Hand Powered Newspaper Briquet Maker

Project developed by ABStilwell & Molson

Template:Statusboxtop Template:Status-design Template:Status-prototype You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

Abstract

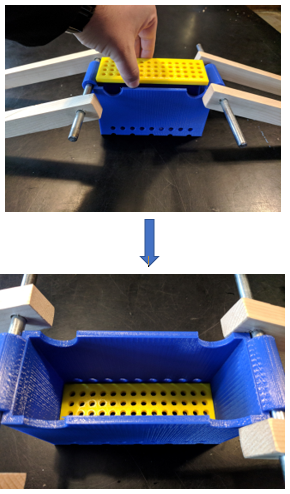

The need was expressed for a device in which could turn waste newspaper and other light paper products into small burnable briquettes. This helps to turn waste in to a usable fuel source, and also allows the paper to burn much longer and more efficiently than just burning the unprocessed paper.

Bill of Materials

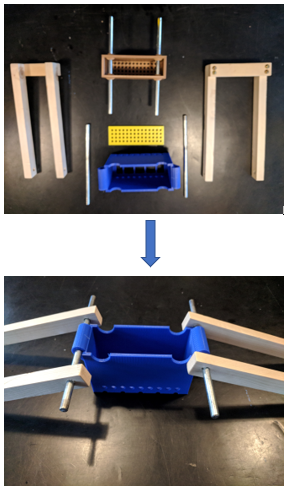

BOM -- Materials needed: are both 3D printed and items picked up at the local hardware store

- The base, lower plate and upper crushing plate are all 3D printed and can be found on the following link

- Thingiverse Link to Files

- Youmagine link coming soon!

- The steel rod was purchased at the local hardware store, can be replaced with alternative source that can fit in 3/8 inch holes.

- The wood handles were made from scrap wood found in the garage, and held together using 8 woods screw.

Tools needed for fabrication of the OSAT

- MOST Delta RepRap or similar RepRap 3-D printer

- Wood/Metal Saw

- Drill or Screwdriver

- Tape measure

Skills and Knowledge Necessary to Make the OSAT

- Basic Woodworking Skills

Technical Specifications and Assembly Instructions

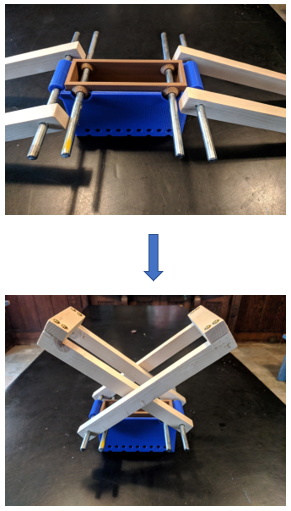

The handles were made of 1x4 I had laying around and ripped it to the following dimensions. You need to cut 4 pieces at 1x.75x12 inches long. On one end drill a 3/8 inch hole centered 1 inch away from the end. For the ends of the handle one is 4.25 inches long and the second is 5.75 inches long, both are 1x1.5 inches. Using 8-1.25 inch flat top screws anchor the tops to the handle.

The handles can be made out of any type of wood or alternate material that is approximately 12 inches long and can have a hole drilled into it to fit over the rod. Same goes for the Steel rod, you can replace it with anything that will fit inside a 3/8 inch hole and handle the forces from the handles being pushed down.

The assembly pictures show much longer rods than you need for the setup, you only 6 inches in length per rod.

Print Time Estimate - 14 to 16 hours dependent on printer speed and infill settings. Assembly time is approximately 30 minutes.

Common Problems and Solutions

- Be sure to not push too hard when the arms are bottomed out. This will cause the plastic to break.

Cost savings

1. Estimated Total Cost - $9.13

Plastic - $6.13

Screws - $0.50

Wood - $1.00

Metal Rod - $2.50

2. Commercial Equivalent - https://www.amazon.com/Bits-Pieces-Newspaper-Maker-Heavy-Measures/dp/B00TR0Z3X8/ref=sr_1_2?ie=UTF8&qid=1544033817&sr=8-2&keywords=newspaper+briquette+maker

3. $ Savings=$25.85 or 74%