| Line 52: | Line 52: | ||

==Testing Results== | ==Testing Results== | ||

To test the durability of some selected materials, our group exposed them to the outside weather for three days, sprayed them with water at a high pressure for a minute, put them in the oven at a temperature of | To test the durability of some selected materials, our group exposed them to the outside weather for three days, sprayed them with water at a high pressure for a minute, put them in the oven at a temperature of 110˚F for thirty minutes, and scratched them with a wire brush 100 times. The results of these tests helped to determine which materials were to be used as our primary building materials. Further testing was implemented upon the completion of the project, where the structure was lightly sprayed with a garden hose for 2 minutes to simulate rain. Upon completing this test there was little to no leakage on all of the constructed outer shells. | ||

==How to build== | ==How to build== | ||

Revision as of 06:30, 30 November 2011

Abstract

Through Engineering 215 Intro to Design at Humboldt State University, Team Skin for the Win was created to address a problem involving a client of Professor Lonny Graffman. This client is the Flock House founded by Mary Mattingly, who is a well known and respected artist in New York City. She is the founder of many projects other than the Flock House Project including the Waterpod Project [1] for which a previous Engineering 215 Intro to Design class were also participants.

- Project Formulation

- Problem Analysis and Literature Review

- Alternative Solutions

- Decision Process

- Specification of Final Solution

Background

Problem Analysis and Criteria

| Criteria | Weight | Description |

|---|---|---|

| Safety | 10 | Protects inhabitants from natural elements |

| Inspiration | 9 | Reuses commonly wasted materials |

| Aesthetics | 8 | Visually appealing |

| Cost | 8 | Less than $375 |

| Durability | 7 | Should withstand New York weather conditions |

Description of final project

- Photos and descriptions

Design Cost

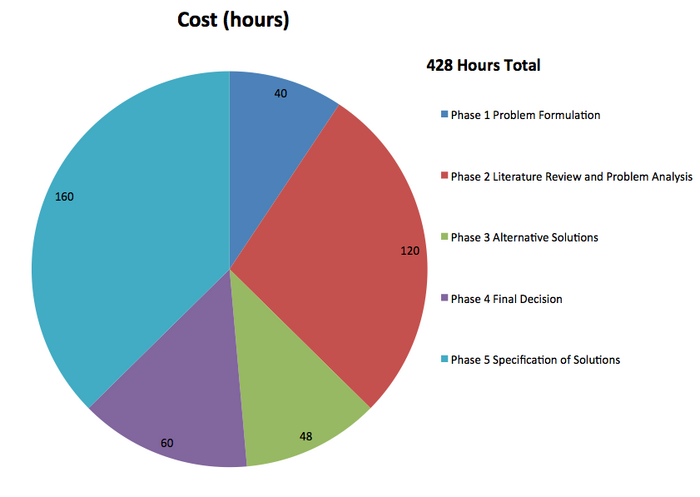

Design cost is measured in hours. The total hours spent on the creation of the Aluminum Awareness are 428 with the total being broken into respective segments as shown in Figure 2.

Implementation Cost

Implementation cost is measured in dollars. The total dollars spent on the creation of the Aluminum Awareness are $153.84 with the total being broken into required materials.

Testing Results

To test the durability of some selected materials, our group exposed them to the outside weather for three days, sprayed them with water at a high pressure for a minute, put them in the oven at a temperature of 110˚F for thirty minutes, and scratched them with a wire brush 100 times. The results of these tests helped to determine which materials were to be used as our primary building materials. Further testing was implemented upon the completion of the project, where the structure was lightly sprayed with a garden hose for 2 minutes to simulate rain. Upon completing this test there was little to no leakage on all of the constructed outer shells.