Background

In Mexico, one household in four still cooks with biomass fuel. [1] As of 2008 almost half of the humans in the world used solid fuels like traditional biomass or coal for cooking, heat, and/ or lighting. [2] Complete combustión of these fuels includes mixing fuel with pure oxygen to simply produce CO2, H20, and energy, but outside the labratory and in the kitchen most combustion is incomplete and byproducts include carbon monoxide, nitrogen oxide, and particulate matter. All these byproducts have adverse health impacts and two million deaths a year are associated with respiratory problems from indoor cooking fires with these traditional fuels in unventilated houses. Children and women are disproportionatly affected by indoor smoke, with children making up 44 percent of these deaths, while women make up 60 percent of these deaths among adults. [3] It is not the fuel that causes the respiratory problems, but the lack of ventilation and the incomplete combustion of the fuel. [4] Along with respiratory problems, the indoor smoke can give families eye problems, and women often have increased back pain from bending over an open fire. In addition, children get burns from playing around the open fire on the floor, and the heavy labor of firewood collection increases incidence of miscarrage. [5][6]

Our project goal is to learn how to build and test two improved cookstoves, the Lorena and Patsari, that can increase ventilation and increase fuel effeciency thus reducing the harmful by products in smoke. The designs for the Patsari and Lorena try to account for these problems by increasing ventilation, raising the stove up to hip height, creating a covering, and reducing the fuel needed by increasing fuel effeciency. Reducing fuel consumption not only improves the families health, it reduces the demand and pressure on local forests facing deforestation and errosion, it saves the family time on gathering wood, it reduces the CO2 emmissions, it reduces the amount of black carbón, and it reduces the non CO2 greenhouse gasses emitted from imcomplete combustión. ref>Todd Milo Johnson,Claudio Alatorre,Zayra Romo,Feng Liu; "Low-Carbon Development for Mexico" [35]</ref> [7]

Project Scope

June 2010, we are building two different improved cook stoves, the Lorena and the Patsari, in Chiapas, Mexico in order to compare the combustion efficiency, cooking time, cooking ability, fuel use, as well as smoke and particulate matter diversion. We also hope to help disseminate information on these improved stoves in the rural communities of Chiapas. We will build two stoves at Otros Mundos, a nonprofit organization that advocates for rural, human, and indigenous rights, fights against corporate biopiracy, agrochemicals, and water privatization, while promoting alternative solutions in rural pueblos. We also hope to install one stove in the Majomut community, which is part of a group called Las Abejas Civiles, who are dedicated to nonviolence, have been displaced from their homes, and who still fight for their right to their land. We created and conducted surveys in order to get community feedback on criticisms of the stove as well as what the women liked about the improved cook stoves they received @ the Majomut community. We hope to not only install and test the stoves, but also to create educational materials for the local and global community about our findings.

We hope these stoves will improve fuel efficiency, reduce biomass consumption, improve the user’s health, and reduce carbon monoxide emissions. They shorten the time it takes to cook traditional meals which regularly would be cooked over an open fire, and we found in our surveys that they don’t necessarily change the flavor of their traditional meals.

We chose this project because we were concerned about improving the living conditions and health of women and children living in rural Mexico and want to learn about their culture and traditions as an inspiration for Appropriate Technology projects. Considering that respiratory problems are one of the top seven reasons for death in women and children in Mexico, we thought this project was an important and often overlooked problem. We hope to give the women of Majomut and greater Chiapas a choice in living a healthier lifestyle, while respecting their traditions and desires.

Community Visit and Surveys

-

Fig 1: Open fire or fogon in use, while improved cook stove goes unused in the background. This might happen due to preference for taste or tradition of open fire or because different cooks in the house might not all know how or even want to cook on the improved stove.

-

Fig 1a: Roof blackened from years of open fire, even with large openings for air circulation between roof and wall smoke rises and then sinks rather than escaping to the outside.

-

Fig 1b: Improved cook stove in use without comal so the dish receives direct heat. In the morning this produces little smoke, but by the afternoon the smoke no longer escapes out the chimney. It rises through the comal opening into the house.

-

Fig 1c: Uncompleted chimney from lack of financial resources after installment from a month before with the Red Cross.

-

Fig 1d: Most families in Majamout purchase their wood rather than collecting it, for this reason it is easier to find income to dedicate to building the stove, since the costs previously used for wood are paid back by the reduced fuel use of the improved stove.

-

Fig 1e: The improved cook stoves are raised off the ground with a base that lifts the comals burners to just under the cooks hip height, reducing back and knee problems associated with open fires.

Survey Results

After conducting a few surveys in a community we can conclude that the Lorena improved cook stove improves health and satisfaction for the women who cook with them. These families spend about $200 to $650 for approximately a square meter of wood, the most common kind being "roble" oak. With an open fire this wood is consumed in about a month, but with the improved cook stove the duration is doubled. Women begin cooking at the age of ten and have severe back pain, knee pain, and respiration illnesses, eye irritation, etc due to the amount of smoke an open fire produces. Not only does health improve with the Lorena, but the roof of the house also lasts longer due to the reduction in smoke inside the house. The food tastes the same, one family even thinks the taste is better with the Lorena, and it takes less time to cook their traditional foods like beans, tortilla, corn and some meats. With the improved cook stoves there is a significant decrease in burns, scalds and cuts with children. There is also less soot on the walls, less ash on the floor, and their dishes last longer because they are no longer exposed to an open flame. The chimney of the new stoves is cleaned about once a month but it is a very difficult process. The chimney has a small diameter, therefore children and women with smaller hands have to clean it. Also women usually remove the main Comal in order to boil their water because the back two comals don’t heat up as much and when the water boils it spills over ruining the comal. This exposes the families to the smoke once again, making them susceptible to certain illnesses. The improved cook stoves have been proven to be beneficial to these communities but there is definite room for enhancement.

