JamesCreek (talk | contribs) (Creating the page and testing how it looks) |

JamesCreek (talk | contribs) (Saving Doc, still needs major edits) |

||

| Line 1: | Line 1: | ||

{{Template:ENGR215inprogress}} | {{Template:ENGR215inprogress}} | ||

Testing the | [[Image:Switch_and_Swap.jpg|thumb|right|440px|The Switch and Swap, located in CCAT's gray water marsh]] | ||

== Abstract == | |||

The purpose of the project was to educate Nature Center visitors on the benefits of living green roofs, to enhance the aesthetics of the Nature Center, and to inspire others to build their own green roofs. The Dune-Gineers Green Roof was built at the Friends of the Dunes Nature Center by students at Humboldt State University Engineering 215 class. | |||

== Background == | |||

The Friends of the Dunes is a non-profit organization, and their Coastal Nature Center is a place where they promote green solutions by educating visitors. They work to protect and preserve the natural habitats of the dunes. | |||

The Friends of the Dunes originally planned to have a living green roof put on their back terrace, so the terrace was built to be able to hold a heavy garden. They tried to get a living green roof built, but the quote given to them by the hired company was too expensive. When they were later presented with the opportunity for student engineers to build a green roof for much cheaper, they decided to give us the job. | |||

== Problem statement == | |||

The FotD wanted a green roof to be installed. They wanted it to have native Californian dune plants to live on it. | |||

== Problem Analysis and Criteria == | |||

{| class="wikitable sortable" | |||

|- | |||

! Criteria | |||

! Weight | |||

! Description | |||

|- | |||

| Aesthetics | |||

| 10 | |||

| Description | |||

|- | |||

| Support Local Plants | |||

| 9 | |||

| Description | |||

|- | |||

| Cost | |||

| 3 | |||

| Entire design must cost less than $400. | |||

|- | |||

| Weight | |||

| 5 | |||

| Constraint description | |||

|- | |||

| Saftey | |||

| 5 | |||

| Don't collapse description | |||

|} | |||

==The Solution== | |||

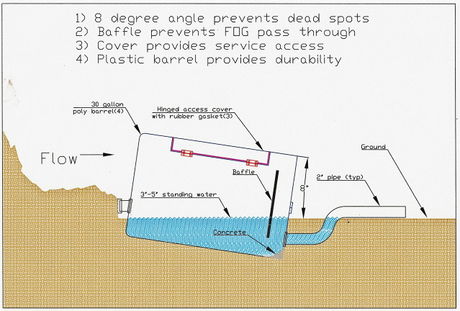

The design solution that best met the criteria for the project required the modification of two seperate components within the CCAT gray water system. The Switch and Swap is the grease removal unit. The Surge tank has been modified to reduce problems during operation. [[Image:Switch_and_Swap_CAD.jpg|thumb|right|460px|Figure 1, Drawing of the Switch and Swap]] | |||

===How to Build=== | |||

The green roof is installed on the smaller awning in the back of the Nature Center. An additional layer of waterproofing paint is added to make sure no leaks occur. Concrete blocks are carried up on a twelve-foot or higher ladder, and stacked two high around the edge of the roof, four inches from the gutter. Gravel is then brought up in buckets and spread to a height of one inch. The separation fabric is placed on top, leaving 4 inches of extra cloth along the edges. The cloth is not wide enough to completely cover the bottom of the roof, and needs to overlap by one inch at any seams. Four inches of sand is then added on top of the separation fabric, excluding the sides. Along the insides of the blocks and against the wall, extra gravel is added to a thickness of one inch and a height of four inches. The extra four inches of separation fabric is then used to separate this column of gravel from the four inches of sand. Extra sand is added to the roof to fill in any low points on the roof. Once the layers are in place, a micro sprinkler system is installed. The erosion control blanket is then placed on top of the sand. On the edges of the roof it is pushed down into the sand to hold it in. Stakes are taken from the surrounding green roof where the erosion control blanket has decomposed and are used to hold down the new blanket. | |||

