(Created page with "== Literature Review == The purpose of this literature review is to present facts and researched information relating to the 2015 Botica/Ecoblock/Destacamento project taking p...") |

|||

| Line 129: | Line 129: | ||

=====2013 Las Malvinas Botica Popular===== | =====2013 Las Malvinas Botica Popular===== | ||

To test the initial plasters, it was decided to add a layer of paper outside of the chicken wire to allow the plaster to adhere to something other than the chicken wire and water bottles. The first layer of plaster was composed of “18 shovels-full of sand and 1/3 of a bag of cement.” The second layer was made to be thinner and again, less sand with the last layer <ref>Appropedia: Las Malvinas botica popular ecoladrillo. (2013) [Online] Available http://www.appropedia.org/Las_Malvinas_botica_popular_ecoladrillo_2013#Plaster, August 28, 2013</ref>. | To test the initial plasters, it was decided to add a layer of paper outside of the chicken wire to allow the plaster to adhere to something other than the chicken wire and water bottles. The first layer of plaster was composed of “18 shovels-full of sand and 1/3 of a bag of cement.” The second layer was made to be thinner and again, less sand with the last layer <ref>Appropedia: Las Malvinas botica popular ecoladrillo. (2013) [Online] Available http://www.appropedia.org/Las_Malvinas_botica_popular_ecoladrillo_2013#Plaster, August 28, 2013</ref>. | ||

==References== | |||

{{Reflist}} | |||

<nowiki>Make sure to include other relevant categories at the bottom, e.g. [[Category:Rainater]], [[Category:Upcycling]], etc.</nowiki> | |||

[[Category:Practivistas Dominicana Program]] | |||

Revision as of 01:44, 2 July 2015

Literature Review

The purpose of this literature review is to present facts and researched information relating to the 2015 Botica/Ecoblock/Destacamento project taking place in a community in the Dominican Republic called Las Malvinas. This information is to guide the decisions made upon different aspects of the designing and building of this assortment of projects, and to further guide those wanting to pursue any future projects related to green building.

Climate and Location

Las Malvinas, the community of interest, is located in the city of Santo Domingo, Dominican Republic. On average, Santo Domingo gets about 200 hours of sunlight each month, with temperatures - on average - ranging from about 19 degrees Celsius to around 32 degrees Celsius. The average monthly rainfall can get up to about 190 millimeters in one month, and is greatest from May to October. The average humidity of the area ranges generally between 80% and 90% [1] Santo Domingo is located in the tropical area of the Caribbean Sea and, as shown previously, has some variation through the seasons in average reports for rainfall and temperatures [2].

Flooring

How to Tutorials for application technique:

Best Concrete Flooring: Free Tutorial over tile

DIY Network: Installing a Concrete Floor

DIY Network: How to Install a Skim Coat for a Concrete Floor

DIY Network: How to Repair Holes in Concrete Floors

Images of Concrete Floors with staining designs

Installation

For installing a concrete floor, some considerations must be taken into consideration such as protecting the inner walls of the room(s) and also laying out the floor in a leveled fashion. Some research shows the steps for installation in the following manner:

- step 1: level the floor in which the cement will be poured upon with gravel and sand.

- step 2: forms should be made to keep the cement contained in the desired area (the walls of a room may be sufficient)

- step 3: pour the concrete mixture into the form and smooth/level with shovels

- step 4: leveling- a piece of ply wood can be dragged across surface to level, or hand towels can be used as well.

These are the recommendations to installing the floor in the botica popular [3]

Level Technique

Thomas from Ghetto2Garden's suggests after the concrete mixture is set, use a towel to even the layer. This technique is cost and labor efficient.

