Drip irrigation is irrigation through small tubes targeted to the roots of the plant. It is the most common form of micro irrigation.

It is low pressure and low volume irrigation. Drip irrigation is differentiated from sprinkle irrigation and furrow irrigation by slow water distribution, 2-8 liters per hour, and constant soil moisture content. [1] Drip irrigation is the targeted delivery of water to plants along water distribution lines emanating from a central water reservoir.

Drip irrigation is differentiated from sprinkle irrigation and furrow irrigation by slow water distribution, 2-8 liters per hour, and constant soil moisture content. [2] The focus of this page is on micro-drip irrigation in developing communities, which precludes subsurface drip irrigation and mechanically pressurized drip irrigation systems. Drip irrigation systems discussed below are pressurized by gravity.

History

Irrigation originated with the diversion of streams and portions of rivers to a crop field. Water was then distributed throughout the crops by means of furrows oriented downgrade. This system uses gravity to move water to all the plants. The method was often referred to as flood irrigation because irrigation events would flood crop fields. Radical changes to irrigation did not occur until the industrial revolution in 1760 made combustion and electric engines available to mechanically increase water pressure. [2] Artificial water pressure allows water to be distributed to crops regardless of gradient. Drip irrigation systems can be used with artificial water pressure or gravity induced water pressure systems. Subsurface drip irrigation was developed in Germany during the 1860s and began using porous pipes in the 1920s in both German and Russia. [2] Farmers have largely avoided subsurface drip irrigation due to clogging of emitters and the difficulty of working on and maintaining a subterranean irrigation system. Surface drip irrigation became popular in the 1970s with Australia, the United States of America, and Israel being the primary leaders.

How it works

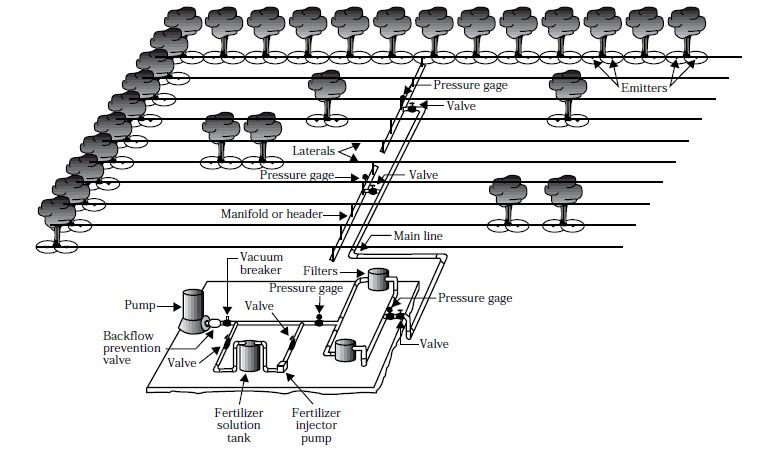

The principle behind drip irrigation seeks efficiency of water usage by directing water to the base of each plant to maintain soil moisture content as per the plant’s needs. A series of pipes carry water from a central source throughout the field. Emitters allow water to drip from point sources along the pipelines at a slow rate, 2-8 liters per hour, directly to the base of the plants. The design of this system has numerous benefits, as discussed at the end of this section. Drip irrigation systems may be very simple, consisting of a water reservoir, a valve to control the flow of water, the main line and drip lines branching off of the main line, and emitters. Industrial drip irrigation systems can include a pressurized water source, backflow prevention valve, pressure gages, fertilizer solution tanks, filters, and an automated control system (Fig. 1)

Typical components for a micro irrigation system include the reservoir, control valve, filter, main pipe, lateral pipe, and micro-tube/emitter. This type of system covers an area between 20 m2 and 1000 m2.[3]

The layout of each drip irrigation system is highly variable, dependent on the crop and field.

Many emitters exist with different methods of water impedance, including vortex, tortuous path, long path, and groove and disk short path. These may be viewed in Figure 2. Different designs attempt to provide the desired quantity of water without allowing particles from the field to clog the emitter.

Figure 2: emitter types U.S. Department of Agriculture Drip irrigation main lines and lateral lines are made from poly vinyl chloride, high density polyethylene, and low density polyethylene. [3]

Irrigation efficiency is the quantity of water used by a crop in comparison to the quantity of water available for farm use. Furrow and other types of ground irrigation typically reach efficiencies of 34% with good water management practices, sprinkler irrigation efficiencies range between 50% and 75%, and drip irrigation has efficiencies between 75% and 90%. Drip irrigation is also capable of doubling crop yields with the same amount of water applied in comparison to sprinkler irrigation, and may use saline water in conjunction with fresh water without harming yield rates. Unlike traditional irrigation methods, the constant flow of water allows salt to be leached away from the root system of the plant. [2] The use of saline water can reduce the demand on fresh water in water-scarce regions, in addition to the doubling the amount of food grown with the same quantity of water. [4]

Water forms a circular pattern on the surface of the field and an onion-shaped volume beneath the surface of the field. Emitters are typically placed at such a distance that the wetted soil slightly overlaps, forming a row along lateral pipelines. Emitter spacing depends on the soil type, and the rate at which water moves through the soil. Typical emitter spacing is given in Should I Use Drip Irrigation, as well as a simple test to determine the best spacing based on the soil in a particular field.

