Anonymous1 (talk | contribs) No edit summary |

Sophivorus (talk | contribs) m (Text replacement - "contact-appropedia-user" to "authors") |

||

| (23 intermediate revisions by 8 users not shown) | |||

| Line 1: | Line 1: | ||

{{ | {{Infobox device | ||

|title=FBP LC Sheller | |||

|image=Sheller.jpg | |||

|description=The Full Belly Project is an organization which creates low cost, simple technological solutions to be implemented in developing countries. One of these solutions, the Universal Nut Sheller, minimizes the work load of women in Western Africa by allowing nuts to be shelled through this device rather than by hand. | |||

|keywords=low cost nut sheller, nutcracker | |||

|intended-use=agriculture, development, industry | |||

|development-stage=Prototype | |||

|made=Yes | |||

|made-independently=No | |||

|countries-of-design=United States | |||

|project-affiliation=Category:Humboldt State University, Category:Engr215 Introduction to Design | |||

|main-materials=cement, sand, clay | |||

|estimated-cost-amount=46.00 | |||

|estimated-cost-currency=USD | |||

|sustainable-development-goal=Sustainable Development Goal 8 | |||

|authors=User:ScottH | |||

|documentation-language=English | |||

|manifest-language=English | |||

|manifest-date-updated=2020-06-04 | |||

|manifest-author-name=Kathy Nativi | |||

|manifest-author-affiliation=Appropedia | |||

|manifest-author-email=info@appropedia.org | |||

}} | |||

{{TOCleft}} | |||

== Abstract == | == Abstract == | ||

<center>''To improve the Universal | <center>''To improve the Universal Nut Sheller(UNS), the LC Sheller(Light, Cheap Sheller) design lowered the cost and weight of existing design using locally available and light weight materials. The reduction in cost makes this technology more accessible to the average farmer. The reduction in weight allows the client to more easily transport the sheller from farm to farm. With the LC Sheller, more nuts could be shelled with a relatively low investment.''</center> | ||

[[Image:sheller.jpg|thumb|right|The LC sheller]] | |||

== Background == | == Background == | ||

The Full | The [[Full Belly Project]] is an organization which creates low cost, simple technological solutions to be implemented in developing countries. One of these solutions, the Universal Nut Sheller, minimizes the work load of women in Western Africa by allowing nuts to be shelled through this device rather than by hand. | ||

== Problem Statement and Criteria == | == Problem Statement and Criteria == | ||

| Line 18: | Line 43: | ||

== Costs == | == Costs == | ||

The | The costs, in both dollars and hours, required to build an LC sheller are estimated to be: | ||

=== Materials === | === Materials === | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 54: | Line 79: | ||

| 46.00 | | 46.00 | ||

|} | |} | ||

===Time=== | |||

== | {| class="wikitable" | ||

|- | |||

! Project Step | |||

! Approximate Time Required | |||

|- | |||

| Mold Assembly, mixing and pouring | |||

| 2 hours | |||

|- | |||

| Roughing the inner surfaces (24 hours later) | |||

| 20 minutes | |||

|- | |||

| Form assembly | |||

| 1 hour | |||

|- | |||

| Total time | |||

| 3-4 hours | |||

|} | |||

== Construction instructions == | == Construction instructions == | ||

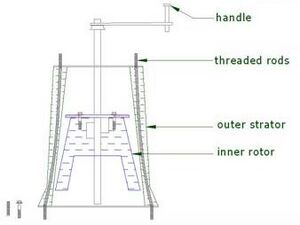

[[Image:Cad.jpg|thumb|right|Diagram of the LC Sheller: Unshelled nuts in the top, shelled nuts out the bottom.]]The construction of the LC Sheller is carried out in the same fashion as the Universal Nut Sheller; the only difference being the materials going into the initial mix. | |||

Follow Full Belly | The changes to the mix include the addition of dry, finely sieved clay and sawdust. | ||

Instructions http://www.fullbellyproject.org/Documents/UNS.pdf | Soak the sawdust in water until it is soaked thoroughly. Mix the sawdust with the clay, sand and cement and mix until a homogeneous material is formed. Additional water might be needed. The mixture should have the consistency slightly less moist than that of cottage cheese. Follow the instructions provided from Full Belly Project for the rest of construction. | ||

