Abstract

Background

The newest project site for the Practivistas Dominicana program is in Arroyo Norte. Arroyo Norte is a sustainable community, which was built in close proximity to the dumpsite for Santo Domingo. The dumpsite is the largest in the country, and the community exemplifies Appropriate Technology by building homes, community centers, and markets out of the materials they have in abundance at the nearby dumpsite. They have asked for us to come in and use the waste materials to build prototypes for furniture and walls to construct a new supermercado in Arroyo Norte, the first large market in the community. The market will be built in the near future, but for this project we will only be experimenting with materials to develop alternative designs for things necessary in a marketplace. The 25-room supermercado will need a funding source, which our prototypes will hope to generate upon completion. Our role in this project is to develop aesthetically pleasing, structurally sound, and economically feasible prototypes for use in the supermercado.

Problem Statement

The objective of this project is to research and develop wall and table prototypes that can be reproduced and used in a sustainably constructed market in Arroyo Norte, Dominican Republic.

Criteria

The following table of criteria was developed in a community meeting and is used to evaluate alternative solutions.

| Criteria | Constraints | Weights |

|---|---|---|

| Resistance | Prototypes must successfully pass the spray test, scratch test, and tensile strength test. | 10 |

| Marketability | The prototypes must have potential for reproduction at minimum, and potential for revenue production at best. | 9 |

| Aesthetics | The prototypes must at least be visually acceptable to the community members involved, and at best look "clean". | 9 |

| Security | The wall prototypes must look secure and be resistant to break-ins. | 9 |

| Educational Value | The prototypes must display reused materials in some way. | 9 |

| Accessibility of Materials | At least 90% of materials used in the prototypes must come from the Arroyo Norte waste station. | 9 |

| Mobility | The furniture must be movable by 2 or less people. | 8 |

| Adaptability | The prototypes shall be created with room adaptability in mind. | 7 |

| Cost | The prototypes should minimize cost where possible. The walls shall not exceed $100 USD each, and the tables shall not exceed $50 USD each. | 6 |

Literature Review

This section is based on research of the most up-to-date information relevant to the Arroyo Norte sustainable market materials project. Most of the information outlined below is pulled from credible sources and project pages of successfully implemented projects or processes to upcycle materials from the waste stream. Upcycling is done by processing previously used materials that would otherwise go to the waste stream, and creating something new that is better aesthetically or more purposeful than the original material(s).[1]

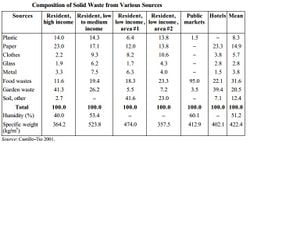

Santo Domingo Waste Stream Study

Santo Domingo creates a total of 11,000 pounds of trash daily. Its population density, nearly 4 million Dominican citizens and 2.5 million tourists annually, is the major contributing factor. The largest landfill in the country, Duquesa, is located in Arroyo Norte. All of the waste at Duquesa is managed by the ADN National District Municipality. According to the an interview with Max Da Silva, manager of operations in Duquesa, by DiarioLibre, there are around 400 trips by grabage trucks a day during the operation times which are from 6:00 am to 8:00 p.m.[2] Management of this waste is too much for the municipality to handle and a disproportionate financial burden(as much as 300 pesos a month according to local accounts) on the citizens of Santo Domingo. Waste pickup is often sporadic due to poorly maintained equipment. There are programs however to combat the waste management issues, including alternative energy projects, non-profit organizations such as trashmountain, and recycling implementation (2009).

As of 2002, 95% of solid waste collection services are privatized in Santo Domingo. The statistics for where the trash ends up in the Dominican Republics are:

- 3.7% throw garbage into the river

- 23.7% burn their waste

- 52.7% of trash from independent homes gets collected by the city council

[4] Environmental concerns arise from the open-air disposal, which is the case for all dumpsites, where 98% of the country's trash resides. This style of waste management creates serious environmental risks and groundwater contaminations.[4]

Common Upcycled Waste Stream Materials

The most common materials re-used from the waste stream include plastics, metals, and paper. For the scope of this project, we will examine all materials present in the waste stream that have potential to be re-used or up-cycled into indoor furniture for a marketplace in Arroyo Norte.

