Hannah Stoll (talk | contribs) |

Sophivorus (talk | contribs) m (Text replacement - "| affiliations = " to "| organizations = ") |

||

| (64 intermediate revisions by 11 users not shown) | |||

| Line 1: | Line 1: | ||

[[File:Peanut mill.jpeg|thumb]] | |||

= | {{Device data | ||

| manufacturing-files = https://www.youmagine.com/designs/peanut-mill | |||

}} | |||

[[ | {{Project data | ||

| authors = User:Hannah Stoll | |||

| completed = 2018 | |||

| made = Yes | |||

| replicated = No | |||

| instance-of = Grinder | |||

}} | |||

{{777 notice}} | |||

This hand powered machine is a food processing tool that will grind peanuts down so they can be made into peanut butter. There aren't many 3D printable milling devices out there. This entire mill is 3D printed and was designed with all open source technology. Food processing mills and machines are expensive to buy, so this printable one allows people in need to have tools that work. | |||

[[File:Peanut mill.jpeg|200px|right]] | |||

== Bill of Materials == | |||

# Fully 3D printable (I used 1.75mm PLA filament) | # Fully 3D printable (I used 1.75mm PLA filament) | ||

# [https://www.youmagine.com/designs/peanut-mill Link to Openscad and STL Files] | |||

## Bearing Bottom, 4 min, 2 g | |||

## Bearing Top, 7 min, 4 g | |||

## Center Rod, 18 min, 11 g | |||

## Connector Arm, 15 min, 8 g | |||

## Funnel, 3 hr 19 min, 111 g | |||

## Bracket, 5 min, 2 g | |||

## Handle, 34 min, 18 g | |||

## Inner Grinder, 34 min, 21 g | |||

## Outer Grinder, 1 hr 27 min, 49 g | |||

### TOTAL: 6 hr 39 min, 226 g | |||

== Tools needed == | |||

# [[Athena Build Overview|MOST Delta RepRap]] or similar RepRap 3-D printer | |||

# [[Athena Build Overview| MOST Delta RepRap]] or similar RepRap 3-D printer | |||

== Skills and knowledge needed == | |||

* https://en.wikipedia.org/wiki/Plastic_joining | * https://en.wikipedia.org/wiki/Plastic_joining | ||

== Technical Specifications and Assembly Instructions== | == Technical Specifications and Assembly Instructions == | ||

Directions for Assembly: | |||

# | # Fit center rod into internal grinder | ||

#Assembly time estimate: 15 minutes | # Place it in the outer grinder | ||

#Drawing of Assembly: | # Put bearing top on the center rod | ||

# Slide funnel on and snap pegs to outside of outer grinder | |||

# Line up bearing top and bottom on funnel with center rod running through them | |||

# Plastic join the bearing top and bottom | |||

# Plastic join the internal grinder with the bracket | |||

# Snap on connector arm to center rod | |||

# Snap on handle to connector arm | |||

# Print time estimate: 6 hours 39 minutes | |||

# Assembly time estimate: 15 minutes | |||

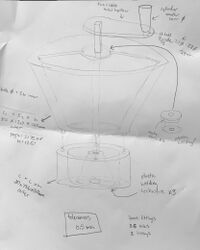

# Drawing of Assembly: | |||

[[ | [[File:Peanut mill layout.jpg|200px]] | ||

=== Common Problems and Solutions === | |||

# Plastic welding: The point of doing this in two places was to eliminate the need for screws and washers to make this completely printable. It is difficult, but placing the nozzle in the holes given and extruding +40 gives a good weld. | |||

#Plastic welding: The point of doing this in two places was to eliminate the need for screws and washers to make this completely printable. It is difficult, but placing the nozzle in the holes given and extruding +40 gives a good weld. | # The pegs on the funnel just snap around the outer grinder. I had an issue with the original part, but this was the quick fix. | ||

== Cost savings == | |||

# This machine can save people over $100 depending on the type of mill wanted. | |||

# Commercial equivalent: [https://www.preparedplanet.com/country-living-mill-peanut-butter-accessory/?gclid=EAIaIQobChMI2Za8meuK3wIVB6rsCh17RQv8EAkYBCABEgJfEfD_BwE Country Living Mill Peanut Butter Accessory] | |||

# | # I saved about $160 compared to the competition above. That's roughly a 97% savings. | ||

# | |||

== Benefited Internet Communities == | == Benefited Internet Communities == | ||

* [[Requests for 3-D printable open source appropriate technology|Requests for OS 3D Printable Objects]] | |||