Instructions from [http://www.fullbellyproject.org/Documents/UNS.pdf Full Belly Project]. | |||

== Next steps == | == Next steps == | ||

While improvements were made to the UNS, additional materials testing could result in a mixture that more thoroughly meets the Fully Belly Project's criteria. The final mixture decided upon is a base to move from. | While improvements were made to the UNS, additional materials testing could result in a mixture that more thoroughly meets the Fully Belly Project's criteria. The final mixture decided upon is a base to move from. Other possible modifications include replacing metal hardware with bamboo. Using bamboo, a local material in parts of West Africa, would further reduce weight and cost. The most easily replaced parts are the top and bottom brackets. | ||

== Contact == | |||

Contact us at: | |||

Scott Hargreaves: [[User:ScottH]] smh80@humboldt.edu | |||

Zach Johnson: zdj1@humboldt.edu | |||

Marcus Grant: [[User:Marcus Grant]] mcg29@humboldt.edu | |||

Sterling Wallstrum: [[User:Sterling]] sjw59@humboldt.edu | |||

See the full documentation of the LC sheller's development [http://humboldt.edu/~smh80/finaldocument.pdf here]. | |||

[[Category:Engr215 Introduction to Design]] | |||

[[Category:Full Belly Project]] | |||

[[Category:Projects]] | |||

Revision as of 13:23, 17 October 2020

Abstract

Background

The Full Belly Project is an organization which creates low cost, simple technological solutions to be implemented in developing countries. One of these solutions, the Universal Nut Sheller, minimizes the work load of women in Western Africa by allowing nuts to be shelled through this device rather than by hand.

Problem Statement and Criteria

Currently in West Africa, the nut sheller that are in use, weighing some ninety pounds are placed on the back of bicycles and transported long distances. This presents serious drawbacks in terms of trasnportability and raises the risk of breakage. Additionally, the cement in West Africa is costly and of poor quality. For these reasons, the Full Belly Project's executive director helped Team Nuts for Peace come up with the following criteria:

- Cost

- To reduce the cost of the Universal Nut Sheller

- Transportability

- To improve the transportability

- Durability

- To maintain or increase the durability of the UNS

- Safety

- The degree of safety required for the final product

- Ease of Construction

- To minimize the number of specialists in the implementation process

Costs

The costs, in both dollars and hours, required to build an LC sheller are estimated to be:

Materials

| Product | Quantity | Price ($) |

|---|---|---|

| Cement | 1 bag (94 lb) | 15.00 |

| sand | 1 bag (60 lb) | 12.00 |

| clay (dry) | 2 gallons | harvested |

| Machine Grease | 1 can | 4.00 |

| Threaded Rod | 1 | 15.00 |

| UNS Mold | 1 | provided by Full Belly Project |

| Total costs | 46.00 |

Time

| Project Step | Approximate Time Required |

|---|---|

| Mold Assembly, mixing and pouring | 2 hours |

| Roughing the inner surfaces (24 hours later) | 20 minutes |

| Form assembly | 1 hour |

| Total time | 3-4 hours |

Construction instructions

The construction of the LC Sheller is carried out in the same fashion as the Universal Nut Sheller; the only difference being the materials going into the initial mix.

The changes to the mix include the addition of dry, finely sieved clay and sawdust. Soak the sawdust in water until it is soaked thoroughly. Mix the sawdust with the clay, sand and cement and mix until a homogeneous material is formed. Additional water might be needed. The mixture should have the consistency slightly less moist than that of cottage cheese. Follow the instructions provided from Full Belly Project for the rest of construction. Instructions from Full Belly Project.

Next steps

While improvements were made to the UNS, additional materials testing could result in a mixture that more thoroughly meets the Fully Belly Project's criteria. The final mixture decided upon is a base to move from. Other possible modifications include replacing metal hardware with bamboo. Using bamboo, a local material in parts of West Africa, would further reduce weight and cost. The most easily replaced parts are the top and bottom brackets.

Contact

Contact us at:

Scott Hargreaves: User:ScottH smh80@humboldt.edu

Zach Johnson: zdj1@humboldt.edu

Marcus Grant: User:Marcus Grant mcg29@humboldt.edu

Sterling Wallstrum: User:Sterling sjw59@humboldt.edu

See the full documentation of the LC sheller's development here.