Abstract

Baling materials on fields such as hay, straw or leafs has many advantages as these bales can be used to store excess materials or feed animals. Straw bales are also used as a building material for construction. This practise started in North America as early as the 1800’s, and has recently Straw is an available material making Straw bales a cheap and available construction material. These bales can provide both building insulation and structural support. The availability of this potential construction material deems its consideration as an appropriate technology. Large costs associated with mechanical combines and farmers with small plots of land necessitate a low cost alternative. There are many options available and this article examines A Hand Powered Hay and Leaf Baler made by Larry McWilliams that is on the CD3WD. The purpose of the CD3WD project is to help the 3rd World help itself, contents can be found here. This article provides a much more detailed how to, for construction and use of this bailer. A discussion on the application of this system and its bales is also included.

Considerations

Access to Baling Materials

Materials to be baled exist in all parts of the world where this is agriculture. Cereal plants grow in all parts of the world, except very dry deserts and the ice-covered poles. ((REFERENCE HERE bbc) But more specifically, straw is a by product of cereal plants. Straw is what remains after the grain and chaff have been removed; it is also known as the stalk of the plant. Africa is home to many native cereal plants, and colonization brought many other species to the area. (REFERENCE HERE crops of africa) In other words this technology can be useful in almost any part of the world.

Access to Building Materials and Ability to Build

The baler that is detailed below was made using power tools and nominal wood sizes. This is because these are the materials and tools I am familiar and have developed skills working with. These are not available around the world, but it is possible to make this structure out of available materials using simpler tools. In the construction section there is a section for suggested and potential tools to build this baler. A skilled craftsman would be able to recreate this structure. In the case where a group was travelling to an area where the tools and materials were unavailable they could pre cut and transport them. A full analysis of alternative balers should be conducted before this occurs.

Applicability of Bales

Straw bales can be used in construction, but most typically for low cost, low environmental impact housing. This seemingly basic provision gives families a place to stay warm, sleep, interact with each other as well as provide a place to shelter themselves from potential dangers in the environment including disease or from other people. Having a home has many benefits and owning one serves as a stepping stone to future success. Straw Bale buildings are cheap and effective use of renewable and local resources. Since straw is also a by-product which is commonly burned (REFERENCE HERE straw heating fuel), using it as a building material sequesters carbon. Bales also have agricultural purposes, as this is a potential source of food for animals. This can be during winter months or periods of drought. It is important to note that regardless of application, bales should be kept dry and free from insects as they will rot.

Engineering Principles

Construction

A prototype of the Hand Powered Hay and Leaf Baler was made using power tools listed in the table below. Figure 1a, shows a picture of the prototype that was built besides the original drawing and recommended layout. Changes were made to the original design for simplification and additional changes are reflected in the design depicted in Figure 1b.

-

Fig 1: Original

-

Fig 1a: Prototype

-

Fig 1b: Recommended

| Preferred Tools | Basic Tools |

|---|---|

| Circular Saw | Hammer |

| Drill | Hand Saw |

| Hammer | Measuring Tape |

| Measuring Tape | Working Bench/Clamp |

| Square | |

| Working Bench/Clamp |

Procedure

For all steps ensure to

|

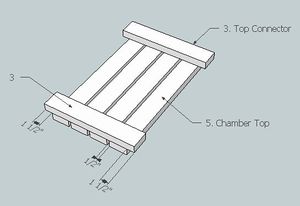

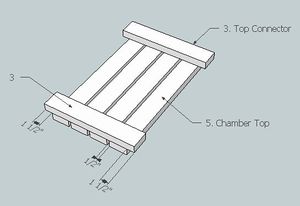

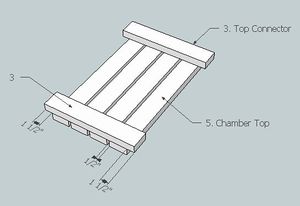

Step 1: Construct the chamber top. Lie the top part flat with a 1/2" Spacing between the pieces. The twine will go through these gaps. |  |

