| Line 18: | Line 18: | ||

==Build Instructions== | ==Build Instructions== | ||

== | ==Test conditions on Athena RepRap 3D printer== | ||

===10/23/15 - Test 0=== | |||

Filament: Maxpower 333605 Residential Grade Round .105-Inch Trimmer Line 690-Foot Length from [http://www.amazon.com/dp/B001BKZT1S/ref=pe_175190_21431760_M2T1_SC_dp_1 Amazon] for $24.35/3 pounds (1.3kg $18.73/kg) | |||

End effector: 3mm Athena print effector | |||

Hot end: Lulzbot Hexagon, 3mm x 0.35mm | |||

Extruder drive: 3mm Phidias extruder drive | |||

Firmware: Franklin (latest) | |||

Temperature: 260 C | |||

Print speed: Variable (testing capabilities) | |||

Slicing: Cura 15.04 set to 3mm filament, 1 multiplier, 0.2mm layer height, 70mm/s, 25% infill, 30mm/s initial layer speed | |||

Bed: Glass mirror with glue stick | |||

Notes: First layer too close to glass requiring decrease in speed. Using a 12V fan on the end effector with pwm. Fan speed too high, end effector would not reach target temperature. Occluded lower half of fan with masking tape. | |||

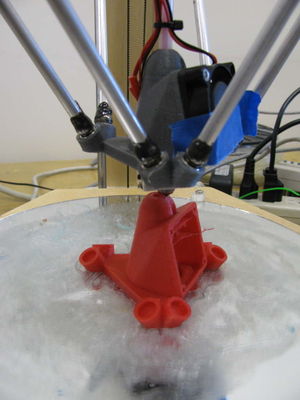

Result: | |||

[[File:Athena_max333605_test0.JPG|thumb|right|Maxpower 333605 print result.]] | |||

*Adjusted speed up to 140% (98mm/s) while printing first ~100 layers | |||

*Lower layers exhibited poor interlayer bonding | |||

*Resulting print is flexible, but makes cracking noise when squeezed due to poor interlayer bonding | |||

==See also== | ==See also== | ||

Revision as of 12:10, 23 October 2015

BOM

- Lulzbot hexagon hotend $70 https://www.lulzbot.com/products/lulzbot-hexagon-hot-end

- 24V/4-5A power supply

- 3mm id x 6mm od PTFE tubing 630mm long

- 2x M6 x 0.8mm hex nut

- 3mm print effector

- 3mm extruder drive body

- ~1m 18ga speaker wire

- 2x ~1m 28ga twisted pair

- Heat shrink tubing

OpenSCAD design

- End effector - download latest version of [Athena SCAD files] and [SCAD libraries]. Change the Bowden dimensions in athena.scad. Render the end effector and print.

- Extruder drive - download latest version of [extruder drive SCAD files] (requires the SCAD library, as above). Change the filament dimensions in extruder_drive_renderer.scad. Render the extruder drive body and print.

Build Instructions

Test conditions on Athena RepRap 3D printer

10/23/15 - Test 0

Filament: Maxpower 333605 Residential Grade Round .105-Inch Trimmer Line 690-Foot Length from Amazon for $24.35/3 pounds (1.3kg $18.73/kg) End effector: 3mm Athena print effector Hot end: Lulzbot Hexagon, 3mm x 0.35mm Extruder drive: 3mm Phidias extruder drive Firmware: Franklin (latest) Temperature: 260 C Print speed: Variable (testing capabilities) Slicing: Cura 15.04 set to 3mm filament, 1 multiplier, 0.2mm layer height, 70mm/s, 25% infill, 30mm/s initial layer speed Bed: Glass mirror with glue stick Notes: First layer too close to glass requiring decrease in speed. Using a 12V fan on the end effector with pwm. Fan speed too high, end effector would not reach target temperature. Occluded lower half of fan with masking tape.

Result:

- Adjusted speed up to 140% (98mm/s) while printing first ~100 layers

- Lower layers exhibited poor interlayer bonding

- Resulting print is flexible, but makes cracking noise when squeezed due to poor interlayer bonding