Limestone Cement Mix

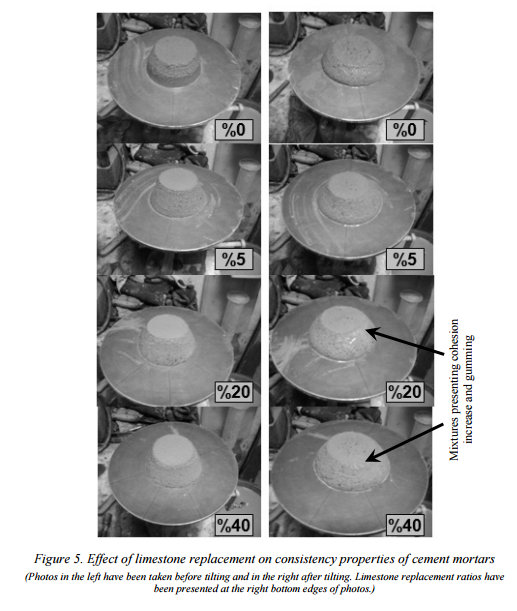

Limestone has been used as a filler when mixing cement. Adding limestone to cement mixes reduces the carbon footprint, saves energy by reducing clinker production in plants and is cost effective.[4] Students from la Universidad Politechnica Bucuresti have conducted experiments pertaining to the strength of cement as well as the resistance to water and the energy needed to mix the blends. The figure below shows an experiment in which students mixed different ratios of lime into the cement and then took a before and after picture of the mounds once they were tilted. The results show that with a 20% and 40% ratio of lime to cement that there was an evident increase in cohesion. However, the mixture requires more water with higher portions of lime and also becomes a bit harder to work with, depending on the cement. Therefore, pre-trial tests are highly recommended before deciding to use a certain ratio.[5]

Pozzolan

Pozzolans strengthen and seal concrete mixtures, and are efficient in reducing the cement content. A pozzolan is defined as "a siliceous or siliceous and aluminous material, which in itself possesses little or no cementing property, but will in a finely divided form--and in the presence of moisture-- chemically react with calcium hydroxide at ordinary temperatures to form compounds possessing cementitious properties." [6] Types of Pozzolan's available:

- Rice Hull Ash

- Fly Ash (from coal)

Gypsum

Gypsum; “is a soft grey mineral consisting of hydrated calcium sulphate, occurring chiefly in sedimentary deposits. It can be used to make plaster and fertilizers, and is used vastly in the construction industry for its strength, malleability and accessibility as a common mineral." [7] Gypsum can sometimes be found at a low cost because it is a byproduct of flue gas desulfurization (FGD), a process used by coal-fired electrical power plants to limit emissions of sulfur dioxide. [7] "This artisan method of manufacturing results in a finished product with exceptional binding capacity, making it suitable for use in outdoor environments." [8] As a soft material, Gypsum should be mixed in order to have cement properties. The ratio of water to gypsum in flooring is 0.8:1 in order to achieve a compressive strength of 6 MPa. [9] This ratio is not valuable in flooring until it is strengthened with a fiber.

Fiber

Potential

- Natural cork from cork Oak--lightens mixture. [9]

- Wool--provides considerable improvement to compression layers in terms of mechanical behaviour. "Wool provides significant improvement, particularly in terms of compression and elasticity. Furthermore, this material is 100% ecological and the cost is significantly lower than that of many artificial fibers." [9]

| Flooring Recipe | |||||

|---|---|---|---|---|---|

| Ingredient | Amount | Description | |||

| Concrete | Six Bags of Concrete. | ||||

| Sand | Aggregate in mixture. | ||||

| Pozzolan | Ash | ||||

| AS 600 | Quick Dry | ||||

Floor Staining

Stains for concrete come in two general categories: acid-based chemical stains and water-based acrylics. Most acid stains are a mixture of water, hydrochloric acid and acid-soluble metallic salts. They work by penetrating the surface and reacting chemically with the hydrated lime (calcium hydroxide) in the concrete. The acid in the stain lightly etches the surface, allowing the metallic salts to penetrate more easily. Once the stain reacts, it becomes a permanent part of the concrete and won't fade, chip off or peel away. The palette for acid-etch staining is generally limited to earthy tones, such as tans, browns, terra cottas and soft blue-greens.

Both types of stain can be applied to new or old concrete, both plain or integrally colored. They are especially effective for revitalizing dull, lackluster surfaces. Because stains must be able to soak into the concrete to achieve full color saturation, they shouldn't be applied to surfaces covered by anything that can inhibit stain penetration, such as dirt, grease, glues, coatings, curing membranes and sealers. [10]

Iron Sulfate

Iron sulfate, also known as ferrous sulfate, is a chemical compound the can be found in different plant fertilizers. It is most commonly used for “greening plants, specifically azaleas and citrus plants.”[11] Ferrous sulfate can also be used to stain concrete and plaster an amber color. The resulting color depends on the amount of layers applied; it begins as an orange color and darkens with the application of more layers. It is a natural stain and creates no waste. Ferrous sulfate can be reapplied after years of wear and tear. One must make sure not to apply too many coats because the concrete or plaster will no longer have room to absorb the chemical. One must also wear gloves as the chemical has been known to burn hands. Ventilation is also important as it will need help drying. Before being stained, the concrete must be properly cleaned and cleared of dust and other unwanted sediments. Once clean, the stainer can be applied using a clean mop or a paint roller.[12] A Humboldt state student used the following ratios to stain concrete floors at their school's appropriate technology center. The step-by-step description of their process can be found here

- 1 lb (16 oz) iron sulfate to 1 gallon (4 quarts) water ratio gives an orange stain.

