Introduction

In many developing countries, Malaria represents the biggest threat to infants under 5 years old. It is responsible for 20% of all infant deaths in Africa and kills over 3000 people per day (mostly children). In countries such as Sierra Leone, the second least developed country on earth, Malaria cases account for 40% of medical expenditures, making malaria one of the most expensive preventable illnesses in Africa today. Currently, malaria is a serious medical concern for over 40% of the world population; mostly in developing countries in Sub-Saharan Africa[1]. Malaria is most commonly transmitted by mosquito bites. As an infected mosquito bites an individual, it deposits the disease directly into the blood stream, where it quickly begins to multiply and spread. As other mosquitoes bite that same individual, drawing blood, they too become infected by the disease. As the infected mosquito isn’t immediately affected by the disease, it continues to bite other individuals, thus spreading the disease. Mosquitoes will often bite people while they sleep, since a sleeping person is unlikely to wake up and swat them away.[2]

Problem Definition

Mosquito bed-netting represents the most inexpensive way of effectively eliminating mosquito bites while sleeping. The net works by simply creating a barrier around the sleeping individual through which mosquitoes can’t pass. In many developing nations such as Togo or Sierra Leone, organizations such as the UN and Red Cross subsidize bed nets for residents, often allowing families to receive nets for free. However, in other countries where these organizations are unable to subsidize the cost of bed nets, individuals must come up with the full price of the bed net in order to be protected. The most reasonably priced bed nets available on the internet retail for approximately 20$[3], while (according to the UN) a majority of Africans affected by malaria earn an average of 14-25$ per month. This makes affording bed nets for an African family very difficult. The solution, therefore, is to come up with a method of building a bed net using inexpensive materials while offering the same protection as a purchased bed net.

Design Criteria

Functionality

In order to block an Anopheles-genus mosquito from passing through the bed net, fabric or mesh with a grid size of less than 1.2mm x 1.2mm must be used. The bed net must be able to completely cover the bed and must not touch the sleeper, since mosquitoes can still bite the sleeper through thin fabrics or meshing if it comes in contact with their skin[4]. The net must also completely encapsulate the bed, leaving no gaps at the seams or where the fabric meets the floor. Ideally, the sleeper should be allowed to sit up in bed as well as sleep while being protected by the bed net. This means the net must be tall enough to allow the occupant to sit up without brushing their head on the net. Finally, the proposed design is ground supported (instead of typical designs that hang the net from the ceiling) because it is difficult to determine how the integrity of a roof will be affected by the net unless it is hung on a ceiling joist. Since many houses in Sub-Saharan Africa are not built to meet any building codes, adequate care must be taken to insure the extra weight of a wood frame won't cause the roof to collapse. For this reason, the ground was chosen to provide support for the frame.

Reproducibility

The goal of this inexpensive net is to save as much money as possible for the person using it. Therefore, any cost savings versus a new mosquito net is considered to be highly beneficial to the people needing them. While some money can be saved by building the nets using the below design and materials, this design of bed net can still be made using a number of widely available and inexpensive materials the builder may already have ready access to. For example, by replacing the brand new wood with branches found outside or with used lumber bought at a mill, the cost of the frame material becomes highly reduced. By replacing the brand new sheet material with some old sheets the builder may have or with locally available, cheap fabrics, the cost of the netting becomes highly reduced as well.

Required Materials

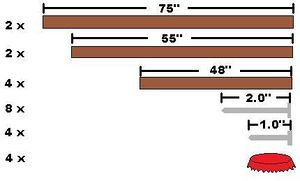

Please refer to Figure 1

The following materials are needed to make a mosquito net capable of covering a double-size bed, and rising 4 feet off the ground:

- Cotton/Polyester/Mesh Sheet (174” x 195” – 449.1cm x 495.3cm – 26 yards)

NOTE: The sheet does not have to come as one piece. Please refer to the Construction section on how to properly sew several pieces of material together

-Needle and Thread (If sheet is not one piece)

-1 x 1 Wood (Total: 38’ – 12.5m, cut into: 4 x 48”, 2 x 55”, 2 x 75”)

- 8 x 2” spiralled nails

-4 x 1” nails

-4 x bottlecaps

Alternate Materials

-Fabric: As long as the material is light, has no holes in it, and is able to allow air through, any material can be used. Some examples include: linens, old clothing, or even combinations of mesh and impermeable materials such as thin plastic sheets (for example, a combination of mosquito mesh and plastic shower curtains can be used – whatever is available and inexpensive)

-Wood: any material can be used in place of wood, provided that it is able to support its own weight and can be easily made into the required frame. Even branches from downed trees can be used.

