSF

Distributed Recycling of Waste Polymer into RepRap Feedstock[edit | edit source]

Abstract[edit | edit source]

Purpose[edit | edit source]

A low-cost, open source, self-replicating rapid prototyper (RepRap) has been developed, which greatly expands the potential user base of rapid prototypers. The operating cost of the RepRap can be further reduced using waste polymers as feedstock. Centralized recycling of polymers is often uneconomic and energy intensive due to transportation embodied energy. This paper provides a proof of concept for high-value recycling of waste polymers at distributed creation sites.

Design/methodology/approach[edit | edit source]

Previous designs of waste plastic extruders (also known as RecycleBots) were evaluated using a weighted evaluation matrix. An updated design was completed and the description and analysis of the design is presented including component summary, testing procedures, a basic life cycle analysis and extrusion results. The filament was tested for consistency of density and diameter while quantifying electricity consumption.

Findings[edit | edit source]

Filament was successfully extruded at an average rate of 90 mm/min and used to print parts. The filament averaged 2.805±0.003mm diameter with 87% of samples between 2.540± 0.003mm and 3.081± 0.003mm. The average mass was 0.564 ± 0.001 g/100mm length. Energy use was 0.06 kWh/m.

Practical implications[edit | edit source]

The success of the Recyclebot further reduces RepRap operating costs, which enables distributed in-home, value added, plastic recycling. This has implications for municipal waste management programs as in-home recycling could reduce cost and greenhouse gas emissions associated with waste collection and transportation as well as the environmental impact of manufacturing custom plastic parts.

Originality/value[edit | edit source]

This paper reports on the first technical evaluation of a feedstock filament for the RepRap from waste plastic material made in a distributed recycling device.

Source[edit | edit source]

Christian Baechler, Matthew DeVuono, and Joshua M. Pearce, "Distributed Recycling of Waste Polymer into RepRap Feedstock" Rapid Prototyping Journal, 19(2), pp. 118-125 (2013). open access

Recyclebot evolution[edit | edit source]

Full technical information, BOMs and build instructions found at the links below. Also when designing consider Improving recyclebot concepts

Recyclebot version 2.0 and 2.1[edit | edit source]

Recyclebot version 2.2[edit | edit source]

Recyclebot version 2.3[edit | edit source]

- 3-D printable Chain guard for the RecycleBot

Recyclebot version 3.0[edit | edit source]

- Nick's Filament Extruder

Recyclebot v4.0ac[edit | edit source]

- Under final development now

Recyclebot v4.0dc[edit | edit source]

- Under final development now

Recyclebot v4.1[edit | edit source]

Recyclebot v5.0[edit | edit source]

- Under development now (NOT FULLY FUNCTIONAL) - please use RepRapable Recyclebot

RepRapable Recyclebot[edit | edit source]

- Functional -- Recyclebot v6

RepRapable Recyclebot 6.1[edit | edit source]

RepRapable Recyclebot 6.2[edit | edit source]

Igor Cudnik of Poznan University of Technology resolved i2c (right now working on adding it as a preproccesor instruction, and move all config to config.h file). He made also a whole new electric scheme, to make it easier for electrical newbies. Eventually he is working on CAD models to make them fully parametric and accessible from FreeCAD.

All of his changes can be found on my codeberg repo: https://codeberg.org/309631/recyclebotV6.2

Other types of RecycleBots[edit | edit source]

- Fused Particle Fabrication 3-D Printing: Recycled Materials' Optimization and Mechanical Properties

- The Plastic Bank has a nice semi-industrial recyclebot - Plastic Bank Extruder v1.0

- There are also several OSH tools being developed by Precious Plastic to reuse plastic waste

- You can buy a commercial open-source recyclebot called the "filastruder" kit for $290 and a Filawinder for $160.

- There are many other commercial filament extruders now including the FilaFab, Noztek, Filabot, EWE, Extrusionbot, Filamaker (also has shredder) and the Strooder, Felfil (OS), which all could potentially be used for recycling.

