| Line 12: | Line 12: | ||

==Plastic Granulator == | ==Plastic Granulator == | ||

Project developed by [[User:Aschaub|Andy Schaub]], [[User:Lwilder|Lucas Wilder]], and [[User: | Project developed by [[User:Aschaub|Andy Schaub]], [[User:Lwilder|Lucas Wilder]], and [[User:Pjgoreck|Peter Gorecki]] | ||

Revision as of 03:41, 25 March 2016

Fall 2015

Current Status of the Project (12/14/2015)

Currently, the plastic granulator is designed and all of the parts that are capable of being machined in the M & M machine shop have been machined. Also, all of the parts that aren't able to be made in the machine shop have been shipped out and are currently being machined. All of the parts that have been shipped out (rotary blades, blade bed, screen, blade mounts, and flywheel) all should be completed and shipped back to us by the time we return for the Spring Semester.

Plastic Granulator

Project developed by Andy Schaub, Lucas Wilder, and Peter Gorecki

Abstract

Our mission is to build an Open Source Hardware Plastic Granulator to granulate old 3D prints to make feedstock for the recyclebot to make 3D printer filament. The eventual goal is to have the ability to granulate both HDPE and PET plastic to make recycled filament to sell through our enterprise.

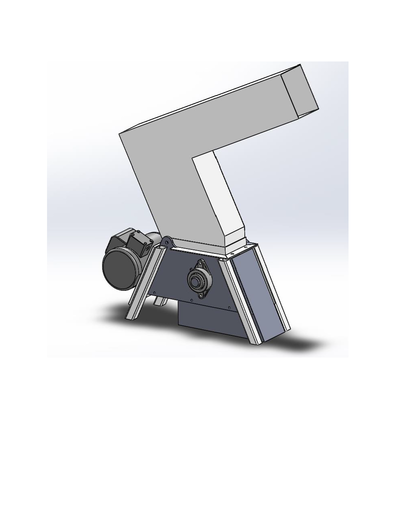

The design our team has created can be seen on the right.

Bill of Materials

All of the detailed drawings for each of the parts used to make the plastic granulator can be found below. Also, the fasteners needed to assemble the parts are listed.

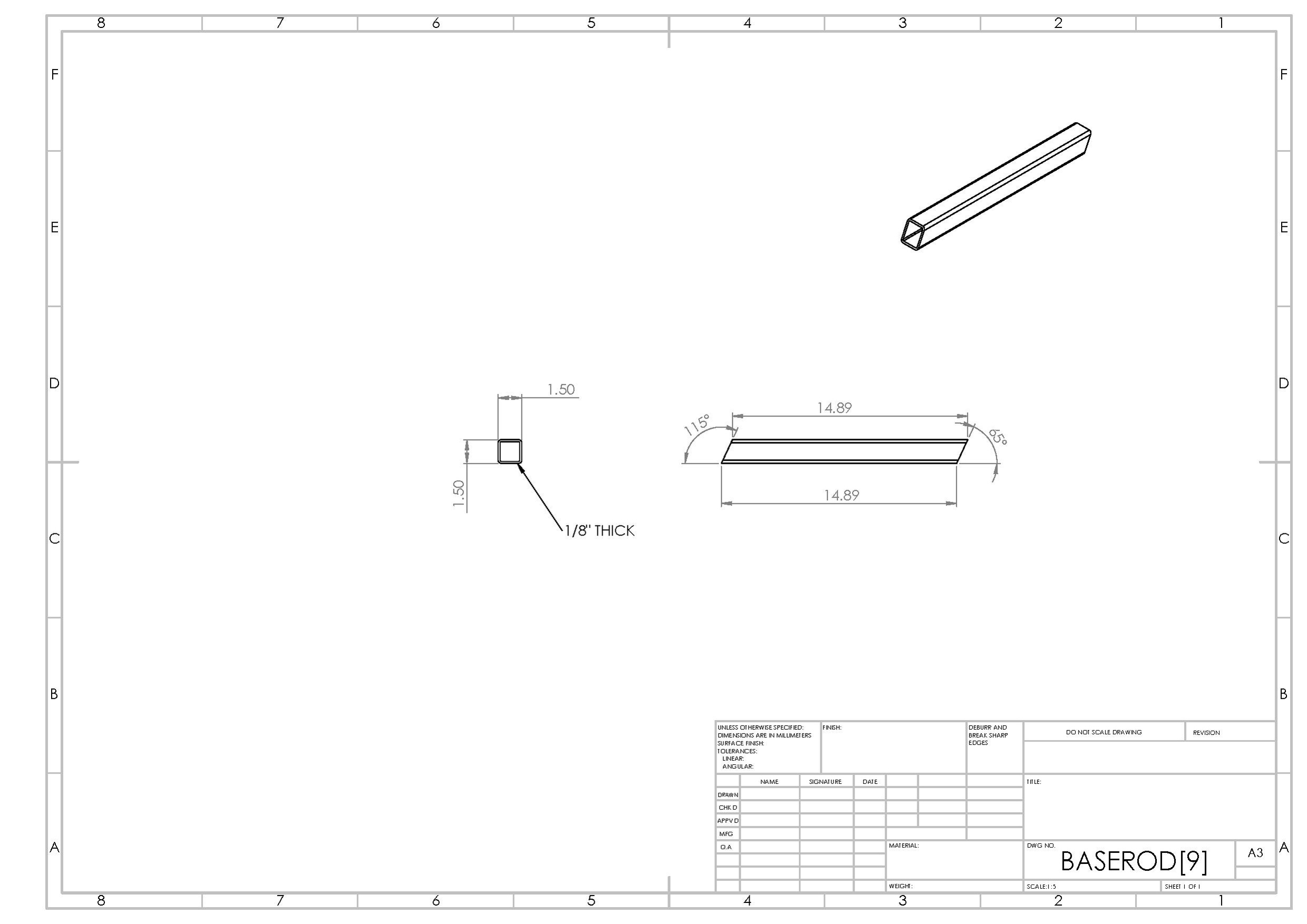

- The base rods are the supports used to hold the shredder up. There are four base rods needed to manufacture one granulator.

