m (+cats) |

|||

| (31 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

== Abstract == | == Abstract == | ||

This page is for the Spring 2012 [http://www.humboldt.edu Humboldt State] [[Engr215 Introduction to Design]] course and project. This specific design was made for the [[Friends of the Dunes]]' visitor center to help improve the acoustics within the center's main room. This page will provide a background of the problem and solution, description of the final design, costs of materials and time, a "how to build" this yourself section , discussion section, and finally references used for the conception of this project. | |||

[[Image:Team Panel.jpg| upright=2|right|thumb|Fig 1: Team SAND ]] | |||

== Acoustic Dampening Project Plan == | == Acoustic Dampening Project Plan == | ||

The acoustic dampening system is a combination of the use of acoustic panels and banners. This system is large, soft, and porous. This combination allows the panels and banners to intersect sound waves and absorb and/or reflect sound waves to decrease the reverberation of sound throughout the [http://www.friendsofthedunes.org/HCNC/ Humboldt Coastal Nature Center]. This system is made through alternative building methods such as recycled materials as well as being relatively cheap. These systems are required to be held up securely since they are installed on the ceiling and walls and could possibly fall. A combination of strong mounting systems and light weight components for panels and banners is key for the success of the system. | |||

== Background == | == Background == | ||

[[Friends of the Dunes]] (FOTD) is a non-profit organization based out of Manila, | |||

California. FOTD objective is the conservation of coastal environments through | |||

ecosystem restoration, education programs, and stewardship. Their visitor center | |||

known as the [http://www.friendsofthedunes.org/HCNC/ Humboldt Coastal Nature Center] (HCNC) is a former home owned by | |||

the Stamps Family. Designed and constructed from an earth shelter kit the house is | |||

mainly constructed from concrete. Therefore the main room at the HCNC has poor | |||

acoustics due to the concrete and unique half cyclical shape of the room. | |||

== Problem Statement and Criteria == | == Problem Statement and Criteria == | ||

| Line 52: | Line 56: | ||

== Description of final project == | == Description of final project == | ||

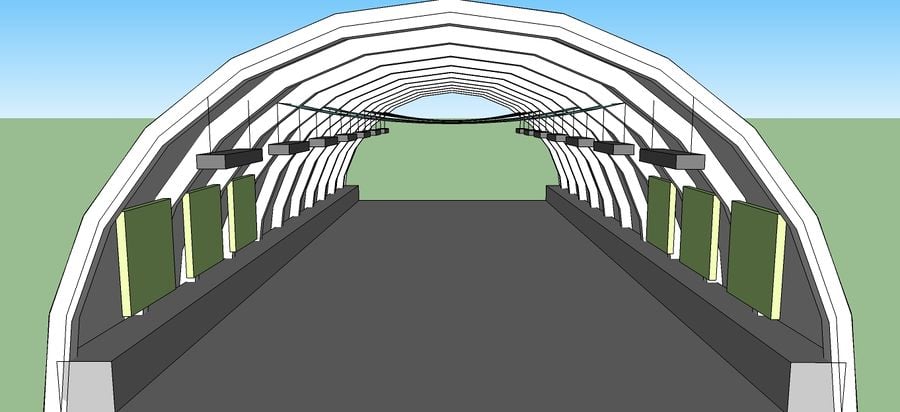

[[Image:HCNC_building.JPG| upright=3|right|thumb|Fig 2: Google SketchUp of the position of the acoustic panels and banners Section ]] | [[Image:HCNC_building.JPG| upright=3|right|thumb|Fig 2: Google SketchUp of the position of the acoustic panels and banners Section ]] | ||

Acoustic panels and acoustic banners are used to improve the acoustics within the [http://www.friendsofthedunes.org/HCNC/ Humboldt Coastal Nature Center]. The acoustic panels are filled with a material that is recycled, and will diffuse sound well. Some recycled, sound absorbing material that are being considered are newspaper, sheared wool, packing peanuts, egg cartons, and dry beachgrass. The panels are constructed with 2x4s, burlap fabric, a recycled sound absorbing material, and chicken wire. The panels are mounted to the walls in the open part of the building. We positioned them here because it is where most of the visitors gather, so this is the area that has the greatest sound generation in the building. The Acoustic banners are hung between the already existing light fixture mounts in the Eastern half of the building and hung vertically between the light fixture mount and the light fixtures themselves in the Western half of the building. Both types of banners are made from a long strip of fabric. For the banners hung between the light fixture mounts there is a specific rigging system. The ends of the banners are secured in between two pieces of wood and bolted together and tightened with a wing nut. A cable is then attached to the banner and then attached to the light fixture mount. | |||

