Abstract

The purpose of this project is to create an edible railing that will be built on the WetLand barge. The Food on Deck team created a prototype and design for the railing that will be replicated in Philadelphia, Pennsylvania. Team Food on Deck has been brought together through the Humboldt State University class, Engineering 215 - Introduction to Design, taught by Lonny Grafman.

Background

In the summer of 2014, an island-based ecosystem and mobile habitat, also known as, Wetland will be launched on the Delaware River in Philadelphia. Wetland is founded by a New York City based artist named Mary Mattingly. Wetland will promote art, community, sustainable living, and environmental technology. The Wetland barge will provide a short-term home for artists, and a venue for educational events. One of the goals of Wetland is to showcase a model for interdependent living where resources are decentralized. This will be achieved by having a percentage of food being grown locally, having power generated by the sun, and the gathering, purification, and storage of water on site.

Objective and Criteria

The objective of the edible railing design is to create a safe perimeter for the barge that also serves as a food source. The railing will provide a percentage of the caloric intake for the three to five people that will be living on the barge. The railing will be constructed mainly of waste stream materials. The table below shows the criteria created by Team Food on Deck in collaboration with the WetLand creators. These criteria were weighted to help choose a design that best fit the client’s needs.

Criteria

| Criteria | Importance | Constraints |

|---|---|---|

| Safety | 10 | The railing must be built to Code of Federal Regulation specifications. |

| Durability | 9 | The railing must last a least three months. |

| Produce Production | 9 | The railing must provide at least 25% of the food for three people per day. |

| Ease of Replication | 9 | The design must be simple enough to be replicated by a high school graduate. |

| Cost | 8 | The model of the railing must not cost more than $100 per 8-foot section. |

| Environmental Justice | 7 | Building materials must be from the Humboldt County, CA waste stream. |

| Plant Locality | 6 | Plants must be able to grow in Philadelphia, Pennsylvania. |

| Ease of Maintenance | 6 | The railing must be designed so maintenance will only take 30 minutes a day for three people. |

| Level of Water Conservation | 5 | The railing must only use 10% of the provided desalinated water. |

| Educational Value | 4 | The literature must be accessible to a fourth grader |

| Ascetically Pleasing | 4 | The railing must be a mix of organic and synthetic material |