Plastic

Plastic is a petroleum-based material that can be manufactured in various sizes, shapes and strengths. Each type of plastic that is produced usually has the chemical formula, or Plastic codes, identified somewhere on the product in the form of a number, surrounded by a recyclable sign. Each of these material signatures helps the end user to sort the plastics accordingly and identify which materials can be used again.

| Image | Description | Melting Temperature |

|---|---|---|

|

PETE #1: Polyethylene Terephthalate (PET) can be found in the form of plastic bottles that contain liquid like water or soda, and also peanut butter containers. | 540 degrees F [6] |

|

HDPE #2: High Density Polyethylene is mostly found in the waste stream in the form of soda caps, milk jugs, but is also used to create juice bottles and some trash bags.[5] | 400 degrees F [6] |

|

PVC #3: Polyvinyl Chloride is a type of plastic used for PVC piping, juice bottles or cling wrap.[5] | 325-350 degrees F [6] |

|

LDPE #4: Low Density Polyethylene is used for flexible items such as ziplock freezer bags, squeezable condiment bottles, and flexible lids.[5]The softening point for this type of plastic is 248 degrees F. [7] | 284 degrees F [6] |

|

PP #5: Polypropylene is used to make many single-use cups, lids, and yogurt containers.[5] This material has the strength to withstand high heat and stress. | 575 degrees F [6] |

|

PS #6: Polystyrene can be used for things such as packing peanuts, egg cartons, disposable cutlery and disposable food containers.[5] | 350-390 degrees F [6] |

|

Other #7: Other plastics refer to polycarbonate or ABS usually, and are used to case electronic equipment, and sometimes are used to make to-go containers, or Legos as shown.[5] | (ABS): 400-420 degrees F [6] |

Melting Plastics Vs. Burning Plastics

The process of melting and reshaping plastics is more safely implemented when the plastic reaches temperature to melt, but never reaches a high enough temperature to burn. Health hazards are associated with burning plastics because once the material reaches a high enough temperature to burn, it off-gasses, which means it releases toxic chemicals into the atmosphere, unique to each type of plastic. Dioxins are the most potent carcinogen when tested on animals, and are present in halogenated plastics, such as PVC and plastics containing chlorine and fluorine. When these halogenated plastics are burned, dioxins pose the highest threat to human health. [8]

Rubber

Tires will be the most applicable form of rubber to be used in the creation of furniture and walls for the marketplace. Another application of upcycled rubber is to find bicycle tire tubes or any rubber tubing of the like, and weave them together to create a seat for a chair.

Metals

Metals enter the waste stream in many types, forms, and conditions. The most common metals that will be examined for this project are tin cans, aluminum cans, and electronic waste. Although many other materials enter the waste stream that can be used to make furniture in Santo Domingo, Dominican Republic, these materials seem to be the most readily available to every one, and can be repurposed in any home before entering the waste stream.

Tin

Tin enters the waste stream in the form of tin cans, mostly intended to store food. Tin cans are a widely distributed material, and are an excellent choice for upcycling because the material is 100% recyclable and is a non-renewable resource. [9]

- Melting point: 449.4 degrees F [10]

Steel

Steel is most commonly found in the waste stream in the form of steel cans. Throughout history, steel cans have been manufactured with different materials to eliminate corrosion of the steel and toxicity of the materials entering the food contained within the cans.