== Costs == | |||

{| class="wikitable sortable" | |||

|- | |||

! Material | |||

! Amount | |||

! Price | |||

! Supplier | |||

|- | |||

|Hydrostop Protection Layer | |||

| 1 bucket | |||

| 0.00 | |||

| FOTD | |||

|- | |||

|12" long 2" PVC | |||

| 1 | |||

| $0.75 | |||

| $0.75 | |||

| $0.75 | |||

|- | |||

| 45 de. Str. elbow | |||

| 2 | |||

| $1.55 | |||

| $3.10 | |||

| $3.10 | |||

|- | |||

| Silicone Caulk | |||

| 1 | |||

| $5.49 | |||

| $5.49 | |||

| $5.49 | |||

|- | |||

|Brass hinge pkg. 2 | |||

| 1 | |||

| $4.39 | |||

| $4.39 | |||

| Salvaged | |||

|- | |||

| 1/4" Plastic 2'x' | |||

| 1 | |||

| $25.14 | |||

| $25.14 | |||

| Salvaged | |||

|- | |||

| 3" Threaded flange assy. | |||

| 1 | |||

| $10.99 | |||

| $10.99 | |||

| Salvaged | |||

|- | |||

| SS Screws pkg. 20 | |||

|1 | |||

| $4.49 | |||

| $4.49 | |||

| Donated | |||

|- | |||

| Rubber gasket 5' | |||

|1 | |||

| $6.00 | |||

| $6.00 | |||

| Donated | |||

|- | |||

| 2 to 11/2 Reducer | |||

| 2 | |||

| $1.55 | |||

| $3.10 | |||

| Salvaged | |||

|- | |||

| 2" Threaded flange | |||

| 1 | |||

| $1.99 | |||

| $1.99 | |||

| Salvaged | |||

|- | |||

|80 lb. Concrete | |||

| 1 | |||

| $4.71 | |||

| $4.71 | |||

| $4.71 | |||

|- | |||

|Tax | |||

| | |||

| | |||

| $11.61 | |||

| $6.84 | |||

|- | |||

! Total | |||

| | |||

| | |||

! $148.25 | |||

! $87.38 | |||

|} | |||

== Discussion == | |||

'''Instructions for Implementation and Use''' | |||

After installation, initial implementation is accomplished by filling the reservoir within the trap. Once full the Switch and Swap is ready for operation. Aside from routine cleaning the Switch and swap will require minimal maintenance or involvement from CCAT personnel. | |||

'''Weekly Cleaning''' | |||

The suggested cleaning schedule requires that accumulated FOG to be removed from the Switch and Swap on a weekly basis. Removing accumulated FOG is accomplished by unlatching and lifting the hinged cover to allow access to the reservoir of the trap. FOG can then be skimmed from the reservoirs surface and be recycled or discarded. Care should be taken when closing the trap to insure proper seating of the gasket. Ideally the cover should form a tight seal that will prevent insect infestation. The weekly cleaning will require approximately 10 to 15 minutes. | |||

'''Quarterly Maintenance''' | |||

The Switch and Swap should be flushed out quarterly. This can be accomplished by running a large volume of potable water directly into the reservoir after routine cleaning. Potable water should also be used to rinse interior components of the Switch and Swap. The cover is then closed as described above. Quarterly flushing if done correctly will remove any sediment that has accumulated on the bottom of the reservoir. Quarterly flushing will also help minimize foul odors sometimes associated with grease removal systems. Quarterly flushing will require approximately 15 to 20 minutes. | |||

'''Safety Precautions''' | |||

As with any gray water system, steps should be taken to minimize direct contact with effluent while cleaning and maintaining the Switch and Swap. Typical precautions include the use of rubber gloves to minimize effluent contact with skin. Also extra care should be taken to avoid exposure to open cuts or wounds. | |||

== next steps == | |||

We look forward to the Switch and Swap receiving additional field testing. Testing was conducted after construction but the varying conditions of regular use were hard to duplicate. Testing was also limited to unit availability after construction and before installation, a time span of approximately one week. | |||

There is also need for field testing of the Surge Tank modifications. Design and implementation efforts have been focused on eliminating grease build up in the Surge Tank.The conceptual model fit the objective for the modifications however physical testing has been impossible without the entire gray water system online. | |||

[[Category:Engr215 Introduction to Design]] | |||

[[Category:Greywater]] | |||

[[Category:CCAT|G]] | |||

[[Category: Projects]] | |||

[[Category:Engr215 Introduction to Design]] | [[Category:Engr215 Introduction to Design]] | ||

[[Category:Friends of the Dunes]] | [[Category:Friends of the Dunes]] | ||

Revision as of 02:06, 6 April 2012

Abstract

The purpose of the project was to educate Nature Center visitors on the benefits of living green roofs, to enhance the aesthetics of the Nature Center, and to inspire others to build their own green roofs. The Dune-Gineers Green Roof was built at the Friends of the Dunes Nature Center by students at Humboldt State University Engineering 215 class.

Background

The Friends of the Dunes is a non-profit organization, and their Coastal Nature Center is a place where they promote green solutions by educating visitors. They work to protect and preserve the natural habitats of the dunes. The Friends of the Dunes originally planned to have a living green roof put on their back terrace, so the terrace was built to be able to hold a heavy garden. They tried to get a living green roof built, but the quote given to them by the hired company was too expensive. When they were later presented with the opportunity for student engineers to build a green roof for much cheaper, they decided to give us the job.

Problem statement

The FotD wanted a green roof to be installed. They wanted it to have native Californian dune plants to live on it.