-Fasteners: Any readily available or inexpensive fasteners can be used to hold the mosquito net together, provided those fasteners are long enough, but not long enough to poke out of the wood - creating a poking-hazard.

Material Considerations

A number of materials can be used to make the net, however certain materials have different qualities that will make them favorable in a variety of conditions. In the case where cost is an issue, delicate fabrics and mosquito meshing should be avoided. If cost is less of an issue, then mosquito meshing is the most favorable material to use, since it allows the sleeper to see through it. An all plastic sheet should also be avoided since it would provide inadequate air circulation for the sleeper. Finally, environmental conditions must be considered. In humid climates, a plastic sheet may be unfavorable since it has a tendency to collect condensation. Cotton sheets may also be unfavorable in humid climates, since cotton retains moisture and may promote mold growth. In hot climates, thicker materials should be avoided, since the insulating effect of the material may make the area underneath the net too warm. Adequate care must also be taken if using wood taken from an outdoor setting. Builders must assure that the wood being used isn't dead or broken, because the frame could cause injury if it were to break apart with someone under it. The builder must also make sure the wood isn't home to other pests such as mites or dangerous spiders.

Required Tools

The following tools are required to build a bed net:

-Hammer

-Saw

-Measuring Tape

Required Expertise

Only basic construction and sewing skills are required to build an inexpensive bed net.

Building The Mosquito Net

Constructing The Frame

1. Cut the wood to the following lengths using the saw if not already done so:

- 4 x 48”

- 2 x 55”

- 2 x 75”

2. Assemble the 55” and 75” pieces into a box frame as outlined in Figure 2 and nail together with 2” nails

3. Attach one of the 4 48” legs at each corner as outlined in Figure 3 using 2” nails

4. Carefully lift the frame and place over the bed to be covered. The frame should be placed such that it completely surrounds the bed.

Preparing The Sheet

NOTE: This step is only necessary if the sheet consists of several pieces that must be stitched together

1. If using several smaller sheets to be sewn into the required dimensions, a modified Haithabu stitch can be used (refer to Figure 4).

-The modified Haithabu stitch is used because the sheets will interlock. This assures that mosquitoes can not enter the bed net through a seam.

Attaching The Sheet To The Frame

1. Gently drape the sheet over the frame as illustrated in Figure 5

2. Adjust the sheet so it is centered on the frame. There should be adequate slack where the sheet meets the floor, such that approximately 6-12” of the sheet is touching the floor on all sides

3. Nail the sheet into place by driving a 1” nail through the bottle cap and sheet and into the wood at one corner. Repeat for the other three corners as illustrated in Figure 6. The bottle cap will act as a washer to reduce the chance of the sheet tearing on the nails.

4. Now, simply lift the sheet on one side, get into the bed, and release the sheet so it drapes back onto the floor. You are now protected from mosquito bites as well as any other small pests while you sleep!

Cost Analysis

The cost of individual materials is found in Table 1:

Table 1: Cost Breakdown of proposed Design

| Component | Cost | Total Cost | Distributor |

| Cotton Sheet | $0.35/yard (60" Wide) | $5.48 | Magna Fabrics[5] |

| 1x1 Lumber (Massaranduba) | $0.13/lin. ft. | $4.94 | Hilde's Lumber Outlet [6] |

| Hardware | ~$0.05/fastener | $0.60 | Home Depot |

The total cost of building your own mosquito bed net is $11.02, making this bed nearly half the cost of the most reasonably priced mosquito nets found online. It is important to note that the UN does provide Mosquito nets in certain countries for only $10.00, but that this design is geared towards populations without access to UN resources. Using used or free materials, the cost can be further driven down to below the cost of the net offered by the UN.

References

- ↑ Red Cross: Sierra Leone 2006 Bed-Net Campaign: Facts and Figures, http://www.redcross.ca/article.asp?id=19724&tid=001, Accessed April 14, 2010

- ↑ MedecineNet: Malaria, http://www.medicinenet.com/malaria/article.htm, Accessed April 14, 2010

- ↑ Travelers Mosquito Net,http://www.cheap-mosquito-nets.com/travelersmosquitonetflatpack-p-1.html, Accessed April 14, 2010

- ↑ All Mosquito Netting Info, http://www.mosquito-netting.com/mosquito-netting.html, Accessed April 14, 2010

- ↑ Magna Fabrics: Specials, http://www.magnafabrics.com/, Accessed April 14, 2010

- ↑ Uncle Hilde's Lumber Outlet: 1x1 Clear Massaranduba, http://www.unclehildes.com/ProductID1533, Accessed April 14, 2010