These were made from a 1/8" 1.5" square tubing

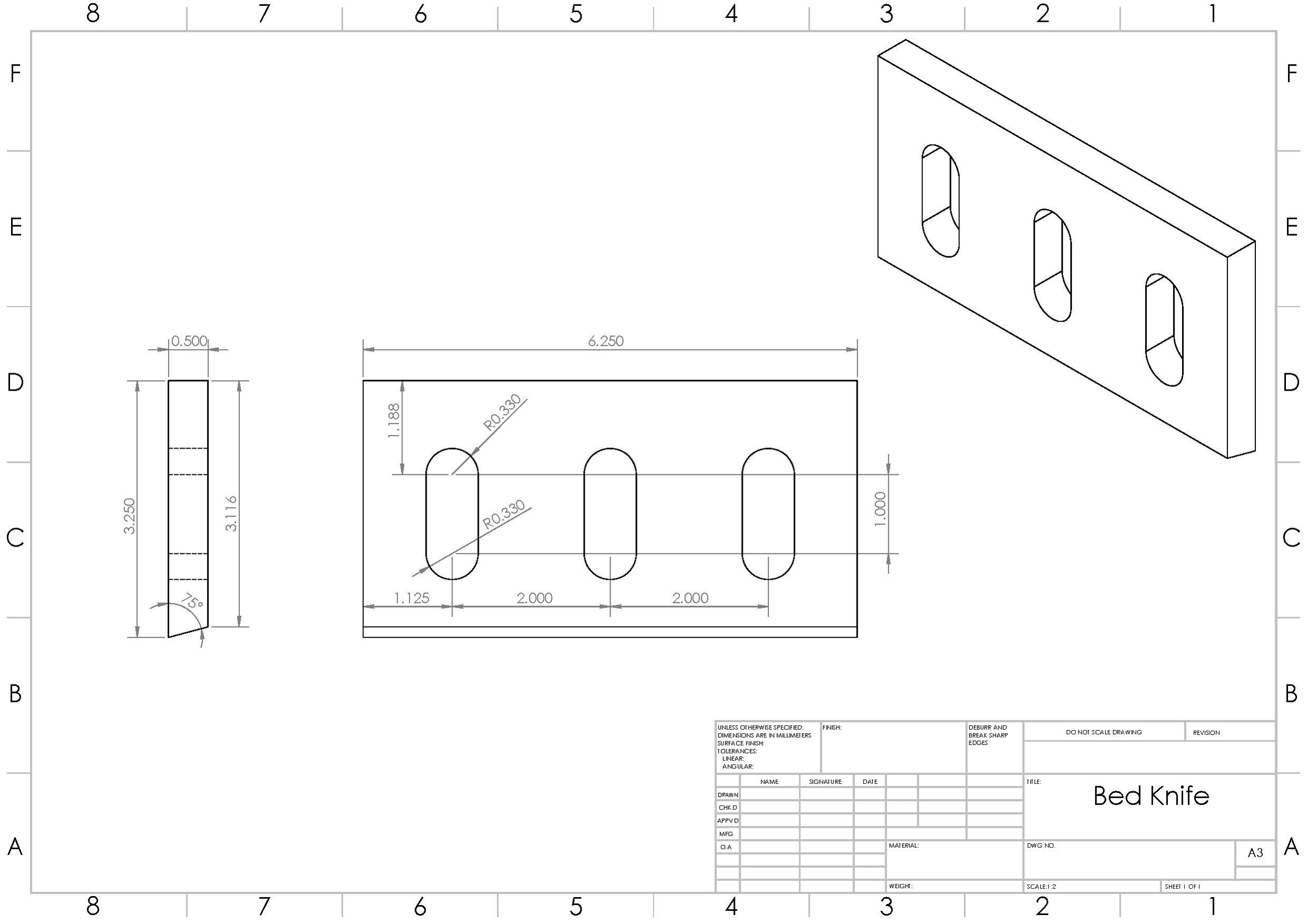

These were made from a 1/8" 1.5" square tubing - The bed knife is what the rotary blades use as a cutting edge. There is only one bed knife needed to manufacture one granulator.

This is the website used to order the bed blade: Services for Plastics

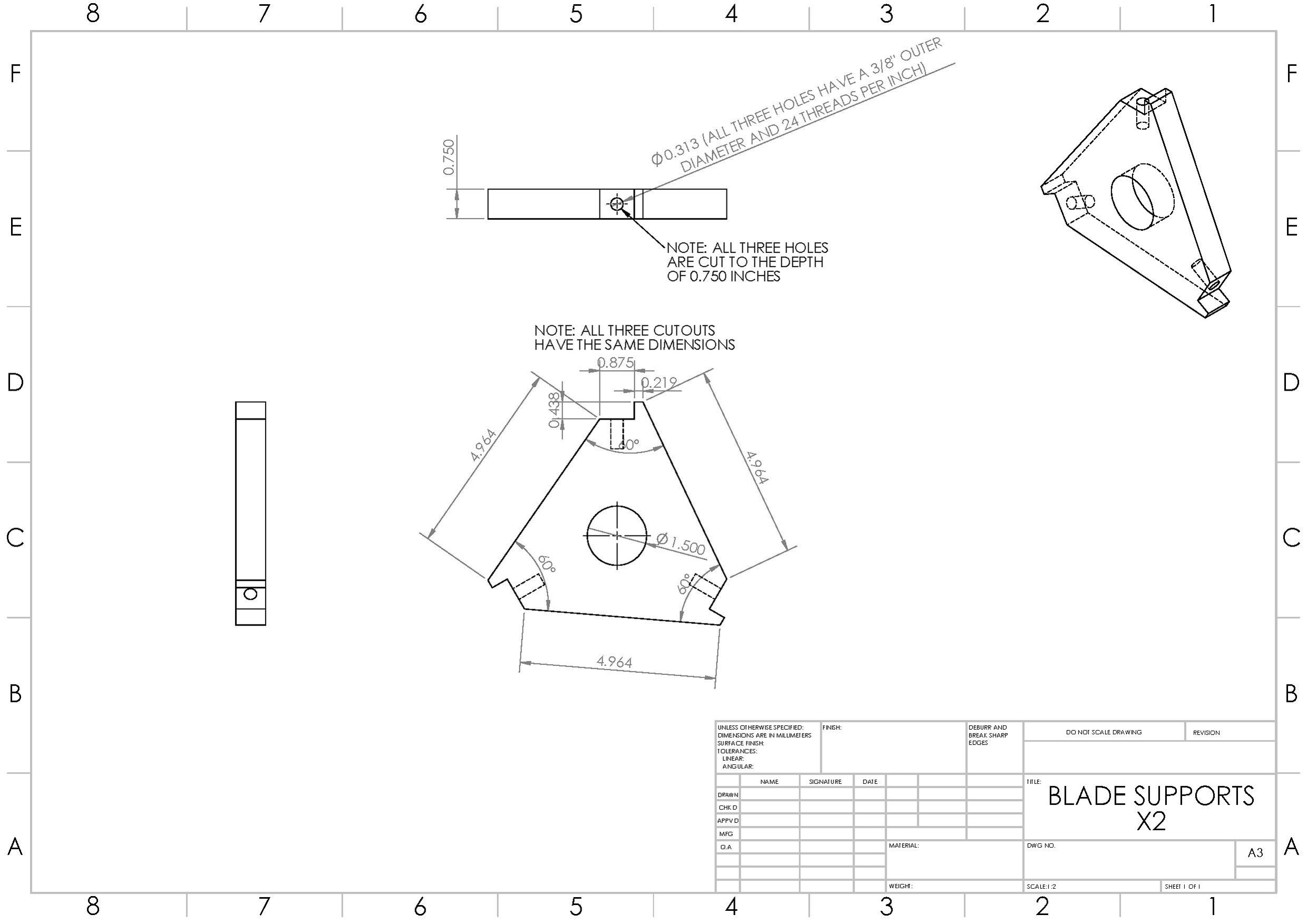

This is the website used to order the bed blade: Services for Plastics - The blade supports are mounted to the shaft and is where the rotary blades mount. There are two blade supports needed to manufacture one granulator.

These were made from a 1" steel plate.

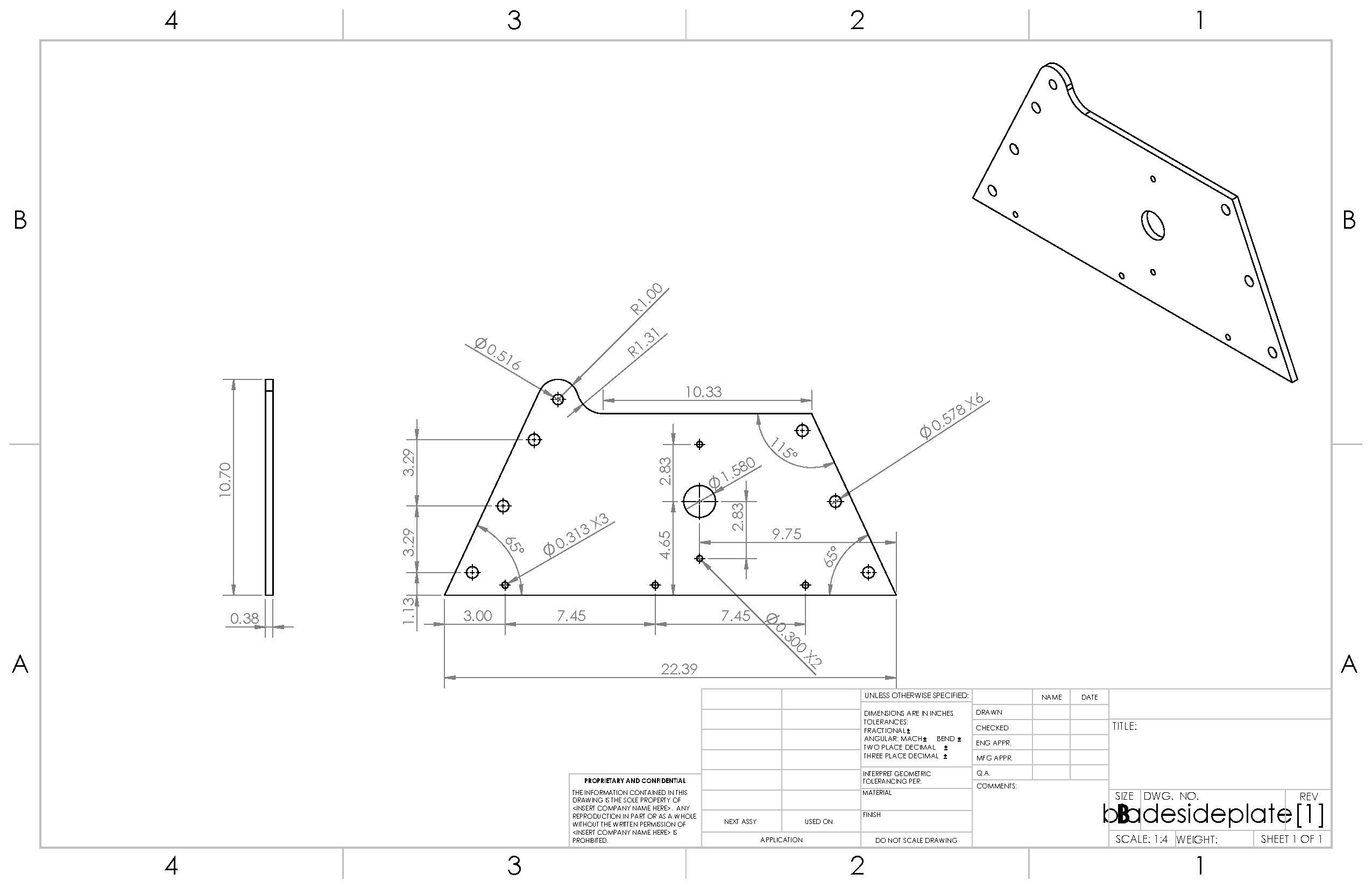

These were made from a 1" steel plate. - The blade side plates are used to plates on the side of the granulator that is used to connect all of the parts. There are two blade side plates needed to manufacture one granulator.

