Saralarson (talk | contribs) |

Saralarson (talk | contribs) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 258: | Line 258: | ||

==References== | ==References== | ||

*Benedettelli, Daniele (2014). The LEGO Mindstorms EV3 Laboratory Build, Program, and Experiment with five wicked cool robots, | |||

William Polock, San Francisco. | |||

*Carbon-Core Corps. (2014). “Foam-Filled Structural Honeycombs.” Carbon Core Honeycomb Engineering, | |||

<http://www.carbon-core.com/honeycomb-foamfilled.htm> (March 27, 2016). | |||

*Griffiths, Alyn. (2014). “Benjamin Hubert's lightweight Ripple table is now strong enough to stand on.” Dezeen Magazine, | |||

<http://www.dezeen.com/2014/03/26/benjamin-hubert-launches-production-ready-version-of-the-ripple-table/> (March 27, 2016). | |||

*Heston, Tim. (October, 2014). “Reinventing the caster wheel.” The Fabricator | |||

<http://www.thefabricator.com/article/materialshandling/reinventing-the-caster-wheel> (March 27, 2016). | |||

*Hexcel Corporation. (2016). “Product Selector Guides.” Hexcel Resources, | |||

<http://www.hexcel.com/resources/selector-guides > (March 27, 2016). | |||

*High Tech Kids. (2009). ‘FLL Coaching Resources’. | |||

<http://www.hightechkids.org/fll-coaching-resources>(March 27, 2016). | |||

*High Tech Kids. (2009). ‘Coach’s Tournament Checklist’. | |||

<http://www.hightechkids.org/sites/default/files/CoachingLibrary/Coaches%27%20Tournament%20Checklist.pdf >(March 27, 2016). | |||

*Martinez, L., and Trevvett, D. (2012). ‘Robotic Firefighting Autonomous Technologies Report‘. Air Force Research Laboratory, 11(1), 3-12. | |||

*Noe, Rain. (June 2, 2014). “The Internal Honeycombs that make Tabletops Rigid, Lightweight, and Cheap.” Core77, | |||

<http://www.core77.com/posts/27035/The-Internal-Honeycombs-That-Make-Tabletops-Rigid-Lightweight-and-Cheap> (March 27, 2016). | |||

*Society of Robots. (2014). ‘Color Sensors Tutorial’. | |||

<http://www.societyofrobots.com/sensorscolor.shtml> (March 27, 2016). | |||

*Taylor, Jonathan.“SuGO Robot Classes (with rules).” (n.d.). SuGO Robot Classes (with rules), | |||

<http://www.sugobot.com/robot.htm> (Feb. 29, 2016). | |||

*Thomasnet. (March 28, 2016). “Evolution of the Hinge.” Thomasnet Hardware Guides | |||

<http://www.thomasnet.com/articles/hardware/hinge-evolution> (March 27, 2016). | |||

See [[Help:Footnotes]] for more. | See [[Help:Footnotes]] for more. | ||

{{Reflist}} | {{Reflist}} | ||

[[Category:Engr215 Introduction to Design]] | [[Category:Engr215 Introduction to Design]] | ||

Revision as of 18:09, 6 May 2016

Overview

The the Roto-Robo-SuGo-Super Table (RS Table) was designed for Zane Middle School and was constructed by Humboldt State University's Engineering 215 Introduction to Design Class, Project team GERL. This design is meant to serve the purpose of providing a competition table for Lego EV3 Mindstorm sumo robotics competitions. The RS Table is a 4' by 8' table which folds into a 4' by 4' square and rotates in order to be portable, incorporating a whiteboard surfacing so that students can customize their competition course. The RS Table features a locking mechanism integrated into the leg system which uses a circular "rod in hole" design allowing for students or teachers to lock the table into its large state at several degrees of inclination. With the main goals of safety and durability in mind, this table attempts to maximize the ability of the students to create their own competition environment or allow their teacher to assign interesting day-to-day tasks or activities for their students to accomplish.

