J.M.Pearce (talk | contribs) mNo edit summary |

J.M.Pearce (talk | contribs) m (→See Also) |

||

| (12 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{MOST}} | {{MOST}} | ||

{{MOST-RepRap}} | {{MOST-RepRap}} | ||

{{Pearce-pubs}} | |||

{{Statusboxtop}} | {{Statusboxtop}} | ||

| Line 7: | Line 8: | ||

{{boxbottom}} | {{boxbottom}} | ||

=Source= | ==Source== | ||

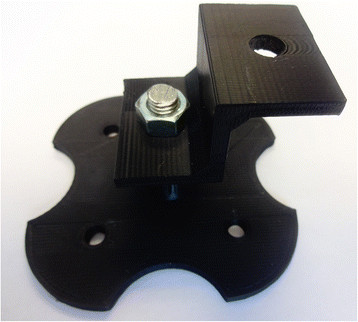

[[image:bracket.jpg|right]] | [[image:bracket.jpg|right]] | ||

* Ben Wittbrodt, John Laureto, Brennan Tymrak and Joshua M Pearce. Distributed manufacturing with 3-D printing: a case study of recreational vehicle solar photovoltaic mounting systems. ''Journal of Frugal Innovation'' '''1'''(1), 1-7 (2015). doi:http://dx.doi.org/10.1186/s40669-014-0001-z 10.1186/s40669-014-0001-z] [open access] | * Ben Wittbrodt, John Laureto, Brennan Tymrak and Joshua M Pearce. Distributed manufacturing with 3-D printing: a case study of recreational vehicle solar photovoltaic mounting systems. ''Journal of Frugal Innovation'' '''1'''(1), 1-7 (2015). doi:[http://dx.doi.org/10.1186/s40669-014-0001-z 10.1186/s40669-014-0001-z] [https://www.academia.edu/17647723/Distributed_manufacturing_with_3-D_printing_a_case_study_of_recreational_vehicle_solar_photovoltaic_mounting_systems open access] | ||

* Source Code: | * Source Code (STLs and SCAD): https://www.youmagine.com/designs/rv-solar-photovoltaic-mount | ||

==Abstract== | ==Abstract== | ||

| Line 19: | Line 20: | ||

==See Also== | ==See Also== | ||

* [[Total U.S. cost evaluation of low-weight tension-based photovoltaic flat-roof mounted racking]]- | * [[Total U.S. cost evaluation of low-weight tension-based photovoltaic flat-roof mounted racking]] | ||

* [[3-D Printing Solar Photovoltaic Racking in Developing World]] | |||

* [[Open source rapid prototyping of OSAT]] | |||

* [[Open-source, self-replicating 3-D printer factory for small-business manufacturing]] | * [[Open-source, self-replicating 3-D printer factory for small-business manufacturing]] | ||

* [[Mobile Open-Source Solar-Powered 3-D Printers for Distributed Manufacturing in Off-Grid Communities]] | |||

* [[Reversing the Trend of Large Scale and Centralization in Manufacturing: The Case of Distributed Manufacturing of Customizable 3-D-Printable Self-Adjustable Glasses]] | |||

* [[Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers]] | |||

* [[Design of Post-Consumer Modification of Standard Solar Modules to Form Large-Area Building-Integrated Photovoltaic Roof Slates]] | |||

* [[3-D printable photovoltaic module spacer]] | |||

* [[Global value chains from a 3D printing perspective]] | |||

* [[Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers]] | |||

* [[Impact of DIY Home Manufacturing with 3D Printing on the Toy and Game Market]] | |||

* [[Development of a Resilient 3-D Printer for Humanitarian Crisis Response]] | |||

* [[Open-source 3-D Printing in Managing Humanitarian Innovation]] | |||

* [[Economic Potential for Distributed Manufacturing of Adaptive Aids for Arthritis Patients in the U.S.]] | |||

{{Solar navbox}} | {{Solar navbox}} | ||

[[Category:MOST completed projects and publications]] | [[Category:MOST completed projects and publications]] | ||

Revision as of 11:03, 6 December 2018

Template:Statusboxtop Template:Status-design Template:Status-prototype Template:Boxbottom

Source

- Ben Wittbrodt, John Laureto, Brennan Tymrak and Joshua M Pearce. Distributed manufacturing with 3-D printing: a case study of recreational vehicle solar photovoltaic mounting systems. Journal of Frugal Innovation 1(1), 1-7 (2015). doi:10.1186/s40669-014-0001-z open access

- Source Code (STLs and SCAD): https://www.youmagine.com/designs/rv-solar-photovoltaic-mount

Abstract

For the first time, low-cost open-source 3-D printing provides the potential for distributed manufacturing at the household scale of customized, high-value, and complex products. To explore the potential of this type of ultra-distributed manufacturing, which has been shown to reduce environmental impact compared to conventional manufacturing, this paper presents a case study of a 3-D printable parametric design for recreational vehicle (RV) solar photovoltaic (PV) racking systems. The design is a four-corner mounting device with the ability to customize the tilt angle and height of the standoff. This enables performance optimization of the PV system for a given latitude, which is variable as RVs are geographically mobile. The open-source 3-D printable designs are fabricated and analyzed for print time, print electricity consumption, mechanical properties, and economic costs. The preliminary results show distributed manufacturing of the case study product results in an order of magnitude reduction in economic cost for equivalent products. In addition, these cost savings are maintained while improving the functionality of the racking system. The additional electrical output for a case study RV PV system with improved tilt angle functionality in three representative locations in the U.S. was found to be on average over 20% higher than that for conventional mass-manufactured racking systems. The preliminary results make it clear that distributed manufacturing - even at the household level - with open-source 3-D printers is technically viable and economically beneficial. Further research is needed to expand the results of this preliminary study to other types of products.

Keywords

3-D printing; Photovoltaic; Racking; Distributed manufacturing; Frugal innovation; Open-source; Household manufacturing; Transportation energy; Additive manufacturing

See Also

- Total U.S. cost evaluation of low-weight tension-based photovoltaic flat-roof mounted racking

- 3-D Printing Solar Photovoltaic Racking in Developing World

- Open source rapid prototyping of OSAT

- Open-source, self-replicating 3-D printer factory for small-business manufacturing

- Mobile Open-Source Solar-Powered 3-D Printers for Distributed Manufacturing in Off-Grid Communities

- Reversing the Trend of Large Scale and Centralization in Manufacturing: The Case of Distributed Manufacturing of Customizable 3-D-Printable Self-Adjustable Glasses

- Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers

- Design of Post-Consumer Modification of Standard Solar Modules to Form Large-Area Building-Integrated Photovoltaic Roof Slates

- 3-D printable photovoltaic module spacer

- Global value chains from a 3D printing perspective

- Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers

- Impact of DIY Home Manufacturing with 3D Printing on the Toy and Game Market

- Development of a Resilient 3-D Printer for Humanitarian Crisis Response

- Open-source 3-D Printing in Managing Humanitarian Innovation

- Economic Potential for Distributed Manufacturing of Adaptive Aids for Arthritis Patients in the U.S.