Criteria

| Criteria | Weight | Constraints |

| culturally Appropriate Design | 9 | accepted by community as indicated by surveys and communication with community |

| educational ability | 6 | at least a brochure with pictures, an appropedia page, some instruction on use to the families & signage near the stoves |

| comfortable in the environment | 8 | family comfortable in cold/ hot/ windy weather |

| level of material locality | 6 | locals have access to these materials |

| maintainability | 8 | less than 1 hours worth of one persons work every month |

| size | 8 | appropriate for kitchen size and as family desires |

| cost | 10 | affordable for the family |

| reduces need for wood | 5 | reduces need for wood... |

| level of embedded energy of materials | 5 | uses the least amount of energy |

| Durability of material | 7 | at least 50 years with maintenance... |

| Life Use of Stove | 6 | at least 30 years of use... |

| Reduces Green House gas effects | 5 | reduces either black carbon, particulate matter, and carbon monoxide... |

| Local labor and Local skills | 9 | must be easily repeatable with local skills and labor |

| Improves Health | 8 | must improve respiratory, back problems, child health for the family... |

Design Differences Between Patsari and Lorena

Patsari Cookstove Design

- Design elements of Patsari:

Comales are sealed to prevent smoke from entering the living area, the exterior is made of brick in order to lengthen the lifetime, a prefabricated chimney base that allows for easier maintenance, and canals are dug out to redirect hot gases to the secondary burners. [8]

- Desired Results found in other Studies:

Lorena Cookstove Design

- Design Elements of Patsari

Canals redirects the heat to back comals. We found in the village of Majamout the secondary burners are not used to cook on, but rather used as warmers. With our heat distribution tests this makes sense given that even after an hour these back comals are 6 times cooler then the front comal.

- Critiscism of Lorena

'"The Lorena stove is an enclosed stove of rammed earth construction, with a chimney built onto it. The Lorena stove was designed with the mistaken belief that rammed earth would act as insulation; there was a basic misunderstanding of the difference between mass and insulation. Good insulation resists the passage of heat; thermal mass does the opposite, it absorbs heat. Testing has shown that the rammed earth used in the Lorena stove does absorb heat, heat that should have gone into heating the cooking pot." The designers, Aprovecho, now state: “The Lorena has been tested over the years by many researchers and has generally been found to use more firewood than an indoor open fire. The stove has other attributes. Its chimney takes smoke out of the kitchen and it is well liked. It is pretty and a nice addition to the house. It is low cost and can be repaired and even built by the home owner. But, it is not a fuel saving or low emission stove.”[11]'

Materials and Tools

1.Patsari Stove Materials:

- 20 cinder blocks for base....?

- 40 bricks (24x12x6cm)for stove

- A brick with two holes 12x24x6cm 8x8x6cm (ea Novaceramic) cut in half for the 2 openings to the back comals

- 5 80 lb bags of sand ....?

- 1 80 lb bag of cement

- 1 40 lb bag of lime

- 3 20 liter buckets of gravel for insulation (sand, broken gravel pieces, etc)

- 1.5 20 liter cans of dirt (fine grind with high clay content of 30-35%)...?

- 1 Chimney Cap

- 3 Galvanized Pipe 4" diameter and 90 cm long.

Tools Patsari:

- 2 Shovels for digging dirt and sand

- 2 trowels for applying mortar

- sifter with very fine mesh of 1cm for clay

- wheelbarrow for transporting dirt and sand and cement

- recycled wood pieces for building a mold (stove inner dimensions..?)

- nails

- hammer

- 1 level

- string

- scissors for cutting galvanized steel (cutting hole in roof for chimney)

2.Lorena stove Materials:

- 30 20 liter buckets of dirt (with a clay content of 20-30%)

- 6 2 liter buckets of sand (or less if you have a high sand content in your dirt)

- 5 meters chicken mesh

- 1 meter of wire for making hooks

- 1 bag of cement

- 1 bag of lime

- 3 comals (dimensions.....)

- 2 galvanized tubes for chimney

- A cap for chimney

- recycled wood pieces for 2 temporary frames (base mold inner dimensions.....and stove mold inner dimensions...)

