Overview

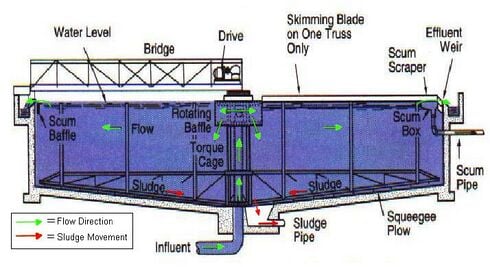

A clarifier operates on the idea of slowing wastewater down so that suspended solids will settle out on the bottom of the tank. These settled solids are called sludge. Less dense oils and solids called scum will float and settle on the top of the tank. The sludge and scum are then removed, and the water is transported onto the next stage in the wastewater treatment plant. After the entire process is completed the clarifier will have removed 40-60% of suspended solids[1].

Arcata

The Arcata Wastewater Treatment Plant is equipped with two clarifiers. Figure 1 shows both of these clarifiers. The first is a 60 foot diameter tank that is used at all times (see Figure 2). The second is a 26 foot diameter tank provides support during more frequent winter rains or can be used when the main tank is being maintenanced[2]. Both of the clarifiers are center fed clarifiers[3], meaning the influent (wastewater flowing into the system) is fed from the center, underneath the tank (see Figure 3).

Slowing the Water

The first task of the clarifier is to slow down the wastewater it recieves from the headworks (see Figure 3 for water flow).

Water Entering

Water first enters the center of the tank through the influent (wastewater entering the system) pipe. A baffle slows down the velocity of the water to about 0.03-0.05 feet per second and directs the flow of water downward[4]. The baffle is a series of concentric cylinders. This reduces velocity, allowing solids to settle out on the bottom of the circular tank.

Water Exiting

To ensure a consistant water flow the clarifier must also slow down the effluent (wastewater leaving the clarifier) evenly. The perimeter of the tank is designed to accomplish this. A series of v-notched weirs along the edge of the tank slow the water as it departs. Once over the weirs the water enters the effluent ladder (a channel around the outside of the clarfier). An inner baffle that rests behind and above the weirs prevents floating solids from passing over. If water does not flow evenly after entering the tank or as it leaves over the weirs, the settling process will not occur evenly, this is also known as hydraulic short-circuiting[5]. From the effluent ladder the water flows into a main collection trough and is piped onto the oxidation ponds via the effluent pipe.

Settling and Removal Process

Suspended solids are removed from the tank in two ways.

Sludge

The denser solids settle on the conical bottom of the tank in the form of sludge. A large rake with a squeegee like assembly rotates and moves the sludge towards a hopper at the bottom of the tank. The sludge is then pumped to the digester (see Figure 3) for treatment.

Scum

Lighter solids and oils rise to the top of the tank in the form of scum. Scum is removed from the tank by a rotating skimmer arm (see Figure 5). The blade like arm collects the scum into a trough on the perimeter of the tank. Once the scum is collected it is transported to a landfill. Both the rakes and arm rotate together as they remove both sludge and scum from the tank.

Footnotes

- ↑ http://ragsdaleassociates.com/WastewaterSystemOperatorsManual/Chapter%203%20-%20Primary%20Treatment.pdf

- ↑ Personal communication with Dave Couch

- ↑ http://www.cee.vt.edu/ewr/environmental/teach/wtprimer/sedimen/sedimen.html

- ↑ http://ragsdaleassociates.com/WastewaterSystemOperatorsManual/Chapter%203%20-%20Primary%20Treatment.pdf

- ↑ http://www.environmentalleverage.com/Primary%20Clarifiers-%20Problem%20Areas.htm

Other References

- All photographs courtesy of Dr. Dustin Poppendieck, Assistant Professor of Environmental Resource Engineering, Humboldt State University.

- Principles of Environmental Engineering and Science/Davis and Masten. 2nd ed

<layout name="Project" />