Tin-coated cans are manufactured by coating the steel can with tin on both sides of the metal before forming the cans. The tin acts as an anti-corrosive material, but acidic foods can cause the tin to corrode, leaching tin into the food and causing gastrointestinal distress. Tin-coated cans are still manufactured today, but are an expensive option so are not used as often as some other anti-corrosion methods. [11]

Tin-free cans are made of tin-free steel, which is coated with a material (originally chromium metal and chromium oxide) to prevent rusting. Although this process is cheaper than tin-coated cans, it is not as effective in preventing corrosion, and these products are more difficult to weld. [11]

Bi-metal cans are made by mixing two different types of metals together. The main body of these type of cans are made of steel, and the top or bottom of the can is made up of another metal, usually aluminum. These cans are difficult to recycle because unlike tin-coated cans, these are not alloy metals (an even mixture of two metals). For this reason, these cans should not be melted down. [11]

- Melting Point of steel: 2600-2800 degrees F [10]

Aluminum

Aluminum cans, like those used to store soda and other single-serving beverages are very commonly found in the waste stream. These cans be be used in a variety of ways, especially by crushing, cutting, and melting them to create larger objects, such as chairs or dividing walls.

- Melting Point: 1220 degrees F [10]

E-Waste

Electronic waste includes computer-chips, motherboards, wires, and sometimes contains precious metals that can be used in the marketplace for purely decorative purposes.

Tree Products

The most relevant tree products that enter the waste stream for this project are wood and cardboard. Wood products will be available in a variety of forms, conditions, shapes and sizes. The most adaptable transformations of waste wood will be complete shelf pieces or clean scrap wood that can be chopped into chips, and molded with glue to create a home-made particle board-type material. Cardboard materials found in the waste stream could be adapted to create end-tables or chairs. In order to do this, the cardboard would need to be relatively clean to begin with. After collecting pieces of cardboard, they can be glued together to create a 3-D cube, which can be pre-cut to shape before the gluing process or can be cut to shape after the glue dries to create customized shapes or designs.

Cement Alternatives

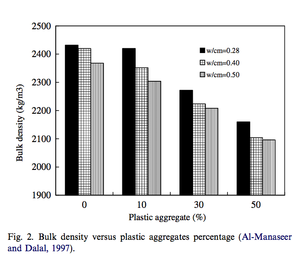

Al-Manaseer and Dalal (1997) conducted a study to determine how much the concrete density can be reduced by mixing recycled plastics into the concrete mixes. The pieces of post-consumer plastic used in the mixtures were no larger than 13 mm. The study concluded that the density of the concrete was reduced by adding plastic to the mixture. In fact, the density of the concrete was reduced by 2.5%, 6%, and 13% for concrete mixtures containing 10%, 30%, and 50% plastic aggregates, respectively.

Furthermore, Bayasi and Zeng (1993) concluded that the addition of polypropylene fibers fibrillated to less than 19mm did enhance the toughness of concrete under pressure and increased the energy absorption of the material. [7]

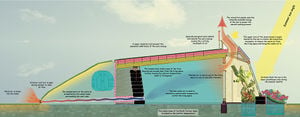

Earthship

In earthship building, spaces are constructed using repurposed rubber tires filled with dirt. The tires filled with dirt are stacked on top of each other, usually with rebar for structural support, making sturdy, hurricane-proof, upcycled homes. Earthship design is appropriate in most climates, and can decrease the indoor temperature during hot days, and heat the indoor temperature during cold nights due to its thermal mass. Earthship structures can be made more aesthetically pleasing by adding a plaster coating over the top as seen in the photo to the left.