- 1 20 liter bucket for part of combustion chamber and large comal temporary mold

- 2 1.5 liter water bottles (filled with water) for back comal temporary molds

Tools Lorena:

- tamper (can be metal tamper or recycled 4 by 4 wood pieces)

- 2 hand shovels

- 1 large sifter for sand and dirt (2-3 cm wide mesh)

- 2 shovels

- wheel barrow for moving dirt, sand, and cement plaster

- wood platform, tarp, or wheelbarrow for mixing cement plaster

- wire cutters

Building Process for Patsari:

-

Fig 1a: The space we started off with

-

Fig 1b: Leveling ground and measuring out area for base

Preparation

- Clean Up site:

- Take out vegetation and brush, where stove will be built

- Clean up material's mess where other stove will be built

- If mixing on the ground, clean the terrain, removing grass, so organic matter does no get in building materials

- Level Ground:

- place stakes in ground to dimensions of base, base is 130 cm deep by 80 cm wide by 60 cm tall

- wrap stakes with thin string so that all stakes are connected into a perfect rectangle needed for your dimensions

- use leveler to see if the string is level, adjust as needed

- Build roof

- roof protects stoves from degradation and makes the stoves more comfortable for users

- Building Base:

- Base dimensions 130 cm deep by 80 cm wide by 60 cm tall

- Sift sand for mortar and cement base untill no rocks larger them 1cm are in the mix.

- Mix cement base, ratio: 1/2 shovel full of lime, 1 shovel full of cement, 1 bucketfull of sand (20L), add water as needed.

- Place cinder blocks around perimeter on top of cement base

- Mix mortar for base, ratio:....

- spread mortar between cinderblocks and ontop

- keep stacking cinderblocks with mortar along perimeter untill reaching 60cm tall

- fill inside with ruble, dirt, or any excess materials that can support the weight of a 2oo pound stove

-

Fig 1d: Cutting bricks to fit in special nooks

-

Fig 1e: Soaking bricks so bricks don't wick water out of mortar

- Building Mold for Stove

- build a wood mold for the stove w/ an inside diameter of 105 deep by 70 wide by 27cm tall, make sure its well leveled and centered

- Adjusting Bricks to Fit Stove Dimensions:

- Lay out bricks to see how many odd sized bricks you have within the dimensions needed for the base given above

- Cut those odd bricks to fit to stoves dimensions, this can be done with a sharp trowel or blade

- Soak bricks¨:

- soak bricks for 1 minute or more, so they do not wick water out of the mortar. Quick drying makes the mortar weaker.

-

Fig 1g: Mixing mortar 1 cement:6 dirt/clay:1/2 lime

-

Fig 1a: Laying brick perimeter within wooden mold (inside dimension 105cm long by 27cm tall by 70cm wide) and laying bricks for combustion chamber opening

-

Fig 1b: Lay back side bricks of combustion chamber 40 degrees flaring out

-

Fig 1c: Lay top side bricks to combustion chamber and fill around outside of chamber with insulation materials like sand or ruble.

- Mortar Mixing

- sift more sand for mortar so rocks no larger then 1 cm

- mix mortar with 6 parts sand: 1 part cement: 1/2 part lime (mix as needed)

- Brick Placing Perimeter

- place the first layer of soaked bricks around the perimeter and spread mortar on their sides and bottom before placing them in mold

- place the second layer of bricks around the perimeter of the stove repeating process with mortar, and repeat process untill you achieve the height desired of 27 cm.

- Combustion Chamber Bricks

- combustion chamber inner dimensions 22cm wide by 36 cm long and 12 cm tall. The combustion chamber is the area for fuel and is directly under the first comal.

- to shape the combustion chamber you have to place two bricks laterally 22cm apart from each other and they have to be centered

- place third one parallel to the front 36 cm from the front edge, the height of the combustion chamber is 12 cm tall

- place two more bricks to fill in the combustion chamber, do no put these bricks exactly straight, but instead at an angle towards the opening.

- the second layer of the combustion chamber includes bricks laying flat

- for the very front pieces cut a brick in half (length wise) and another (width wise) then lay the bricks cut width wise on the edges and the bricks cut length wise in the front near the entrance to the chamber

- Stick three more bricks laying down flat face two on the edges and one in the back framing the combustion chamber. The opening of the sombustion chamber will be for the large comal, so that it recieves direct heat from the fire.

- Fill:

- fill with the mix of sand and ruble, only on up to the edge outside of the combustion chamber. This fill of sand or ruble acts as insulation preventing the flow of heat out of the sides of our stove. This insulation could increase our fuel efficiency, since any heat is going directly to and psat the pots rather then radiating out the sides.[12]

-

Fig 1f: Place chimney flue piece on top of sand and ruble

-

Fig 1f: Sifting clay with fine mesh for top of Patsari

-

Fig 1h:

-

Fig 1i:

- Canal from Combustion Chamber:

- cut the celosia blocks in half width wise so each becomes its own square with a large whole

- Place each half by the back edge of the combustion chamber , the celocia blocks have a hole which acts as a canal for the smoke and heat of the first combustion chamber to the two back combustion chambers.

- the celosia pieces should be placed 2 cm under the level of the mold and should be centered as the picture shows, 18 cms from the side wall.

- Chimney

- place chimjney mold base 3-4 cm from back. It is important that the top of the chimney base will rise 2 cm over the level of the mold inorder to place on the galvanized steel tubes that make the chimney

- Top Mix

- your top mix will be made of a ratio of 2 buckets of finely sifted clay (1/2 cm mesh): 2 buckets of sand : 1 handful of lime: 1/4bucket of cement.

- fill mix to the top of the tallest bricks or to the level of the mold.

- Back Comals

- grab small metal comale molds with diameter a little less then the 28 cm diamter-comal-top and press into top mix. Press them about 6 cm from the sides and 14 cm from the back. Their form should indent into the mix creating a sloping hole for the back comals.

- (the measurements shown in the "lateral view" are very important for the efficiency of the stove) thats why they should be followed to the T.