* [http://www.fpsa.org/ Food Processing Suppliers Association] | |||

* [[Open Source Appropriate Technology|OSAT]] | |||

* [http://www1.wfp.org/ World Food Programme] | |||

* [https://www.actionagainsthunger.org/ Action Against Hunger] | |||

==References==<ref>web page: Department of Energy (DOE) Landscaping and Energy Efficiency, DOE/GO-10095 (1995) Available: [https://web.archive.org/web/20021201231338/http://www.eren.doe.gov:80/erec/factsheets/landscape.html http://web.archive.org/web/20021201231338/http://www.eren.doe.gov:80/erec/factsheets/landscape.html]</ref><ref>web page: Grain Mill Reviews: Basic Overview of the Different Grain Mills (Video 1 in a Series) Available: https://www.youtube.com/watch?v=2biIDfbWRIkl</ref><ref>web page: Troubleshooting Guide Available:http://www.countrylivinggrainmills.com/support/grinder/</ref><ref>web page: Hand Crank Mill for pregrinding nuts for Nut Butter Grinder Available:https://www.youtube.com/watch?v=G0khTvo5Ag4</ref> | |||

<references/> | <references /> | ||

<nowiki> | <nowiki> | ||

</nowiki> | |||

{{Page data | |||

| keywords = 3D printing, food processor, grinder, kitchen appliance, osat, plastic | |||

| sdg = SDG03 Good health and well-being, SDG08 Decent work and economic growth | |||

| published = 2018 | |||

| organizations = Michigan_Tech's_Open_Sustainability_Technology_Lab, MY4777, MTU | |||

| license = CC-BY-SA-3.0 | |||

| language = en | |||

}} | |||

[[Category: | [[Category:Food Processing]] | ||

[[Category: | [[Category:Grinder]] | ||

[[Category: | [[Category:Mill]] | ||

[[Category:OSAT 3D-Printable Designs]] | |||

[[Category:3D printing]] | |||

[[Category:Plastic]] | |||

[[ | |||

Latest revision as of 14:02, 28 February 2024

This hand powered machine is a food processing tool that will grind peanuts down so they can be made into peanut butter. There aren't many 3D printable milling devices out there. This entire mill is 3D printed and was designed with all open source technology. Food processing mills and machines are expensive to buy, so this printable one allows people in need to have tools that work.

Bill of Materials[edit | edit source]

- Fully 3D printable (I used 1.75mm PLA filament)

- Link to Openscad and STL Files

- Bearing Bottom, 4 min, 2 g

- Bearing Top, 7 min, 4 g

- Center Rod, 18 min, 11 g

- Connector Arm, 15 min, 8 g

- Funnel, 3 hr 19 min, 111 g

- Bracket, 5 min, 2 g

- Handle, 34 min, 18 g

- Inner Grinder, 34 min, 21 g

- Outer Grinder, 1 hr 27 min, 49 g

- TOTAL: 6 hr 39 min, 226 g

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

Skills and knowledge needed[edit | edit source]

Technical Specifications and Assembly Instructions[edit | edit source]

Directions for Assembly:

- Fit center rod into internal grinder

- Place it in the outer grinder

- Put bearing top on the center rod

- Slide funnel on and snap pegs to outside of outer grinder

- Line up bearing top and bottom on funnel with center rod running through them

- Plastic join the bearing top and bottom

- Plastic join the internal grinder with the bracket

- Snap on connector arm to center rod

- Snap on handle to connector arm

- Print time estimate: 6 hours 39 minutes

- Assembly time estimate: 15 minutes

- Drawing of Assembly:

Common Problems and Solutions[edit | edit source]

- Plastic welding: The point of doing this in two places was to eliminate the need for screws and washers to make this completely printable. It is difficult, but placing the nozzle in the holes given and extruding +40 gives a good weld.

- The pegs on the funnel just snap around the outer grinder. I had an issue with the original part, but this was the quick fix.

Cost savings[edit | edit source]

- This machine can save people over $100 depending on the type of mill wanted.

- Commercial equivalent: Country Living Mill Peanut Butter Accessory

- I saved about $160 compared to the competition above. That's roughly a 97% savings.

Benefited Internet Communities[edit | edit source]

- Requests for OS 3D Printable Objects

- Food Processing Suppliers Association

- OSAT

- World Food Programme

- Action Against Hunger

- ↑ web page: Department of Energy (DOE) Landscaping and Energy Efficiency, DOE/GO-10095 (1995) Available: http://web.archive.org/web/20021201231338/http://www.eren.doe.gov:80/erec/factsheets/landscape.html

- ↑ web page: Grain Mill Reviews: Basic Overview of the Different Grain Mills (Video 1 in a Series) Available: https://www.youtube.com/watch?v=2biIDfbWRIkl

- ↑ web page: Troubleshooting Guide Available:http://www.countrylivinggrainmills.com/support/grinder/

- ↑ web page: Hand Crank Mill for pregrinding nuts for Nut Butter Grinder Available:https://www.youtube.com/watch?v=G0khTvo5Ag4