Sophivorus (talk | contribs) m (Text replacement - "{{OpenKnowHowManifest" to "{{Device") |

mNo edit summary |

||

| Line 15: | Line 15: | ||

|manifest-language=eng | |manifest-language=eng | ||

|documentation-language=English | |documentation-language=English | ||

|countries-of-design=Category:United States | |||

|sustainable-development-goal=Sustainable Development Goal 9 | |sustainable-development-goal=Sustainable Development Goal 9 | ||

}} | }} | ||

{{Statusboxtop}} | {{Statusboxtop}} | ||

Revision as of 07:47, 18 September 2020

Template:Statusboxtop Template:Status-design Template:Status-prototype Template:Boxbottom

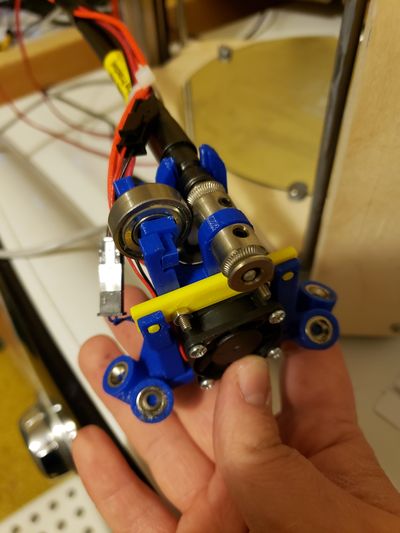

Direct drive extrusion hot end for flexible materials

This page lays out the steps required to convert your current Delta Athena II printer to have a newly designed flexible driveshaft printer, which makes printing in flexible materials a reality.

Original Author: User:Molson

Design and Printing

Design

The current setup on the Athena II printer is not suited for flexible materials like ninja flex. Due to the bowndeth sheath setup we mostly use stiff filaments such as PLA. The new design was based off of the desire to remove the bowden sheath from the printer and to get the same impact as a direct drive printer. Using a flexible shaft I was able to mount the motor to the Athena II's frame and still have the extruder feed directly above the print nozzle, removing the need for a long bowden sheath.

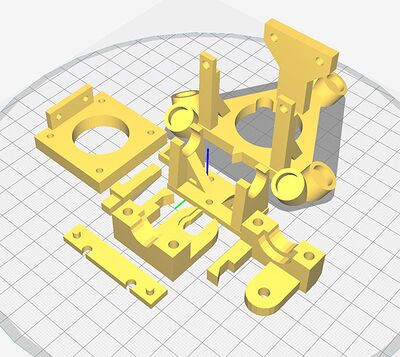

Printing

The design required that I modify the hotend, and extruder stepper motor bracket. So after some research on direct drive designs I was able to complete my new design with as little mass as possible. In the picture below is a screen shot of cura with all the parts needed for the mod fitting in one print. A total of 40g of PLA is needed to complete the print. Files can be found here, Thingiverse Link to Files

Installation

Installation

Below you will find a list of new materials required to modify the printer, followed by a list of re-purposed components from your Athena II

| Description | Link | Price | Count |

|---|---|---|---|

| Hot end bearing shaft spacer | Print it! | $0.01 | 1 |

| Hot end bearing shaft | Print it! | $0.02 | 1 |

| Flexible shaft sheath holder | Print it! | $0.10 | 1 |

| Left clip | Print it! | $0.10 | 1 |

| right clip | Print it! | $0.08 | 1 |

| Motor Bracket | Print it! | $0.14 | 1 |

| Hot end small plat | Print it! | $0.01 | 1 |

| End effector | Print it! | $0.36 | 1 |

| 5mm to 8mm 3/4 long aluminum spacer | https://www.newark.com/raf-electronic-hardware/m0594-5-ss/spacer-round-ss-8mm-x-5mm/dp/27T7690?gclid=Cj0KCQiA3b3gBRDAARIsAL6D-N9PIWyRhVJGl4RjfqHyJk6AVZ6ru8DOA5eNo0eHSd9AJuF0j6hQlmMaApRjEALw_wcB&gross_price=true&CAGPSPN=pla&CAWELAID=120185550001092786&CAAGID=49810475012&CMP=KNC-GUSA-GEN-SHOPPING&CATCI=pla-333930564467 | $0.60 | 1 |

| M3 x 10 screws for motor | Local hardware store | $0.25 | 4 |

| FOREDOM FLEXSHAFT SET MOTOR MAINTENANCE KIT S-93 INNER SHAFT & S-77 OUTER SHEATH (E 12) NOVELTOOLS | https://www.amazon.com/gp/product/B00WTE6ZL8/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1 | $25.75 | 1 |

| Witbot MK7 Stainless Steel Extruder Drive Gear Wheel 5mm Bore for 3D Printer(Pack of 5pcs) | https://www.amazon.com/gp/product/B01KJONSRS/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1 | $6.99 | 1 |

| E3D Lite6 Full Kit - 1.75mm Universal (Direct) (12v) | https://www.amazon.com/gp/product/B00W4E5ITI/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1 | $36.99 | 1 |

| Description | Count |

|---|---|

| Nema Extruder stepper Motor | 1 |

| Bolts... | 2 |

| nuts... | 2 |

| Washers... | 2 |

| Bearing | 1 |

| RepRap Athena | 1 |

| Ethernet Cable | 1 |

- Step by step

- instructions

- go here

Calibrating

- Again list goes here

- as long as it needs to be...

additional title?

Direct Drive extrusion hot end Example

This video shows a simple snowflake from Thingiverse printing flamingo ninjaflex at 40mm/s

| Direct Drive in Motion |

|---|