Extruder and X-carriage

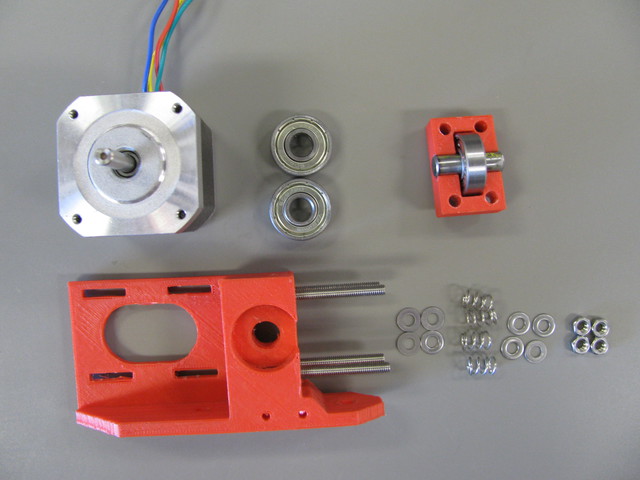

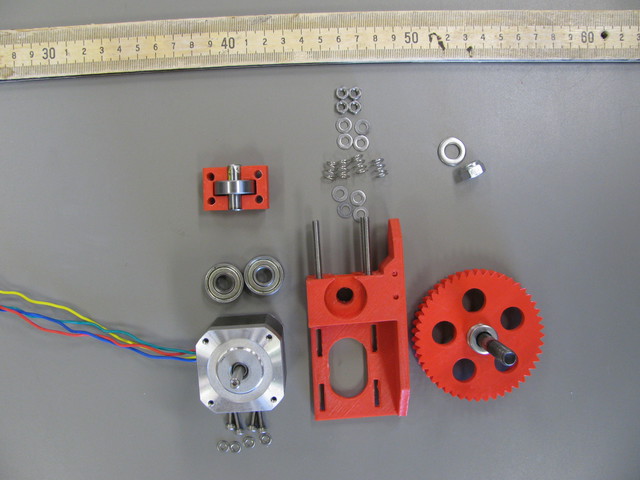

Printed Parts

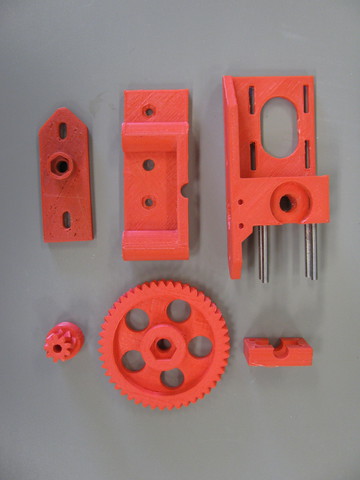

| Description | Count |

|---|---|

| X-carriage | 1 |

| Hot end retainer | 1 |

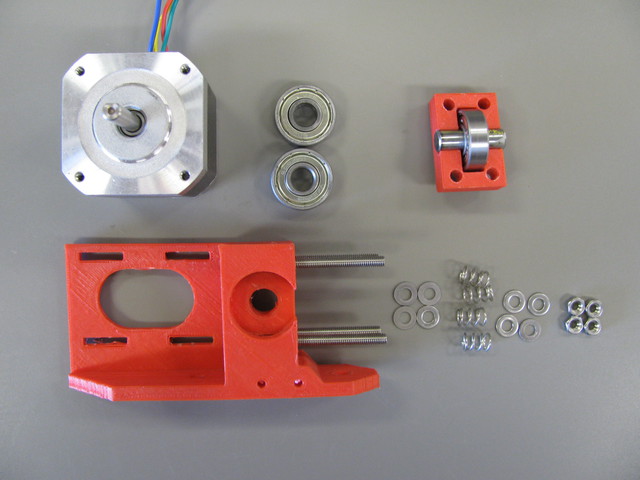

| Drive mount | 1 |

| Drive spacer | 1 |

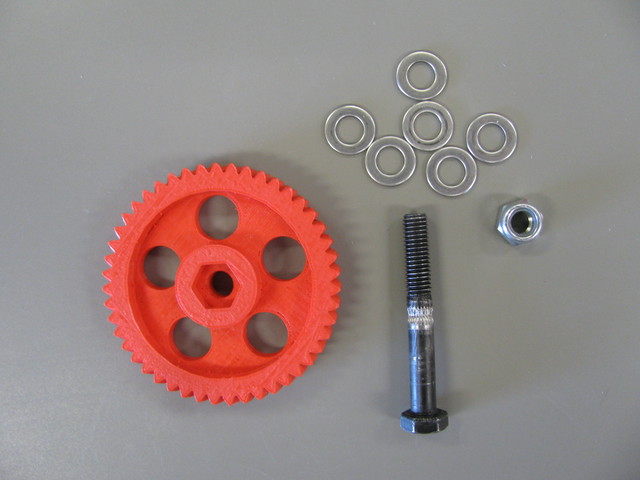

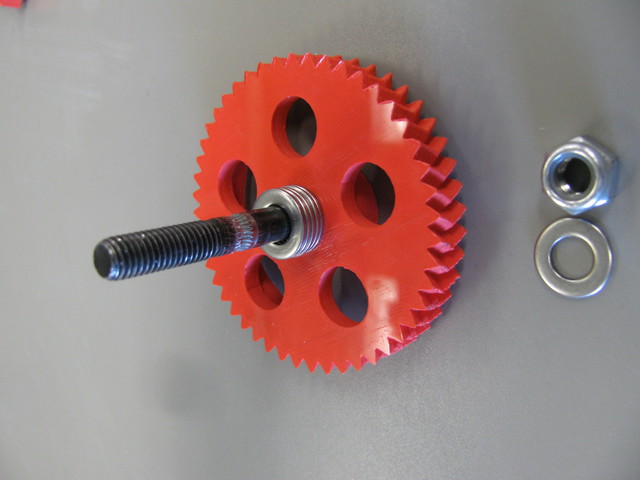

| Large helical gear | 1 |

| Small helical gear | 1 |

| Drive body | 1 |

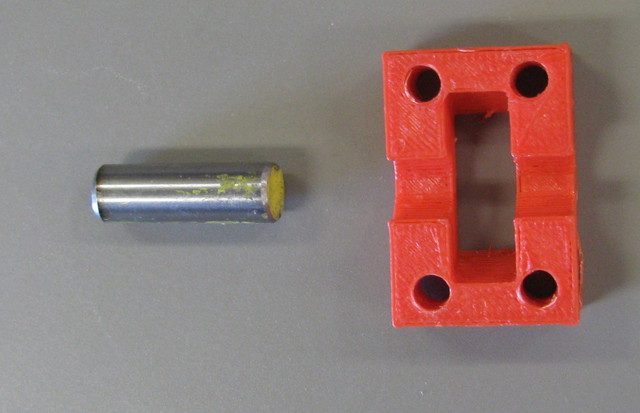

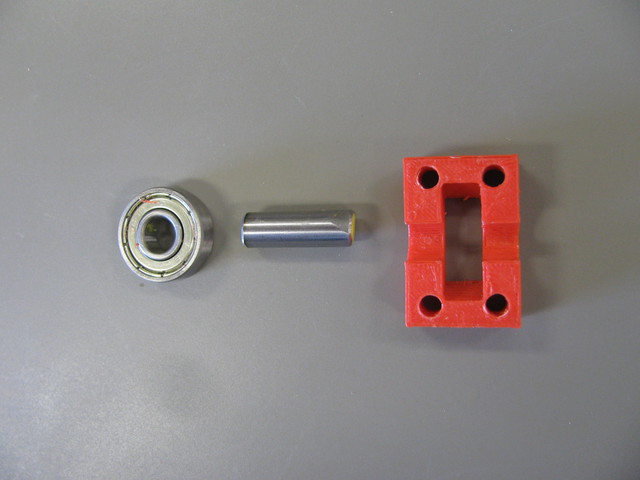

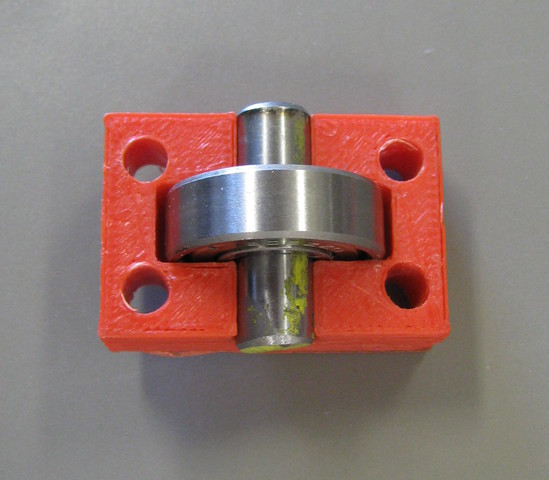

| Drive idler | 1 |

Vitamins

| Description | Count |

|---|---|

| M6 nut | 2 |

