Colman, Daniel Lauren Lamet Mark Ambercino Engr 305

Photovoltaic System for Vaccine Refrigeration

at Centro De Salud

Purpose:

This photovoltaic system was designed to power a DC Vaccine Refrigerator at the hospital Centro De Salud in Parras, Mexico. Centro De Salud had a list of items that needed to be purchased at their hospital. Among these was a new vaccine refrigerator. After learning of this, the project group members set out to design a PV system for the hospital that could fulfill this need.

Photovoltaics for Vaccine Refrigeration:

PV systems are well suited for vaccine refrigeration for a few reasons. PV arrays are becoming an increasingly popular alternative to gas generators for supplying energy to off-grid vaccine refrigeration because of their ability to create reliable energy that requires little system maintenance. LINK PDF According to the World Health Organization, PV refrigeration systems are much more efficient at maintaining internal temperatures in refrigerators than gas generators. This creates for an overall greater reliability of the refrigerator system. In the case of Centro De Salud, having a PV powered vaccine refrigerator could prevent vaccine spoilage due to grid power outages, which can be very costly.

System Specifications:

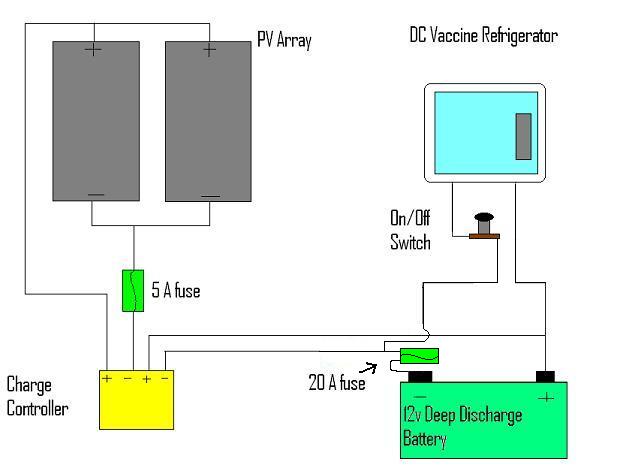

These are the primary supplies used in the system:

• 2 12v 40 watt Uni-Solar PV laminate panels • Charge Controller 4.5 Amp • Trojan Deep Cycle Battery 215 AH • 6 gauge wires, 10 gauge wires • Fuses • Sun Frost RFVB-134a Solar Powered Vaccine Storage DC Refrigerator LINK

- For in depth explanation of these supplies refer to the Photovoltaic page on Appropedia.

System Calculations:

Usually when designing a system, it is ideal to use calculations to figure out the appropriate sizes for the PV array, the charge controller, and the battery, and then purchase the appropriate supplies. In this case, the panels and charge controller had already been donated, and sizing the system was simply a matter of plugging in the numbers and seeing if the system was sufficiently sized for our load.

Where to get the values?

In order to obtain values for use in the system sizing calculations, research and testing is necessary. If the values in your system calculations are inaccurate, they could throw off your entire system.

Load: The first thing to figure out when designing your system is how much does your load need? This system is for a DC refrigerator, and therefore an inverter is not needed to convert to AC. Designing a PV system for a refrigerator is a bit harder to plan for because of the fact that the refrigerators draw requirements are static based upon the weather. In 70° F weather, this refrigerator pulls only 14 Amp Hours a day. In 90° F weather the refrigerator uses 23 AH/ day. According to the official Municipal Profile of Parras, the average annual temperature is 68° F with a maximum average temperature of 77.36 ° F in the months of June and July. However, some days the temperatures can spike. For this reason, calculations were done for both values, to be safe.

Array Sizing

Panels: First the two panels were tested with a multimeter for voltage and amperage. Each panel put out 2A and 20 Volts. Using P=IV we calculated that P=2A x 20V. Therefore P= 40 W. However, this value is not the real value for how much wattage each panel can put out. The reason is that all panels have a specific IV curve which gives the real possible output values of the panels. According to The Encyclopedia of Alternative Energy and Sustainable living, is A current/voltage curve which expresses the possible combinations of current and voltage output of a photovoltaic device. Most PV manufacturers list the IV curve either on the panels themselves or online. However, because the panels used in this system are no longer in make, it was impossible to find the real IV curve of the panels. Fortunately, for calculating array size, the only information needed from the panels is the module peak amps, and the nominal module voltage. Therefore our module peak amps are 2A based upon our measurements, and our voltage for the panels is 12V. Because this project already had the panels, array sizing calculations were done only to measure if our system could handle the loads required.

Battery Efficiency- Deep Cycle Lead Acid batteries have an average efficiency of 80%

Peak Sun Hrs/Day According to the Advanced Energy Group website, the average low peak sun hours in this part of Mexico are between 4 and 5 hours. Therefore 4.5 peak sun hours was the value used to calculate our array size. Controller Sizing

Orientation of the Panels

It is important to orient your panels properly so that they receive the maximum amount of solar radiation throughout the year. There are two important factors when determining where to face your panels.

1) Direction

In the northern hemisphere, panels should be faced southward and the opposite for the southern hemisphere. However, for maximum efficiency, the panels should be faced towards true south, not magnetic south. True south can be found simply by using a compass and a declination map reading based on your location, which tells you how much to adjust your reading for magnetic south. The National Geophysical Data Center has a great online declination calculator that allows one to calculate declination based upon time and location. This can be found at this link: http://www.ngdc.noaa.gov/seg/geomag/jsp/Declination.jsp

2) Angle towards the Sun

Photovoltaic panels produce the most power when perpendicularly facing the sun. For this reason it is important to mount your panels so that receive that greatest perpendicular exposure to the sun. When deciding what angle to mount your PV array, it is generally a good idea to use the corresponding latitude of your location. Because Parras, Mexico resides at 25 N 102W, this system’s panels were mounted at a 25°. However, depending on your systems needs, it may be beneficial to adjust your panel’s angles as much as 4 times a year to boost your system output. Whole Sale Solar (http://www.wholesalesolar.com/products.folder/mount-folder/mount-info.html) recommends adjusting your panels as follows:

February 5th - Set to same angle as your latitude. May 5th - Set at the same angle as your latitude minus 15 degrees. At noon the panel will be almost horizontal to the ground. August 5th - Set at the same angle as your latitude. November 5th - Set at the angle of latitude plus 15 degrees. This tilts your panels towards the sun as it travels low in the southern sky during the winter.

Connecting the Wiring

Connecting the wiring proved to be one the more challenging tasks in this project. Most wire to wire connections use wire nuts to safely connect the two cables. However, 6 gauge wires are extremely thick, and not a single hardware store in town carried the wire nuts at the size we needed. A secure water proof connection was required especially for the wires on the roof that connect to the panels, which will receive large amounts of rain. Instead of using wire nuts, the wires were simply connected with electrical tape. Then PVC piping was used to cover the connections, making it both water and sun resistant. Then with zip ties, the pipes were held both together, as well as to the panel mount to keep them from blowing in the wind. While not a perfect solution, the PVC pipe should prolong the life of the system’s wiring connections greatly, as well as reduce the wear on the wires.