(moved info from "composting toilets") |

m (Text replace - " trough" to " through") |

||

| Line 6: | Line 6: | ||

The composting toilet comprises a raised slab over two chambers. The chambers are built on the ground, not in it. In very waterlogged areas, or those prone to flooding, a slightly raised plinth can be made. The chambers are plastered with cement internally in order to waterproof them and make compost removal tidier. Over each chamber there is a hole in the slab for faeces and a funnel to receive the urine. | The composting toilet comprises a raised slab over two chambers. The chambers are built on the ground, not in it. In very waterlogged areas, or those prone to flooding, a slightly raised plinth can be made. The chambers are plastered with cement internally in order to waterproof them and make compost removal tidier. Over each chamber there is a hole in the slab for faeces and a funnel to receive the urine. | ||

In some toilets, in the centre of the slab, between the two chambers, there is a | In some toilets, in the centre of the slab, between the two chambers, there is a through over which the anal cleansing is performed. The anal cleansing water through and urine funnel is inter-connected and flow to an evaporative plant bed outside the latrine. | ||

Other composting toilets may have a box with plant leaves that can be used instead. | Other composting toilets may have a box with plant leaves that can be used instead. | ||

Revision as of 07:44, 10 February 2013

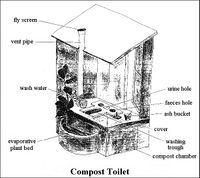

This technical brief describes a composting toilet that has proved to be most effective in water-logged areas where pit-latrines and septic tanks are inappropriate. It is a simple design that does not require electricity or great investment. Built using local materials, it is a self-contained unit that produces good compost and protects the soil and water from any contamination.

The composting toilet is built with two chambers for simplicity of construction and operation. The two chambers are used alternately; after the first chamber is filled, it is left to decompose and only emptied just prior to the other one becoming full. Each chamber has its own opening for removal of mature, non-odorous compost. Some types of composting toilet batch the waste in movable receptacles on trolleys or turntables whilst others generate the compost slowly and continuously as the material progresses through the device. Some require electricity for small heating elements (in cold climates) or fans (to ensure a positive airflow through the system). Some composting toilets combine the urine and faeces whilst others separate them. The compost formed by the combination of urine and faeces is better but these toilets are more likely to smell if used carelessly and they require much greater quantities of carbonaceous residues like sawdust and straw. Many of the more complex types require dry access under the toilet via a basement or cellar room.

The composting toilet comprises a raised slab over two chambers. The chambers are built on the ground, not in it. In very waterlogged areas, or those prone to flooding, a slightly raised plinth can be made. The chambers are plastered with cement internally in order to waterproof them and make compost removal tidier. Over each chamber there is a hole in the slab for faeces and a funnel to receive the urine.

In some toilets, in the centre of the slab, between the two chambers, there is a through over which the anal cleansing is performed. The anal cleansing water through and urine funnel is inter-connected and flow to an evaporative plant bed outside the latrine.

Other composting toilets may have a box with plant leaves that can be used instead.

In the simplest version, the chamber doors are closed by bricks and mud mortar, both of which can be reused to close it again. However, ferrocement, timber, marine ply or other materials may also be used where they are appropriate locally.

The chambers are designed to have an accumulation time of about nine months to allow thorough composting of the contents and elimination of pathogens. The compost produced is an almost dry, crumbly, black product having a light, pleasant, earthy odour. There is no fly nuisance or any odour problem and the toilets remain clean and pleasant to use. The plant bed needs almost no maintenance and the only requirement is to cut back excessive growth which can be chopped up and added to the compost chamber if required.

Appropriate use

The composting toilet described here was designed to be a highly effective solution to sanitation in high water table and waterlogged areas. However, it can be used as a reliable and low cost water conserving technology in many other areas as well. It can be built beside or as part of a house in rural, urban or peri-urban areas and can even be established inside a house or apartment. It has the potential to make a significant contribution to domestic water conservation in towns and cities as well as rural areas. Also, since there is no need to connect it to sewerage systems, there is no extra burden on often already overloaded services.

The composting toilet is suitable for use by a family, or it can be built in clusters for institutions, schools, hostels and so on. However, it is recommended that the use of composting toilets is managed within the community and that very good education and awareness raising is done before building begins. Open access community composting toilets are not recommended other than in well-educated and highly motivated communities.

Cost

The compost toilet described above is being built in India for around GBP£90 (1999) using fired bricks, cement mortar, a reinforced concrete slab and a ferrocement roof. It can be built for more or less depending on the complexity and permanence of the materials used and the level of refinement of the details sought by the owners. The roof, superstructure, internal finish and the door are the chief variables and can significantly affect the cost.