- 2 lb iron sulfate to 1 gallon water + 1~2 cups coffee grounds gives a more saturated, darker look.

Plaster

About

Before delving into the specifics of plaster, it is beneficial to first know what plaster actually is. Plaster is “a material used to cover walls-- often both interior and exterior. It provides protection as well as texture and color”. There are many types of plasters, which will function better with different building materials, and some kinds of plasters are more environmentally sound and beneficial than others. For instance, earthen plasters- which include lime, gypsum, and clay are said to be "water resistant". [13]Below, different types of plaster will be presented and discussed.

Types

Lime and clay plaster types were mainly researched below as viable options; however, gypsum and cement mixtures were added to provide information about alternative plaster types that could be an option in building projects in general.

Clay

There are a variety of different clay-based plasters. Generally, they share similar components: about 20% clay, combined with sand, fiber, and any additional/optional ingredients. The clay is sticky- one of its sole purposes is to act as the binding agent which holds all of the ingredients together in a mixture. The sand not only provides strength, but it also prevents the plaster from cracking. The fiber ingredient, which could be "hair, straw, hemp, cattail fluff, [or] manure, adds reinforcement and strength to the structure as well. Additional ingredients could include flour paste (flour and water), prickly pear juice, lime, mica, or fine fiber." [14]

As mentioned previously, earthen plasters like clay are considered water resistant. The specific reason behind why clay plaster contains this property is because of its molecular make up. "According to soil scientists, clay consists of tiny flat plates. When moisture comes into contact with an earthen plaster, it binds to clay molecules and forms a bridge between them, causing the clay to expand. The binding of water molecules to clay also prevents water from migrating into the deeper layers: the plaster self seals."[13]

Although erosion may occur on the surface layers of an earthen plaster due to rain and change of temperature/weather, the deeper layers will still protect the wall through it all. [13]

Lime

Lime plaster is typically composed of lime and sand, and can be utilized for exterior or interior walls. Oftentimes, however, lime plaster is "usually applied on exterior walls where it provides excellent protection against the elements." [13] Lime differs from other earthen plasters in the fact that it takes a somewhat energy-intensive process to get the lime from its naturally occurring source, such as limestone. To create lime, a type of powder called quicklime (heated and crushed limestone) must be hydrated in a process called 'slaking'. This is basically the calcium oxide and magnesium oxide reacting with water to create the lime paste that is used in lime-based plasters. This process works best over a large time frame. If lime plaster dries too quickly, it can destroy it completely as an efficient plaster. While lime is caustic and can cause extreme damage upon contact with skin or inhalation, there are many advantages to using lime. Lime plasters are not only aesthetically pleasing, but they are also "vapor permeable." [13] This allows for the movement of water molecules through the material, protecting against moisture-related issues such as rot and mold.

It is also important to note that lime plaster requires a lime wash every 4-5 years. [15] The wash is needed to allow the building to breath. Though it is expensive, it improves the condition of the underlying plaster. Lime plaster is best composed of high calcium and low amounts of magnesium. When stored, it is vital to have one or two inches of water on top to prevent carbonation from exposure to the air - just like in the process of making the plaster - and must be fully slaked before the application may begin. A desirable technique is to apply lime plaster in one to three coats of varying composition, and using a mortar mixer rather than a cement mixer, to avoid the material sticking to the walls of the drum. The first two coats use one part lime putty and two to three parts sand, while the last coat has a higher ratio of one and a half to three parts sand. Sand within the plaster adds tensile strength, but it is important to be aware of the type of sand being used. Small grains can cause the plaster to crack or rub off because of the lack of strength. Additionally, uniformly sized particles cause cracking due to the ability of the material to shear along many edges. The best sand to use is one that has non-uniformly sized particles, as well as particles without smooth edges that may shear easily. It is important to note that beach sand must be cleaned prior to use because of the salt content. Salt has a tendency to move out from the plaster, which creates white patches on the surface. [13]

Gypsum

In addition to requiring heat to create the Gypsum plaster, it is also unsuitable for outdoors in humid environments. [15] Gypsum plaster is "a more delicate wall plaster. It is rather soft and water soluble, and is therefore typically reserved for interior work." [13]

Cement Stucco

In cement stucco, which is actually different from plaster, cement is the binding agent. This type of mixture is generally containing "cement, sand, and (frequently) lime." Cement stucco "wicks moisture into the walls and tends to crack," which can ultimately allow moisture into the building. [13] Concrete made of portland cement is usually composed of 15-20% portland cement- and for each pound of cement produced, one pound of carbon dioxide is released into the atmosphere, originating from the machines needed to produce it as well as the chemical reaction.[16]