- one of the more important ones is the hight from the highest clay molded surface to the back end of each comal.¿¿¿¿¿¿¿¿¿¿¿¿¿¿

-

Fig 1j:

-

Fig 1k:

-

Fig 1l:

-

Fig 1e: Penetrating roof to make hole for chimney, using sharp file and hammer

-

Fig 1e: Cutting hole

- Connecting the Back and Front Comals

- to connect the secondary comales to the big comal you need to remove the excess mix out of the holes with a spoon

¿¿¿¿¿¿¿¿

- Placing and Shaping Comal Tops:

- place on front comal top pushing down on comal to mark area where the top will go.

- Lift up the top and shape sides so that their is a steady slope for 4- 5 cm from the top sloping in towards the combustion chamber. This shape will increase the amount of surface area the comal top is exposed to the direct heat of the fire.

- now place on the comal tops and press down so that the tops are sealed on all sides, use extra mix to seal any open areas around comal.

- Chimney

- line up chimney base with where your hole should be in your roof, mark this area.

- puncture and cut hole in chimney. we have a galvanized steal roof, so we punctured it first with a metal bar and hammer, then we used large cutting shears to open the hole.

- attach chimney metal tubes together depending on the height from your roof.

- once through roof, get on top of roof and attach top hat to prevent rain from entering your stove.

- seal the area around your roof with something that can withstand high temptures being emmited from the chimney. We used a mixture of cement, clay and sand similar to the top mix of the stove.

- Test Out your Stove

your stove should now be complete, just give it a test run with some quesadillas.

Lorena Building Process

-

Fig 1f:messy beginnings and materials pile

-

Fig 1fa: the area after it was cleaned

-

Fig 1g: digging dirt from site in the city

-

Fig 1h: bringing the dirt to our site

-

Fig 1ha: Lonny Grafman & student sifting dirt with wire mesh (2-3cm wide) nailed to two by fours

-

Fig 1i:mixing dirt w/ sifted sand (for us 5 dirt:1 sand), wet very little, only enough to bind into a ball when squeezed in your hand, test by throwing the ball into the dirt pile to see if it holds its form

-

Fig 1j:make the wooden mold (with inside dimension 130cm long by 80 cm wide by 30cm tall)

-

Fig 1k:wrap the ends of your mold together with wire to prevent the pressure from filling with dirt from breaking apart your wooden mold

-

Fig 1: a 20 liter bucket acts as the mold for part of the combustion chamber as well as a placement for the largest comal, 30.5 cm in diameter, while two 1.5 liter water bottles are the mold for the back two comals, with a 7.3 cm diameter.

-

Fig 1a: tamping down the dirt within the mold

-

Fig 1a: Since the mixture does not have much moisture within it its important to tamp down with a lot of force, here we used 5 by 5 thick wood pieces as well as a metal 10lb tamper.

-

Fig 1b:

-

Fig 1c:

-

Fig 1d:

-

Fig 1e:

-

Fig 1l:

-

Fig 1b: laying out wire mesh on to stove in order to give cement plaster a criss crossing network to key into

-

Fig 1e: making hooks by bending wire and cutting with wire cutters

-

Fig 1e: finished hooks

-

Fig 1e: tapping hooks in to keep wire mesh close to stove surface

-

Fig 1b: cutting holes in mesh were comals will be

-

Fig 1e: sloping holes by cutting at dirt with hand shovels for comales to fit in snugly and evenly, comal goes over the opening by about 3cm, this slope also helps expose more of the comal to the direct heat from combustion.

-

Fig 1c: wire mesh with holes cut out for comales and combustion chamber opening

-

Fig 1e:top is chimney hole with wire mesh bent in to hole. The two bottom are the back comales with a 3cm cut wider then the hole and a sloped edge into the holes inorder to give comal increased surface area exposure to direct heat of combustion.

-

Fig 1e: Clay cement plaster with 2 parts fine clay:2 parts sand: 1 handful of lime:1/4 of cement. Spoon plaster on trowel.

-

Fig 1e: Splatter some water onto stove. Clay has a "memory" and if you simply apply the plaster without wetting the other clay/dirt surface your very wet plaster can just peel off.

-

Fig 1e: Spread clay cement plaster on lorena moving from bottom up, 2.5cm thick

-

Fig 1ee

-

Testing

Collect Data On

- water consumed (g)(in mass or weight)

how many grams of water consumed to get to boiling - thermal efficiency= (kJ to boil/ kJ used in fuel)

kJ = kilojoule, is a unit of energy

How many kJ did you use of fuel = ...? - burning rate = mass of fuel consumed/ time of test (g/min)

- specific fuel consumption = mass of wood/ mass of water or food (g/g)

- fire power = (Mass of fuel X Calorific value of fuel)/time of high power phase

time of high power phase = any time really using it to boil, cook, etc

(kg X kJ/kg)/seconds = kJ/s = kW = power

remember Power = Energy over Time - Turn Down Ratio = high fire power/ low fire power (W/W)

W = Watts = a unit of energy

[13]

Tools for Testing

- Moisture Meter for measuring moisture in wood. Measuring range 5%-50% in wood and 1.5%-33% in building material, Resolution .1%, and Accuracy +/-3%

- Temperature Measurement Probe, for pipes or odd shaped objects. Range -30C to 105 C (-22F to 221 F), Accuracy +/- 2.2 C (4F), Display Reolution +/- .1C (.1 F)

- Compact Scale, for measuring wood, ashes, water, and food weight. Max 200g.