Background

HSU's Spring 2016 Engineering 215, Introduction to Design, was commissioned by Zane Middle School to design and implement a table for the battling of EV3 Lego Mindstorm sumo robots. This table will drastically reduce the time and complexity required to setup an EV3 regulation competition table. Hopefully the ability to draw tracks and vary incline will make for an interesting change to the robotic battles fought between middle-schoolers.

Problem statement and criteria

| Criteria | Weight | Rational | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Safety | 10 | As this project is designed to be used by young children we thought it essential that it abide by the highest safety constraints we could design. | |||||||

| Durability | 9 | As this project is designed to be used by young children we thought it essential that it be as durable as physically possible as long as we didn't sacrifice safety for durability. | |||||||

| Portability | 8 | As this project needs to be able to move classroom to classroom and on occasion school to school, it was essential to the client that it be as portable as possible. | |||||||

| Ingenuity | 7 | Since this project was to be used by kids and it should be designed to be thought provoking, in order to help provide education (since this is and educational setting). | |||||||

| Cost | 6 | Since all of our funding is self generated it would be ideal if we could minimize cost without sacrificing quality in materials. Ideally this is incentive to use renewable or up-cycled sources. | |||||||

| Aesthetic | 4 | Since this project is in all essence a fancy table, we didn't consider appearance of primary concern or importance. | |||||||

Description of final project

Photos and descriptions. Use gallery. Include a how to use and maintain section. See the how to template below.

Costs

This table represents a rough estimate of the costs associated with the production of the Roto-Robo-Sugo-Super Table.

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 1 | Dry Erase Roll | Amazon.com | 15.99 | 15.99 |