- Also grinder to go with extruder (vid shows PET but no crystallization)

- See collection: http://www.thingiverse.com/jpearce/collections/recyclebot-and-friends

- Also a plastic shredder from Filamaker used in project Seafood to turn waste ocean HDPE into useful items

- Recent list of companies in this space [1]

- Also a plastic shredder from Filamaker used in project Seafood to turn waste ocean HDPE into useful items

- Recent list of companies in this space [2]

- https://www.greenbatch.com/

- Shred buddy https://openbuilds.com/builds/shred-buddy3d-upcycler-open-source-multi-material-cutter-pelletizer.4275/ by http://web.archive.org/web/20180425131019/http://www.venture-bit.com/

- Filamentive, 3d fuel , Ecoreprap - commercialized recycled filament

- and Manufacturing of a 3D printer filaments extruder

- pullstruder https://hackaday.io/project/185196-pullstruder-from-plastic-bottle-to-pet-filament

- mini shredder https://www.youtube.com/watch?v=qoxxyttw3HQ

- Polyformer for PET https://www.reiten.design/polyformer

- https://recyclingfabrik.com/shop/

Quick payback time calculation[edit | edit source]

Assumptions:

- commercial filament currently sells for about $35/kg

- electricity cost from [3] is $0.10/kg

- plastic if recycled cost $0/kg

- if you buy pellets sells from $1-$10/kg

Payback time in kg produced = recyclebot cost/(commercial filament cost avoided - (elec+plastic))

Worst case = (filastruder+filawinder)/(commercial filament cost avoided - high end pellets -elec recyclebot)=$450/($35-$10.10)=18kg

Best case = filastruder plus floor winding/(commercial filament cost avoided - recycled plastic) = $290/($35-0.1) = 8.3kg

Rich case = filastruder+filawinder/(commercial filament cost avoided - recycled plastic) = $450/($35-0.1) = 12.8kg

Then you stick the filament in your RepRap and print $1000s of dollars of goods for pennies: see Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers

Recyclable Polymers[edit | edit source]

These symbols are meant to indicate the type of plastic, not its recyclability.

- Types 1 and 2 are commonly recycled.

- Type 4 is less commonly recycled.

- The other types are generally not recycled, except perhaps in small test programs.

- Common plastics polycarbonate (PC) and acrylonitrile-butadiene-styrene (ABS) do not have recycling numbers.

- Plastics 3, 6, and 7 probably contain BPA and should not be used to store anything that will be consumed by humans.

- The majority of plastic packaging was made with one of six resins there are codes for those six as well as a seventh, 7-OTHER, to be used when the product in question is made with a plastic other than the common six, or is made of more than one plastic used in combination. Currently, 7 plastics can sometimes be recycled into bottles or plastic lumber. However, polycarbonate plastic, one variety coded number 7, is made with the chemical bisphenol A, or BPA. The National Toxicology Program reports that BPA may have adverse effects on the development of the brain and behavior of fetuses, infants and children, and advises consumers to limit BPA exposure by avoiding number 7 plastic containers.[4]. There is a potential academic project here to call for greater granularity in the plastic codes - if anyone wants to work on this please contact me. -- Joshua 17:18, 31 July 2013 (PDT)

See also[edit | edit source]

| Perpetual Plastic Project |

|---|

|

Perpetual Plastic Project - Giant Room Size RecycleBot that takes people through all the steps now joined by Ultimaker |

- Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing

- Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System

- Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament

- Wood Furniture Waste-Based Recycled 3-D Printing Filament

- Recyclebot on RepRap wiki

- 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing

- Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament

- Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions

- Plastic bank

- Polymer recycling codes for distributed manufacturing with 3-D printers

- Mechanical testing of polymer components made with the RepRap 3-D printer

- Development and feasibility of applications for the RepRap 3-D printer

- Life cycle analysis of distributed polymer recycling

- Solar powered distributed customized manufacturing

- Distributed recycling of post-consumer plastic waste in rural areas

- Ethical Filament Foundation

- Expanding the Consumer Bill of Rights for material ingredients

- LDPE recycling on a bike with a RepRap from Taipei-based company Fabraft

- UBC recycling of old prints with blender and liquid nitrogen

- Filament By Filacycle Is 100% Recycled! - 3D Printing Industry 12-16-2014

- Dr. Recare- nice concept to have automated plastic beach cleaner/3D printer make recyclebins