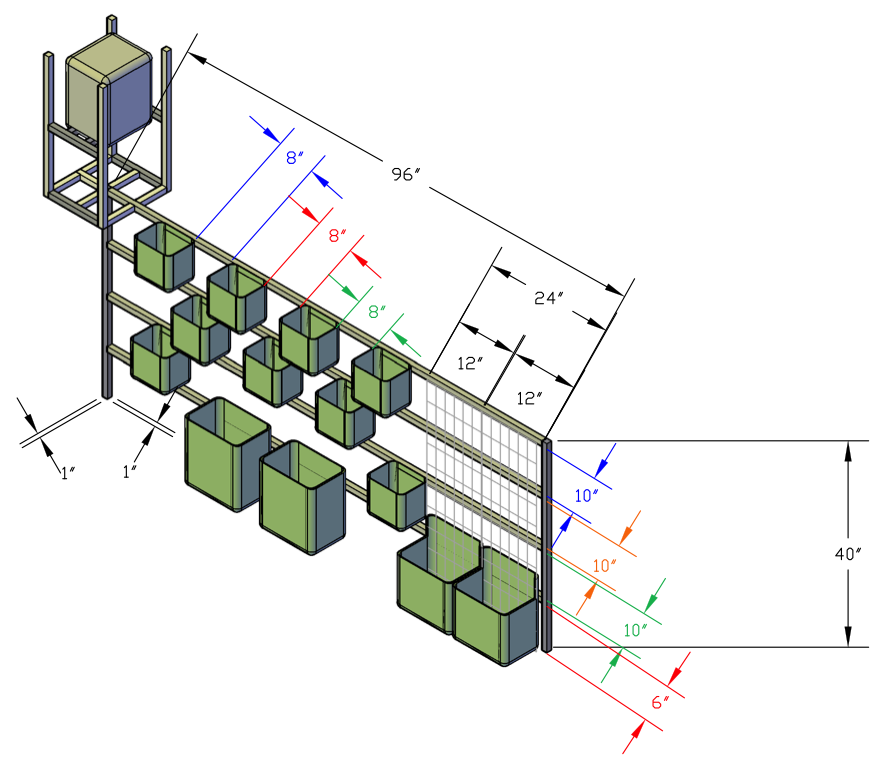

Description of Final Design

The following sections contain the specifications and details for one 8-foot section of the edible railing structure. When applied to the barge, this 8-foot template will be repeated in fifteen sections to cover the 140-foot perimeter. These sections include a description of the materials, costs, and implementation instructions.

Materials and Our Costs

The following table lists the materials used to build the attachments for the railing.

| Image | Description | Quantity per 8-foot Section | Quantity for Whole Railing | Price per Quantity | Price per 8-foot Section | Price for Whole Railing | Place Bought |

|---|---|---|---|---|---|---|---|

|

Small Plastic Nutrient Solution Containers | 10 | 135 | Donated | $0.00 | $0.00 | Water Planet |

|

Large Plastic Nutrient Solution Containers | 4 | 60 | Donated | $0.00 | $0.00 | Water Planet |

|

Zip Ties | 36 | 540 | $15.00/100 | $15.00 | $90.00 | Ace Hardware |

|

Sandpaper | 1 | 15 | $5/3 pack | $5.00 | $75.00 | Ace Hardware |

|

Trellis | 2 ft | 30 ft | Donated | $0.00 | $0.00 | Michael Otten |

|

1/2 Hose | 3.7 feet | 55.5 feet | $0.13/1 foot | $0.48 | $7.22 | Miller Farms Nursery |

|

1/4 Hose | 18.8 feet | 282 feet | $0.07/1 foot | $1.32 | $19.74 | Miller Farms Nursery |

|

1/2 90 Degree Connector | 1 | 15 | $1.00/1 | $1.00 | $15.00 | Miller Farms Nursery |

|

1/2 T Connector | 2 | 30 | $1.00/1 | $2.00 | $30.00 | Miller Farms Nursery |

|

Large Ball Valve with Hose Thread to Pipe Thread Converter and Valve to Pipe Thread Converter | 1 | 15 | $5.70/1 | $5.70 | $85.50 | Miller Farms Nursery |

|

Small Ball Valve | 3 | 45 | $2.60/1 | $7.80 | $117.00 | Miller Farms Nursery |

|

1/2 Connector with Thread | 3 | 45 | $2.00/1 | $6.00 | $90.00 | Miller Farms Nursery |

|

1/4 Converter with Thread | 3 | 45 | $0.10/1 | $0.30 | $4.50 | Miller Farms Nursery |

|

1/4 T Connectors | 13 | 195 | $0.10/1 | $1.30 | $4.50 | Miller Farms Nursery |

|

1/4 End Plugs | 3 | 45 | $0.10/1 | $0.30 | $4.50 | Miller Farms Nursery |

|

Weed Mat | 7.5 square feet | 112.5 square feet | $40/150 square feet | $2.00 | $30.00 | Miller Farms Nursery |

|

Volcanic Rock | 14 inches | 210 inches | Donated | $0.00 | $0.00 | A Fertile World |

|

Coconut Fiber | 1.5 cubic feet | 22.5 cubic feet | Donated | $0.00 | $0.00 | A Fertile World |

|

Fox Farm's Ocean Forest Potting Soil | 1.5 cubic feet | 22.5 cubic feet | $13.00/1.5 cubic feet | $13.00 | $260.00 | Ace Hardware |

| Total | $61.20 | $782.96 |

Plant Selection

The following table lists the recommended plants to be planted in each type of container on the edible railing.

| Plant | Container Type | Quantity of Seeds Per Container | Quantity of Transplants per Container |

|---|---|---|---|

| Lettuce | Small | 6-8 | N/A |

| Spinach | Small | 6-8 | N/A |

| Strawberries | Small | N/A | 1 |

| Radishes | Small | 10-12 | N/A |

| Carrots | Small | 10-12 | N/A |

| Potatoes | Large | 4 pieces | N/A |

| Peppers | Large | 1 to 5 | 1 |

| Tomatoes | Large | 1-5 | 1 |

| Beans | Trellis | 6 | 2-3 |

| Peas | Trellis | 6 | 2-3 |

| Cucumbers | 1-5 | 6 | 1 |

DIY

The following is a series of steps on how to build the attachments for an edible railing.

