Rok duncan (talk | contribs) |

Rok duncan (talk | contribs) (→Criteria: Cleaned up extra lines) |

||

| Line 52: | Line 52: | ||

|- | |- | ||

|Cost | |Cost | ||

| | |Needs to have enough spending to support project but not enough to bankrupt the community | ||

|align="right"|9 | |align="right"|9 | ||

|- | |- | ||

| Line 67: | Line 67: | ||

|align="right"|10 | |align="right"|10 | ||

|- | |- | ||

|} | |} | ||

Revision as of 23:00, 22 July 2010

Team Biogas

International Renewable Resources Institute-Mexico

Appropedia Page: International Renewable Resources Institute-Mexico

General Information: info@irrimexico.org

Executive Director Alex Eaton: alex@irrimexico.org

Director of the Board Ilan Adler: ilan@irrimexico.org

Telephone: 011 (52) 55 3547 0221 or 011 (52 1) 55 1886 8210

Instituto Internacional de Recursos Renovables, A.C. Tlacotalpan No. 6 Bis, Int 301, Col Roma Mexico D.F. 06760 (52) 55 3547 0221

Objective and Background

In the summer of 2010, a collaboration between students of Humboldt State University and the International Institute of Renewable Resources (IRRI) will seek the construction and dissemination of a biodigestion system, the Biobolsa, within the community of San Cristobal de las Casas, Chiapas. The objective of this project is to promote the realization of further Biobolsa projects in the San Cristobal de las Casas area by constructing a successful Biodigester demonstration system in the eco-home of architect Juan Hidalgo.

In Chiapas, Mexico, wood is used as a primary cooking fuel in rural communities. Wood as a fuel has several drawbacks: it is labor intensive to collect, it contributes to deforestation, and upon combustion poses significant respiratory risks to users. (ADD REFERENCE) For these reasons, biogas as an alternative to wood fuel can improve the indoor air quality and overall quality of life for consumers in select applications (ADD REFERENCE)(Robert: What are the select application?).

The current management practices for livestock manure typically consist of xxxxxx. These practices result in the uncontrolled release of methane gas into the atmosphere. Methane gas as a greenhouse gas is approximately four times more potent than carbon dioxide (REFERENCE). In addition, the release of manure into public waterways contributes to the proliferation of waterborne disease in rural communities(Robert: Site Reference). The controlled decomposition of animal waste in a biodigester is one alternative to the existing management practices. Use of the Biobolsa system results in the sequestration of greehouse gases and conversion of the animal waste into a safe fertilizer. (REFERENCES)

Criteria

| Criteria | Description | Weight |

|---|---|---|

| Level of Energy Generation | Amount of Methane Produced | 7 |

| Level of Fertilizer Generation | Amount of Fertilizer Bi-product Produced | 5 |

| Durability | Needs to withstand use with no more than of $5-10 yearly maintenance. | 8 |

| Cost | Needs to have enough spending to support project but not enough to bankrupt the community | 9 |

| Adherence to the Mission of IRRI | Meets IRRI's educational standards | 8 |

| Level of Cultural Appropriateness | Project must be able to be incorporated in the cultural setting of client. | 9 |

| Potential for Community Involvement | Must be a demonstration biodigestor designed for educating the community. | 10 |

Literature Review

Overview

Animal Waste

Bhattacharya A. N. and Taylor J. C. Recycling Animal Waste as a Feedstuff: A Review J Anim Sci 1975. 41:1438-1457. http://jas.fass.org/cgi/reprint/41/5/1438.pdf

- "Manure is a complex mixture of undigested dietary residues, endogenous

secretions, and bacterial cells and their metabolic end points. Manure is subject to anaerobic degradation under a variety of moisture and temperature conditions, resulting in the generation of odorous volatile compounds. When manure undergoing degradation has a surface exposed to the atmosphere, volatile products and intermediates are emitted into the environment."

Decomposition

Palmisano, Anna C. Microbiology of Solid Waste. 1996, CRC PRESS http://books.google.com.mx/books?hl=es&lr=&id=U0n69b90wAQC&oi=fnd&pg=PA2&dq=microbiology+of+solid+waste&ots=ANew6o40Fy&sig=p45UKc8RaGfYPX3BuuhEJpxeLco#v=onepage&q&f=false

- "New methods of molecular analysis are confirming that less than 1% of

the microbes present in natural environments are culturable." (Amann et al., 1995)

- "An immature compost can introduce phytoxic material to the soil, such

as ammonia and volatile fatty acids, and it can result in a reduction of the pH of the ammended soil." (Iglesias-Jimenez and Perez-Garcia, 1992.)