|

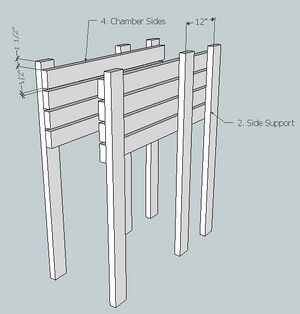

Step 2: Construct the two chamber sides. Piece 2, the side support, is on the opposite side for the second chamber side. Otherwise the two pieces are identical. There is also a 1/2" gap in between pieces. | thumb|Fig 1: Chamber Top Construction |

|

Step 3: Construct the chamber bottom similar to the top |  |

|

Step 4: Construct the chamber top |  |

Cost

Baling

Baling Procedure:

- Thread twine through gaps

- 2, 4 or 6 pieces can be used depending on material

- Thread twine only by door

- Cut enough twine to wrap around the entire bale, 6’ is recommended but make sure there is enough initially because adding additional twine after is difficult

- Close door and begin baling by pushing piston

- Use small amounts to ensure good compaction

- Remove insert when enough material has been baled

- Thread twine around bale and tie

- Open door

- Remove bale by pushing piston

Please see the following video for the baling procedure:

Please Note: This video shows the very first time I created a bale on the prototype. The entire process took under 20 minutes. With a helper and more practise this time will be greatly reduced so in a day enough bales could be made for a small home. The material being baled is also old and moist, both not useful properties. This was simply due to available materials.

Recommendations

As the video showed it is possible for an individual to operate this baler, however it is more efficient to have two. One person can load the material to be baled while the second operates the piston.

Further improvements to the baler would include making it mobile by adding wheels. These wheels would have to flip up during the baling procedure to ensure the contraption does not move. This would allow the baler to be moved around a field to additional material that needs to be bailed. Placing two wheels at the door end would allow this contraption to be pulled by human or preferably an animal. Since there is a large force being applied during the baling procedure, the entire structure is prone to moving in this direction. If this is a nuisance or hampers the bailing process dead weight can be added to the base of the structure which increases the frictional force resisting movement. Alternatively wedges or spikes that are attached to the structure would resist this motion as they act as anchors.

Bales expand once they have left the bailing chamber, if a specific bale size is required, experimentation or further work can be done to match chamber sizes with actual bale sizes. All bales made from non conventional methods, or mechanical balers, should undergo testing to assess their suitability for construction. Indicators of moisture content, dry density, wetting history, fibre length and material constitution are all necessary to determine usefulness as a building material. (REFERENCE HERE king)

Additional problems arise when using bales produced by machines like this for structural applications. The nature of the machine produces bales with some variability. Changes in bale density can be attributed to different piston packing force and the amount of material baled at a time. Hand tying in an enclosed area also introduces variability. Additional information on strawbale construction can be found [Straw bale construction| here] on appropedia, while the Wikibook on Straw bale construction is a slightly more comprehensive resource.

Alternative Technologies

There are alternative low cost baling contraptions, Unfortunately these were found after the prototype was built. Box baling is a simple method, with a self-explanatory method. A simple backwoods hay baler can be found on the CD3WD. A research study conducted by the UK Department for International Development as part of the Livestock Production Programme provided evidence for the benefits of box bailing forage for milk producers in Tanzania. There are devices like Clark Dorman’s Mobile pinestraw baler but this although significantly smaller and cheaper than combines it is still powered by a gasoline engine. The best alternative is used and developed by the Pakistan Straw Bale and Appropriate Building organization (PAKSBAB). PAKSBAB strives to apply appropriate building methods in this region of seismic activity to create earthquake resistant homes. For Straw Bale Fabrication a compression mould and human powered farm jack is used. This device is presumably more expensive than Larry McWilliams’ design because it is steel, but it is simpler, faster, requires less human effort, and reduces variability in bales.