== Costs == | == Costs == | ||

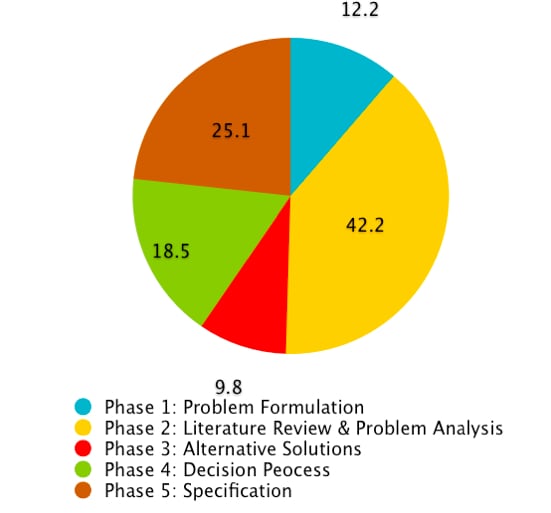

[[Image:Acoustic Dampening Design Hours.jpg|thumb|upright=2.5| right| Fig 3: A pie chart showing hours spent per section of the design process. Total design hours were 107.8]] | |||

=== Material Costs === | === Material Costs === | ||

{| class="wikitable" | |||

{| class="wikitable sortable" | |||

! Material !! Use !! Quantity !! Project Cost ($) !! Projected Project Cost ($) | |||

|- | |||

| Burlap || Panels/Banners || 54 yds. | |||

|align="right"| $158.87 | |||

|align="right"| $158.87 | |||

|- | |||

| Strike Anchors || Panels ||6 | |||

|align="right"| $7.74 | |||

|align="right"| $7.74 | |||

|- | |- | ||

| Lumber (2x4)||Panels||24 | |||

|align="right"| $32.00 | |||

|align="right"| $54.00 | |||

|- | |- | ||

| | | Angle Brackets||Panels||8 | ||

| $ | |align="right"| $10.00 | ||

| $ | |align="right"| $10.00 | ||

|- | |- | ||

| | | 2” Bolts||Panels||6 | ||

| $ | |align="right"| $1.50 | ||

| $ | |align="right"| $1.50 | ||

|- | |- | ||

| | | Newspaper||Panels||30 ed. | ||

| $ | |align="right"| $0.00 | ||

| $12. | |align="right"| $12.00 | ||

|- | |- | ||

| | | ChickenWire ||Panels||2'x25' | ||

| $ | |align="right"| $25.00 | ||

| $ | |align="right"| $25.00 | ||

|- | |- | ||

| | | Lumber (plywood)||Banners|| 1’x4’ (6) | ||

| $ | |align="right"| $0.00 | ||

| $ | |align="right"| $20.00 | ||

|- | |- | ||

| | | Cable||Banners|| 50 ft. | ||

| | |align="right"| $8.69 | ||

| $ | |align="right"| $8.69 | ||

|- | |- | ||

| | | Cable Clamps||Banners|| 1/8" (24) | ||

| $ | |align="right"| $12.00 | ||

| $ | |align="right"| $12.00 | ||

|- | |- | ||

| '''Total''' | |-class="sortbottom" | ||

| '''$ | |colspan="3" align="right" | '''Total''' | ||

| '''$ | |align="right"| '''$247.11''' | ||

|align="right"| '''$308.80''' | |||

|} | |} | ||

===Design Hours=== | ===Design Hours=== | ||

The | The total design hours were 107.8 as shown in Figure 3. | ||

== Testing Results == | == Testing Results == | ||

| Line 114: | Line 125: | ||

| Image: Panel Build Step 3.jpg | Figure 3:|3| Putting the cut sides of the frame together which are ready for assembly... (Photo by Amy Gabriel) | | Image: Panel Build Step 3.jpg | Figure 3:|3| Putting the cut sides of the frame together which are ready for assembly... (Photo by Amy Gabriel) | ||