- Thermometer/Timer, 32 to 482F (0 to 250C), counts to 24 hrs,

Heat Distribution Test

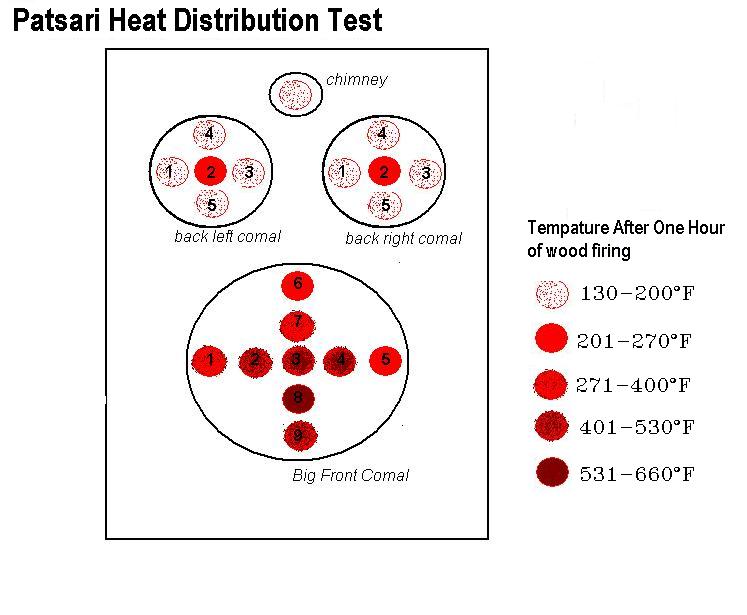

Comparing the Patsari and Lorena. Some of the women in Majamout seem to use the back comals of the Lorena just as warmers, rather then for actual cooking. This heat lost to the back comals would then be considered a loss in fuel efficiency, since the heat is not being utilized for cooking. Other surveiors have found that the reason some women do not use the back comals for actual cooking is that the women notice that the back comals do not heat up hot enough. At other times the front comal gets too hot and burns the tortillas. Understanding the distribution of heat is an important factor in how the stove can be utilized by the cook and in the overall fuel efficiency of the stove.

Patsari

Big Comal 1.309°F 2. 444°F 3.585°F 4.525°F 5. 256°F 6. 263°F 7.399°F 8. 612°F 9. 429°F Left Back Comal 1. 163°F 2.204°F 3.146°F 4.143°F 5.182°F Right Back Comal 1. 147°F 2.2 17°F 3. 192°F 4. 178°F 5.192°F

Outcomes and Suggestions for Patsari Use After Heat Distribution Test

The Controlled Cooking Test

The controlled cooking test tries to cook a local cuisine with help from a local cook to find the amount of fuel consumption, the length of time needed to cook one meal, and the actual emissions when a the stove is in use. Controlled variables in the tests include : food- with the same cook, the same meal, and the same amount of food; and the room - with the same room size, in order to better isolate the difference in the stoves alone. During the test the cooks are observed in order to identify any troubles they have and to ensure that the stove is well designed for use by cooks. The pots used should be the ones the cook commonly uses and the fuel used should be the same fuel that is most commonly used in the community. The fuel is preweighed before the cooking, then again after. The ingredients should be weighed prior to giving to the cook and the meal will be weighed before drained after finished cooking. One test = 3 meals on traditional stove + 3 meals on alternative stove with same cook and same food. A CCT series = 3 different cooks each with 6 meals amounting to 18 meals total.[14]

The Water Boiling Test

Measures the high boiling power and the low simmering power to compare stoves performance of a standard task and to find which stove can most effectively combust the fuel and transfer the heat into the cooking vessel. It can not test field performance, since that varies by local foods and cooks, but it can test the stove design's ability to perform a standard task. Fuel with different composition and moisture level may behave differently. Materials needed: 5L pot, electronic scale (10-15kg capacity, 1-2g resolution), thermometer, wood, water, and tools for removing charcoal. Tests: bring 5L to boil on a stove starting cold, bring 5L to boil on a stove starting hot, continue into simmer for 45 min @ 3 degrees below boiling; between each record the time, mass of fuel, mass of water in pot, mass of charcoal remaining. With help from a WBT spreadsheet online for free you can calculate the time to boil, fire power, and thermal efficiency of each stove. Testing emissions can be done using a hood and measuring the concentration and flow rate leaving the hood, or by having a test kitchen and by measuring levels of indoor air pollution (IAP).[15]

Kitchen Performance Test

Consisting of Household Surveys and Fuel Consumption Measurements, it is conducted when the families have become accustomed to the stove and when the stove has done well with the controlled cooking and water boiling tests. The KPT is done to find the difference in fuel being used by the new stove models and the traditional stoves by the choice of two testing procedures, paired or cross-sectional. By finding out the medium or long term fuel use helps determine if changes are sustained in the long term use of stove and assess qualitative aspects of stove performance, so for about a week weighing the fuel supply each day and checking how many people ate that day.

- PAIRED

- By doing fuel use measurements of the traditional stove for a week and then doing measurements as the families use the improved stove for a week. This is a longitudinal or panel study.

