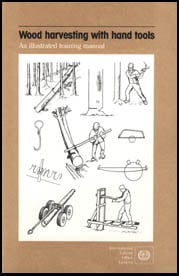

Basic Work and Maintenance Tools[edit | edit source]

HAND TOOLS FOR WOOD HARVESTING[edit | edit source]

The following tools are needed for efficient manual wood harvesting:

(1) Axe (weight between 0.8 and 1.5 kg)

(2) One-man bow saw (length approx. 1 m)

(3) Cross-cut saw (length usually 1.20-1.60 m)

(4) Machete

(5) Splitting hammer (weight about 2.5 kg)

(6) Wedges (for felling, cross-cutting and splitting)

(7) Turning hook

(8) Timber tong and timber pick

(9) Measuring stick or tape measure

(10) Caliper (to measure diameter)

(11) Debarking spade

More detailed information is given in: Equipment planning guide for vocational and technical training and education programmes: No. 17 - Forestry (Geneva, ILO, 1981).

FILES[edit | edit source]

The following types of file will commonly be used for maintaining forest tools. An effort has been made to keep these to the minimum to simplify stocking and distribution.

For cross-cut saws

Millsaw file, 20 cm, single cut, smooth (22.4 cuts per cm), flat with two round edges for sharpening cutter and raker teeth and for deepening small gullets (1).

A worn file of this sort can be used for jointing the saw and for lowering the raker.

Round file, 25 cm, constant diameter of 12.5 mm for deepening the big gullets between rakers (2).

For axes and other edged tools

Millsaw file, 25 cm, single cut, tapered or blunt for reshaping (3).

For tool handles

Wood rasps are used for shaping wooden handles (4). They must never be used on metal.

File handles

A file or rasp must never be used without a handle (5). The handle should have a length of 12 cm.

Care of files

When file or rasp teeth become clogged, they must be cleaned with a wire brush (file card) which must be kept clean and dry (6).

Files must never be allowed to become rusty, knocked or dropped and are best kept in a canvas holder when not in use.

GRINDSTONES AND WHETSTONES[edit | edit source]

For sharpening axes, debarking spades and other cutting tools, revolving grindstones operated by hand or foot are used for regular overhauls (1). They should have a minimum diameter of 50 cm and a minimum width of 10 cm, be made of sandstone or appropriate artificial material and be used with water. When not in use, the stone must be kept dry to prevent moisture softening the part of the stone under water. From time to time, the stone must be "dressed", that is, restored to its original circular shape.

Grindstones can easily be made locally from 20 litres of good quality cement and 50 litres of quartzitic sand with 1 mm or smaller particle size. The sand must be sieved (e.g. with mosquito netting), be washed and clean from clay or salt. In addition, an iron tube or rod is needed, about 60 cm length and 2 cm diameter with a nail welded to its middle.

The grindstone is made in a wooden mould (2) which is set up in a shady place. The mould is approximately 50 by 50 cm in size and 15 cm high. It consists of two parts (2a) which are placed on a board (2b) resting on two supports (2c).

Exactly in the centre of the mould the iron rod is placed, forming a perfect right angle with the mould and securely held in position by small boards nailed on the mould (3a).

After filling the mould with mortar and compacting it carefully, the grindstone is left to dry for about three days. Some sprinkling with water may be required to avoid too rapid drying.

After removing the grindstone from the mould, the stone is placed in a trestle with a piece of an old tyre fitted underneath as a water container (4a).

This type of grindstone is also handy for sharpening agricultural tools such as hoes and spades and should be available in any village.

In addition to grindstones, whetstones are necessary where edged tools are in use for frequently touching them up during the day. They are also used for finishing axes after grindstone work and saws and axes after filing. Whetstones with a coarse and a fine side, of pocket size (5 by 10 cm), are required (5).

SPLITTING HAMMER AND WEDGES[edit | edit source]

To avoid the saw blade getting caught in the saw cut (pinching), and to lift the tree into the intended direction of fall and for splitting wood, a splitting hammer (1) and wedges (2) are needed.

The splitting hammer should have a weight of about 2.5 kg and a straight handle about 90 cm long. For splitting, the edge should be kept sharp.

Wedges should preferably be made from aluminium alloys. They can also be made from hard wood. Steel wedges have the disadvantage of being very heavy and dangerous if splinters break off.

Three types of wedges are suggested for use:

|

Type 2a |

is a wedge commonly used for tree felling with a rather large surface and a narrow angle, opening up closed saw cuts even under very high pressure. |

|

Type 2b |

consists of a metal shoe and a wooden head which can be replaced after wear. Additionally, the wooden head is secured with a metal ring. This type of wedge has a wider angle and therefore opens the saw cut farther up than type 2a. In the absence of a metal shoe, the head of a wooden wedge may be fitted with an iron ring to reduce wear. |

|

Type 2c |

made from metal, is very convenient for cross-cutting and felling. It can be carried in the pocket and should be inserted in the saw cut as a measure of precaution before the saw cut closes. |

MAKING TOOL HANDLES[edit | edit source]

This simple construction made from wood and two pieces of an old tyre (1a) is very practical for holding a piece of wood when making a handle.

The vice is closed when the platform is down (1b). It opens when the platform is lifted (2a). The tool is firmly held between the two rubber pieces when the worker is standing on the platform. His elbow height should then correspond to the height of the opening of the vice.

Good tool handles, for instance of axes, hooks and hoes, are extremely important to ensure that work can be done conveniently and efficiently. The handle should fit the worker (size of hand, length of arm, height) and the size and weight of the tool. It should be made from suitable wood in order to last for a long time,

The vice can be used for other purposes as well, such as holding an axe during sharpening.