| Image: Panel Build Step 4.jpg| Figure 4:|4| Drilling pilot holes on the joint. One and half inch screws were then used to attach the two sides... (Photo by Amy Gabriel) | | Image: Panel Build Step 4.jpg| Figure 4:|4| Drilling pilot holes on the joint. One and half inch screws were then used to attach the two sides... (Photo by Amy Gabriel) | ||

| Image: Panel Build Step 5.jpg| Figure 5:|5| Repeat step 3 and 4 until frame is fully assembled. | | Image: Panel Build Step 5.jpg| Figure 5:|5| Repeat step 3 and 4 until frame is fully assembled... (Photo by Amy Gabriel) | ||

| Image: Panel Build Step 6.JPG | Figure 6:|6| Using a newspaper template, mark on the previously cut fabric to properly fold on the corner of the panel frame. This can be done in multiple ways and is mostly based on the users preference.... (Photo by Cole Humphrey) | |||

| Image: Panel Build Step 7.JPG | Figure 7:|7| After cuts have been made. Stretch fabric over frame and staple. Depending on the fabric the may require multiple people and/ or stretching processes.... (Photo by Michael Harrow) | |||

| Image: Panel Build Step 8.JPG| Figure 8:|8| Fold left over fabric corner over and staple within frame. We did not cut it due to fear of fraying. The corners will be hidden once panel is filled.... (Photo by Michael Harrow) | |||

| Image: Panel Build Step 9.JPG| Figure 9:|9|Panels after fabric covering.... (Photo by Michael Harrow) | |||

| Image: Panel Build Step 10.jpg| Figure 10:|10|Fill fabric covered panel with filling such as newspaper, dry trash, wool, or (but not limited to) insulation. Then cover with chicken wire and staple secure.... (Photo by Kayla Morris) | |||

| Image: Panel Build Step 11.jpg| Figure 11:|11| Drill a centered 1/8 inch hole at the top of the frame for a 2 inch long bolt to connect to the mounting bracket..... (Photo by Kayla Morris) | |||

| Image: Panel Build Step 12.jpg| Figure 12:|12| Panel is finished!..... (Photo by Kayla Morris)}} | |||

== Discussion and next steps == | == Discussion and next steps == | ||

The acoustic banners and panels were built to last at least ten years or when [[Friends of the Dunes]] decide to go through with their remodeling plans. The panels were also specifically designed so that they can be taken off the walls at anytime or during the inspections every couple of months. This process is as easy as removing the top connecting bolt from the brackets which the panels are resting on. Possible future plans for the banners and panels consist of painting on wildlife or ocean designs by [[Friends of the Dunes]]. | |||

== References == | == References == | ||

* Online Discount Drapery Fabrics and Upholstery Fabric Super Store! Web. 5 Apr. 2012. <http://warehousefabricsinc.com/>. | |||

* "Project Overview." Humboldt Coastal Nature Center. Web. 15 Mar. 2012. <http://www.friendsofthedunes.org/HCNC/>. | |||

* "Quiet Classrooms - How to Measure Reverberation Time?" QuietClassrooms.org, ClassroomAcoustics.org and SchoolNoise.org - Homeroom. Web. 28 Apr. 2012. <http://www.quietclassrooms.org/library/test2.htm>. | |||

[[Category:Engr215 Introduction to Design]] | |||

[[Category:Friends of the Dunes]] | |||

Revision as of 11:39, 11 November 2015

Abstract

This page is for the Spring 2012 Humboldt State Engr215 Introduction to Design course and project. This specific design was made for the Friends of the Dunes' visitor center to help improve the acoustics within the center's main room. This page will provide a background of the problem and solution, description of the final design, costs of materials and time, a "how to build" this yourself section , discussion section, and finally references used for the conception of this project.

Acoustic Dampening Project Plan

The acoustic dampening system is a combination of the use of acoustic panels and banners. This system is large, soft, and porous. This combination allows the panels and banners to intersect sound waves and absorb and/or reflect sound waves to decrease the reverberation of sound throughout the Humboldt Coastal Nature Center. This system is made through alternative building methods such as recycled materials as well as being relatively cheap. These systems are required to be held up securely since they are installed on the ceiling and walls and could possibly fall. A combination of strong mounting systems and light weight components for panels and banners is key for the success of the system.