| M4 x 50mm hex head cap screws | 4 |

| M4 washers | 10 |

| M4 nut | 6 |

| M4 x 16mm cap screws | 2 |

| M3 washer | 4 |

| M3 x 10mm cap screw | 4 |

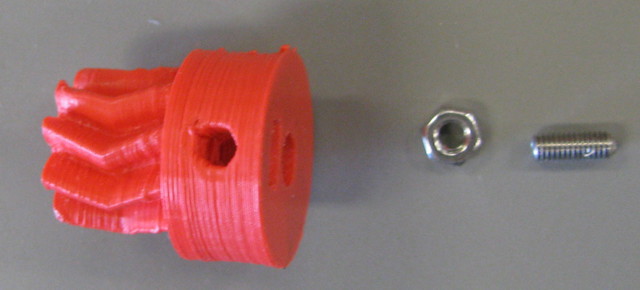

| M3 x 8mm set screw | 1 |

| M3 nut | 1 |

| M8 nut | 2 |

| M8 washer | 8 |

| Hobbed bolt | 1 |

| M8 nylon lock nut | 1 |

| 3/8" x 9/32" spring | 4 |

| 8mm x 25mm drill rod | 1 |

| Hot end retainer | 1 |

| 608zz bearing | 3 |

| 1/8" ID x 1/4" OD x 630mm PTFE tubing | 1 |

| Stepper motor | 1 |

| J-head hotend, assembled | 1 |

Assembly - Summary

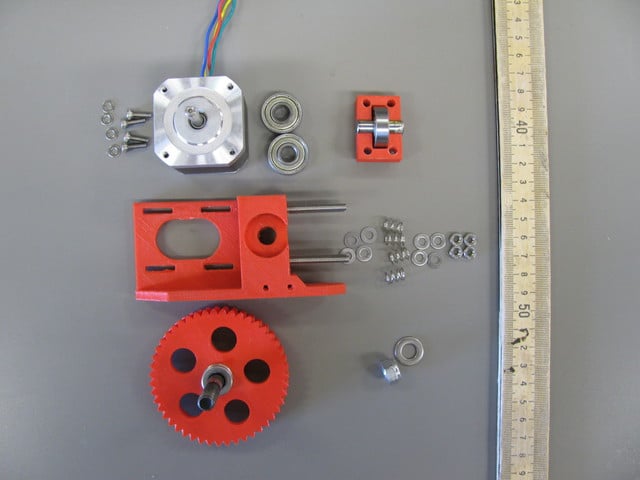

- Prepare printed parts

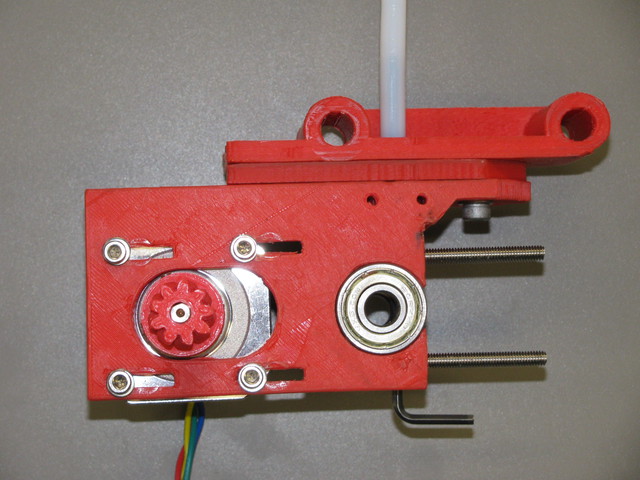

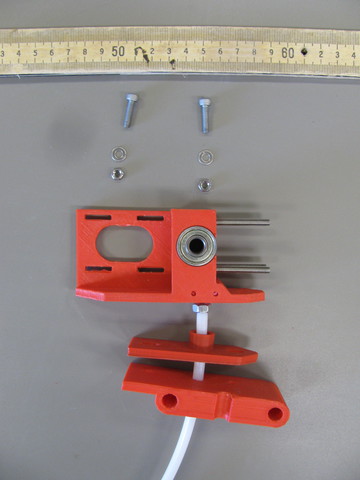

- Assemble extruder drive

- Assemble x-carriage

Assembly - Step-by-Step

- With a 3mm drill but, ream out the filament path through the extruder drive body and clean up the slots for the motor mounts. Used the 3mm drill bit like a file to ream out the 4mm openings for the idler mounts.

- Clean up gears with a sharp knife, removing any protrusions from teeth, flashing from the print-surface-side of the gears and open up the set screw nut trap on the small gear. With a 5mm drill bit, ream the small gear shaft opening. Use a 3mm drill bit to ream the set screw opening in the small gear.

- Ream the filament path in the extruder drive spacer and mount with a 3mm drill bit.