- CROSS-SECTIONAL

- Alternatively, testing can be done by comparing fuel use in two groups of families for a week, with one group using the traditional stove and the other group using the improved stove. This is a case-control study, where the control group is a group of families that still use the old type of stove."

| Year | KwH | Average Monthly Bill |

| 2007 | 3172 | 499.05 |

| 2008 | 3085 | 487.09 |

| 2009 | 2839 | 468.01 |

Literature Review

Heat Basics

- Temperature = thermal energy available

- Heat Flow = the movement of thermal energy

- Greater Temperature = Greater Thermal Agitation of constituent molecules in the form of Kinetic Energy

- Places containing greater molecular kinetic energy pass off that energy to places with less Kinetic Energy[17]

- Energy = Force/Distance (or a quantity equivalent to the capacity of a physical systems ability to perform work)

- Force = mass * acceleration (or distance per time)

- Energy units include: J (or joules), calories, BTU, and kWh

- Power = Energy / time (or the rate at which work is performed)

- Power units include: BTU/hr, kilocalories/hr, and W (or Watts) [18]

Heat Transfer

- Conduction

- Convection

- needs medium for transfer of heat [21]

- Radiation

- materials radiate based on their temperature, this energy is carried by photons within the infrared and visible part of the electro magnetic spectrum.

- thermal radiation results from a difference in temperature between two bodies [22]

- NO MEDIUM needs to exist between the two bodies for the heat to be transfered by these photons [23]

- Affected by surface reflectivity, emissivity, surface area, temperature, and geometric orientation with respect to other thermally participating objects. [24]

Combustion Science

- Combustion is the burning of any substance. Combustion can also be thought of as heat releasing chemical reactions. [25] A fuel (often made of hydrocarbons) mixes with an oxidant (like oxygen) and this mixing may be catalyzed by igniting the materials with a heat source. During the chemical reaction, the energy is released in the form of heat, generating highly reactive atoms and free radicals, which act as the energy released from the process. [26] This energy can be seen as flames, emissions of light, and heat.

- One equation for complete combustion:

CH4 + 2O2 → CO2 + 2H2O + energy

methane mixes with two oxygen to create carbon dioxide plus 2 water molecules and energy

- This oversimplified equation works in laboratories, but in reality most combustion is incomplete and byproducts include carbon monoxide and pure carbons (or ash). Complete combustion occurs in the presence of oxygen, while incomplete combustion occurs in the absence of oxygen. When combustion occurs with air as the oxidant, nitrogen oxides are created, since the nitrogen in air combines with radical oxygens. [27] Both carbon monoxide and nitrogen oxides produced from incomplete combustion can have adverse respiratory effects and can aggravate existing heart conditions. [28]

Wood Combustion

Wood as a fuel does not burn directly, but rather undergoes thermal degredation, where some of the products are combustible gases. If enough heat is released during the gases combustion and this heat is retained by the wood, then the incineration of wood can continue in the absence of oxygen (or pyrolysis) until the entire wood is consumed and only pure carbon remains (or ash). [29] Though the fuel and oxygen may need ignition with a heat source, the heat released in the reaction creates a selfsustaining process.

Fuel Basics

Local Fuels

- oak

- pine

- ocote

- coffee bean srubs

- gas (rare in rural areas)

Earthen Construction

Earthen Plasters

Stove Designs

Some of the common local stove types are:

Lorena Cookstove Design

- Tools Needed:

hoe, shovel, bucket, sieve 4mm, trowel, measuring tape, and level (optional).

- Materials:

- 8-12 wheel barrows clay, 8-12 wheelbarrows of sawdust (or dry chopped grass or dry chopped banana leafs), 60-80 mud bricks, clay tile (25* 13 * 1cm), 7 20 liter buckets of water, and 8-12 wheel barrows of sand.

- Prepare materials 2 days in advance,

- crush clay then sieve clay

- sift an equal amount of sawdust

- mix clay and sawdust 1:1

- add water

- mix with your feet

size of the stove will depend on the size of the pots that will be used with it if designing for two different sized pots the bigger pot should be positioned directly above the combustion chamber.[30]

Community Feedback

- Some cook stove programs have overlooked:

- that the fuel type changes in season and the stove must be efficient at burning these different types of fuel,

- also though costs may be low the women might not control the income and thus can not purchase the improved stove,

- that though the smoke is an irritant it might perform important functions in pest control or in curing the food,

- and that different environments change the functions of the stove as the stove might also serve the double purpose of heating the house in colder climates.

Weather in Chiapas

Temperature in Chiapas, Mexico can vary from 40˚C to 0˚C with an average of 20˚C. It is generally sunny, however, during the rainy season it pours in the late afternoon and nights can get a bit chilly. The rainy seasons occur between the months of October- September and June- July.

Encyclopedia of Mexican States

Health Impacts

- As of 2008 almost half of the humans in the world used solid fuels like traditional biomass or coal for cooking, heat, and/ or lighting.

- Two million deaths a year are associated with respiratory problems from indoor cooking fires with these traditional fuels in unventilated houses.

- It is not the fuel that causes the respiratory problems, but the lack of ventilation and the incomplete combustion of fuel into Carbon monoxide and particulate matter that comes from the inefficient open fires.

- Children make up 44 percent of these deaths, while women make up 60 percent of these deaths among adults.

- As of 2008, 27% of the people in developing countries use improved cook stoves, which attempt to reduce indoor air pollution.

