No edit summary |

(moving over info from the biomass page) |

||

| Line 3: | Line 3: | ||

==Methods== | ==Methods== | ||

Charcoal has been made by various methods. | Charcoal has been made by various methods. | ||

==Using traditional kilns== | |||

There are several methods for processing wood residues to make them cleaner and easier to use as well as easier to transport. Production of charcoal is the most common. | |||

It is worth mentioning at this point that the conversion of woodfuel to charcoal does not increase the energy content of the fuel - in fact the energy content is decreased. Charcoal is often produced in rural areas and transported for use in urban areas. | |||

The process can be described by considering the combustion process discussed above. The wood is heated in the absence of sufficient oxygen which means that full combustion does not occur. This allows pyrolysis to take place, driving off the volatile gases and leaving the carbon or charcoal remaining. The removal of the moisture means that the charcoal has a much higher specific energy content than wood. Other biomass residues such as millet stems or corncobs can also be converted to charcoal. | |||

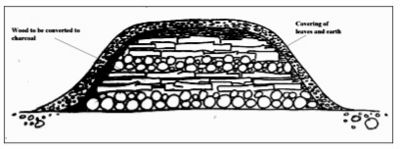

[[Image:Biomass3.jpg|thumb|400px|left|Figure 3: Traditional Earth Kiln for Charcoal Production]] | |||

<br clear="all" /> | |||

Charcoal is produced in a kiln or pit. A typical traditional earth kiln (see figure 3) will comprise the fuel to be carbonised, which is stacked in a pile and covered with a layer of leaves and earth. Once the combustion process is underway the kiln is sealed, and then only once process is complete and cooling has taken place can the charcoal be removed. | |||

[[Image:Biomass4.jpg|thumb|400px|left|Figure 4: Charcoal Kiln, Kenya ©Heinz Muller/Practical Action]] | |||

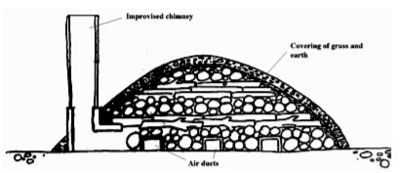

A simple improvement to the traditional kiln is also shown in Figure 5. A chimney and air ducts have been introduced which allow for a sophisticated gas and heat circulation system and with very little capital investment a significant increase in yield is achieved. | |||

[[Image:Biomass5.jpg|thumb|400px|right|Figure 5: Improved Charcoal Kiln Found in Brazil, Sudan and Malawi]] | |||

<br clear="all" /> | |||

==Using a clamp== | ==Using a clamp== | ||

[[File:Charcoal clamp.JPG|thumb|right| | [[File:Charcoal clamp.JPG|thumb|right|200px|A clamp for charcoal production]] | ||

The traditional method in Britain used a clamp. This is essentially a pile of wooden logs (e.g. seasoned oak) leaning against a chimney (logs are placed in a circle). The chimney consists of 4 wooden stakes held up by some rope. The logs are completely covered with soil & straw allowing no air to enter. It has to be lit by introducing some burning fuel into the chimney; the logs burn very slowly (cold fire) and transform into charcoal in a period of 5 days burning. If the soil covering gets torn (cracked) due to the fire, additional soil is placed on the cracks. Once the burn is complete, the chimney is plugged to prevent air to enter.[3] | The traditional method in Britain used a clamp which is itself allready a relatively advanced yet locally-constructable kiln. This is essentially a pile of wooden logs (e.g. seasoned oak) leaning against a chimney (logs are placed in a circle). The chimney consists of 4 wooden stakes held up by some rope. The logs are completely covered with soil & straw allowing no air to enter. It has to be lit by introducing some burning fuel into the chimney; the logs burn very slowly (cold fire) and transform into charcoal in a period of 5 days burning. If the soil covering gets torn (cracked) due to the fire, additional soil is placed on the cracks. Once the burn is complete, the chimney is plugged to prevent air to enter.[3] | ||