These were made from a 3/8" steel sheet.

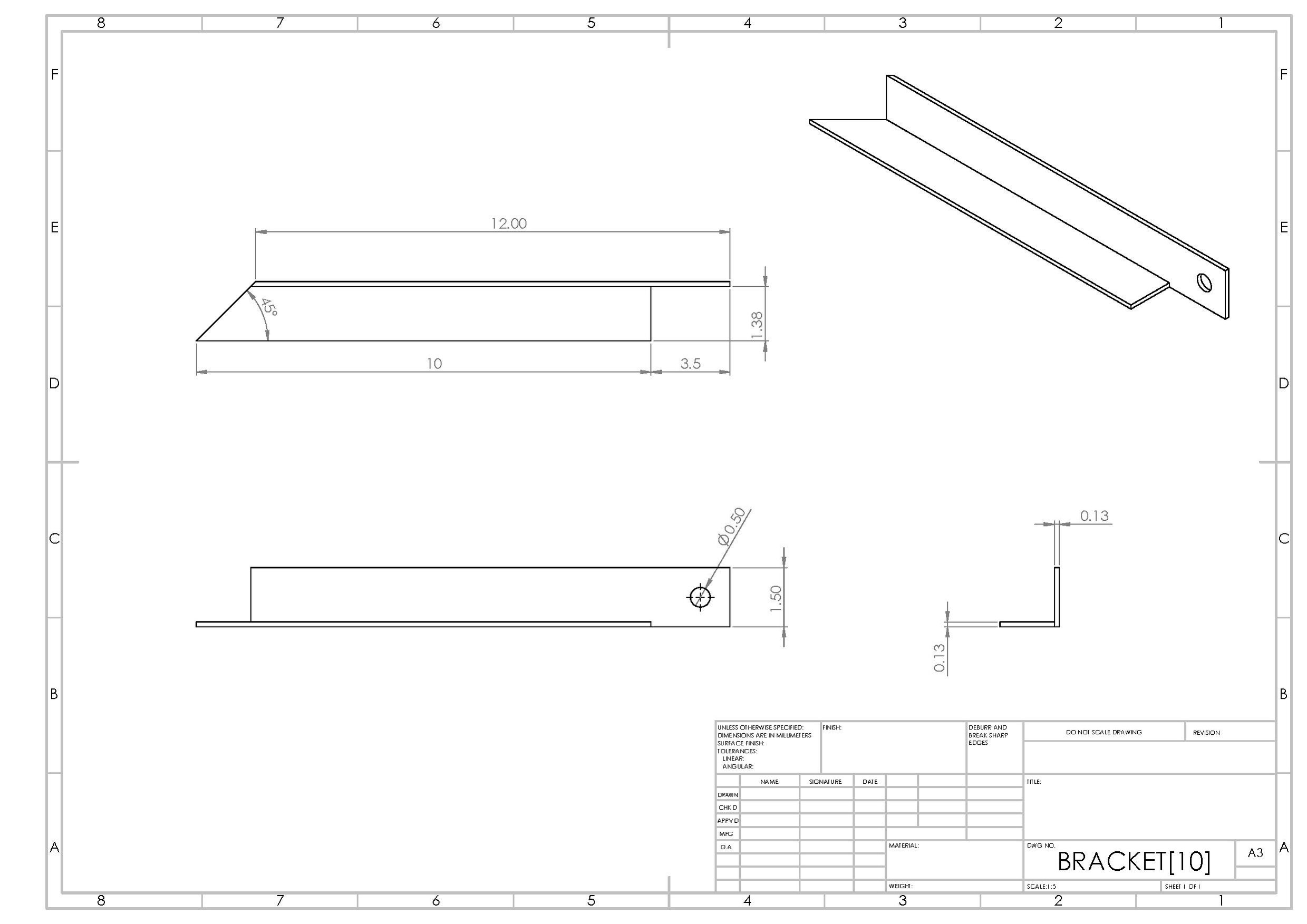

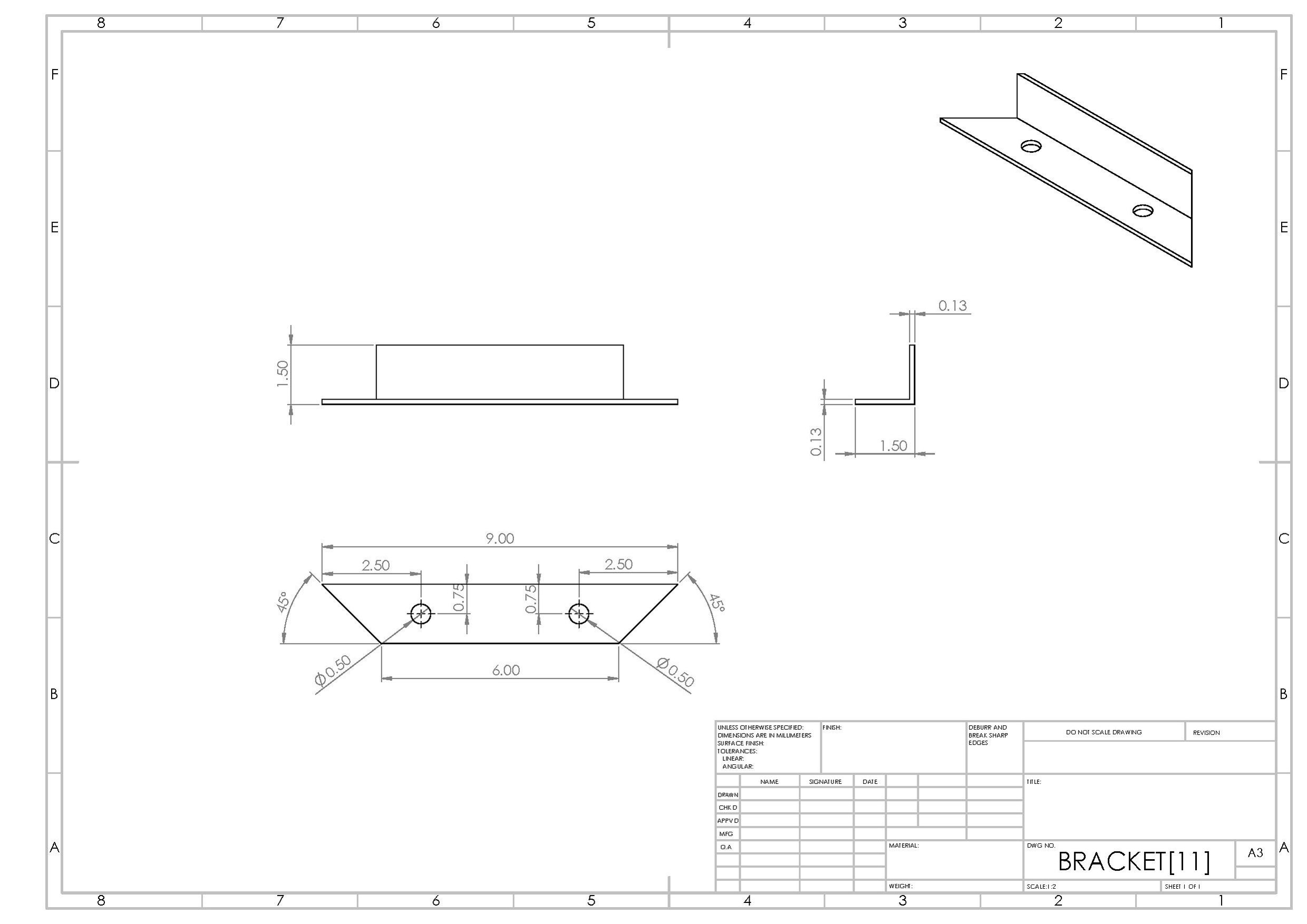

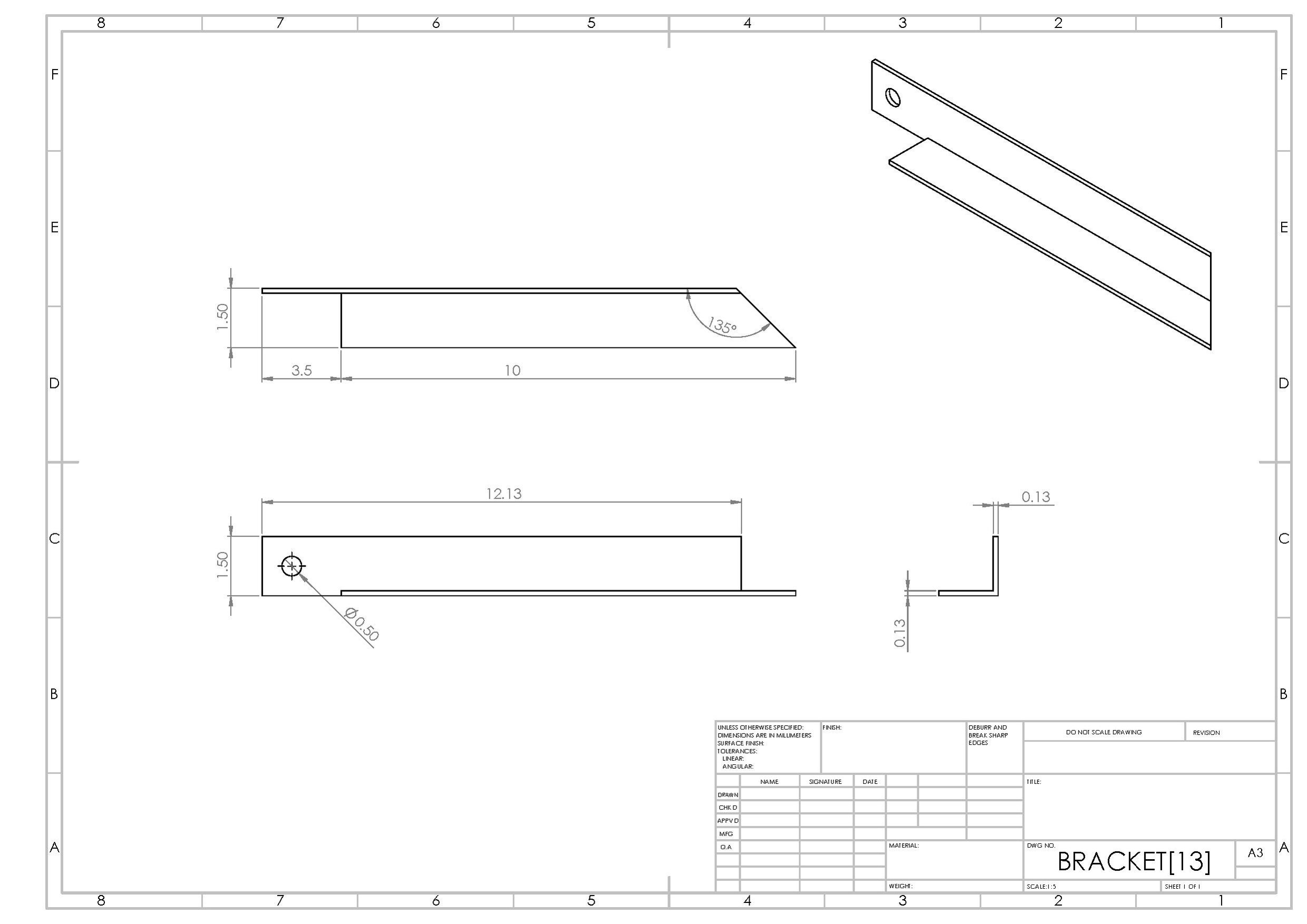

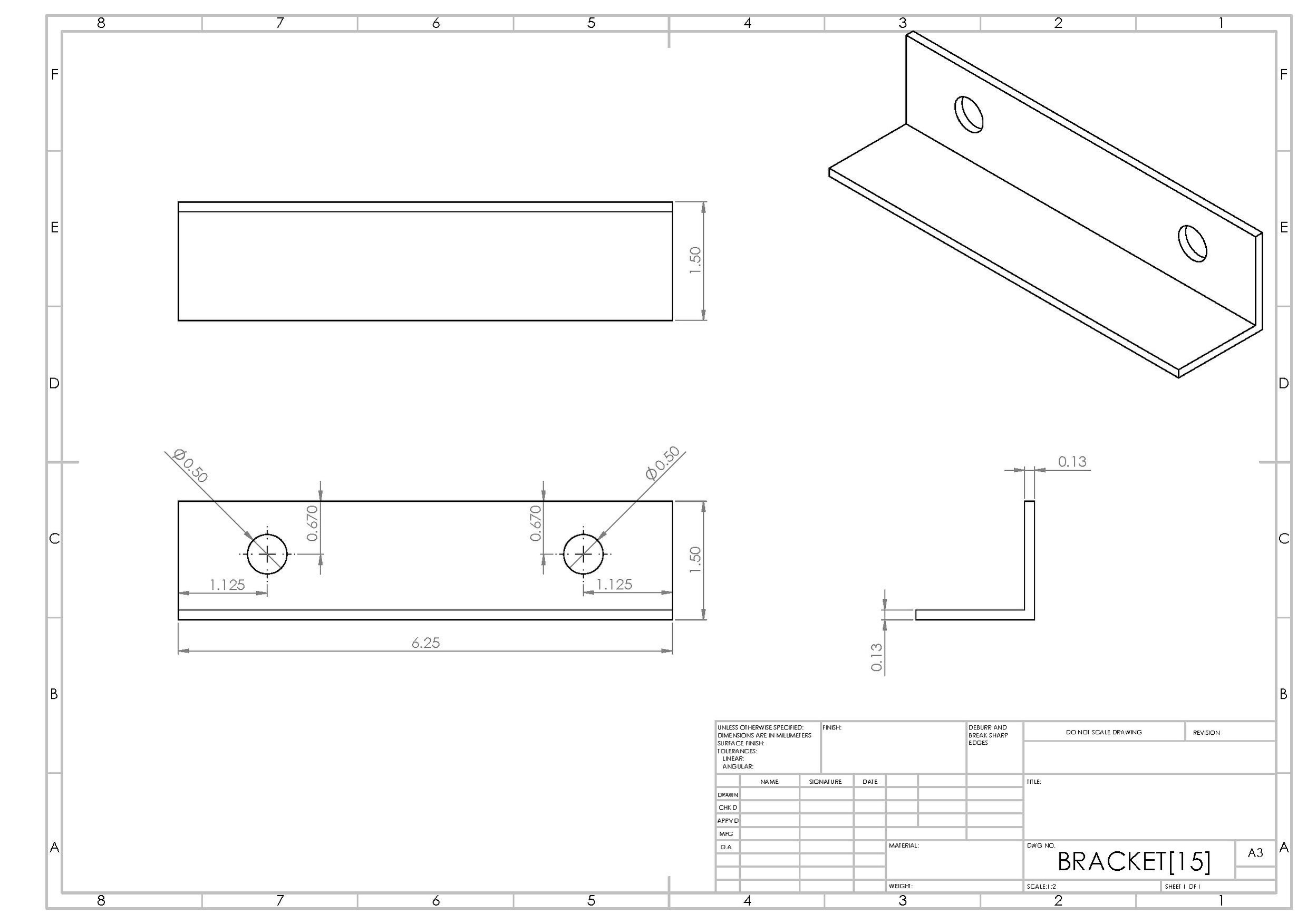

These were made from a 3/8" steel sheet. - These next four files are the bracket mounts that connect the hopper to the main body of the granulator. These were all made from 1/8" thick 1.5" angle iron.