| 8 | Hinges (3” x 3”) | ACE Hardware | 4.99 | 39.92 |

| 2 | Plywood (8’ x 4’ x 0.5”) | The Mill Yard | 40.00 | 80.00 |

| 1 | Frame and Metal Caster | Donation (Zane) | n/a | n/a |

| 1 | Dry Erase Sheets | Amazon.com | 6.36 | 6.36 |

| 2 | Sandpaper (5ct-60 Grit) | ACE Hardware | 4.99 | 9.98 |

| 1 | Rustoleum Dry Erase Paint | ACE Hardware | 23.99 | 23.99 |

| 1 | White Latex Primer | ACE Hardware | 17.99 | 17.99 |

| 3 | Sandpaper (5ct-100 Grit) | ACE Hardware | 2.49 | 7.47 |

| 2 | L Brackets (4ct-2") | ACE Hardware | 3.49 | 6.98 |

| 16 | 0.5" Flathead Screws | ACE Hardware | 0.09 | 1.44 |

| 4 | L Brackets (individual-2") | The Mill Yard | 0.89 | 3.56 |

| 3 | Pine Board (8' x 3.5" x 0.5") | The Mill Yard | 7.13 | 21.40 |

| 1 | Black Spray Paint | ACE Hardware | 4.31 | 4.31 |

| 13 | Vinyl Remnants by the sq-ft | Arcata Pro Floor | 1.00 | 13.00 |

| 1 | Rubber Cement and Brush | ACE Hardware | 13.28 | 13.28 |

| 3 | Saw Blades | ACE Hardware | 3.04 | 9.13 |

| 36 | Wood Screws | Donation | n/a | n/a |

| 10 | Steel Bolts | Donation | n/a | n/a |

| 10 | Steel Washers | Donation | n/a | n/a |

| 10 | Steel Nuts | Donation | n/a | n/a |

| 2 | Pipe Chunks | ACE Hardware | 20.00 | 40.00 |

| Total Cost | $314.80 | |||

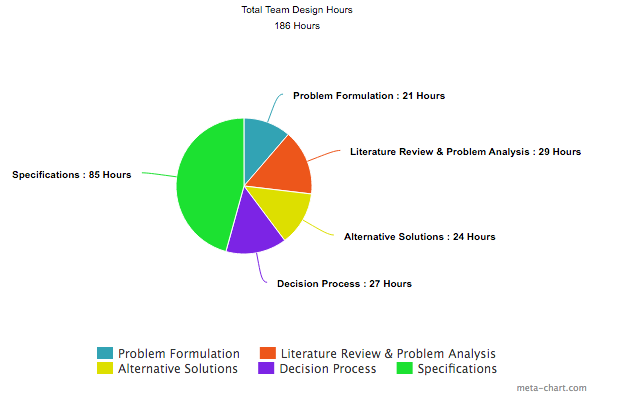

This pie chart represents a rough estimate of the hours spent designing and producing the RS Table.

Testing Results

Stress

- The RS Table was designed to support the weight of several lego robots and potentially ramps placed around it, all at one time. As such a stress test implemented by placing 30lb in varying locations around the tabletop while extended and locked out should be more than enough to ensure that during proper day-to-day as intended use, the RS Table will not collapse under the weight of its load.

Balance

- The RS Table was designed to freely rotate. As such it is vital to have an even balance about its rotational axis. In its unfolded form the RS Table does not rotate indicating that it is roughly balanced about the axle.

Our Build Process

Project Assembly

1. Assemble Frame

- 1a. Cut and weld preexisting frame base (portion with casters) to desired size (match width to desired width of table with space for locking mechanism and leeway for rotation).

- 1b. Assemble frame vertically (bolt together preexisting tv frame sections welding in scrap metal to match dimensions of base as necessary).

- 1c. Mount locking disc to crossbar (our mechanism for locking our table into a horizontal or variable inclination was a 3d-printed disc mounted to the table around the pipe with several holes drilled into it so that it rotates around the bar and is lockable whenever two of the holes are level).

- 1d. Mount Axel of rotation/A-frame crossbar (weld pipe to frame, we used a raised metal segment which we bolted to the tv frame).

2. Assemble Tabletop

- 2a. Cut Plywood to desired dimensions (our table was 4'x 8' x 0.5" with 5 segments; a central 4'x 4' segment with a 4' x 4" folding joint section and a 4' x 20" end-wing on either side)

- 2b. Hinge plywood at desired locations (we used 2 door hinges rated to hold 100lb loads on each cut of the plywood anchored by 0.5" wood screws).

3. Mount Tabletop

- 3a. Stabilize tabletop over frame (we used 2' x 4' beams to hold the table in place over the pipe/axle).

- 3b. Attach Tabletop to frame (we used pipe brackets to fit our tabletop to our pipe crossbar snugly anchored by 0.5" wood screws).

4. Make Table Extend

- 4a. Add Telescoping Bar to underside of table to cause hinged sections to lockout in flat manner (we used board brackets to mount 1' sections of 2" x 4" flat to the underside of the table). Boards slide to lock tabletop in a plane.

- 4b. Make sure to adjust table to zero inclination using a level. Tabletop will be difficult to adjust later (we had issues with tabletop alignment with our frame and ended up having to cut both down to rotate fully).

5. Add Rail to top of Table to meet competition standard

- 5a. Align rail with table edge (we used 8' x 3.5" x 0.75" pine board) and clamp in place.

- 5b. Prep rail (drill hole, countersink to account for screw head).

- 5c. Mount rail to pre-drilled holes (we used 2" wood screws and "L" brackets on end portions).

6. Apply Whiteboard Surface (we recommend the use of whiteboard paint)

- 6a. Prep surface (we originally attempted to use whiteboard sheets and gorilla glue to affix our surface, removal of these things lead to many hours of scraping with an exacto knife and sanding to remove remaining glue and adhesive).

- 6b. Prime surface (after sanding remove wood dust/debris and paint surface with white latex primer [2-3 coats recommended]).

- 6c. Apply whiteboard paint (mix activator and base paint and layer over primer as manufacturers instruct [2-3 coats recommended]).