Hazards

Bhattacharya A. N. and Taylor J. C. Recycling Animal Waste as a Feedstuff: A Review J Anim Sci 1975. 41:1438-1457. http://jas.fass.org/cgi/reprint/41/5/1438.pdf

- "Many pathogenic organisms (bacteria, viruses and

fungi) capable of causing disease in humans, livestock and poultry have been isolated from animal waste (U.S.D.A., 1957; Schwabe, 1964); several toxigenic fungi have also been isolated from samples of poultry waste" (Lovett, 1972). Mackie, R.I., Stroot P. G. and Varel, V. H. Biochemical identification and biological origin of key odor components in livestock J Anim Sci 1998. 76:1331-1342. http://www.animal-science.org/cgi/reprint/76/5/1331

- "Worldwide CH4 production is estimated at 400 ´ 106 t; animals are held responsible for 15 to 25% of this amount.¨

- "Manure degradation can be a major source of methane (CH4)

and nitrogen oxides (NOx) , which contribute to accumulation of greenhouse gases. Volatilization of ammonia (NH3) causes acid rain, which contributes to forest die-back in western Europe where animal sources are responsible for 50% of the acid precipitation (Lowe, 1995; Likens et al., 1996). Emissions of nitrous oxide (N2O) during the nitrification-denitrification cycle can contribute to ozone depletion" (Schulte, 1997). Harada, Yasuo Quality of Compost Produced from Animal Wastes JARQ 26 238-246 (1993.) http://www.jircas.affrc.go.jp/english/publication/jarq/26-4/26-4-238-246.pdf

- "Pathogen, parasites and weed seeds and are all generally killed during composting at temperatures of 60*C or higher."

Potential as Fertilizer

Bailey L.D., Choudhary M. Grant, C.A., Review of the Use of Swine Manure in Crop Production: Effects On Yield and Composition and On Soil and Water Quality Waste Management & Research, Vol. 14, No. 6, 581-595 (1996) http://wmr.sagepub.com/cgi/content/abstract/14/6/581

- "The world swine population produces about 1.7 billion tonnes of liquid manure annually. At an application rate of 20 tonnes per hectare, this could fertilize about 85 million hectares of land annually."

- "Research has shown that manure application increased soil N, P, K, Ca, Mg and Na. However, heavy or excessive application of manureincreased leaching of NO3-N, P and Mg. Swine manure is reported to be effective in increasing the yields of cereals, legumes, oilseeds,

vegetables and pastures, and in increasing plant nutrient concentration, especially N, P and K."

Anaerobic Processes

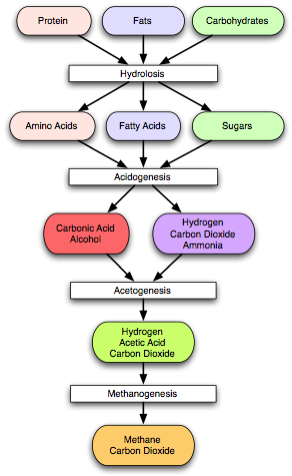

Anaerobic digestion is a series of processes in which microorganisms break down biodegradable material without oxygen. In order to promote this anaerobic process biobolsas and similiar systems are sealed to keep out as much air as possible. Anaerobic processes have the benefits of producing less biological sludge, minimal amount of energy required and methane is produced which can be used as an energy source. [1]

The digestion process begins with bacterial hydrolysis of the input materials in order to break down insoluble organic polymers such as carbohydrates and make them available for other bacteria. Acidogenic bacteria then convert the sugars and amino acids into carbon dioxide, hydrogen, ammonia, and organic acids. Acetogenic bacteria then convert these resulting organic acids into acetic acid, hydrogen, and carbon dioxide. Methanogens, finally are able to convert these products to methane and carbon dioxide.[2] The methanogenic bacteria in stage three of the anaerobic digestion is responsible for the formation of methane. There are two common ways of forming methane, by splitting acetate (Equation 1) and by the reduction of carbon dioxide (Equation 2). The methanogens which splits the acetate is about half as common as the methanogens that reduced carbon dioxide which explains why the resulting biogas is normally around 65% methane and 35% carbon dioxide. Biogas is also made up of small amounts of other gases such as hydrogen sulfide and some water vapor. [3]