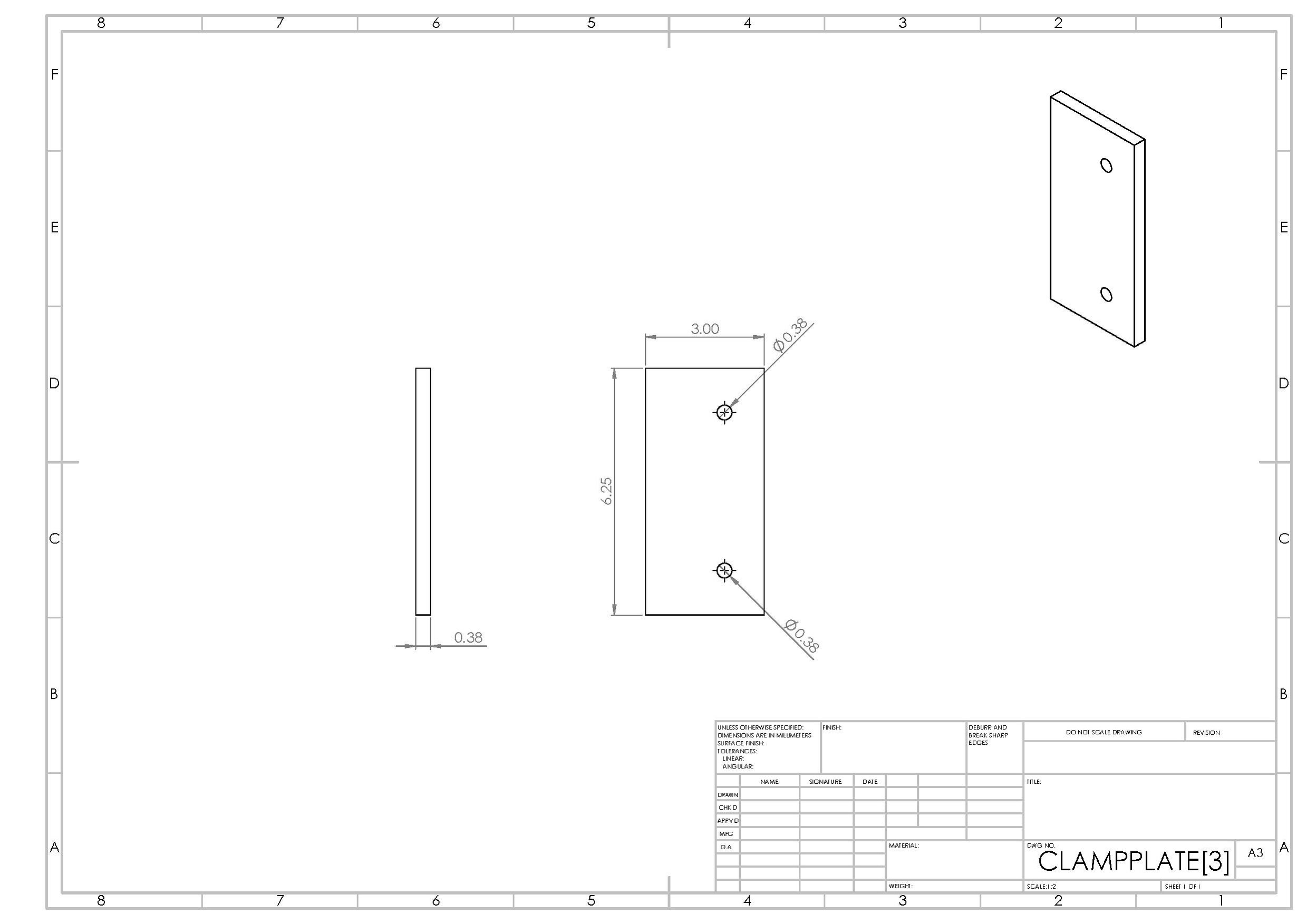

- The clampplates are used to mount the screen and blade bed to the shredder. There are four clampplates needed to manufacture the granulator.

These were made from a 3/8" steel sheet.

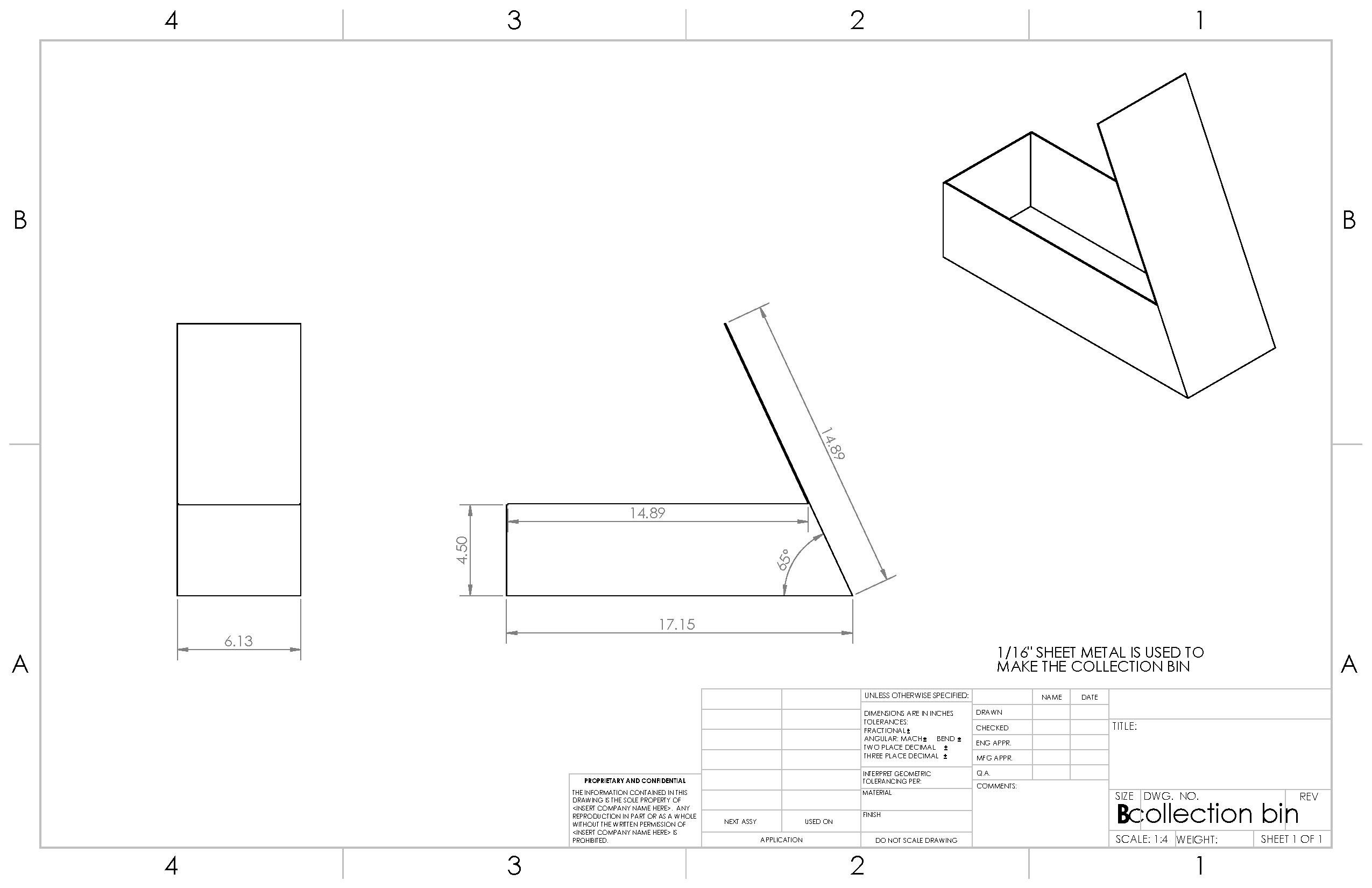

These were made from a 3/8" steel sheet. - The collection bin is what is used to collect the plastic that is expelled from the granulator. There is only one collection bin required to manufacture the granulator.

This was made from 1/16" thick sheet metal.