7. Create folding mechanism

- 7a. Mount fixing mechanism to either end rail (we mounted two 45 lb rated eyehooks onto either end rail [also the rail with the bracketed reinforcements]).

- 7b. Add fixing connector (we used a double ended gatelatch to connect the two eyehooks so that when folded the end-wings were still connected).

8. Add Rotational Locking Mechanism

- 8a. Mount Handle to locking mechanism (we glued metal rods into a 3d printed plastic handle, metal rods are placed such that they go through the frame and into holes present in plastic disc [see step 1c] pinning disc [and consequentially table] in place at desired inclination)

- 8b. Place locking mechanism through holes drilled in frame and disc (this prevents the frame from rotating in relation to the disc [and tabletop]) (we drilled holes at 0, 15, and 90 degrees of inclination).

9. Reinforce frame

- 9a. Cut plywood siding to fit into metal frame across the base and walls.

- 9b. Bolt wood into place (we drilled through the frame and board in an attempt to bolt one to the other). Ideally wood siding should be square to the base and therefor frame and floor.

Discussion and next steps

The RS Table fulfilled the criteria and needs of the client representative. It is sturdy, lightweight and aesthetically pleasing. A few improvements would be to work on the construction earlier, considering the amount of time and labor needed to build the table.

References

- Benedettelli, Daniele (2014). The LEGO Mindstorms EV3 Laboratory Build, Program, and Experiment with five wicked cool robots,

William Polock, San Francisco.

- Carbon-Core Corps. (2014). “Foam-Filled Structural Honeycombs.” Carbon Core Honeycomb Engineering,

<http://www.carbon-core.com/honeycomb-foamfilled.htm> (March 27, 2016).

- Griffiths, Alyn. (2014). “Benjamin Hubert's lightweight Ripple table is now strong enough to stand on.” Dezeen Magazine,

<http://www.dezeen.com/2014/03/26/benjamin-hubert-launches-production-ready-version-of-the-ripple-table/> (March 27, 2016).

- Heston, Tim. (October, 2014). “Reinventing the caster wheel.” The Fabricator

<http://www.thefabricator.com/article/materialshandling/reinventing-the-caster-wheel> (March 27, 2016).

- Hexcel Corporation. (2016). “Product Selector Guides.” Hexcel Resources,

<http://www.hexcel.com/resources/selector-guides > (March 27, 2016).

- High Tech Kids. (2009). ‘FLL Coaching Resources’.

<http://www.hightechkids.org/fll-coaching-resources>(March 27, 2016).

- High Tech Kids. (2009). ‘Coach’s Tournament Checklist’.

<http://www.hightechkids.org/sites/default/files/CoachingLibrary/Coaches%27%20Tournament%20Checklist.pdf >(March 27, 2016).

- Martinez, L., and Trevvett, D. (2012). ‘Robotic Firefighting Autonomous Technologies Report‘. Air Force Research Laboratory, 11(1), 3-12.

- Noe, Rain. (June 2, 2014). “The Internal Honeycombs that make Tabletops Rigid, Lightweight, and Cheap.” Core77,

<http://www.core77.com/posts/27035/The-Internal-Honeycombs-That-Make-Tabletops-Rigid-Lightweight-and-Cheap> (March 27, 2016).

- Society of Robots. (2014). ‘Color Sensors Tutorial’.

<http://www.societyofrobots.com/sensorscolor.shtml> (March 27, 2016).

- Taylor, Jonathan.“SuGO Robot Classes (with rules).” (n.d.). SuGO Robot Classes (with rules),

<http://www.sugobot.com/robot.htm> (Feb. 29, 2016).

- Thomasnet. (March 28, 2016). “Evolution of the Hinge.” Thomasnet Hardware Guides

<http://www.thomasnet.com/articles/hardware/hinge-evolution> (March 27, 2016).

See Help:Footnotes for more. Template:Reflist