Problem Analysis and Criteria

| Criteria | Weight | Description |

|---|---|---|

| Aesthetics | 10 | Description |

| Support Local Plants | 9 | Description |

| Cost | 3 | Entire design must cost less than $400. |

| Weight | 5 | Constraint description |

| Saftey | 5 | Don't collapse description |

The Solution

The design solution that best met the criteria for the project required the modification of two seperate components within the CCAT gray water system. The Switch and Swap is the grease removal unit. The Surge tank has been modified to reduce problems during operation.

How to Build

The green roof is installed on the smaller awning in the back of the Nature Center. An additional layer of waterproofing paint is added to make sure no leaks occur. Concrete blocks are carried up on a twelve-foot or higher ladder, and stacked two high around the edge of the roof, four inches from the gutter. Gravel is then brought up in buckets and spread to a height of one inch. The separation fabric is placed on top, leaving 4 inches of extra cloth along the edges. The cloth is not wide enough to completely cover the bottom of the roof, and needs to overlap by one inch at any seams. Four inches of sand is then added on top of the separation fabric, excluding the sides. Along the insides of the blocks and against the wall, extra gravel is added to a thickness of one inch and a height of four inches. The extra four inches of separation fabric is then used to separate this column of gravel from the four inches of sand. Extra sand is added to the roof to fill in any low points on the roof. Once the layers are in place, a micro sprinkler system is installed. The erosion control blanket is then placed on top of the sand. On the edges of the roof it is pushed down into the sand to hold it in. Stakes are taken from the surrounding green roof where the erosion control blanket has decomposed and are used to hold down the new blanket.

Costs

| Material | Amount | Price | Supplier | |

|---|---|---|---|---|

| Hydrostop Protection Layer | 1 bucket | 0.00 | FOTD | |

| 12" long 2" PVC | 1 | $0.75 | $0.75 | $0.75 |

| 45 de. Str. elbow | 2 | $1.55 | $3.10 | $3.10 |

| Silicone Caulk | 1 | $5.49 | $5.49 | $5.49 |

| Brass hinge pkg. 2 | 1 | $4.39 | $4.39 | Salvaged |

| 1/4" Plastic 2'x' | 1 | $25.14 | $25.14 | Salvaged |

| 3" Threaded flange assy. | 1 | $10.99 | $10.99 | Salvaged |

| SS Screws pkg. 20 | 1 | $4.49 | $4.49 | Donated |

| Rubber gasket 5' | 1 | $6.00 | $6.00 | Donated |

| 2 to 11/2 Reducer | 2 | $1.55 | $3.10 | Salvaged |

| 2" Threaded flange | 1 | $1.99 | $1.99 | Salvaged |

| 80 lb. Concrete | 1 | $4.71 | $4.71 | $4.71 |

| Tax | $11.61 | $6.84 | ||

| Total | $148.25 | $87.38 |

Discussion

Instructions for Implementation and Use After installation, initial implementation is accomplished by filling the reservoir within the trap. Once full the Switch and Swap is ready for operation. Aside from routine cleaning the Switch and swap will require minimal maintenance or involvement from CCAT personnel.

Weekly Cleaning The suggested cleaning schedule requires that accumulated FOG to be removed from the Switch and Swap on a weekly basis. Removing accumulated FOG is accomplished by unlatching and lifting the hinged cover to allow access to the reservoir of the trap. FOG can then be skimmed from the reservoirs surface and be recycled or discarded. Care should be taken when closing the trap to insure proper seating of the gasket. Ideally the cover should form a tight seal that will prevent insect infestation. The weekly cleaning will require approximately 10 to 15 minutes.

Quarterly Maintenance The Switch and Swap should be flushed out quarterly. This can be accomplished by running a large volume of potable water directly into the reservoir after routine cleaning. Potable water should also be used to rinse interior components of the Switch and Swap. The cover is then closed as described above. Quarterly flushing if done correctly will remove any sediment that has accumulated on the bottom of the reservoir. Quarterly flushing will also help minimize foul odors sometimes associated with grease removal systems. Quarterly flushing will require approximately 15 to 20 minutes.

Safety Precautions As with any gray water system, steps should be taken to minimize direct contact with effluent while cleaning and maintaining the Switch and Swap. Typical precautions include the use of rubber gloves to minimize effluent contact with skin. Also extra care should be taken to avoid exposure to open cuts or wounds.

next steps

We look forward to the Switch and Swap receiving additional field testing. Testing was conducted after construction but the varying conditions of regular use were hard to duplicate. Testing was also limited to unit availability after construction and before installation, a time span of approximately one week.

There is also need for field testing of the Surge Tank modifications. Design and implementation efforts have been focused on eliminating grease build up in the Surge Tank.The conceptual model fit the objective for the modifications however physical testing has been impossible without the entire gray water system online.