| Line 25: | Line 25: | ||

== Technical Specifications and Assembly Instructions== | == Technical Specifications and Assembly Instructions== | ||

{{Gallery | |||

|width=173 | |||

|height=200 | |||

|lines=4 | |||

|title=Fabrication Instructions | |||

|Image:1_Pedal.JPG| Print bottle cap at .2mm layer height or less, with the threads at the top, without supports. Support material clogs up the threads, creating unnecessary cleanup work. Estimated print time at 70mm/s: 22 minutes. | |||

|Image:2_Pedal.JPG| Print the tea bag holder as shown at .3mm layer height. Estimated print time at 70mm/s: 42 minutes. | |||

|Image:3_Pedal.JPG| Cut open a teabag at an edge and add one teaspoon activated carbon. | |||

|Image:4_Pedal1.JPG| Stuff tea bag with carbon into the large end of the bag holder. | |||

|Image:5_Pedal.jpg| Screw cap onto bottle threads. | |||

|Image:6_Pedal.jpg| Fully seat the cap into the tea bag holder. | |||

}} | |||

# Download all .STL files from above or within the Youmagine link | |||

# Load Pedal_Half_Final.STL into a slicer | |||

# Orient pedal half so that the clip holes are on the top. Add support everywhere to ensure quality | |||

# Print two pedal halves(These will clip together later) | |||

# Load Axle_Final.STL into a slicer | |||

# Orient it so that it requires no support | |||

# Print one axle | |||

# Load Clip_Final.STL into a slicer | |||

# Orient the clip so that the greatest amount of surface area is touching the build plate | |||

# Print six clips | |||

# Place all six clips in one half of the pedal | |||

# Place Axle within the trough | |||

# Connect other half of the pedal with the other half of the clips | |||

# Provide directions for print/assembly - be detailed enough in your “how to” to ensure that someone could construct the device from your description. Consider the elegance of IKEA like instructions. | # Provide directions for print/assembly - be detailed enough in your “how to” to ensure that someone could construct the device from your description. Consider the elegance of IKEA like instructions. | ||

# Include print time estimate | # Include print time estimate | ||

Revision as of 01:44, 5 December 2019

Bike Pedals

Project developed by [Mitchell DeNooyer]

Template:Statusboxtop Template:Status-design Template:Status-prototype You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

Abstract

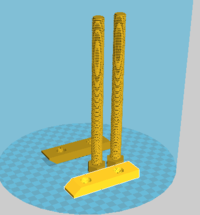

- A bike is a very useful mode of transportation that many people in first-world countries take for granted. There has been a goal set to create a cheap bike using primarily 3D printed parts. This bike pedal is a good prototype for what the possibilities are for this project. This pedal is fully 3D printed and clips together around a bar/axle. The goal is that this pedal would be easy to switch out and allows for rotation around the axle but not in other directions. This is still a rough prototype and would need more work to be implemented fully onto the bike.

- Picture of completed print using your printer

Bill of Materials

- Plastic Filament (PLA preferred)

- Upload and link to all source files from open source CAD

- Upload and link to all STLs

Tools needed for fabrication of the OSAT

- MOST Delta RepRap or similar RepRap 3-D printer

- Knife of some sort to clean up parts

Skills and Knowledge Necessary to Make the OSAT

- Be sure you are able to load an STL into a slicer and orient it the correct way

Technical Specifications and Assembly Instructions

- Download all .STL files from above or within the Youmagine link

- Load Pedal_Half_Final.STL into a slicer

- Orient pedal half so that the clip holes are on the top. Add support everywhere to ensure quality

- Print two pedal halves(These will clip together later)

- Load Axle_Final.STL into a slicer

- Orient it so that it requires no support

- Print one axle

- Load Clip_Final.STL into a slicer

- Orient the clip so that the greatest amount of surface area is touching the build plate

- Print six clips

- Place all six clips in one half of the pedal

- Place Axle within the trough

- Connect other half of the pedal with the other half of the clips

- Provide directions for print/assembly - be detailed enough in your “how to” to ensure that someone could construct the device from your description. Consider the elegance of IKEA like instructions.

- Include print time estimate

- Include assembly time estimate

- Including drawings or pictures of the device at stage of assembly at minimum. (http://www.appropedia.org/Special:Upload)

- Consider video if appropriate

| Example video summary of textbook |

|---|

Error in widget YouTube: Unable to load template 'wiki:YouTube' |

Common Problems and Solutions

- Include common mistakes/problems to avoid in building your OSAT and how to overcome them

Cost savings

- If your solution is not a low cost one then it is not really appropriate.

- Estimate your costs

- Find a commercial equivalent, cite it and put the [url in square brackets]

- Calculate $ savings and % savings

Benefited Internet Communities

- Name and add links to at least 5 using single brackets around [url name]

References

- The sources of information (e.g. engineering handbooks, journal articles, government documents, webpages, books, magazine articles etc.). References should use the <ref> </ref> and <references/> tags and can be in any format but should include all the information necessary for someone else to find the same information you did. For example: [1]

- ↑ web page: Department of Energy (DOE) Landscaping and Energy Efficiency, DOE/GO-10095 (1995) Available: http://www.eren.doe.gov/erec/factsheets/landscape.html

Based on the developmental needs addressed (e.g. food, heat, electricity, clean water, health care, etc.) be sure to label your device in the proper categories e.g. use [[Category:Water]]. Be sure to categorize your device so that it will be easy to find – for example “Low voltage connection basics” is categorized in [[Category:How tos]] [[Category:Electricity]] [[Category:Electric lighting]].