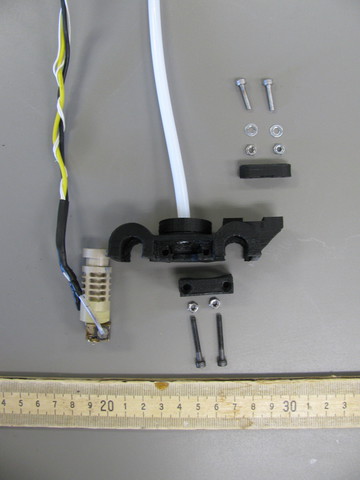

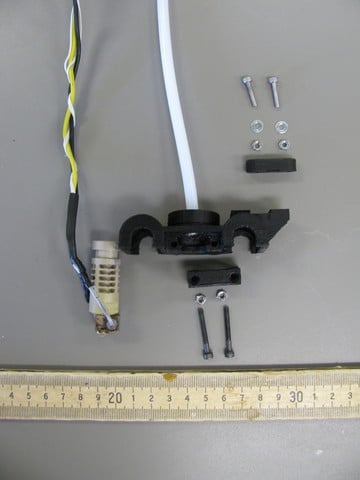

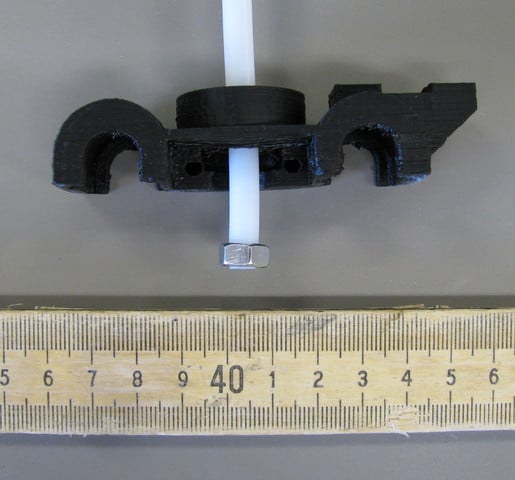

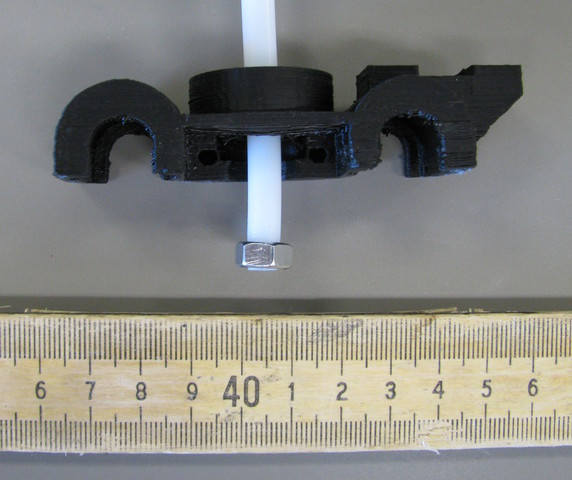

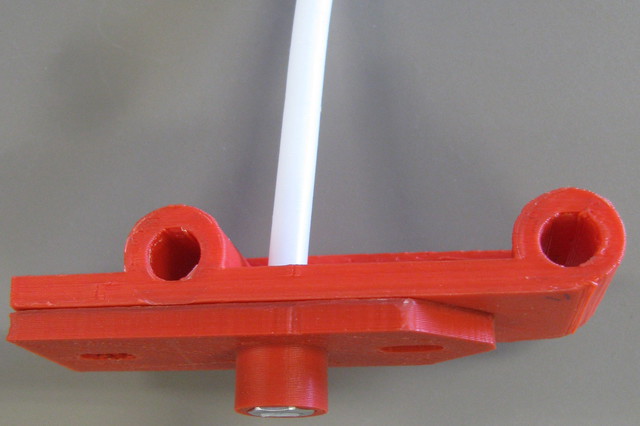

- Push the hot end retainer into its slot in the x-carriage and use a 3mm drill bit to ream the retainer screw holes. Use a sharp