Dominican Republic Natural Building

The climate in the Dominican Republic is considered tropical maritime, it has small temperature changes throughout the year, and is consistently humid. The rainfall varies with the seasons, which creates flooding. Hurricanes are frequent in the area, and severe storms occur between the months of June and October. [4]

The building code followed in the Dominican Republic is ACI 318 and ASTM. ACI 318 covers the strength evaluation of existing concrete structures, and the design, materials, and construction of structural concrete that is used in buildings. ASTM is the American Society for Testing and Materials, which is a wide-range standards for services, systems, materials, and products.[4]

Existing building materials primarily used in Dominican Republic housing structures include: concrete blocks, pinewood, palm wood (tabla de palma), tejamanil, yagua, and any materials laying around that could make a wall.[4]

Upon further research, potential natural building materials for construction of the walls in this sustainable market include:

- papercrete blocks

- One papercrete block can be produced for 66 pesos less than the cost to produce one typical cement block. [13]

- hullcrete blocks

- compressed earth brick (with a little cement)

- Auroville in India specializes in this technology

- Factor E Farms has an open-source machine for making the bricks

[14] source for further research www.csuchico.edu/~jpgreene/itec144/m144_ch03.../m144_ch03-01.ppt

Construction

Timeline

| Date | Activity |

|---|---|

| Monday, June 16 | Complete Budget/Finish negotiations with practivistas |

| Tuesday, June 17 | Brainstorm Explosion/Plastic Bottle cap Mold Extravaganza |

| Wednesday, June 18 | Complete plastic research/Brainstorm Explosion #2 |

| Thursday, June 19 | Work day - Melt massive amounts of HDPE Plastic #2/Finalize caps & bottles |

| Friday, June 20 | Purchase plastic tools to mass produce plastic tiles |

| Saturday, June 21 | Finish all plastic prototypes/Finish wood chips and resin |

| Sunday, June 22 | BEACH DAY |

| Sunday, June 29 | Build on and perfect prototypes/Beauty with Mama |

| Monday, June 30 | Work on presentations |

| Thursday, July 3 | Present Projects |

Costs

The table below describes the desired budget for this project, including experimental materials and tools.

| Quantity | Material | Source | Cost ($)DR | Total ($) |

|---|---|---|---|---|

| 3 | "Calentador"/Sterno cans | La Sirena | 48.41 | 145.23 |

| 1 | Wood resin 10 oz. | Ferreteria U&P | 150.00 | 150.00 |

| 2 | Wood palettes | Duquesa | 150.00 | 300.00 |

| 1 bag | Wood chips | Duquesa | 150.00 | 150.00 |

| 1 bin | Plastic #2 HDPE | Duquesa | 200.00 | 200.00 |

| 1 | Transportation of duquesa materials | Duquesa | 500.00 | 500.00 |

| 1 | Wood resin catalyst 1 oz. | Ferreteria U&P | 40.00 | 40.00 |

| 1 | Floral snippers | Ferreteria U&P | 350.00 | 350.00 |

| 2 | 4" clamps | Ferreteria U&P | 275.00 | 550.00 |

| 1 | Box cutter | La Sirena | 63.33 | 63.33 |

| 1 | Plastic melting machine | 2,500 | 2,500 | |

| 1 | Plastic cutting machine | 2,500 | 2,500 | |

| 1 | Scissors | La Sirena | 100.21 | 100.21 |

| Total Cost | $7,548.77 | |||

Design Renderings

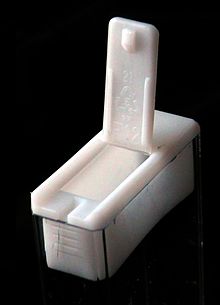

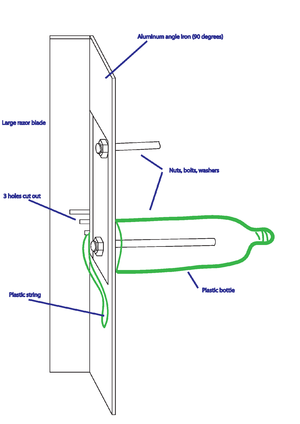

This design is a Plastic Bottle Ripper, which turns large plastic bottles into long spools of plastic string of uniform width. The design utilizes a 90 degree aluminum angle iron, a razor blade, and a few nuts bolts and washers. To create this Plastic Bottle Ripper, take your angle iron, and cut 3 holes into it at various lengths to create various widths of plastic string. Next, drill 2 holes into the angle iron where the bolts will be attached. Then, place the razor blade near the holes and add the nuts, washers, and bolts to secure the blade (sharp side facing the corner of the angle iron). Lastly, secure the angle iron vertically, put a 2 liter bottle on the long bolt, feed a small piece of soda bottle through the hole, and pull the string.

