No edit summary |

No edit summary |

||

| Line 5: | Line 5: | ||

On the basis of the literature review, I had to compare all the commercialized solar cells ie c-Si, a-Si, Cadmium Telluride and CIGS. I had to find out the materials used in the cell for a particular design and in what quantities it was used. Knowing the materials used in the cells, it is very important to know the reserves available to us in the lithosphere of a particular material. For example crystalline silicon is used in monocrystalline and multicrystalline solar cells and it is well established that it is the second most abundantly available material in earth's crust.[http://www.webelements.com/silicon/geology.html Abundance of materials]<ref>http://www.webelements.com/silicon/geology.html</ref> Also in these designs, a critical factor is the thickness of the materials used i.e the more thicker the layer the more material is required. For this analysis, the cell design was considered by me in each of the above technologies. My effort here was to find out the designs which were most recent with the highest conversion efficiency available in each of the technologies so as to know the current state of the art in photovoltaic industry. | On the basis of the literature review, I had to compare all the commercialized solar cells ie c-Si, a-Si, Cadmium Telluride and CIGS. I had to find out the materials used in the cell for a particular design and in what quantities it was used. Knowing the materials used in the cells, it is very important to know the reserves available to us in the lithosphere of a particular material. For example crystalline silicon is used in monocrystalline and multicrystalline solar cells and it is well established that it is the second most abundantly available material in earth's crust.[http://www.webelements.com/silicon/geology.html Abundance of materials]<ref>http://www.webelements.com/silicon/geology.html</ref> Also in these designs, a critical factor is the thickness of the materials used i.e the more thicker the layer the more material is required. For this analysis, the cell design was considered by me in each of the above technologies. My effort here was to find out the designs which were most recent with the highest conversion efficiency available in each of the technologies so as to know the current state of the art in photovoltaic industry. | ||

==Crystalline Silicon== | |||

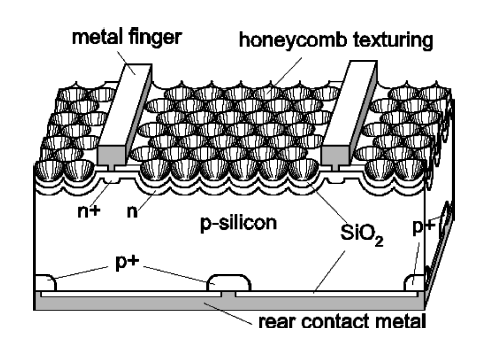

====[http://scitation.aip.org/docserver/fulltext/aip/journal/apl/73/14/1.122345.pdf?expires=1393292378&id=id&accname=424599&checksum=B5CAE94C671761B3BAF7C0D9013C425E 19.8% efficient ‘‘honeycomb’’ textured multicrystalline and 24.4% monocrystalline silicon solar cells]<ref> | ====[http://scitation.aip.org/docserver/fulltext/aip/journal/apl/73/14/1.122345.pdf?expires=1393292378&id=id&accname=424599&checksum=B5CAE94C671761B3BAF7C0D9013C425E 19.8% efficient ‘‘honeycomb’’ textured multicrystalline and 24.4% monocrystalline silicon solar cells]<ref> | ||

Zhao, Jianhua, Aihua Wang, Martin A. Green, and Francesca Ferrazza. “19.8% Efficient ‘honeycomb’ Textured Multicrystalline and 24.4% Monocrystalline Silicon Solar Cells.” Applied Physics Letters 73, no. 14 (October 5, 1998): 1991–1993. doi:10.1063/1.122345.</ref>==== | Zhao, Jianhua, Aihua Wang, Martin A. Green, and Francesca Ferrazza. “19.8% Efficient ‘honeycomb’ Textured Multicrystalline and 24.4% Monocrystalline Silicon Solar Cells.” Applied Physics Letters 73, no. 14 (October 5, 1998): 1991–1993. doi:10.1063/1.122345.</ref>==== | ||

