Introduction

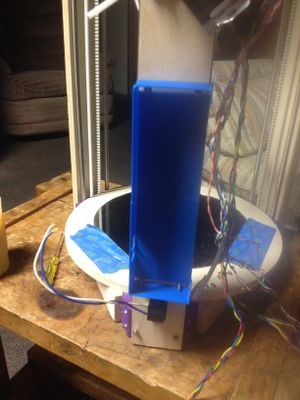

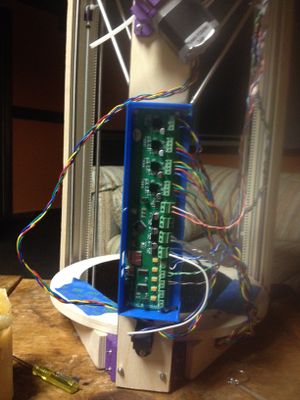

A detachable snap fit 3 d printed casing is created making the board protected from dust and physical contact. Instead of being one single casing the design of the casing is two parts, the reason behind it is while printing the single casing it exceeds the maximum printing radius of the existing Delta Model hence the exact dimension of the Melziboard casing cannot be printed. in this design there is an opening for the USB and the SD card slot and the other side is also has opening for the wires to be connected to the controller board. The detachable snap fit concept is for the easy accessibility of changing the wires on the board if needed.

Files

The SCAD and STL files are provided here to improvise on it if required [[1]]

Instruction

Download the .stl files from the link given above and slice it using the Cura software with fill density of 20% and printing temperature set at 220 degree Celsius. Save the gcode and use the Repetier host software to print out the component. The scad files are also provided if desired further modifications.

Tools

- Slide callipers.

- OpenScad software for designing the casing.

- Cura software for slicing.

- Repetier Host.

Bill of material

80 gms of 1.75mm PLA(polylactic acid) filament.