Small Plastic Containers

Large Plastic Containers

Trellis

Soil

Plants

The following table lists the recommended plants to be planted in each type of container and how they should be planted.

| Plant | Container Type | Planting Seeds | Planting Transplants |

|---|---|---|---|

| Lettuce | Small | Plant seeds 1/4 to 1/2 inch deep | N/A |

| Spinach | Small | Plant seeds 1/2 inch deep | N/A |

| Strawberries | Small | N/A | Plant deep enough to cover the roots with soil and so the bottom of the "crown" is level with the top of the soil |

| Radishes | Small | Plant seeds 1/4 to 1/2 inch deep | N/A |

| Carrots | Small | Plant seeds 1/4 to 1/2 inch deep | N/A |

| Potatoes | Large | Plant potato pieces 1 to 3 inches deep | N/A |

| Peppers | Large | Plant seeds 1/4 to 1/2 inches deep. | Plant deep enough so the top of the root ball is level with the top of the soil. |

| Tomatoes | Large | Plant seeds 1/4 to 1/2 inch deep. | Place in the soil covering the roots and stem up to the first set of leaves |

| Beans | Trellis | Plant seeds 1 inch deep | Plant just deep enough to cover the roots with soil. |

| Peas | Trellis | Plant seeds 1 to 1 and 1/2 inches deep | Plant just deep enough to cover the roots with soil. |

| Cucumbers | Trellis | Plant seeds 1/2 to 1 inch deep | Plant just deep enough to cover the roots with soil. |

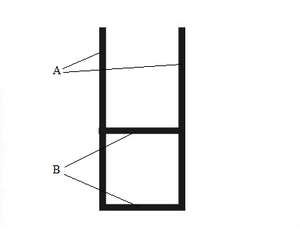

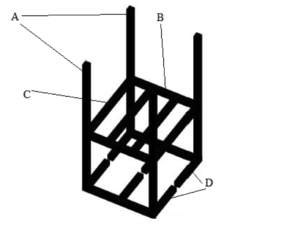

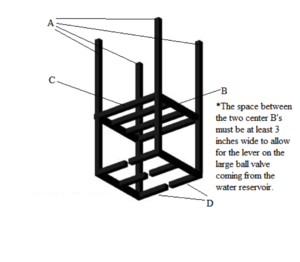

Reservoir Cage

| Step | Description |

|---|---|

| 1 | Cut 1-inch,square, steel conduit into: (A) four, 27-inch pieces; (B) four, 11-inch pieces; (C) six, 13-inch pieces; and (D) six, 6-inch pieces. |

| 2 | Weld each section together as shown in Figures 3 through 6. |

| 3 | Align the 1-inch space at the base of the water reservoir cage with the top crossbar of the barge railing and weld together. |

Irrigation System

Maintenance Guidelines

The maintenance of Life Support involves caring for the plants and checking that various components of the attachments are working properly. At least three people living on the barge are responsible for the maintenance of Life Support. The Table below lists the tasks to be performed to maintain Life Support, the frequency these tasks should be performed, and the cost in minutes to perform these tasks. The total time spent on maintenance per month is estimated to be 7 hours per person. The total time spent on maintenance per week is estimated to be 1 hour and 45 minutes per person. Full descriptions of the maintenance tasks are provides in the following sections.

| Task | Frequency | Cost (minutes) |

|---|---|---|

| Water plants | Once per day | 20 |

| Check that each plant is getting watered. | Twice per week | 15 |

| Check that all zip ties are as tight as possible. | Once per week | 15 |

| Remove any weeds and dead foliage from containers. | Once per week | 15 |

| Harvest Produce | Once per day | 10 |

| Replace any missing soil in the containers | Once per month | 30 |

Containers

Once per week, check that the zip ties connecting the containers to the railing are as tight as possible.

