No edit summary |

|||

| Line 52: | Line 52: | ||

# Improve the overall experience of recycling wastes produced by the school's cafeteria | # Improve the overall experience of recycling wastes produced by the school's cafeteria | ||

== Description of Final | == Description of Final Design == | ||

The final design includes a restaurant grade stainless steel sink(with three sinks) for durability and ease of maintenance. The sink is connected to garden cart equipped with pneumatic wheels on an axle, providing the cart with an amazing turn radius with the wagon style steering. The sink is attached to the cart with steel bars to elevate the sink and for reinforcement. The sink has a custom made lid with fitted seal for each sink to ensure the lid is stationary during transportation. The lid has two convenient handles right outside of the replicated school logo(painted by hand by Erin McDannold. Underneath the sinks they are connected to a simple ABS drainage system....TO BE CONTINUED | |||

The | |||

=== Costs === | === Costs === | ||

| Line 198: | Line 187: | ||

== Contact details == | == Contact details == | ||

Revision as of 02:43, 4 May 2015

Abstract

Our team, Porta Possibilities, consists of four Humboldt State University Environmental Resources Engineering students. For our Engr215 Introduction to Design class, Merissa Coello, Brent Davis, Isaiah Duarte and Erin Mcdannold were given the opportunity to work with a local school, Zane Middle School, and improve their process of recycling. Our project was to improve the process that was currently in place of cleaning the recyclables from the school's cafeteria.

Background

Zane Middle School currently uses 5 gallon buckets and a simple cart to wash and transport recyclables throughout the facility. This project will focus on creating a new more portable and durable means of processing the wastes produced by the schools cafeteria.

Problem Statement and Criteria

The aim of this project is to create a more durable, transportable, and safe cart to enhance the recycling workflow for staff at Zane Middle School.

Table 1: Client Criteria Listed by Weight.

| Criteria | Weight |

|---|---|

| Portability | 10 |

| Durability | 10 |

| Stability | 9 |

| Safety | 9 |

| Ease of Cleaning | 7 |

| Upcycled | 6 |

| Aesthetics | 6 |

Project Goals

- Create a very durable cart to wash recyclables before recycling

- Improve ease of portability of the cart

- Enhance the workflow of the recycler

- Improve the overall experience of recycling wastes produced by the school's cafeteria

Description of Final Design

The final design includes a restaurant grade stainless steel sink(with three sinks) for durability and ease of maintenance. The sink is connected to garden cart equipped with pneumatic wheels on an axle, providing the cart with an amazing turn radius with the wagon style steering. The sink is attached to the cart with steel bars to elevate the sink and for reinforcement. The sink has a custom made lid with fitted seal for each sink to ensure the lid is stationary during transportation. The lid has two convenient handles right outside of the replicated school logo(painted by hand by Erin McDannold. Underneath the sinks they are connected to a simple ABS drainage system....TO BE CONTINUED

Costs

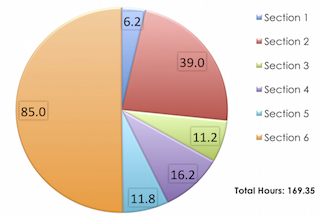

The amount of hours spent by Porta Possibilities for the SmartCart is shown in a pie chart demonstrated in Figure 2. The pie chart is split up into the 6 Sections of the document. Building hours are included in the Section 6. About 60 hours of the 85 hours in Section 6 are building hours. A total of 169 hours was spent on the SmartCart.

Figure 1(above): Time spent for the SmartCart.

All the materials used in building the SmartCart are recorded below in Table 1. Each item is accompanied by the amount used in the SmartCart, the retail cost, and the team cost. Multiple items were donated as reused materials and reduced the team cost by around $200. A total of $240.16 was spent by Porta Possibilities on the SmartCart, using $459.86 worth of materials.

Table 2: Material Cost

| Item | Quantity | Retail Cost | Our Cost |

|---|---|---|---|

| Sinks | 1 | 84.00 | Donated |

| Garden Wagon | 1 | 81.55 | 81.55 |

| Clip Tension | 1 | 3.99 | 3.99 |

| Paint (Cans) | 2 | 48.59 | 48.59 |

| Lid | 1 | 40.00 | Donated |

| Lid Handles | 2 | 9.98 | 9.98 |

| Edge Tubing (feet) | 8 | 1.52 | 1.52 |

| Lid Seal | 1 | 10.00 | 10.00 |

| Sink Insulation (Cans) | 2 | 13.98 | 13.98 |

| Drainage System | 1 | 70.55 | 70.55 |

| Steel Legs | 6 | 86.70 | Donated |

| Total Cost | 450.86 | 240.16 |

Results

- Finalized SmartCart

-

Figure 2: SmartCart being filled before use

-

Figure 3: Client transporting SmartCart over uneven pavement

-

Figure 4: Client sing SmartCart to clean recycables

-

Figure 5: SmartCart going through narrow cafeteria door way

-

Figure 6: SmartCart draining directly over sewer drain

How to Build

Required Materials:

- Restaurant grade sink

- Garden Cart (or other cart with pneumatic wheels on an axle)

- Steel corner bars (17" long) [6]

- Hoses (and appropriate sink attachments)

- Sink drain strainers

- Wooden Lid

- Rubber tubing (used as lid sealant)

- Plastic tubing (used as liner on sharp edges)

- Metal cylinders[3]

- Tension clip

- Paint

- ABS cement glue

- ABS piping with appropriate corners,valves, etc.

- 5 gallon bucket

- Tension Clip

Discussion and Next Steps

To be edited!

References

to be edited

Contact details

Isaiah Duarte - iad31@humboldt.edu Merissa Coello - mlc633@humboldt.edu Erin McDannold - emm614@humboldt.edu Brent Davis - bad67@humboldt.edu