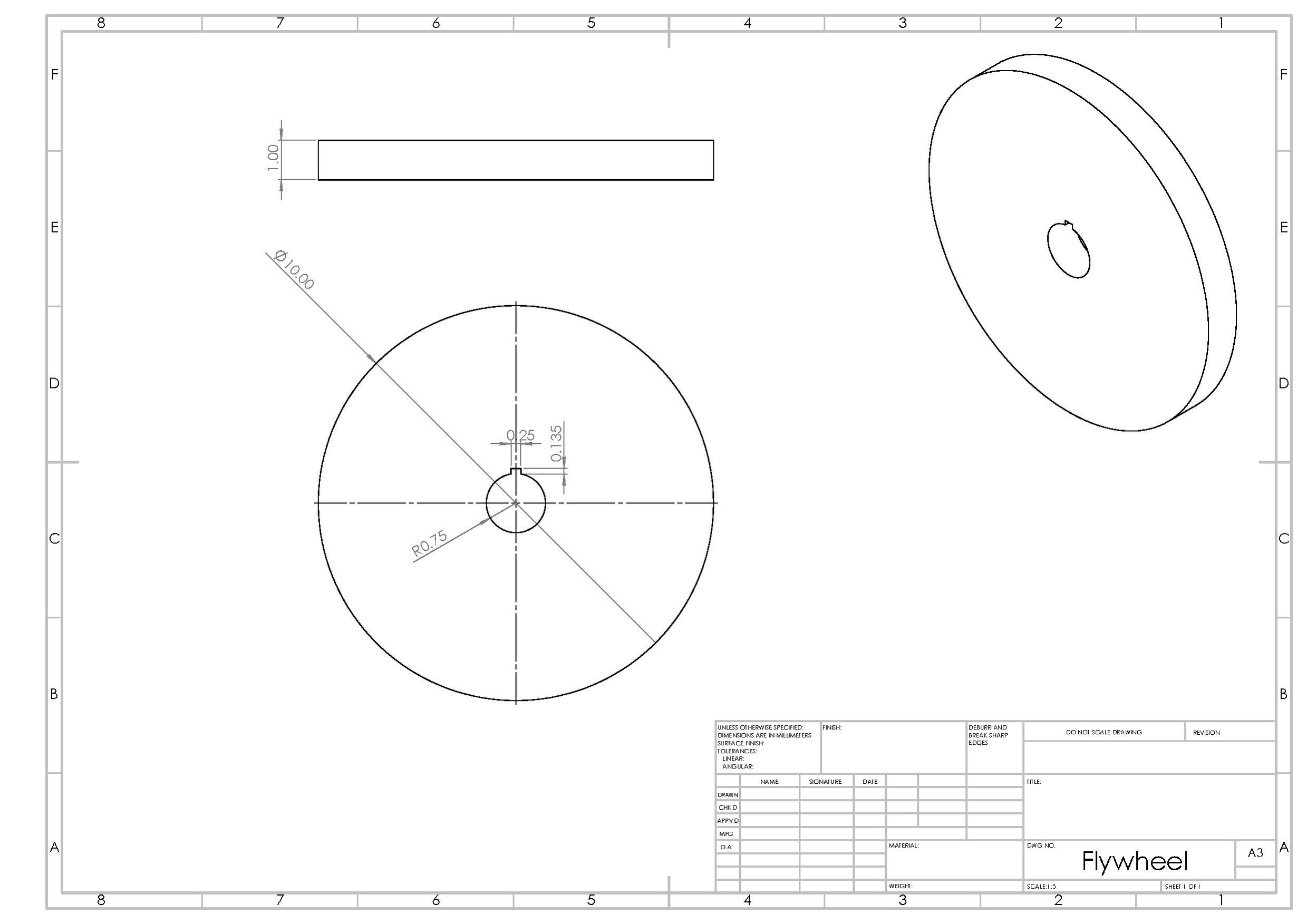

This was made from 1/16" thick sheet metal. - The flywheel is used to assist the blades to provide more force to shred the plastic. There is only one flywheel required to manufacture the granulator.

This was made from a 3/4" steel plate.

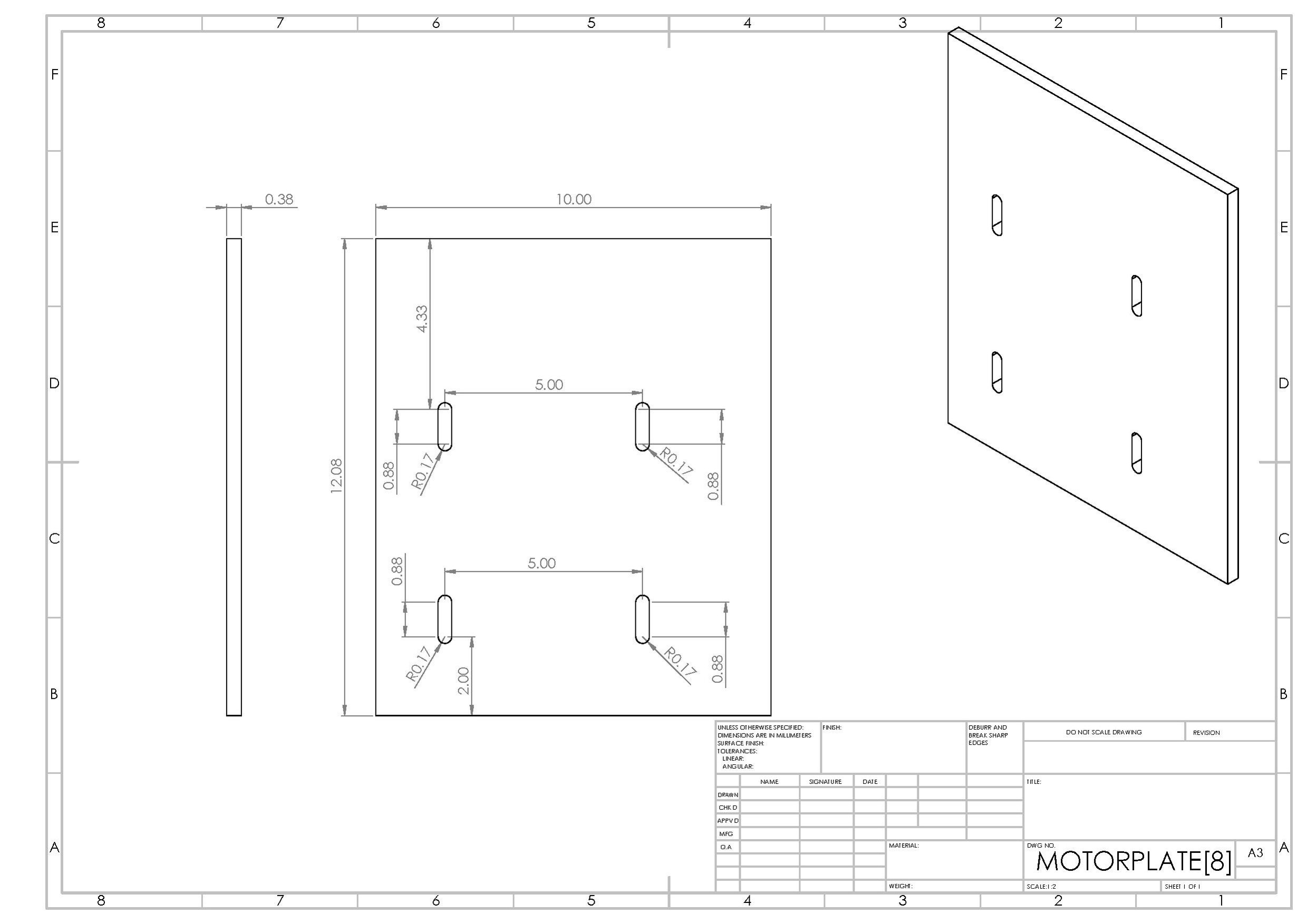

This was made from a 3/4" steel plate. - The motorplate is used to mount the motor to the granulator. There is only one motorplate needed to manufacture the granulator.

This was made from a 3/8" steel sheet.