CO2 +8H‐>CH4 +2H2O

Equation 2:

CH3COOH ‐> CH4 + CO2 [4]Economic Incentive

"Before a biogas plant is built or a biogas program is implemented, a techno-economic assessment should be made. For this, two sets of cost-benefit analyses have to be carried out: · The macro-economic analysis (economic analysis) which compares the costs of a biogas program and the benefits for the country or the society. · The micro-economic analysis (financial analysis) which judges the profitability of a biogas unit from the point of view of the user. In judging the economic viability of biogas programs and -units the objectives of each decision-maker are of importance. Biogas programs (macro-level) and biogas units (microlevel) can serve the following purposes: · the production of energy at low cost (mainly micro-level); · a crop increase in agriculture by the production of bio-fertilizer (micro-level); · the improvement of sanitation and hygiene (micro and macro level); · the conservation of tree and forest reserves and a reduction in soil erosion (mainly macro-level); · an improvement in the conditions of members of poorer levels of the population (mainly macro-level); · a saving in foreign exchange (macro-level); · provision of skills enhancement and employment for rural areas (macro-level)."

Habermehl Stefan, Kossmann Werner, Pönitz Uta, Biogas Digest:Volume III Biogas - Costs and Benefits and Biogas – Programme Implementation <www.gtz.co.za/de/dokumente/en-biogas-volume3.pdf> (July 11, 2010)

Social Incentive

"Biogas technology not only supports national economies and the environmental protection, but as its main outcome for the local population it provides for a wide range of improvements in overall living conditions. Sanitary and health conditions improve and the quality of nutrition is enhanced by an improved energy availability. Through the provision of lighting and the reduction of time-consuming fuel gathering cultural and educational activities are supported. Employment, professional qualification and overall food supply of the local population can be improved as well. But biogas technology can also contribute to an accentuation of existing differences in family income and property. Establishing community-level biogas systems is a way to ensure that the technology benefits a greater number of residents. If social policies of a developing country are clearly focusing on poverty alleviation, biogas technology may not be the first choice among other "village technologies". It’s place is shifting rather towards the rural agricultural middle class, communities (for waste water treatment) and industries." Habermehl Stefan, Kossmann Werner, Pönitz Uta, Biogas Digest:Volume III Biogas - Costs and Benefits and Biogas – Programme Implementation <www.gtz.co.za/de/dokumente/en-biogas-volume3.pdf> (July 11, 2010)

"Considerable workload reduction in rural areas: This is particularly true for rural women engaged in day to day household work. Installing a biogas unit will relieve her of the tiring and tedious job of collecting and ferrying firewood. Since, biogas burns cleanly, the rural homes will not suffer from smoke and consequently rural denizens will suffer less from physical problems like bronchial complications. Cooking is also easier with a gas stove and takes less time."

Economy watch (2010) <http://www.economywatch.com/renewable-energy/advantages-of-biogas.html> (July 11, 2010)

"Visible improvement in rural hygiene: Biogas contributes positively to rural health conditions. Biogas plants lower the incidence of respiratory diseases. Diseases like asthma, lung problems, and eye infections have considerably decreased in the same area when compared to the pre-biogas plant times. Biogas plants also kill pathogens like cholera, dysentery, typhoid, and paratyphoid."

Economy Watch (2010) <http://www.economywatch.com/renewable-energy/advantages-of-biogas.html> (July 11, 2010)

"Conversion of natural organic waste into fertilizer: The conversion is carried out in a machine called the polythene bio gas digester. Cow dung slurry is put into the machine. The product is organic fertilizer of high quality. The fertilizer obtained is rich in nitrogen. It has been analyzed, that, fertilizer made by the polythene bio gas digester contains nitrogen content 3 times more than the product made by conventional processes. It is completely natural and free from harmful synthetic chemicals."

