Jordan Null (talk | contribs) (Custom build your own 3D printed motor) |

Jordan Null (talk | contribs) |

||

| Line 70: | Line 70: | ||

This Motor was designed by Andy Sledder, John Stough, and Jordan Null. Please reach out via our Appropedia pages for more custom designs. | This Motor was designed by Andy Sledder, John Stough, and Jordan Null. Please reach out via our Appropedia pages for more custom designs. | ||

[[User:StowieJ|John Stough]] [[User:Jordan Null|Jordan Null]] ([[User talk:Jordan Null|talk]]) [[User:Aesleder|Aesleder]] ([[User talk:Aesleder|talk]]) | |||

<!-- Don't change the next line unless you intend to change the categorization --> | <!-- Don't change the next line unless you intend to change the categorization --> | ||

<!-- Do add additional, appropriate categories. See http://www.appropedia.org/Appropedia:CategoryTree for ideas. --> | <!-- Do add additional, appropriate categories. See http://www.appropedia.org/Appropedia:CategoryTree for ideas. --> | ||

[[Category:Projects]] | [[Category:Projects]] | ||

Revision as of 06:11, 8 November 2019

Some introduction text and background can go here.

Understanding the market

An [1] by DC Micro Motors People looking to purchase motors similar to the ones produce here would be our target audience.

Things lacking from this design that are to be improved upon:

- There is a lot of expensive composite materials in this design. This can be cut down to improve cost savings.

- Being able to build your own at home can cut down on downtime and failures

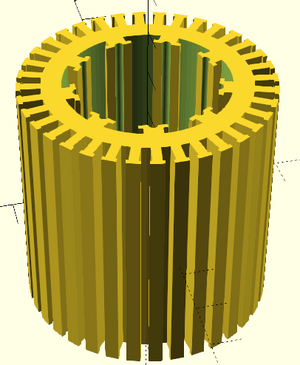

- Product is designed for future applications to insert printed magnets.

- The design is parametric for different pole combinations.

The first prototype of the motor had clearance issues, and we are hoping to have this issue resolved through design iterations and slower print speeds. This has not been tested for comparison metrics, but once we get the magnets and ESC we will begin to track data.

Project goals

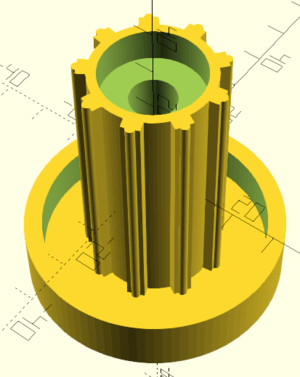

- Create a repeatable and cost effective motor design

- Design magnetic slots for future applications

- Updating design for coil winding ease

- Track data to compare to market motors

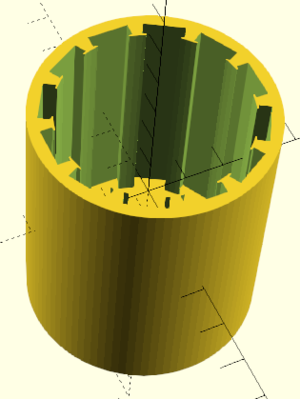

Design

Hardware

3-D Printable Parts

- File:Rotor test.scad

- File:6N Stator Short.scad

- File:8P Rotor Short.scad

- File:8P Rotor Short V2.scad

- File:9N Stator Long.scad

- File:9N Stator Short.scad

- File:12N Stator Short.scad

- File:12P Rotor Short.scad

- File:Mount Bot V1.scad

- File:Mount Top V1.scad

- File:StatorNoTooth.scad

- File:WindingPole Single.scad

Discussion

Here are all the files for multiple motor poles and lengths

The next steps

Our teams next steps are to finish gathering materials, running tests and collecting data for comparison. We could fine tune our designs for tighter tolerances to get better efficiency.

References

Contact details

This Motor was designed by Andy Sledder, John Stough, and Jordan Null. Please reach out via our Appropedia pages for more custom designs. John Stough Jordan Null (talk) Aesleder (talk)