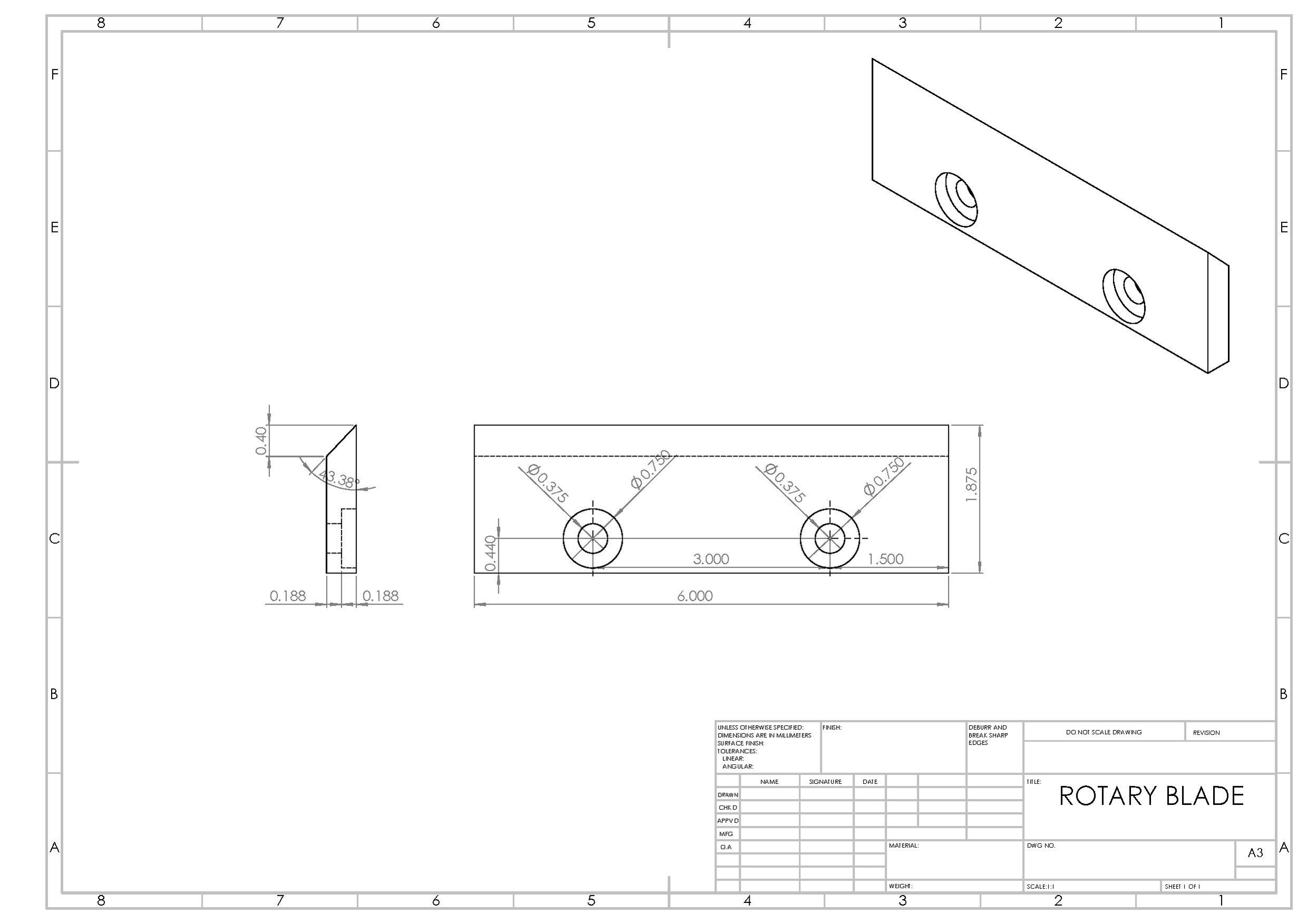

This was made from a 3/8" steel sheet. - The rotary blades are the blades that spin around on the shaft to shred the plastic. There are three rotary blades needed to manufacture one granulator.

This is the website used to order the rotary blades: Services for Plastics

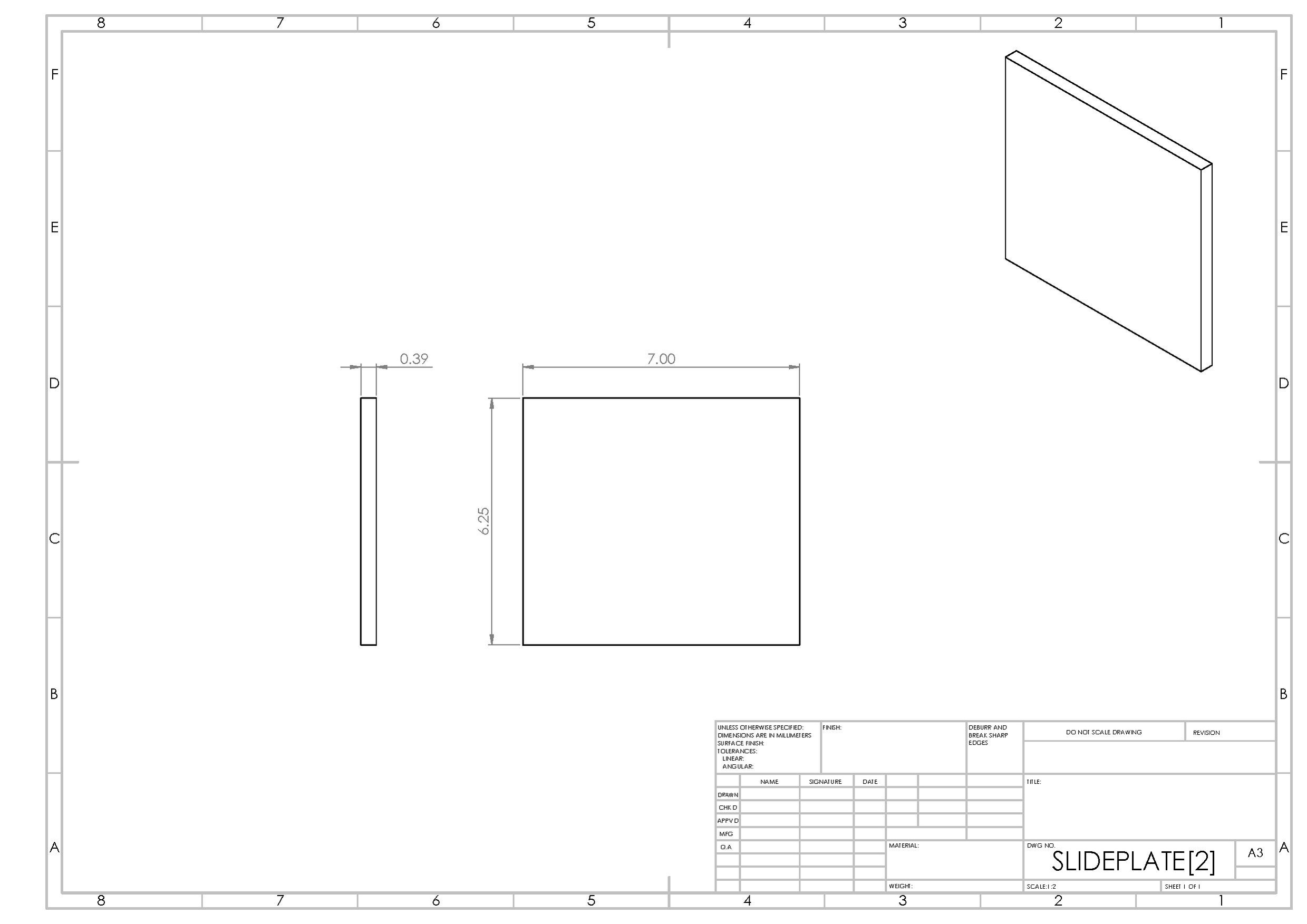

This is the website used to order the rotary blades: Services for Plastics - The slideplate is the plate that is used as the backing between the hopper and the blade bed and to guide the recycled plastic to the cutting edge. There is one slideplate needed to manufacture the granulator.

This was made from a 3/8" steel sheet.