Economy watch (2010) <http://www.economywatch.com/renewable-energy/advantages-of-biogas.html> (July 11, 2010)

Environmental Incentive

Carbon Offset & Methane Reduction

"Each year some 590-880 million tons of methane are released worldwide into the atmosphere through microbial activity. About 90% of the emitted methane derives from biogenic sources, i.e. from the decomposition of biomass. The remainder is of fossil origin (e.g. petrochemical processes). In the northern hemisphere, the present tropospheric methane concentration amounts to about 1.65 ppm(parts per million)...Unlike fossil fuel combustion, biogas production from biomass is considered CO2 neutral and therefore does not emit additional Greenhouse Gases (GHG) into the atmosphere...However, if biogas is not recovered properly, it will contribute to a GHG effect 20 times worst than if methane is simply combusted. Therefore, there is a real incentive to transfer biogas combustion energy into heat and/or electricity."

Singh, Chandan (2006) <http://projectsimilipal.blogspot.com/2006/07/benefits-of-using-biogas.html> (July 11, 2010)

"Biogas not only releases far less carbon dioxide than fossil fuels, but it also produces smaller quantities of other pollutants such as heavy metals, sulfur dioxide, nitrogen and particulates...One of the gases produced by the decomposition of manure is methane gas, which is estimated to trap 20 to 30 times as much atmospheric heat as carbon dioxide, and reducing methane releases into the air is a crucial element of the fight to limit global warming. The relatively simple digestion process that produces biogas converts a foul-smelling manure pile from a methane-emitting climate villain to high-quality... fuel. And digestion doesn’t reduce the value of manure as an agricultural fertilizer. The important substance for plant growth is nitrogen, which remains in place after extraction of biogas...This leads to further environmental advantages. By reducing the weight and volume of fertilizer, biogas extraction cuts down on transportation pollution. And increasing the amount of fertilizer available from composted waste reduces the need for artificial fertilizers, which release the extremely powerful greenhouse gas nitrous oxide."

Advantage Environment (2009) <http://advantage-environment.com/upplevelser/double-environmental-benefit-from-biogas/ > (July 11, 2010)

The size of the biodigester determines offsets in regards to wood and carbon as well as the methane reductions. For example, "1 biogas plant is computed to save 32 liters of kerosene and 4 tons of firewood every year."

Economy Watch (2010) <http://www.economywatch.com/renewable-energy/advantages-of-biogas.html> (July 11, 2010)

Another type:"Each biogas plant saves about 2.5 tonnes/year of fuelwood, equivalent to about four tonnes/year of CO2. And incidence of respiratory diseases has reduced among users."

The Ashden Awards (2010) <http://www.ashdenawards.org/winners/vknardep> (July 11, 2010)

"Another major environmental target is the mitigation of deforestation and soil erosion through the substitution of firewood as an energy source." Habermehl Stefan, Kossmann Werner, Pönitz Uta, Biogas Digest:Volume III Biogas - Costs and Benefits and Biogas – Programme Implementation <www.gtz.co.za/de/dokumente/en-biogas-volume3.pdf> (July 11, 2010)

IRRI

"IRRI Mexico is dedicated to promoting sustainable use of natural resources. We provide education, develop new technologies, and install systems that help low income families meet their basic energy, water, and sanitation needs in a sustainable way. Our projects aim to empower families, communities, and businesses to produce their own clean energy, obtain their own water, and manage their own resources and wastes in ways that benefit them and the environment simultaneously."[5]

Mission

Our Mission is to promote programs and businesses that produce sustainable goods and services and help reduce reliance on fossil fuels. IRRI supports rural and low-income communities with the objective of improving the quality of life through generating, developing, and conserving local resources. IRRI’s vision is sustainable and equitable prosperity in a world without contamination."[6]

Dissemination

Mexico

- Current:

- Of the approximately 250 industrial biodigester projects that the Clean Development Mechanism (a mechanism of the Kyoto Protocol) has funded 200 of those are in Brazil and Mexcio. Additionally, nearly 30% of all the 'waste gas recovery projects' are in Mexico making up about 110 projects of which the great majority are anaerobic digesters. [7]

- Future:

- Anaerobic digester systems may not be possible in some areas of Mexico due to water shortages. [8]

Logistical Analysis of Site

- Address + GPS

Client: Juan Hidalgo Calle Tapachula #55 San Cristóbal de las Casas, Chiapas Mexico 16° 44’ 27.46’’ N 92° 37’ 39.78’’ W Elev. 2154m Espacio: 7m x 2.7m

