J.M.Pearce (talk | contribs) m (→OpenSCAD) |

J.M.Pearce (talk | contribs) m (→See also) |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 5: | Line 5: | ||

The concept and testing of the design was performed by [http://www.solarup.org/ SolarUP] | The concept and testing of the design was performed by [http://www.solarup.org/ SolarUP] | ||

The device is 100% 3-D printable and should be printed with a reasonable infill as this is a tool that will be used on a construction site. PLA is fine although other materials can be used. | |||

| Line 47: | Line 49: | ||

==See also== | ==See also== | ||

* [[Distributed manufacturing with 3-D printing: a case study of recreational vehicle solar photovoltaic mounting systems]] | * [[Distributed manufacturing with 3-D printing: a case study of recreational vehicle solar photovoltaic mounting systems]] | ||

* [[3-D Printing Solar Photovoltaic Racking in Developing World]] | |||

* [[Total U.S. cost evaluation of low-weight tension-based photovoltaic flat-roof mounted racking]] | * [[Total U.S. cost evaluation of low-weight tension-based photovoltaic flat-roof mounted racking]] | ||

* [[Design of Post-Consumer Modification of Standard Solar Modules to Form Large-Area Building-Integrated Photovoltaic Roof Slates]] | |||

{{Solar navbox}} | {{Solar navbox}} | ||

Revision as of 09:45, 19 November 2017

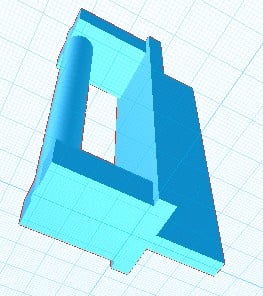

RepRap 3-D printing has already been shown to be a versatile tool for fabricating novel photovoltaic racking designs, however, they can also be useful for installing conventional PV modules on conventional racking. In order to ensure appropriate spacing and well oriented array these open-source photovoltaic spacers can be printed. The design has been created to be parametric in OpenSCAD so this design can be used for any conventional array.

The concept and testing of the design was performed by SolarUP

The device is 100% 3-D printable and should be printed with a reasonable infill as this is a tool that will be used on a construction site. PLA is fine although other materials can be used.

Source Code

OpenSCAD

Template:Statusboxtop Template:Status-design Template:Status-model Template:Status-prototype Template:Status-verified You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

All measurements in mm

- s=6.35; //1/4 inch spacing

- l=12.7; // 1/2 inch lip

- d=25.5; // 1 inch down

- x=127; //5 inch length

- $fn=100;

- union(){

- cube([l+l+s,s,x], center=true); //lip

- translate([0,-d/2-s/2,0])cube([s,d,x], center=true); //spacer

- translate([0,d+5,0])cylinder(r=s, h=x, center=true);// handle

- translate([0,d/1.5,d*2.25-.25])cube([d,1.5*d,d/2], center=true);// handle connector

- translate([0,d/1.5,-d*2.25+.25])cube([d,1.5*d,d/2], center=true);// handle connector

- }

See also

- Distributed manufacturing with 3-D printing: a case study of recreational vehicle solar photovoltaic mounting systems

- 3-D Printing Solar Photovoltaic Racking in Developing World

- Total U.S. cost evaluation of low-weight tension-based photovoltaic flat-roof mounted racking

- Design of Post-Consumer Modification of Standard Solar Modules to Form Large-Area Building-Integrated Photovoltaic Roof Slates