Introduction

Our design team, Fujis and Fugees, consists of four Humboldt State University engineering students. For our Engineering 215 class we were given the assignment of designing a solar powered food dehydrator which could be replicated at home by kids with the help of an adult. As a part of our assignment we will be working closely with the group Locally Delicious. Our final design will be integrated into Locally Delicious's upcoming cookbook along with instructions on how to build our solar dehydrator. In the following page you can overview our documented design process, as well as step by step instructions on how to build this project in your own home.

- Client: Locally Delicious

- Class: Engineering 215

Objective

The objective of our project is to design a simple, yet effective, model of a solar dehydrator. Our model will have an efficient design and will be easily replicable for a child with the assistance of an adult. We hope that by designing this solar dehydrator we help children learn about solar energy and healthy food choices.

Criteria

The following table is a sortable list of our design criteria, which were developed by both our design group and our client, Locally Delicious.

| Criteria | Weight | Constraints |

|---|---|---|

| Cost | 9 | Less than $100 |

| Educational Value | 8 | Teach about measurements, solar radiation, solar dehydration, as well as healthy eating, at a 4th to 8th grade level |

| Reproducibility | 9 | Minimal tool usage, easily obtainable materials |

| Maintenance | 6 | Less than 30 minutes of maintenance required per usage |

| Durability | 7 | Must last at least 12 uses |

| Safety | 10 | Should not exceed 200 degrees Fahrenheit, also must be structurally sound |

| Functional | 10 | Must be able to adequately dehydrate fruits and vegetables |

| Portability | 5 | Must be movable by two or less people |

Design

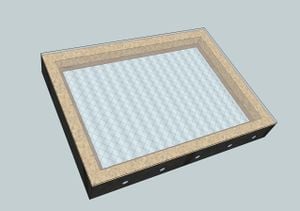

Our design incorporates a simple but effective model which requires very little materials to construct, yet is very efficient for dehydrating a small to moderate amount of food. Our design is 2'x3'x4" and is built on a plywood base, with a 2"x4" frame, corregated roofing, removable nylon mesh food screens framed in 1/2"x1", with a clear acrylic glass cover held in place by L-brackets, and vent holes on the top and bottom to promote air flow. This model is simple to build and the materials are easily found at your local hardware store, or recycled material can be used to reduce costs. The adjustable angle of inclination allows for maximum sunlight capture throughout the year, for data on the angle of inclination of the sun in your particular area, check out this Calculator.

Cost

The following table is a list of the materials used to build our project and their relative retail cost. In our project we used recycled wood and corregated roofing which brought the cost of our project down significantly.

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 2 | 2"x4"x8' Boards | Ace | 6.99 | 13.98 |

| 2 | 1"x1"x4' Framing | Ace | 3.44 | 6.88 |

| 1 | 1/2"x4'x4' Plywood | Ace | 12.55 | 12.55 |

| 1 | Corrugated Roofing Sheet | Scrapyard | 5.99 | 5.99 |

| 1 | 3'x6' Nylon Mesh | Jo-Ann's Fabrics | 7.28 | 7.28 |

| 1 | 2'x4' Clear Acrylic | Ace | 28.99 | 28.99 |

| 8 | Sheet Metal Screws | Ace | .11 | .88 |

| 16 | Wood Screws | Ace | .08 | 1.28 |

| 8 | Washers | Ace | .09 | .72 |

| 1 (Box) | L-Brackets | Ace | 3.79 | 3.79 |

| Total Cost | $82.34 | |||

Instructions

If you would like to build this project in your own home, please check out our instructions page on appropedia.

Inspirational Video

Shout out to Haddaway.

Fuji's and Fugees

- David Ullrich

- Jake Lodeen

- Dylan Kahle

- Matt Bruder