knife to open the retainer nut traps being careful to not remove too much material; remove any obstructions in the Bowden sheath opening.

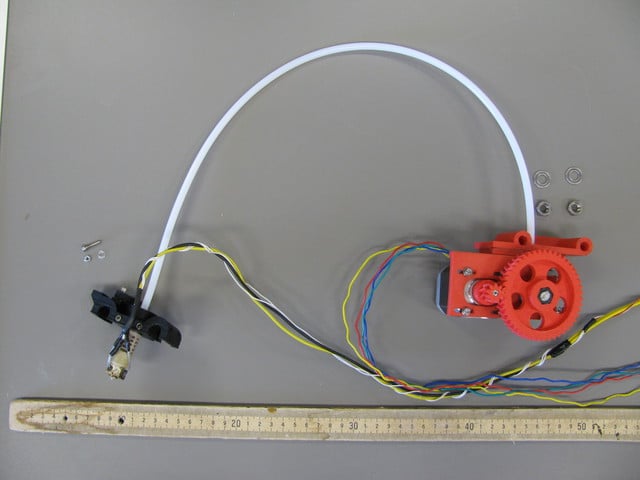

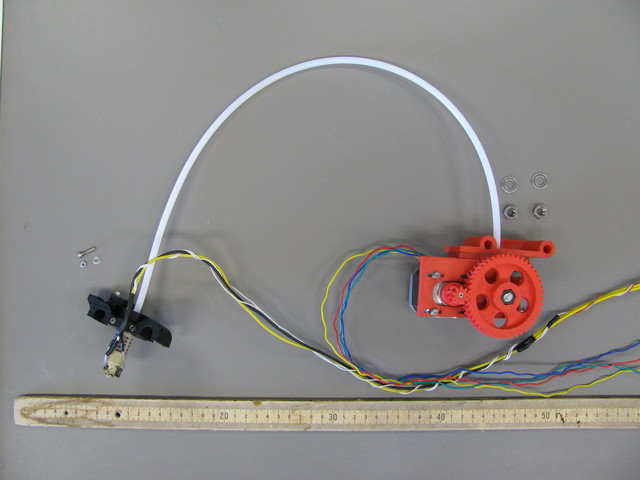

- To facilitate threading the Bowden sheath retainer nut, taper the ends of the PTFE tubing in a pencil sharpener.

