MarieFarson (talk | contribs) |

MarieFarson (talk | contribs) |

||

| Line 12: | Line 12: | ||

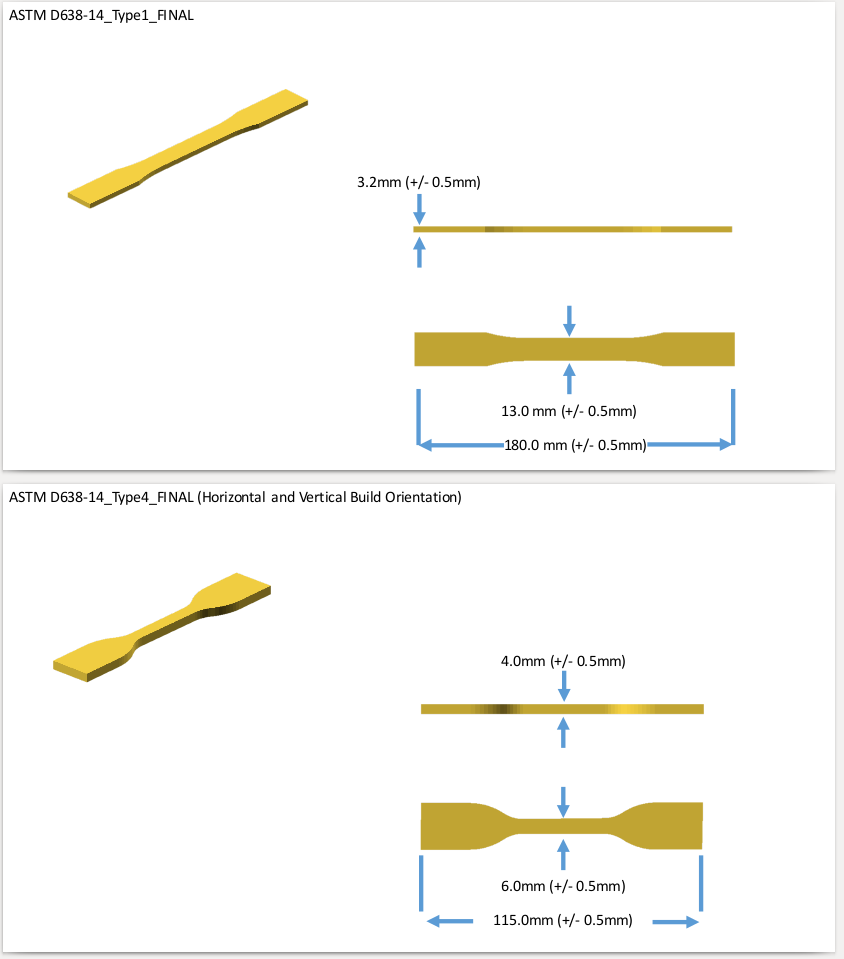

#*Note: Parts must conform to dimensional specifications as indicated on right to be acceptable per ASTM D628-14 Type IV. | #*Note: Parts must conform to dimensional specifications as indicated on right to be acceptable per ASTM D628-14 Type IV. | ||

# Put your specimens in a bag with your name and course labelled on/in the bag | # Put your specimens in a bag with your name and course labelled on/in the bag | ||

# Input your variable parameters with your name to the course data spread sheet in a single line [https://docs.google.com/spreadsheets/d/1qv0wUorCnyX8hHGvGdcFZjMqM2WhbFmDQMp9srSK6oQ/edit#gid=0 here] | # Input your variable parameters with your name to the course data spread sheet in a single line [https://docs.google.com/spreadsheets/d/1qv0wUorCnyX8hHGvGdcFZjMqM2WhbFmDQMp9srSK6oQ/edit#gid=0 '''here'''] | ||

# Test your sames for tension in the Engineering Lab and record your max tensile strength (just before rupture) as well as strain (elongation) at that max strength for each of your 6 samples. | |||

# Post your best stress strain curve (output from the tester) on your Appropedia page as well as your conclusions | |||

===Having Trouble?=== | ===Having Trouble?=== | ||

Revision as of 22:27, 21 February 2017

Assignment

- Download files for the Type 4 test coupon from the Open Science Framework (click on the one you want and then click "download") Ideally you only need 2 stl files and one ini file.

- The .ini is the profile. The provided .ini contains all parameter settings for getting a good quality slice file. I have intentionally left layer thickness, print temperature, print speed, flow %, and bed temperature blank. These are the variables you can play with. This .ini is to be used for all specimens - it has already been shown to work on other RepRap printers. Note: Loading the .ini file provide will REMOVE the current profile in Cura. Please save your standard default profile before loading. If you happen to lose the profile, you can reload it from an old .gcode file without trouble.

- Choose your optimal print settings (e.g. what you think gives you the best looking part and max strength) and then using PLA from any vendor you like print:

- 3X small horizontal, and

- 3X small vertical

- Note: Parts must conform to dimensional specifications as indicated on right to be acceptable per ASTM D628-14 Type IV.

- Put your specimens in a bag with your name and course labelled on/in the bag

- Input your variable parameters with your name to the course data spread sheet in a single line here

- Test your sames for tension in the Engineering Lab and record your max tensile strength (just before rupture) as well as strain (elongation) at that max strength for each of your 6 samples.

- Post your best stress strain curve (output from the tester) on your Appropedia page as well as your conclusions

Having Trouble?

Basic inputs to start with:

- Layer Thickness: 0.2mm

- Temperature: 210C

- Flow: 100%

- Speed: 80mm/s

- Bed Temp: N/A unless you have a heated bed then put it in the comments

Make sure the horizontal ones are printing flat and the vertical one prints on the circle (see image below).