(Created page with "{{777}} ==Bike Fork Support == Project developed by Kyle Price Kprice (talk) 08:23, 8 December 2016 (PST) {{Statusboxtop}} {{status-desig...") |

m (Standardize wikitext) |

||

| (59 intermediate revisions by 10 users not shown) | |||

| Line 1: | Line 1: | ||

{{777 | {{777 notice}} | ||

[[File:Fork Support.jpg|thumb]] | |||

== | {{Project data | ||

| authors = User:Kprice | |||

| completed = 2016 | |||

| made = Yes | |||

| replicated = No | |||

| cost = USD 1.75 | |||

}} | |||

== Tools needed | A fork support is inserted in between the fork of a bike to help hold the suspension rigid during transportation the bike. | ||

# [[Athena Build Overview| MOST Delta RepRap]] or similar RepRap 3-D printer | |||

If the suspension is not held rigid during transportation, it will be constantly activated due to the vibrations from the vehicle. This leads to early failure of the suspension. To prevent any damage and provide a longer life of the suspension, a support is inserted so that the suspension can no longer be active during transportation. | |||

{{Notready| | |||

* insufficient stability in all x-y plane forces}} | |||

https://www.youmagine.com/designs/fork-support-for-bike | |||

== Bill of Materials == | |||

* PLA Filament, 1.75 mm Diameter | |||

== Tools needed == | |||

# [[Athena Build Overview|MOST Delta RepRap]] or similar RepRap 3-D printer | |||

# Utility Knife (Help to clean up edges and fit parts together) | # Utility Knife (Help to clean up edges and fit parts together) | ||

== Skills and | == Skills and knowledge needed == | ||

* A basic understanding of basic CAD software & 3D-printing | * A basic understanding of basic CAD software & 3D-printing | ||

== Technical Specifications and Assembly Instructions== | == Technical Specifications and Assembly Instructions == | ||

# Printer settings: Layer Height - 0.3 mm, Fill Density - 20%, Print Speed - 80 mm/s, Extruder Temp. - 210 degrees Celsius, Nozzle Size - 0.5 mm | # Printer settings: Layer Height - 0.3 mm, Fill Density - 20%, Print Speed - 80 mm/s, Extruder Temp. - 210 degrees Celsius, Nozzle Size - 0.5 mm | ||

# Print Times: Main Body - 1 hr. 11 min.; Attachments: 41 min. | # Print Times: Main Body - 1 hr. 11 min.; Attachments: 41 min. | ||

# Assembly Time: 5-10 minutes depending on print quality and meshing of parts | # Assembly Time: 5-10 minutes depending on print quality and meshing of parts | ||

# Including drawings or pictures of the device at stage of assembly at minimum. ( | # Including drawings or pictures of the device at stage of assembly at minimum. ([[Special:UploadWizard|Upload]]) | ||

=== Common Problems and Solutions === | |||

* None | * None | ||

== Cost savings== | == Cost savings == | ||

* If your solution is not a low cost one then it is not really appropriate. | * If your solution is not a low cost one then it is not really appropriate. | ||

# Total mass of parts = 0.066 kg; Cost of spool of PLA = $26.45/1 kg; Total cost to fabricate parts: $1.75 | # Total mass of parts = 0.066 kg; Cost of spool of PLA = $26.45/1 kg; Total cost to fabricate parts: $1.75 | ||

| Line 37: | Line 52: | ||

# Saved $13.24 (88%) | # Saved $13.24 (88%) | ||

==References== | == References == | ||

* None | |||

{{Page data | |||

| keywords = 3D printing, bicycle, bike fork support, plastic | |||

| sdg = SDG09 Industry innovation and infrastructure | |||

| published = 2016 | |||

| organizations = MTU, Michigan_Tech's_Open_Sustainability_Technology_Lab, MY4777 | |||

| license = CC-BY-SA-3.0 | |||

| language = en | |||

}} | |||

[[Category:3D printing]] | |||

[[Category:Plastic]] | |||

Latest revision as of 09:17, 29 March 2024

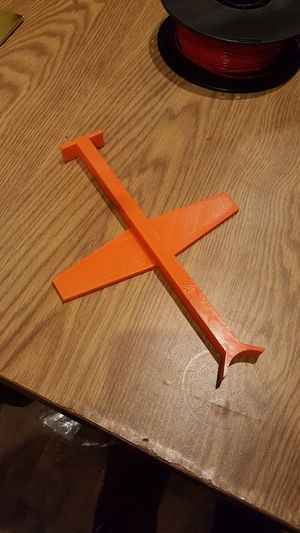

A fork support is inserted in between the fork of a bike to help hold the suspension rigid during transportation the bike.

If the suspension is not held rigid during transportation, it will be constantly activated due to the vibrations from the vehicle. This leads to early failure of the suspension. To prevent any damage and provide a longer life of the suspension, a support is inserted so that the suspension can no longer be active during transportation.

https://www.youmagine.com/designs/fork-support-for-bike

Bill of Materials[edit | edit source]

- PLA Filament, 1.75 mm Diameter

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

- Utility Knife (Help to clean up edges and fit parts together)

Skills and knowledge needed[edit | edit source]

- A basic understanding of basic CAD software & 3D-printing

Technical Specifications and Assembly Instructions[edit | edit source]

- Printer settings: Layer Height - 0.3 mm, Fill Density - 20%, Print Speed - 80 mm/s, Extruder Temp. - 210 degrees Celsius, Nozzle Size - 0.5 mm

- Print Times: Main Body - 1 hr. 11 min.; Attachments: 41 min.

- Assembly Time: 5-10 minutes depending on print quality and meshing of parts

- Including drawings or pictures of the device at stage of assembly at minimum. (Upload)

Common Problems and Solutions[edit | edit source]

- None

Cost savings[edit | edit source]

- If your solution is not a low cost one then it is not really appropriate.

- Total mass of parts = 0.066 kg; Cost of spool of PLA = $26.45/1 kg; Total cost to fabricate parts: $1.75

- Commercial equivalent cost: $14.99; http://www.motorcycle-superstore.com/48559/i/bikemaster-fork-support-for-tiedowns?SITEID=Google+SEARCH+NON-BRAND+Product+Level+Ads+-+Google+Shopping+Campaign&P_ID=1327457057&adpos=1o4&creative=93111299933&device=c&matchtype=&network=s&gclid=Cj0KEQiApqTCBRC-977Hi9Ov8pkBEiQA5B_ipS2TNlLoZ-8zdUu_BksAUxd_f7rGUYU9OFqNjXyuwxAaApXe8P8HAQ

- Saved $13.24 (88%)

References[edit | edit source]

- None