B.S.Kukreja (talk | contribs) No edit summary |

B.S.Kukreja (talk | contribs) No edit summary |

||

| Line 19: | Line 19: | ||

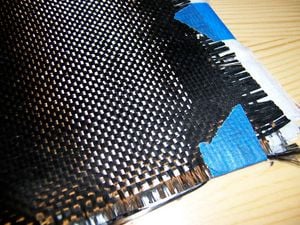

[[Image:Basic composite.jpg|thumb|Example of a basic composite material.]] | [[Image:Basic composite.jpg|thumb|Example of a basic composite material.]] | ||

In a basic composite, one material acts as a supporting matrix, while another material builds on this base scaffolding and reinforces the entire material. | In a basic composite, one material acts as a supporting matrix, while another material builds on this base scaffolding and reinforces the entire material. Formation of the material can be an expensive and complex process. In essence, a base composite material matrix is laid out in a mould under high temperature and pressure. An [http://en.wikipedia.org/wiki/Epoxy epoxy] or [http://en.wikipedia.org/wiki/Resin resin] is then poured over the base composite material, creating a strong material when heat is removed and solidification occurs. The composite can also be produced by embedding fibres of a secondary material into the base matrix. | ||

Composites have good tensile strength and resistance to compression, making them a suitable material for use in aircraft part manufacture. The tensile strength of the material comes from its fibrous nature. When a tensile force is applied, the fibres within the composite line up with the direction of the applied force, giving its tensile strength. | Composites have good tensile strength and resistance to compression, making them a suitable material for use in aircraft part manufacture. The tensile strength of the material comes from its fibrous nature. When a tensile force is applied, the fibres within the composite line up with the direction of the applied force, giving its tensile strength. | ||

Revision as of 06:46, 4 December 2009

Template:MECH370by: Balpreet S. Kukreja

To leave your comments, please click the 'discussion' tab at the top of this page.

This page is still under construction.

Come back within the next few days for the completed piece!

Introduction

Composite materials are widely used in the Aircraft Industry and have allowed engineers to overcome obstacles that have been met when using the materials individually. The constituent materials retain their identities in the composites and do not dissolve or otherwise merge completely into each other. Together, the materials create a 'hybrid' material that has improved structural properties.

The development of light-weight, high-temperature resistant composite materials will allow the next generation of high-performance, economical aircraft designs to materialize. Usage of such materials will reduce fuel consumption, improve efficiency and reduce direct operating costs of aircraft.

Composite materials can be formed into various shapes and, if desired, the fibres can be wound tightly to increase strength. A useful feature of composites is that they can be layered, with the fibres in each layer running in a different direction. This allows an engineer to design structures with unique properties. For example, a structure can be designed so that it will bend in one direction, but not another.

Synthesis of Basic Composites

In a basic composite, one material acts as a supporting matrix, while another material builds on this base scaffolding and reinforces the entire material. Formation of the material can be an expensive and complex process. In essence, a base composite material matrix is laid out in a mould under high temperature and pressure. An epoxy or resin is then poured over the base composite material, creating a strong material when heat is removed and solidification occurs. The composite can also be produced by embedding fibres of a secondary material into the base matrix.

Composites have good tensile strength and resistance to compression, making them a suitable material for use in aircraft part manufacture. The tensile strength of the material comes from its fibrous nature. When a tensile force is applied, the fibres within the composite line up with the direction of the applied force, giving its tensile strength.

Aviation and Composites

Composite materials are important to the Aviation Industry because they provide structural strength comparable to metallic alloys, but at a lighter weight. This leads to improved fuel efficiency and performance from an aircraft. [1][2]

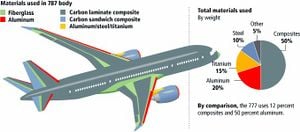

Boeing 787 Dreamliner

Boeing's 787 Dreamliner will be the first commercial aircraft in which major structural elements are made of composite materials rather than aluminum alloys.[3] Problems have been encountered with the Dreamliner's wing box, which have been attributed to insufficient stiffness in the composite materials used to build the part. This has lead to delays in the initial delivery dates of the aircraft.[3] In order to resolve these problems, Boeing is stiffening the wing boxes by adding new brackets to wing boxes already built, while modifying wing boxes that are yet to be built.[3]

Testing of Composite Materials

It has been found difficult to accurately model the performance of a composite-made part by computer simulation due to the complex nature of the material. Composites are often layered on top of each other for added strength, but this complicates the pre-manufacture phase, as the layers are oriented in different directions, making it difficult to predict how they will behave when tested.[3]

Mechanical stress tests can also be performed on the parts. These tests start with small scale models, then move on to progressively larger parts of the structure, and finally to the full structure. The structural parts are put into hydraulic machines that bend and twist them to mimic stresses that go far beyond worst-expected conditions in real flights.