| Line 10: | Line 11: | ||

[[File:C-Si.PNG]] | [[File:C-Si.PNG]] | ||

==Amorphous Silicon== | |||

====[http://www.sciencedirect.com/science/article/pii/S0040609005011685 Towards very low-cost mass production of thin-film silicon photovoltaic (PV) solar modules on glass]<ref>1.Shah, A., J. Meier, A. Buechel, U. Kroll, J. Steinhauser, F. Meillaud, H. Schade, and D. Dominé. “Towards Very Low-Cost Mass Production of Thin-Film Silicon Photovoltaic (PV) Solar Modules on Glass.” Thin Solid Films 502, no. 1–2 (April 28, 2006): 292–299. doi:10.1016/j.tsf.2005.07.299.</ref>==== | ====[http://www.sciencedirect.com/science/article/pii/S0040609005011685 Towards very low-cost mass production of thin-film silicon photovoltaic (PV) solar modules on glass]<ref>1.Shah, A., J. Meier, A. Buechel, U. Kroll, J. Steinhauser, F. Meillaud, H. Schade, and D. Dominé. “Towards Very Low-Cost Mass Production of Thin-Film Silicon Photovoltaic (PV) Solar Modules on Glass.” Thin Solid Films 502, no. 1–2 (April 28, 2006): 292–299. doi:10.1016/j.tsf.2005.07.299.</ref>==== | ||

====[http://www.researchgate.net/publication/237150668_High-efficiency_amorphous_silicon_devices_on_LPCVD-ZnO_TCO_prepared_in_industrial_KAI-M_RD_reactor HIGH-EFFICIENCY AMORPHOUS SILICON DEVICES ON LPCVD-ZNO TCO PREPARED IN INDUSTRIAL KAITM-M R&D REACTOR]<ref> | ====[http://www.researchgate.net/publication/237150668_High-efficiency_amorphous_silicon_devices_on_LPCVD-ZnO_TCO_prepared_in_industrial_KAI-M_RD_reactor HIGH-EFFICIENCY AMORPHOUS SILICON DEVICES ON LPCVD-ZNO TCO PREPARED IN INDUSTRIAL KAITM-M R&D REACTOR]<ref> | ||

S Benagli, D. Borrello. “High-Efficiency Amorphous Silicon Devices on LPCVD-ZnO TCO Prepared in Industrial KAI-M R&D Reactor.” 24th European Photovoltaic Solar Energy Conference, Hamburg (2009): 344–349.</ref>==== | S Benagli, D. Borrello. “High-Efficiency Amorphous Silicon Devices on LPCVD-ZnO TCO Prepared in Industrial KAI-M R&D Reactor.” 24th European Photovoltaic Solar Energy Conference, Hamburg (2009): 344–349.</ref>==== | ||

The model used in A. Shah et al has been taken as the reference | The above to literature references from which the model used in A. Shah et al has been taken as the reference solar cell for a-Si technology. Also a study done by S. Benagli et al presented results on optimal i-layer thickness for amorphous silicon solar cell using p-i-n type deposited on doped LPCVD-ZnO. A common feature to all thin film solar cell is that Transparent Conductive Oxide (TCO) is used as a transparent electrode on the side where the light enters the solar cell. Surface texturing help the TCO layer to achieve additional scattering of incoming light. The backreflector (typically Al or Ag) ensure light trapping within the solar cell. The i-layer thickness of the cell used was 250nm with ZnO type B which gave a recored efficiency of 10.09% confirmed by NREL. | ||

== References == | == References == | ||

Revision as of 07:29, 25 February 2014

As we all know that the photovoltaic industry is growing at an astonishing speed and by the end of 2012, 100 GW was already installed worldwide [1]. It has now been confirmed that solar photovoltaics is the third most important renewable energy source after hydro and wind power. With that being said there is a emerging necessity for us to analyse the solar cell materials that have been commercialized. This analysis could give us an estimated idea of the best material available in terms of availability, cost, material thickness, environmental hazards, cost for recycling and many mare. With this idea in mind, I worked on it, with the available literature. The consolidated data can be found here: Literature Review on Photovoltaic Materials