- Haruna Hamod. 2015.Suitability of recycled HDPE for 3D printing filament. Arcada University of Applied Science. Thesis covering recycling HDPE to filament

- Tisserat, Brent, Zengshe Liu, Victoria Finkenstadt, Branden Lewandowski, Steven Ott, and Louis Reifschneider. "3D printing biocomposites." 3D printing biocomposites

- Closing the Sustainability Cycle with InnoCirlce Recycled 3D Printing Filaments - 3D Printing and Industry

- Terracycle

- Reflow Filament - commercial recycled PET filament producer

- Innofil3D - Recycled PET 3D Filament Manufacturer

- Filamentive PET vs PETG

- Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing

- Systems Analysis for PET and Olefin Polymers in a Circular Economy

- US Military's efforts

- Material Recycling free ebook

- Intrusion molding

- 3D Printer File Format

Peer Reviewed articles covering recyclebot technology[edit | edit source]

- Christian Baechler, Matthew DeVuono, and Joshua M. Pearce, "Distributed Recycling of Waste Polymer into RepRap Feedstock" Rapid Prototyping Journal 19(2), pp. 118-125 (2013). open access

- M.A. Kreiger, M.L. Mulder, A.G. Glover, J. M. Pearce, Life Cycle Analysis of Distributed Recycling of Post-consumer High Density Polyethylene for 3-D Printing Filament, Journal of Cleaner Production, 70, pp. 90–96 (2014). open access

- Megan Kreiger and Joshua M. Pearce (2013). Environmental Life Cycle Analysis of Distributed 3-D Printing and Conventional Manufacturing of Polymer Products, ACS Sustainable Chemistry & Engineering, Engineering, 1 (12), (2013) pp. 1511–1519DOI: 10.1021/sc400093k Open access*

- Megan Kreiger and Joshua M. Pearce (2013). Environmental Impacts of Distributed Manufacturing from 3-D Printing of Polymer Components and Products. MRS Online Proceedings Library, 1492, mrsf12-1492-g01-02 open access

- M. Kreiger, G. C. Anzalone, M. L. Mulder, A. Glover and J. M Pearce (2013). Distributed Recycling of Post-Consumer Plastic Waste in Rural Areas. MRS Online Proceedings Library, 1492, mrsf12-1492-g04-06 open access

- Emily J. Hunt, Chenlong Zhang, Nick Anzalone, Joshua M. Pearce, Polymer recycling codes for distributed manufacturing with 3-D printers, Resources, Conservation and Recycling, 97, pp. 24-30 (2015). DOI:10.1016/j.resconrec.2015.02.004 open access

- Feeley, S. R., Wijnen, B., & Pearce, J. M. (2014). Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament. Journal of Sustainable Development, 7(5), 1-12. DOI: 10.5539/jsd.v7n5p1 open access

- Hunt, R., 3D Printing Applications for Creating Products Made from Reclaimed Fishing Nets-Rhiannon Hunt, Martin Charter. 2016.[5]

- Okshtein, Y., 2009. RecycleBot 2.0: An Integrated Recycling Sorting and Separating System (Doctoral dissertation, The Cooper Union).

- Chong, S., Pan, G.T., Khalid, M., Yang, T.C.K., Hung, S.T. and Huang, C.M., Physical Characterization and Pre-assessment of Recycled High-Density Polyethylene as 3D Printing Material. Journal of Polymers and the Environment, pp.1-10.

- Knips, C., Bertling, J., Blömer, J. and Janssen, W., 2014. FabLabs, 3D-printing and degrowth–Democratisation and deceleration of production or a new consumptive boom producing more waste?.http://web.archive.org/web/20210308083016/https://co-munity.net/system/files/Knip.pdf