(New page: {{TOCright}} == Background == The Full belly Project is an organization which creates low cost, simple technological solutions to be implemented in developing countries. One of these solu...) |

No edit summary |

||

| Line 5: | Line 5: | ||

== Abstract == | == Abstract == | ||

<center>''To improve the Universal nut sheller, the LC Sheller design lowered the cost and weight of existing design using locally available and | <center>''To improve the Universal nut sheller, the LC Sheller design lowered the cost and weight of existing design using locally available and light weight materials. ''</center> | ||

Keywords: | Keywords: Full Belly Project, Sheller, lightweight concrete | ||

== | == Problem Statement and Criteria == | ||

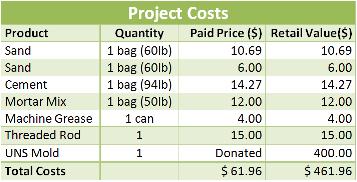

== Costs == | == Costs == | ||

=== Materials === | === Materials === | ||

Revision as of 23:54, 11 December 2008

Background

The Full belly Project is an organization which creates low cost, simple technological solutions to be implemented in developing countries. One of these solutions, the Universal Nut Sheller, minimizes the work load of women in Western Africa by allowing nuts to be shelled through this device rather than by hand.

Abstract

Keywords: Full Belly Project, Sheller, lightweight concrete

Problem Statement and Criteria

Costs

Materials

Specifications

Technical specifications including a schematic (CAD, pictures of the device).

Here is some help uploading files.

Construction instructions

Equal mix (by volume) of cement, sand, clay and sawdust. Use fine grained clay, obtained by running dry, crushed clay through a sieve or screen. Also use fine sawdust, as opposed to wood shavings. Mix material dry, then slowly add water while mixing until desired consistency is obtained. This should be enough water for all materials (especially cement) to be wet, but is not too hard to mix. A slightly less-than cottage cheese wetness is acceptable. Follow Full Belly instructions as normal. Instructions [1]

Next steps

-Additional materials testing could result in a mixture that more thoroughly meets the Fully Belly Project's criteria (lighter and cheaper). -Research into long term strength of organic aggregates in cement mixtures. -

Possible alternatives devices

- Building a wheeled trailor to attach to a bicycle would increase transportability

Location

References

See Help:Footnotes for more.

Categories

<layout name="AT device" />