Completed Prototypes

This section illustrates a step-by-step tutorial on how to replicate the prototypes we created for the Arroyo Norte sustainable market.

Glass Bottle Wall

Plastic #2: Melted and Molded Tile

These tiles were melted using a sandwich grill to melt HDPE Plastic #2, which was taken from the waste stream in Arroyo Norte.

Plastic #2 Experiments: Efficiently Melting HDPE

The Experiments in this table were performed using a common household electric sandwich grill.

The experiments documented in the table below were performed using a large grill powered by propane.

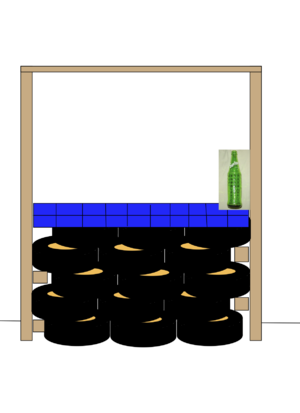

Earthship Bar

The image on the right margin below depicts a pony wall and bar design constructed of repurposed tires and earth found commonly in Arroyo Norte. The tires are bonded with moist earth (mostly clay), which is packed in and around the tires. Rebar was used to provide further structural integrity. Once the filled tires are leveled and the earth dried they will be covered in a plaster mixture of lime, sawdust, and a concrete mixture containing extra fine sand. The bar top design will be made with pallet wood and tiled with our prototype tiles made from recycled HDPE #2 plastic bottles.

This bar was created using old tires found in Arroyo Norte, filled with clay and dirt on site, and supported with rebar. The bar top was built using old palette wood.

Maintenance

Schedule

Instructions

Conclusion

Testing Results

Discussion

Lessons Learned

Next Steps

Troubleshooting

Team

References

- ↑ http://dictionary.reference.com/browse/upcycling

- ↑ Nikaury Arias (April, 2008) "Duquesa Recibe el Ultimo Camion a las 7:15 pm", DiaroLibre.http://www.diariolibre.com/noticias/2014/04/02/i551441_duquesa-recibe-ltimo-camin-las-715.html.

- ↑ http://pdf.usaid.gov/pdf_docs/Pnadc949.pdf

- ↑ 4.0 4.1 4.2 4.3 4.4 http://hj.diva-portal.org/smash/get/diva2:232910/FULLTEXT01.pdf

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 5.6 http://www.greenworld365.com/plastic-recycling-numbers/

- ↑ 6.0 6.1 6.2 6.3 6.4 6.5 6.6 http://plastictroubleshooter.com/ThePlasticTroubleshooter/melt_temps.htm

- ↑ 7.0 7.1 7.2 http://www.sciencedirect.com/science/article/pii/S0956053X07003054

- ↑ Siddique, Rafat Khatib, Jamal, and Kaur, Inderpreet. (2008). "Use of recycled plastic in concrete: A review " Waste Management, 28(10), 1835–1852 http://plasticisrubbish.com/2008/06/02/dioxins-why-you-dont-want-to-be-burning-plastic/

- ↑ http://www.chasinggreen.org/article/pros-and-cons-tin-or-steel-cans/

- ↑ 10.0 10.1 10.2 http://www.engineeringtoolbox.com/melting-temperature-metals-d_860.html

- ↑ 11.0 11.1 11.2 http://www.ehow.com/list_5977264_types-steel-cans.html

- ↑ http://commons.wikimedia.org/wiki/File:Convection_banner_1.jpg

- ↑ Cite error: Invalid

<ref>tag; no text was provided for refs namedPapercrete - ↑ Conversation with Lonny Grafman, June 17,2014