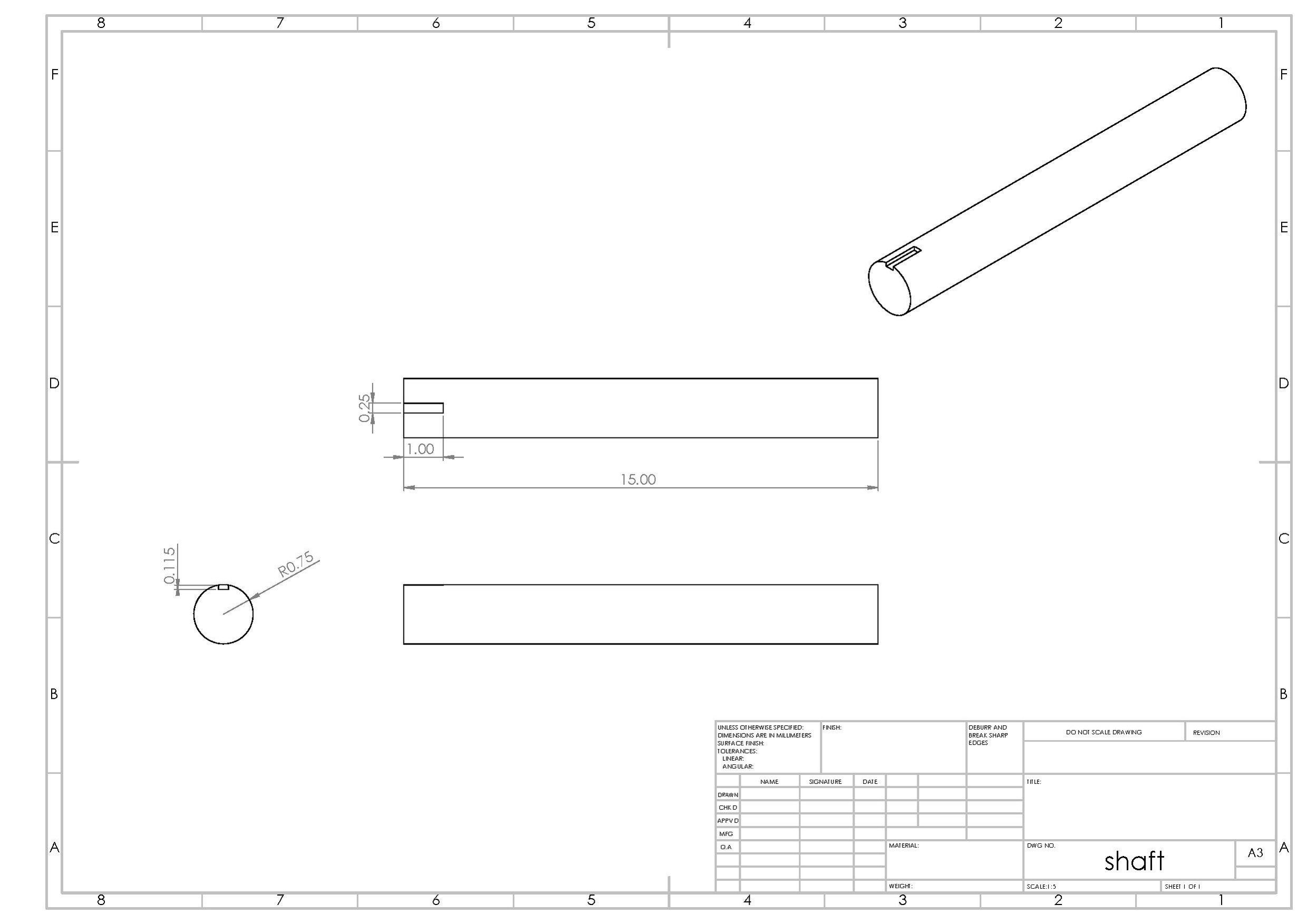

This was made from a 3/8" steel sheet. - The shaft is what the blade mounts are mounted to and is what they rotate about. There is one shaft needed to manufacture the granulator.

. The shaft is made out of a 1.5" diameter rod.

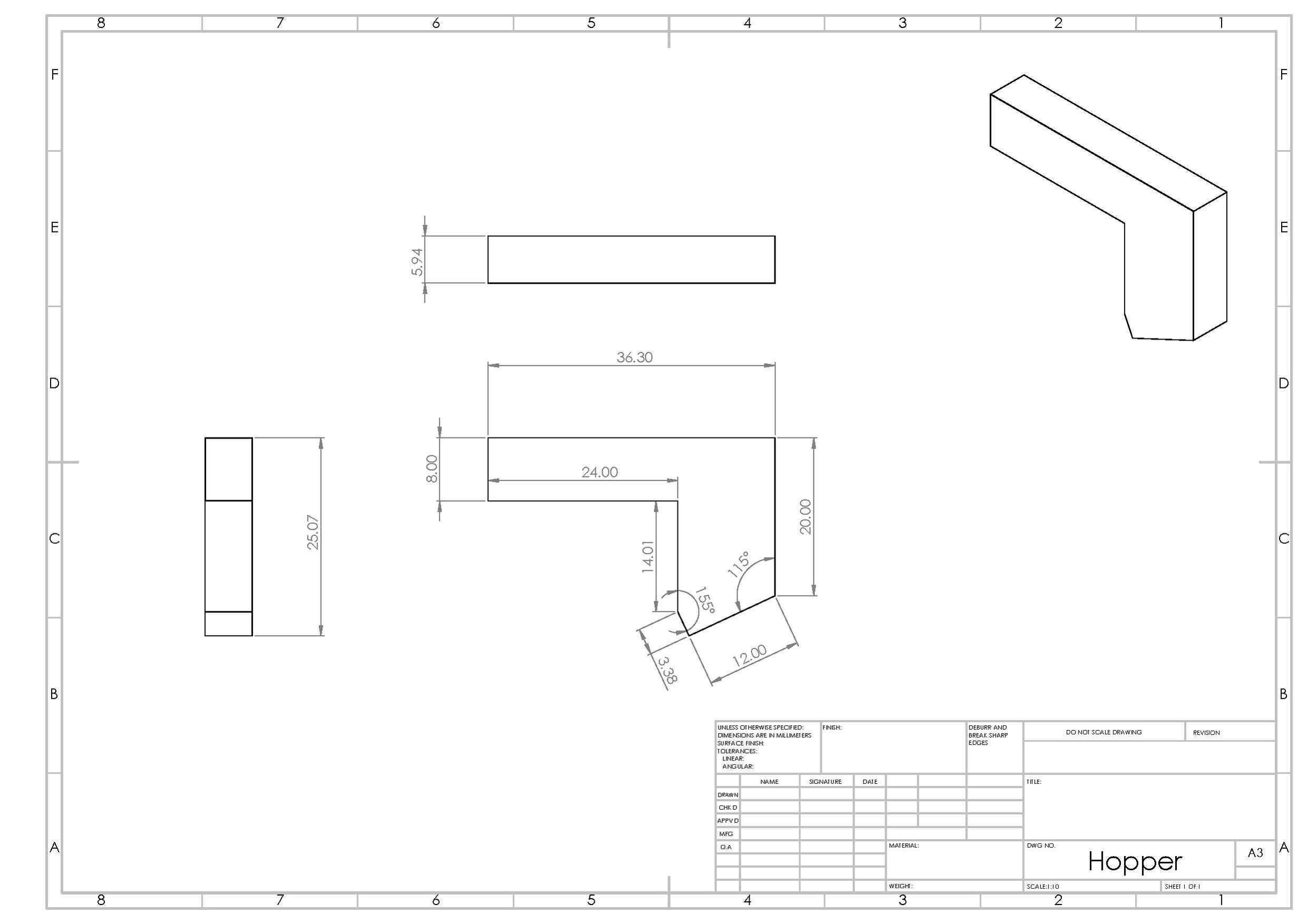

. The shaft is made out of a 1.5" diameter rod. - The hopper is what is mounted on top of the granulator and is what is used to help the user dispense waste plastic into the machine without the user getting too close to the blades. Only one hopper is needed to manufacture the granulator.

The hopper is made out of 1/16" thick steel.

The hopper is made out of 1/16" thick steel. - These next parts were all purchased from the McMasterCarr website.

A 2 HP motor that runs off of a standard wall outlet was chosen to run the shredder.

To mount the blades onto the blade mounts, two 3/4" long, 3/8" diameter bolts are needed to fasten each of the three blades.

To mount the frame, blade bed, and support rods on, 1" long, 9/16" diameter bolts will be needed.

Finally, two bearings will be needed to mount the 1.5" shaft on the frame. These bearings will need to have mounting bolts to fit the respective holes for the bearings that are chosen.

Update:

Free CAD 3D models will be uploaded as soon as Appropedia allows these types of files to be uploaded.

Tools needed for fabrication of the Plastic Granulator

There are several manufacturing methods that we needed to use to create the Granulator, causing us to need many different pieces of equipment:

- CNC plasma cutter

- MIG welder

- Drill press

- Brake press

Skills and Knowledge Necessary to Make the Plastic Granulator

There are several specialized skills that will be required to produce the shredder these include:

Manufacturing Skills

- Ability to produce high quality welds on 3/8 in steel plate. This is incredibly important for the safety of the project as many parts in the machine will be under very high shock loads.

- The ability to operate a plasma cutter and a water jet cutter.

- The ability to operate a brake press

Assembly Skills

- Must be proficient with the proper torque for bolts to be tightened to

- Must be able to read and properly follow assembly drawings

- Need to have the ability to set the blade to blade gap to the proper tolerance, if this is wrong, there could be a catastrophic failure

Technical Specifications and Assembly Instructions

- The following three pictures are the manufactured parts before being assembled. The picture on the left is the assembled hopper. The middle picture is the assembled body, and the picture on the right is the returned blade mounts and flywheel from the manufacturer.

- The following as a picture of the 1.5 HP 120-240 AC motor we will be using.

- The following is a picture of the screen from the old granulator. The screen that we have ordered is very similar. Our screen will be narrower and slightly smaller in diameter due to the use of a lower powered motor for the purpose of downsizing to a 120 AC circuit.

- The following steps are required to manufacture the components before assembly:

(SAFETY GLASSES MUST BE WORN WHEN PERFORMING THE FOLLOWING TASKS, A FACE SHIELD SHOULD ALSO BE WORN OVER THE GLASSES WHEN USING THE CUT OFF WHEEL)

-Drilling:

Make sure to use a smaller bit first to make a pilot hole, then drill out with a 9/16 in bit for the square stock holes and a 1/2 in bit for the angle stock holes. Adding cutting oil or motor oil can help this process go more smoothly.

-Cutting:

Change the back stop to the correct angle according to the manufacturing drawings

- Once the granulator build starts in the Spring 2016 Semester, this page will be populated with updates regarding the build regularly.

Common Problems and Solutions

- Once the granulator build is finished, the problems we ran into and their solutions will be posted.

Cost savings

- As soon as all of the pieces to the granulator are ordered and the final prototype is complete a cost savings page will be made.