- In Mexico, one household in four still cooks with biomass fuel and the use of the Patsari stove was significantly associated with a reduction of repratory symptoms and a reduction in lung function decline. [33]

- Carbon monoxide is produced from incomplete combustion as in open fires and fogons and is an odorless, tasteless, invisible, potentially deadly gas in unventilated areas.

- Chimney flues and sealed comals help divert smoke out of the house, while the combustion chamber and stove design can help increase the combustion efficiency so that less smoke is produced. The natural buoyancy of the hot gases and smoke want to naturally rise up and leave through the chimney. Houses in the Abeejas were built with large gaps between the roof and walls, but much of the smoke is still trapped within the home as the hotter denser smoke hits the cooler lighter air outside and the smoke then cycles back down into the house.

National Heart Lung and Blood institute

- Asthma is a respiratory disease in the lungs which impairs the ability to breathe. It is mostly affected by the type of climate an individual is exposed to, humidity, cold, and heat can all affect the severity of this disease.

Health effects of air pollution “Recent studies have shown that ultrafine particles penetrate the systemic circulation and exert more toxicity than coarse and fine particles because of a higher content of transition metals and redox cycling chemicals.12-15” Environmental health: bridging the gaps p. 157-162

- Open fire cook stoves and the use of bio-fuel is one of the major causes of respiratory infections and low birth rates. These stoves are not only being used because of cultural reasons but also because it is an affordable source for poor communities. Women and their offspring are the most affected because the stoves are indoors and homes in rural Mexico have poor ventilation. Gathering the firewood is hard labor and many times causes pregnant women to have miscarriages. Some women try to conserve wood and end up undercooking their food, or not boiling their drinking water all the way. This makes individuals more susceptible to having a parasite, diarrhea, and stomachaches, vomiting and in some cases poisoning. All of the previously mentioned symptoms can then cause malnutrition along with the respiratory problems caused by the emissions of these open fires. Along with bad health, if these women continue collecting wood it could lead to deforestation which would then make the communities victims of possible landslides and floods.

- Along with these diseases come more permanent scars, because these women cook inside the home often on the floor where kids easily slip and fall into the fire causing burns. Women will cut themselves on the wood and at times pots of water spill over on them causing scalds. The fires are sometimes left unattended and houses are burned down leaving the families in a worse situation than before.

(insert picture here)

Form of Renewable Heat Supply

[35] "The intervention entails replacing traditional open fires by more efficient devices in rural households. Penetration by 2030 is assumed to reach 100 percent of rural people who use traditional open fires. Improved cook stoves reduce fuelwood consumption and improve combustion efficiency, thereby reducing both the net CO2 emissions linked to the nonrenewable fraction of biomass and non-CO2 emissions linked to incomplete combustion. At least two government programs and several nongovernmental projects are currently operating Mexico, providing reason for optimism that the assumed penetration rate can be achieved."

Box 4.1 Reducing Emissions, Saving Time, and Providing Health Benefits through Improved Cookstoves[36] "Improved cookstoves are a cost-effective tool for reducing greenhouse gas emissions even without valuing the time family members save by not having to collect as much fuelwood and the health benefits from reduced indoor air pollution impacts. When time savings and the positive health impacts of reducing exposure to fine particulate matter IPM2.5) and carbon monoxide are considered, the intervention provides major benefits to households and society. The net benefit of the intervention rises from essentially zero to $2.34/t CO2e when time savings are included and to $18.90 when both time and health benefits are included. With about 80 percent of the rural population in Mexico dependent on wood for cooking and heating, the greenhouse gas mitigation potential of widespread introduction of improved cookstoves is substantial."

Table 4.1 Summary of MEDEC Interventions in the Energy End-Use Sectors [37]

| Intervention | Maximum annual emissions reduction (mt CO2e/year) | Net cost or benefit of mitigation ($/t CO2e) |

| Electricity end-use efficiency | ||

| Residential air conditioning | 2.6 | 3.7 (benefit) |

| Residential lighting | 5.7 | 22.6 (benefit) |

| Residential refrigeration | 3.3 | 6.7 (benefit) |

| Nonresidential air conditioning | 1.7 | 9.6(benefit) |

| Street lighting | 0.9 | 24.2 (benefit) |

| Industrial motors | 6.0 | 19.5 (benefit) |

| Cogeneration | ||

| Cogeneration in industry | 6.5 | 15.0 (benefit) |

| Bagasse cogeneration | 6.0 | 4.9 (cost) |

| Renewable heat supply | ||

| Solar water heating | 18.9 | 13.8 (benefit) |

| IMPROVED COOKSTOVES | 19.4 | 2.3 (benefit) |

[38]

"Entre el 30 y 50% de la población en el mundo usa la combustión de leña, rastrojo, carbón y excretas para satisfacer sus necesidades energéticas. El uso de estos materiales como combustible tiene diversas consecuencias a nivel global. La tecnología de combustión utilizada tanto en pequeña como en gran escala provoca la emisión de diferentes gases que son peligrosos para el ambiente y cuyo efecto es evidente actualmente en los cambios climáticos que se están dando a nivel mundial."