Past Projects

Las Malvinas Schoolroom

With a coffin manufacturer in the area, obtaining sawdust is easy and should be considered as a viable option to make plaster. In 2012, the Ecoladrillo school room was constructed using “3 layers of sawdust plaster,” where the layers were composed of different ratios of cement and sawdust, as previously discussed. The final layer does not contain sawdust for possible aesthetic reasons, but a tint was added to eliminate a need to paint [17]. To make the plaster, 16 parts water were added to 1 part lime to dissolve the lime. Then, 16 parts sawdust were added and left to soak for one hour. According to the past project reviews, this mixture was then added to 12 parts sifted sand and mixed on a tarp on the ground. Then, 8 parts cement were added, and water as needed for the desired consistency [17]. The final layer of plaster should be applied after the second layer is mostly dry. Then, using a “long thin piece of wood to plane the wall, scrape off bulges and fill in holes with more plaster.” Apply the final layer and water as needed to create a smooth surface [17].

2013 Las Malvinas Botica Popular

To test the initial plasters, it was decided to add a layer of paper outside of the chicken wire to allow the plaster to adhere to something other than the chicken wire and water bottles. The first layer of plaster was composed of “18 shovels-full of sand and 1/3 of a bag of cement.” The second layer was made to be thinner and again, less sand with the last layer [18].

References

Make sure to include other relevant categories at the bottom, e.g. [[Category:Rainater]], [[Category:Upcycling]], etc.

- ↑ http://www.weather-and-climate.com/average-monthly-Rainfall-Temperature-Sunshine,Santo-Domingo,Dominican-Republic

- ↑ 2.0 2.1 http://geography.about.com/library/cia/blcdominican.htm

- ↑ http://www.doityourself.com/stry/how-to-lay-a-concrete-basement-floor-part-2

- ↑ https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&ved=0CB0QFjAA&url=https%3A%2F%2Fsites.udel.edu%2Fdct%2Ffiles%2F2014%2F06%2FPortland-Limestone-PCA-Show-2014-2-1e9k2wx.pptx&ei=FW9sVaGFKJf_yQTcjoOIDg&usg=AFQjCNFLP3jtu9a4pi9A65eswkc1wOFR6w&sig2=WzkPZg91z7h3QhnLgOft2w&bvm=bv.94455598,d.aWw&cad=rja

- ↑ http://www.imo.org.tr/resimler/dosya_ekler/db64e9634c94de4_ek.pdf?dergi=474

- ↑ http://ferrocement.net/ferro/files/pozzolans-uwe.html

- ↑ 7.0 7.1 http://minerals.usgs.gov/minerals/pubs/country/1994/9510094.pdf

- ↑ http://valentinacristini.blogs.upv.es/files/2014/02/10.11648.j.am_.20130204.11.pdf

- ↑ 9.0 9.1 9.2 http://valentinacristini.blogs.upv.es/files/2014/02/10.11648.j.am_.20130204.11.pdf

- ↑ http://www.concretenetwork.com/stained-concrete/

- ↑ http://www.appropedia.org/CCAT_natural_concrete_stain

- ↑ http://www.solarhaven.org/FerrousSulfateStaining.htm

- ↑ 13.0 13.1 13.2 13.3 13.4 13.5 13.6 13.7 Guelberth, Cedar, Chiras, Dan (2002). The Natural Plaster Book: Earth, Lime, and Gypsum Plasters for Natural Homes. New Society Publishers.

- ↑ Earthen Plaster. [Online] Available http://sustainablenations.org/Resources/NATURALPLASTERS.pdf

- ↑ 15.0 15.1 One Community [Online] Available http://www.onecommunityglobal.org/plaster/#types

- ↑ Gadja, John W., VanGeem, Martha G.(2001). A comparison of Six Environmental Impacts of Portland Cement Concrete and Asphalt Cement Concrete Pavements. Portland Cement Association.

- ↑ 17.0 17.1 17.2 Appropedia: Las Malvinas ecoladrillo schoolroom. (2013) [Online] Available http://www.appropedia.org/Las_Malvinas_ecoladrillo_schoolroom_2012/Literature_Review , June 24, 2013

- ↑ Appropedia: Las Malvinas botica popular ecoladrillo. (2013) [Online] Available http://www.appropedia.org/Las_Malvinas_botica_popular_ecoladrillo_2013#Plaster, August 28, 2013