J.M.Pearce (talk | contribs) m (→Citation) |

J.M.Pearce (talk | contribs) mNo edit summary |

||

| Line 2: | Line 2: | ||

===Citation=== | ===Citation=== | ||

[[image:Nanocolumns_ingan.jpg|200px|right]] | |||

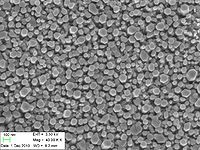

S. Keating, M.G. Urquhart, D.V.P. McLaughlin and J.M. Pearce, [http://pubs.acs.org/doi/abs/10.1021/cg101450n “Effects of Substrate Temperature on Indium Gallium Nitride Nanocolumn Crystal Growth”], ''Crystal Growth & Design'', 11 (2), pp 565–568, 2011. [http://mtu.academia.edu/JoshuaPearce/Papers/1540241/Effects_of_Substrate_Temperature_on_Indium_Gallium_Nitride_Nanocolumn_Crystal_Growth free and open access] | S. Keating, M.G. Urquhart, D.V.P. McLaughlin and J.M. Pearce, [http://pubs.acs.org/doi/abs/10.1021/cg101450n “Effects of Substrate Temperature on Indium Gallium Nitride Nanocolumn Crystal Growth”], ''Crystal Growth & Design'', 11 (2), pp 565–568, 2011. [http://mtu.academia.edu/JoshuaPearce/Papers/1540241/Effects_of_Substrate_Temperature_on_Indium_Gallium_Nitride_Nanocolumn_Crystal_Growth free and open access] | ||

| Line 8: | Line 8: | ||

Indium gallium nitride films with nanocolumnar microstructure were deposited with varying indium content and substrate temperatures using plasma-enhanced evaporation on amorphous SiO2 substrates. Field emission scanning electron microscopy and X-ray diffraction results are presented, showing that more crystalline nanocolumnar microstructures can be engineered at lower indium compositions. Nanocolumn diameter and packing factor (void fraction) was found to be highly dependent on substrate temperature, with thinner and more closely packed nanocolumns observed at lower substrate temperatures. | Indium gallium nitride films with nanocolumnar microstructure were deposited with varying indium content and substrate temperatures using plasma-enhanced evaporation on amorphous SiO2 substrates. Field emission scanning electron microscopy and X-ray diffraction results are presented, showing that more crystalline nanocolumnar microstructures can be engineered at lower indium compositions. Nanocolumn diameter and packing factor (void fraction) was found to be highly dependent on substrate temperature, with thinner and more closely packed nanocolumns observed at lower substrate temperatures. | ||

[[Category:QAS completed projects and publications]] | [[Category:QAS completed projects and publications]] | ||

[[Category:Photovoltaics]] | [[Category:Photovoltaics]] | ||

[[Category:Dirk McLaughlin Thesis]] | [[Category:Dirk McLaughlin Thesis]] | ||

Revision as of 01:56, 4 February 2013

Citation

S. Keating, M.G. Urquhart, D.V.P. McLaughlin and J.M. Pearce, “Effects of Substrate Temperature on Indium Gallium Nitride Nanocolumn Crystal Growth”, Crystal Growth & Design, 11 (2), pp 565–568, 2011. free and open access

Abstract

Indium gallium nitride films with nanocolumnar microstructure were deposited with varying indium content and substrate temperatures using plasma-enhanced evaporation on amorphous SiO2 substrates. Field emission scanning electron microscopy and X-ray diffraction results are presented, showing that more crystalline nanocolumnar microstructures can be engineered at lower indium compositions. Nanocolumn diameter and packing factor (void fraction) was found to be highly dependent on substrate temperature, with thinner and more closely packed nanocolumns observed at lower substrate temperatures.