Selective watering through discreet emitters reduces weed growth and reduces labor costs. Traditional furrow or flood irrigation provides water to the entire field, which leads to 10 to 14 times more weed biomass at harvest and restricts access to the field by farmers. Furrow irrigation fields require 5 to 15 times more labor to remove weeds than fields utilizing drip irrigation. [5]

Should I use Drip Irrigation?

The United States Department of Agriculture rates micro irrigation using emitters as more effective than traditional means of irrigation in the following soil conditions: low available water content, high infiltration rate, variable infiltration rate, highly erodible, steep & undulating topography, odd shaped fields, and stony or cobbly fields. [6] Drip irrigation is able to increase crop yields through low tension water availability, which simultaneously increases quality of the crops. Crops may also be grown in with higher salinity water due to the soil water’s constant movement away from the root bulbs of the plants. [6] Micro irrigation technology is prone to clogging, due to the nature of small diameter emitters laying on the soil. Chemical buildup, soil particulates, and biological materials are sources of clogged emitters. Pests, such as rodents, may damage surface irrigation systems as well. Salts present in the soil surrounding the plant roots may move toward the roots if the soil is allowed to dry, or if the irrigation system is turned off during a light rain. [6]

The use of equipment makes drip irrigation more expensive than traditional irrigation techniques. Industrial drip irrigation systems in the United States cost around $1000 to $3000 per hectare. iDE provides smallholder irrigation kits, containing all the necessary equipment to construct a 20 to 1000 m2 irrigation system, for $10 to $20. [7] Drip irrigation can be advantageous for families to grow supplementary food in backyard gardens, allowing minimal water usage to produce fresh vegetables for added food security or income. Water management is required to achieve efficiencies of 90%, which includes altering the watering schedule based on the lifecycle of the plant. [7]

Notes and references

See also

- Drip Irrigation Helps Farmers Save Money

- Drip Irrigation Turns Gravel into Green

- CCAT Gravity fed drip irrigation

- Drip line placement

- Micro-irrigation

- Irrigation methods

Interwiki links

External links

- [Solar-powered drip irrigation enhances food security in the Sudano–Sahel] Jennifer Burney, Lennart Woltering, Marshall Burke, Rosamond Naylor, and Dov Pasternak, Proceedings of the National Academy of Sciences of the United States of America, 2010 February 2.</ref>

- ↑ Goldberg, D., Gornat, B., & Rimon, D. (1976). Drip irrigation: Principles, design, and agricultural practices. Kfar Shmaryahu, Israel: Drip Irrigation Scientific Publications

- ↑ 2.0 2.1 2.2 2.3 Goldberg, D., Gornat, B., & Rimon, D. (1976). Drip irrigation: Principles, design, and agricultural practices. Kfar Shmaryahu, Israel: Drip Irrigation Scientific Publications

- ↑ 3.0 3.1 Technical Manual for IDEal Micro Irrigation Systems. IDEorg.org. Web. 23 Apr. 2012. < http://www.ideorg.org/OurTechnologies/DripIrrigation.aspx >

- ↑ Entering an Era of Water Scarcity: The Challenges Ahead. Sandra L. Postel. Ecological Applications , Vol. 10, No. 4 (Aug., 2000), pp. 941-948. Published by: Ecological Society of America. Article Stable URL: <http://www.jstor.org/stable/2641009>

- ↑ Weed Control, Yield, and Quality of Processing Tomato Production under Different Irrigation, Tillage, and Herbicide Systems. Kipp F. Sutton, W. Thomas Lanini, Jefferey P. Mitchell, Eugene M. Miyao and Anil Shrestha. Weed Technology , Vol. 20, No. 4 (Oct. - Dec., 2006), pp. 831-838. Published by: Weed Science Society of America and Allen Press Article Stable URL:< http://www.jstor.org/stable/4495762>

- ↑ 6.0 6.1 6.2 Ross, Elwin A., Hardy, Leeland A. (1997) National Engineering Handbook: Irrigation Guide. United States Department of Agriculture.

- ↑ 7.0 7.1 Smallholder Drip Irrigation Technology: Potentials and Constraints in the Highlands of Eritrea. Abraham Mehari Haile, Herman Depeweg and Brigitta Stillhardt. Mountain Research and Development , Vol. 23, No. 1 (Feb., 2003), pp. 27-31. Published by: International Mountain Society. Article Stable URL: <http://www.jstor.org/stable/3674532>