Background

Friends of the Dunes (FOTD) is a non-profit organization based out of Manila, California. FOTD objective is the conservation of coastal environments through ecosystem restoration, education programs, and stewardship. Their visitor center known as the Humboldt Coastal Nature Center (HCNC) is a former home owned by the Stamps Family. Designed and constructed from an earth shelter kit the house is mainly constructed from concrete. Therefore the main room at the HCNC has poor acoustics due to the concrete and unique half cyclical shape of the room.

Problem Statement and Criteria

| Criteria | Weight | Description |

|---|---|---|

| Safety | 10 | Must be designed to... |

| Aesthetics | 8 | Design must be aesthetically pleasing. |

| Cost | 3 | Entire design must cost less than $400. |

| Durability | 5 | Must last until Humboldt Coastal Nature Center's remodel |

| Inspiration | 7 | Design inspirational quality of using alternative building methods. |

| Ease of Maintenance and Installation | 7 | Design must be easy to install and free of a lot of maintenance |

| Functionality | 10 | Design must improve acoustics within Humboldt Coastal Nature Center. |

Description of final project

Acoustic panels and acoustic banners are used to improve the acoustics within the Humboldt Coastal Nature Center. The acoustic panels are filled with a material that is recycled, and will diffuse sound well. Some recycled, sound absorbing material that are being considered are newspaper, sheared wool, packing peanuts, egg cartons, and dry beachgrass. The panels are constructed with 2x4s, burlap fabric, a recycled sound absorbing material, and chicken wire. The panels are mounted to the walls in the open part of the building. We positioned them here because it is where most of the visitors gather, so this is the area that has the greatest sound generation in the building. The Acoustic banners are hung between the already existing light fixture mounts in the Eastern half of the building and hung vertically between the light fixture mount and the light fixtures themselves in the Western half of the building. Both types of banners are made from a long strip of fabric. For the banners hung between the light fixture mounts there is a specific rigging system. The ends of the banners are secured in between two pieces of wood and bolted together and tightened with a wing nut. A cable is then attached to the banner and then attached to the light fixture mount.

Costs

Material Costs

| Material | Use | Quantity | Project Cost ($) | Projected Project Cost ($) |

|---|---|---|---|---|

| Burlap | Panels/Banners | 54 yds. | $158.87 | $158.87 |

| Strike Anchors | Panels | 6 | $7.74 | $7.74 |

| Lumber (2x4) | Panels | 24 | $32.00 | $54.00 |

| Angle Brackets | Panels | 8 | $10.00 | $10.00 |

| 2” Bolts | Panels | 6 | $1.50 | $1.50 |

| Newspaper | Panels | 30 ed. | $0.00 | $12.00 |

| ChickenWire | Panels | 2'x25' | $25.00 | $25.00 |

| Lumber (plywood) | Banners | 1’x4’ (6) | $0.00 | $20.00 |

| Cable | Banners | 50 ft. | $8.69 | $8.69 |

| Cable Clamps | Banners | 1/8" (24) | $12.00 | $12.00 |

| Total | $247.11 | $308.80 | ||

Design Hours

The total design hours were 107.8 as shown in Figure 3.

Testing Results

How to build

Discussion and next steps

The acoustic banners and panels were built to last at least ten years or when Friends of the Dunes decide to go through with their remodeling plans. The panels were also specifically designed so that they can be taken off the walls at anytime or during the inspections every couple of months. This process is as easy as removing the top connecting bolt from the brackets which the panels are resting on. Possible future plans for the banners and panels consist of painting on wildlife or ocean designs by Friends of the Dunes.

References

- Online Discount Drapery Fabrics and Upholstery Fabric Super Store! Web. 5 Apr. 2012. <http://warehousefabricsinc.com/>.

- "Project Overview." Humboldt Coastal Nature Center. Web. 15 Mar. 2012. <http://www.friendsofthedunes.org/HCNC/>.

- "Quiet Classrooms - How to Measure Reverberation Time?" QuietClassrooms.org, ClassroomAcoustics.org and SchoolNoise.org - Homeroom. Web. 28 Apr. 2012. <http://www.quietclassrooms.org/library/test2.htm>.