Irrigation System

The amount of water Life Support should receive is highly variable. The variables controlling the amount of water that should be supplied to each plant are climate conditions, season, type of plant, and location. Therefore the following guideline is a general recommendation for irrigating Life Support.

Once every other day, fill each reservoir. Before filling make sure the big ball valve and all three small ball valves are turned off (the tab is perpendicular to the pipe). Once the reservoir is filled, open the main ball valve. Open the first small ball valve. Leave this first valve open for approximately 3 minutes. After approximately 3 minutes, close the first small ball valve and open the second small ball valve. Leave the second valve open for approximately 3 minutes. After approximately 3 minutes close the second small ball valve and open the third small ball valve. Leave the third valve open for approximately 3 minutes. After approximately 3 minutes close the large ball valve. After approximately 3 minutes close the third small ball valve. Closing the large ball valve first allows any water stored in the tubing to drain out through the third line.

Check each container to make sure water is draining from each 0.25 inch T connector.

Plants

Once per week, or more often as necessary, remove any weeds and dead foliage from the containers.

Once per day, check each plant for ripe produce.

Results

The edible railing is successful in providing a safe food source for the people living on the WetLand barge.

Life Support was displayed outdoors for a period of two weeks and was watered in the technique described in the Maintenance Guidelines Section. The plants in the containers are growing and are anticipated to yield food as planned. All of the zip ties are tight and the containers have remained stable. All components of the irrigation system have operated properly.

Crop yields are highly variable, dependent upon the variety of plant selected, growing conditions, and the amount of maintenance each plant receives. For the recommended varieties of plants, estimated crop yield over the summer growing season, per plant, is as follows:

| Plant | Yield |

|---|---|

| Carrots | 6 to 10 carrots |

| Radishes | 6 to 12 radishes |

| Lettuce | 0.5 pounds to 1 pound |

| Spinach | 0.5 pounds to 1 pound |

| Potatoes | 1.5 pounds |

| Tomatoes | 0.75 pounds to 2 pounds |

| Peppers | 0.5 pounds |

| Beans | 0.3 pounds to 0.5 pounds |

| Peas | 0.3 pounds to 0.5 pounds |

| Cucumbers | 10-15 cucumbers |

| Strawberries | 0.5 pounds to 1 pound |

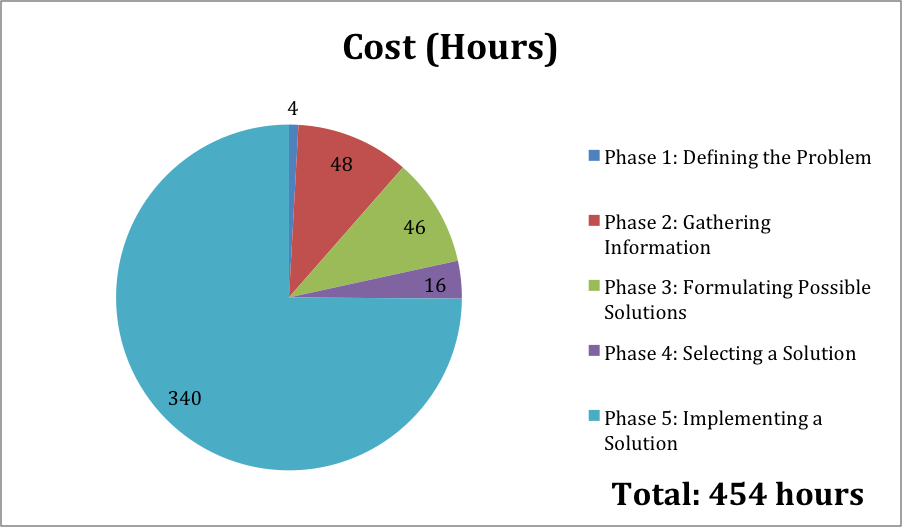

Design Costs

The design cost measured in hours, shown in the Figure below, displays the hours spent on each step of the design process. The estimated time to replicate one 8-foot section of Life Support is 8 hours for 4 people. This is based on the time Team Food On Deck projects that a high school graduate could replicate one 8 foot section using detailed instructions.