Factors of Composite Material Usage

Weight reduction is the greatest advantage of composite material usage and is one of the key factors in decisions regarding its selection. Other advantages include its high corrosion resistance and its resistance to damage from fatigue. These factors play a role in reducing operating costs of the aircraft in the long run, further improving its efficiency. Composites have the advantage that they can be formed into almost any shape using the moulding process, but this compounds the already difficult modelling problem.

A major disadvantage about use of composites is that they are a relatively new material, and as such have a high cost. The high cost is also attributed to the labour intensive and often complex fabrication process. Composites are hard to inspect for flaws, while some of them absorb moisture.[4]

Even though it is heavier, aluminum, by contrast, is easy to manufacture and repair. It can be dented or punctured and still hold together. Composites are not like this; if they are damaged, they require immediate repair, which is difficult and expensive.[4]

Energy Savings

It is difficult to accurately quantify exact energy savings from switching to a lighter, composite based aircraft. This is because fuel consumption depends on several variables; dry aircraft weight, payload weight, age of aircraft, quality of fuel, air speed, weather, among other things. The weight of an aircraft is reduced by approximately 20% with the use of composite materials, such as in the case of the 787 Dreamliner.[2] In a greatly simplified view of the situation, where weight of an aircraft was directly proportional to amount of fuel consumed, a 20% weight reduction would correlate to a 20% saving in fuel costs.

As the 787 Dreamliner has not entered production yet, it is not possible to quantify its fuel consumption. Past aircrafts from Boeing such as the Boeing 747 consume approximately 150,000 litres of fuel during the course of a 10 hour flight.[5] Taking an average cost of $1 (Canadian) per litre of fuel, a 20% reduction in fuel consumption would net a $30,000 saving in fuel costs per 10 hour flight for a reduced weight Boeing 747. Even though the initial cost of implementation of composite materials is greater, in the long term, as indicated, costs are cut with improved fuel efficiency.

Environmental Impact

Future Composite Materials

Ceramic Matrix Composites

Major efforts are underway to develop light-weight, high-temperature composite materials at National Aeronautics and Space Administration (NASA) for use in aircraft parts. Temperatures as high as 1650°C are anticipated for the turbine inlets of a conceptual engine based on preliminary calculations.[1] In order for materials to withstand such temperatures, the use of Ceramic Matrix Composites (CMCs) is required. The use of CMCs in advanced engines will also allow an increase in the temperature at which the engine can be operated, leading to increased yield. [6] Although CMCs are promising structural materials, their applications are limited due to lack of suitable reinforcement materials, processing difficulties, lifetime and cost.

Spider Silk Fibres

Spider silk is another promising material for composite material usage. Spider silk exhibits high ductility, allowing stretching of a fibre up to 140% of its normal length.[7] Spider silk also holds its strength at temperatures as low as -40°C.[7] These properties make spider silk ideal for use as a fibre material in the production of ductile composite materials that will retain their strength even at abnormal temperatures. Ductile composite materials will be beneficial to an aircraft in parts that will be subject to variable stresses, such as the joining of a wing with the main fuselage. The increased strength, toughness and ductility of such a composite will allow greater stresses to be applied to the part or joining before catastrophic failure occurs. Many unsuccessful attempts have been made at reproducing spider silk in a laboratory, but perfect re-synthesis has not yet been achieved. [8]

References

- ↑ 1.0 1.1 INI International - Key to Metals - Retrieved at http://www.keytometals.com/Article103.htm

- ↑ 2.0 2.1 Boeing's 787 Dreamliner Has a Composite Problem - Zimbio - Retrieved at http://www.zimbio.com/Boeing+787+Dreamliner/articles/18/Boeing+787+Dreamliner+composite+problem

- ↑ 3.0 3.1 3.2 3.3 Surface Modelling for Composite Materials - SIAG GD - Retrieved at http://www.ifi.uio.no/siag/problems/grandine/

- ↑ 4.0 4.1 U.S. Centennial of Flight Commission - Composites and Advanced Materials - Retrieved at http://www.centennialofflight.gov/essay/Evolution_of_Technology/composites/Tech40.htm

- ↑ How much fuel does an international plane use for a trip? - HowStuffWorks.com - Retrieved at http://www.howstuffworks.com/question192.htm

- ↑ R. Naslain - Universite Bordeaux - Ceramic Matrix Composites - Retrieved at http://www.mpg.de/pdf/europeanWhiteBook/wb_materials_213_216.pdf

- ↑ 7.0 7.1 Department of Chemistry - University of Bristol - Retrieved at http://www.chm.bris.ac.uk/motm/spider/page2.htm

- ↑ Wired Science - Spiders Make Golden Silk - Retrieved at http://www.wired.com/wiredscience/2009/09/spider-silk/