Modern methods use a sealed metal container, as this does not have to be watched lest fire break through the covering. | Modern methods use a sealed metal container, as this does not have to be watched lest fire break through the covering. | ||

==Using charcoal kilns== | ==Using charcoal kilns== | ||

[[Image:Emissionless biochar production.JPG|thumb|right| | [[Image:Emissionless biochar production.JPG|thumb|right|200px|A customised pyrolysis unit may be used to generate soil additive and to sterilise planting soil]] | ||

Several (relatively inexpensive) charcoal kilns can be made which can be used to make charcoal/ See [http://www.biochar-international.org/technology/production the designs at Biochar-international page 1] and [http://www.biochar-international.org/technology/stoves page 2] Most of these require atleast some parts which can not be found in a natural environment (ie metal parts). On the upside however, such parts typically last longer and may be more efficient. Some very simple designs also exist consisting of only a few metal parts (ie 2 barrels), see [http://www.nasa.gov/topics/nasalife/features/biochar.html NASA Langley Research Center's low-tech kiln] | Several (relatively inexpensive) charcoal kilns can be made which can be used to make charcoal/ See [http://www.biochar-international.org/technology/production the designs at Biochar-international page 1] and [http://www.biochar-international.org/technology/stoves page 2] Most of these require atleast some parts which can not be found in a natural environment (ie metal parts). On the upside however, such parts typically last longer and may be more efficient. Some very simple designs also exist consisting of only a few metal parts (ie 2 barrels), see [http://www.nasa.gov/topics/nasalife/features/biochar.html NASA Langley Research Center's low-tech kiln] | ||

Revision as of 09:32, 24 July 2012

This article deals about the production of charcoal.

Methods

Charcoal has been made by various methods.

Using traditional kilns

There are several methods for processing wood residues to make them cleaner and easier to use as well as easier to transport. Production of charcoal is the most common.

It is worth mentioning at this point that the conversion of woodfuel to charcoal does not increase the energy content of the fuel - in fact the energy content is decreased. Charcoal is often produced in rural areas and transported for use in urban areas.

The process can be described by considering the combustion process discussed above. The wood is heated in the absence of sufficient oxygen which means that full combustion does not occur. This allows pyrolysis to take place, driving off the volatile gases and leaving the carbon or charcoal remaining. The removal of the moisture means that the charcoal has a much higher specific energy content than wood. Other biomass residues such as millet stems or corncobs can also be converted to charcoal.

Charcoal is produced in a kiln or pit. A typical traditional earth kiln (see figure 3) will comprise the fuel to be carbonised, which is stacked in a pile and covered with a layer of leaves and earth. Once the combustion process is underway the kiln is sealed, and then only once process is complete and cooling has taken place can the charcoal be removed.

A simple improvement to the traditional kiln is also shown in Figure 5. A chimney and air ducts have been introduced which allow for a sophisticated gas and heat circulation system and with very little capital investment a significant increase in yield is achieved.

Using a clamp

The traditional method in Britain used a clamp which is itself allready a relatively advanced yet locally-constructable kiln. This is essentially a pile of wooden logs (e.g. seasoned oak) leaning against a chimney (logs are placed in a circle). The chimney consists of 4 wooden stakes held up by some rope. The logs are completely covered with soil & straw allowing no air to enter. It has to be lit by introducing some burning fuel into the chimney; the logs burn very slowly (cold fire) and transform into charcoal in a period of 5 days burning. If the soil covering gets torn (cracked) due to the fire, additional soil is placed on the cracks. Once the burn is complete, the chimney is plugged to prevent air to enter.[3] Modern methods use a sealed metal container, as this does not have to be watched lest fire break through the covering.

Using charcoal kilns

Several (relatively inexpensive) charcoal kilns can be made which can be used to make charcoal/ See the designs at Biochar-international page 1 and page 2 Most of these require atleast some parts which can not be found in a natural environment (ie metal parts). On the upside however, such parts typically last longer and may be more efficient. Some very simple designs also exist consisting of only a few metal parts (ie 2 barrels), see NASA Langley Research Center's low-tech kiln