- Patsari Design Advantages

- El diseño de la estufa Patsari permite el ahorro del 60% de la leña que se consume con el fogón tradicional

- La calidad del aire dentro de la cocina mejora un 95% con el uso del modelo Patsari

[39] "La tecnología usada comúnmente para la cocción de alimentos y elaboración de tortillas es el fogón tradicional (tres piedras, tipo U o herradura, doble U y tambos adaptados).

Los principales problemas de estos fogones son:

- baja eficiencia y alto consumo de leña

- no tienen chimenea y por tanto el humo se queda en el interior de la cocina

- el fuego se sale del fogón lo cual representa riesgo de quemaduras y calentamientos.

Estos problemas ocasionan impactos negativos a la salud de mujeres y niños principalmente, y al ambiente cuando la leña es usada de manera inadecuada. "

References

- ↑ I. Romieu, H. Riojas-Rodriguez, A. T. Marron-Mares, A. Schilmann, R. Perez-Padilla, O. Masera, “Improved Biomass Stove Intervention in Rural Mexico: Impact on the Respiratory Health of Women” Am. J. Respir. Crit. Care Med. 2009;180:649-656 [1]

- ↑ Rasmussen, Erin. Energy Access in Developing Countries, 29 June 2010 [2] This reports on an article by Doug Barnes of the World Bank with statistics drawn from the WHO United Nations Report.

- ↑ Rasmussen, Erin. Energy Access in Developing Countries, 29 June 2010 [3] This reports on an article by Doug Barnes of the World Bank with statistics drawn from the WHO United Nations Report.

- ↑ Rasmussen, Erin. Energy Access in Developing Countries, 29 June 2010 [4] This reports on an article by Doug Barnes of the World Bank with statistics drawn from the WHO United Nations Report.

- ↑ Household Energy Network

- ↑ Environmental health: bridging the gaps p. 157-162

- ↑ Todd Milo Johnson,Claudio Alatorre,Zayra Romo,Feng Liu; "Low-Carbon Development for Mexico" [5]

- ↑ Technologies for Conservation and Development "Patsari Stove" [6]

- ↑ Technologies for Conservation and Development "Patsari Stove" [7]

- ↑ Technologies for Conservation and Development "Patsari Stove" [8]

- ↑ fckLRWorld Lingo,"Biomass cook stove", [9]

- ↑ ?

- ↑ Mink, Tirian. Lecture at Chiapas Appropriate Technology Program directed by Lonny Grafman. Wednesday, July 14, 10:00-1:00.

- ↑ MacCarty, Nordica; "The Controlled Cooking Test", Aprovecho Research Center, [10]

- ↑ MacCarty, Nordica; "The Water Boiling Test", Aprovecho Research Center, [11]

- ↑ MacCarty, Nordica; "Stove Testing - The Kitchen Performance Test", Aprovecho Research Center, [12]

- ↑ [13]

- ↑ Grafman, Lonny. Lecture at Chiapas Appropriate Technology Program.

- ↑ [14]

- ↑ [15]

- ↑ [16]

- ↑ [17]

- ↑ [18]

- ↑ [19]

- ↑ McGraw-Hill Concise Encyclopedia of Engineering. © 2002 by The McGraw-Hill Companies, Inc. [20]

- ↑ Chenn Zhou. "Combustion", The Encyclopedia of Earth, July 14, 2010. [21]

- ↑ Wikipedia, "Combustion" [22]

- ↑ U.S. Environmental Protection Agency, "Nitrogen Oxide" [23]

- ↑ F.L. BROWNE, "Theories of the Combustion of Wood and It's Control: A Survey of Literature", Forest Products Laboratory, Forest Service U.S. Department of Agriculture. [24]

- ↑ Rosette K. Kabuleta. "Energy Advisory Project; How to Build the Improved Household Stoves". The Republic of Uganda: Ministry of Energy and Mineral Development. November, 2004. [25]

- ↑ Jiggins, Janice. "Changing the boundaries: women-centered perspectives on population and the environment", Island Press, 1994. [26]

- ↑ Rasmussen, Erin. Energy Access in Developing Countries, 29 June 2010 [27] This reports on an article by Doug Barnes of the World Bank with statistics drawn from the WHO United Nations Report.

- ↑ I. Romieu, H. Riojas-Rodriguez, A. T. Marron-Mares, A. Schilmann, R. Perez-Padilla, O. Masera, “Improved Biomass Stove Intervention in Rural Mexico: Impact on the Respiratory Health of Women” Am. J. Respir. Crit. Care Med. 2009;180:649-656 [28]

- ↑ OIKOS Focused on Energy Efficient Building and Environmentally Sound Construction, “A Simple Test Can Spot Carbon Monoxide Danger” [29]

- ↑ Todd Milo Johnson,Claudio Alatorre,Zayra Romo,Feng Liu; "Low-Carbon Development for Mexico" [30]

- ↑ Todd Milo Johnson,Claudio Alatorre,Zayra Romo,Feng Liu; "Low-Carbon Development for Mexico" [31]

- ↑ Todd Milo Johnson,Claudio Alatorre,Zayra Romo,Feng Liu; "Low-Carbon Development for Mexico" [32]

- ↑ "Estudio Gases Efecto Invernadero"; GIRA, [33]

- ↑ "Proyecto PATSARI"; GIRA, [34]

See Also

Improved Cookstoves

GIRA,Grupo Interdisciplinario de Tecnologia Rural Apropiada a nonprofit in Mexico, who created the designs for the Patsari for this project.