On the basis of the literature review, I had to compare all the commercialized solar cells ie c-Si, a-Si, Cadmium Telluride and CIGS. I had to find out the materials used in the cell for a particular design and in what quantities it was used. Knowing the materials used in the cells, it is very important to know the reserves available to us in the lithosphere of a particular material. For example crystalline silicon is used in monocrystalline and multicrystalline solar cells and it is well established that it is the second most abundantly available material in earth's crust.Abundance of materials[1] Also in these designs, a critical factor is the thickness of the materials used i.e the more thicker the layer the more material is required. For this analysis, the cell design was considered by me in each of the above technologies. My effort here was to find out the designs which were most recent with the highest conversion efficiency available in each of the technologies so as to know the current state of the art in photovoltaic industry.

Crystalline Silicon

19.8% efficient ‘‘honeycomb’’ textured multicrystalline and 24.4% monocrystalline silicon solar cells[2]

Zhao et al showed in this paper that "honeycomb" texturing help in increasing the efficiency. Especially the previous monocrystalline device which had the efficiency of 24% made use of "inverted pyramid" which are formed due to anisotropic etching to expost intersecting {111} crystal plane. There is also a very thin layer of SiO2 used so as to keep the recombination losses in oxide covered area to be low. Very narrow slots of the order of few microns are opens to make contacts of the finger contacts with the highly doped n type region while small opening are made for the back contact with the p type material. The reason for these narrow openings are to reduce contact resistance and recombination by suppressing minority carrier concentration near the contact. With the novel honeycomb texturing cascaded with the inverted pyradmids a cell efficiency of 24.4% was achieved successfully. With the cell design used the thickness of crystalline material used is 260 microns. The below figure shows the c-Si solar cell.

Amorphous Silicon

Towards very low-cost mass production of thin-film silicon photovoltaic (PV) solar modules on glass[3]

HIGH-EFFICIENCY AMORPHOUS SILICON DEVICES ON LPCVD-ZNO TCO PREPARED IN INDUSTRIAL KAITM-M R&D REACTOR[4]

The above to literature references from which the model used in A. Shah et al has been taken as the reference solar cell for a-Si technology. Also a study done by S. Benagli et al presented results on optimal i-layer thickness for amorphous silicon solar cell using p-i-n type deposited on doped LPCVD-ZnO. A common feature to all thin film solar cell is that Transparent Conductive Oxide (TCO) is used as a transparent electrode on the side where the light enters the solar cell. Surface texturing help the TCO layer to achieve additional scattering of incoming light. The backreflector (typically Al or Ag) ensure light trapping within the solar cell. The i-layer thickness of the cell used was 250nm with ZnO type B which gave a recored efficiency of 10.09% confirmed by NREL.

References

- ↑ http://www.webelements.com/silicon/geology.html

- ↑ Zhao, Jianhua, Aihua Wang, Martin A. Green, and Francesca Ferrazza. “19.8% Efficient ‘honeycomb’ Textured Multicrystalline and 24.4% Monocrystalline Silicon Solar Cells.” Applied Physics Letters 73, no. 14 (October 5, 1998): 1991–1993. doi:10.1063/1.122345.

- ↑ 1.Shah, A., J. Meier, A. Buechel, U. Kroll, J. Steinhauser, F. Meillaud, H. Schade, and D. Dominé. “Towards Very Low-Cost Mass Production of Thin-Film Silicon Photovoltaic (PV) Solar Modules on Glass.” Thin Solid Films 502, no. 1–2 (April 28, 2006): 292–299. doi:10.1016/j.tsf.2005.07.299.

- ↑ S Benagli, D. Borrello. “High-Efficiency Amorphous Silicon Devices on LPCVD-ZnO TCO Prepared in Industrial KAI-M R&D Reactor.” 24th European Photovoltaic Solar Energy Conference, Hamburg (2009): 344–349.

See also

Interwiki links

- Wikipedia:

- []

External links

- []

[[Category:]] [[Category:]]