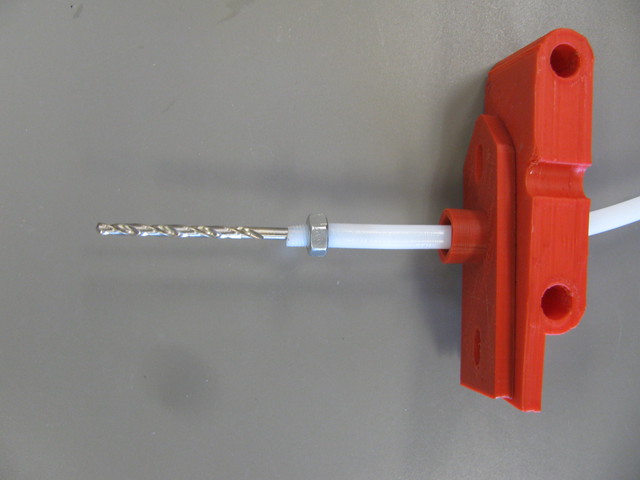

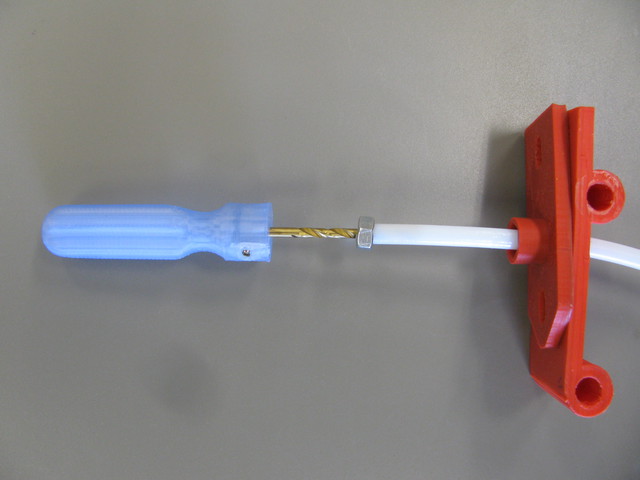

- Insert a 3mm drill bit into one end of the PTFE tubing and start a 6mm nut threading over the tube, use a wrench if necessary. (The drill bit reduces collapsing of the tube walls, making higher quality thread.) Thread the nut such that all of the tapered portion extends beyond it. Pull the drill bit out and using like a file, ream the interior of the tubing. Cut the excess tubing flush with the face of the nut. Repeat the process on the opposite end of the tubing and then remove a retainer nut from one end. Blow through the tube to remove any PTFE shavings - they will ruin the day come commissioning!

- Slide the tubing through the x-carriage and seat the sheath retainer nut in the nut trap.

- Rotate and push the hot end into the slot in the x-carriage until it is firmly seated. Push the hot end retainer into its slot and then insert a pair of M3 x 25mm screws through the retainer and carriage. Start M3 nuts on the opposite side and tighten the screws such that the whole assembly is firmly clamped together.

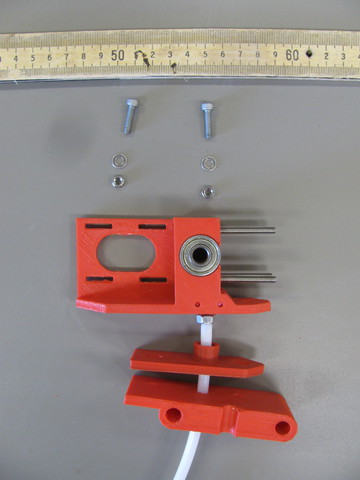

File:MOST HSPrusa extruder 20.jpg

File:MOST HSPrusa extruder 20.jpg

File:MOST HSPrusa extruder 31.jpg

File:MOST HSPrusa extruder 31.jpg