Climate of San Cristobal

• Monthly temperature averages for San Cristóbal de las Casas

"January Avg low: 17° Avg hi: 29° Avg precip: 0.03 cm February Avg low: 18° Avg hi: 30° Avg precip: 0.19 cm March Avg low: 19° Avg hi: 33° Avg precip: 0.02 cm April Avg low: 21° Avg hi: 35° Avg precip: 0.61 cm May Avg low: 22° Avg hi: 34° Avg precip: 3.45 cm June Avg low: 22° Avg hi: 32° Avg precip: 14.23 cm July Avg low: 21° Avg hi: 31° Avg precip: 9.64 cm August Avg low: 21° Avg hi: 31° Avg precip: 12.78 cm September Avg low: 21° Avg hi: 30° Avg precip: 12.15 cm October Avg low: 20° Avg hi: 30° Avg precip: 3.45 cm November Avg low: 19° Avg hi: 30° Avg precip: 0.77 cm December Avg low: 18° Avg hi: 29° Avg precip: 0.28 cm"

Foreca 2010 <http://weather.msn.com/monthly_averages.aspx?&wealocations=wc%3a7246&q=San+Crist%C3%B3bal+de+las+Casas%2c+MEX&setunit=C> (July 11, 2010)

• Daytime temperatures average from 19° C. (66° F.) in winter and 23° C. (73° F.) in summer. Overnight lows average from 5° C. (41° F.) in winter and 13° C. (55° F.) in summer. < http://www.innvista.com/culture/travel/mexico/sclc.htm > (July 11, 2010)

Thermophilic Bacteria

Micro-organisms which live in temperatures of 40°C-80°C are "thermophiles" and those that live in 10°C-47°C "mesophiles."[9] A study was performed to assess the effect of temperature variations on the performance of a mesophilic (35 degreesC) and a thermophilic (55 degreesC) upflow anaerobic filter treating a simulated papermill wastewater. It was found that the thermophilic produced much less diversity in bacteria than the mesophilic. The study showed that both systems had a decrease in productivity (produced less biogas) when temperatures were dropped to 35 degrees C.[10]

Tentative Schedule

- Week 2:

- Continue Investigation

- Site Evaluation (Wed 7/14)

- Arrange Site with IRRI and report to Lonny

- Week 3:

- Class Installation (Tue/Wed)

- Week 4:

- Assist IRRI with public course

- Second Installation

- Tests and Infrastructure

- Week 5:

- Complete page on biodigestion on IRRI's website

References

- ↑ Ibanez, J. G., Hernandez-Esparza, M., Doria-Seranno, C., Singh, M. M. (2007).Environmental Chemistry: Fundamentals, 1st Ed., Springer, New York.

- ↑ TerraForm (2009)."Anaerobic Digestion" <http://terraformenergy.net/anaerobic.html>.

- ↑ Eaton, A.B. (2009) "The Role of Small-Scale Biodigesters in the Engery, Health and Climate Change Baseline in Mexico" Masters Thesis, HSU Environmental Resource Engineering.

- ↑ Gerardi, M. H. (2003) “Microbiology of Anaerobic Digesters” 1st Ed., Hoboken, New Jersey.

- ↑ Instituto Internacional de Recursos Renovables (2010). "Welcome." IRRI, <http://www.irrimexico.com/english/> (Jul. 12, 2010).

- ↑ Instituto Internacional de Recursos Renovables (2010). "Mission." IRRI, <http://www.irrimexico.com/english/> (Jul. 12, 2010).

- ↑ Eaton, A.B. (2009) "The Role of Small-Scale Biodigesters in the Engery, Health and Climate Change Baseline in Mexico" Masters Thesis, HSU Environmental Resource Engineering.

- ↑ Secretaría de Medio Ambiente y Recursos Naturales (2008) "Animal Waste Management Methane Emissions" Presentation prepared for Methane to Market. <http://www.methanetomarkets.org/documents/ag_cap_mexico.pdf>

- ↑ Rose, A. H., and Wilkinson, J. F. (1979) "Advances in Microbial Physiology" Vol. 19, 1st Ed., New York, New York.

- ↑ Ahn, JH and Forster, CF (2002) The effect of temperature variations on the performance of mesophilic and thermophilic anaerobic filters treating a simulated papermill wasterwater. Process Biochemistry, 37 . pp. 589-594. ISSN 0032-9592