Honey Forge

In the industrialized world in which we live, bees are constantly losing their natural habitat. To address this issue, although on a rather small scale, and to tickle my own fancy, I built a beehive i my senior year in high school. I took woods class twice before; the first time I made a keepsake box; the second I made a wooden bike (which is to be continued), and this year I decided to make a beehive. Due to my extensive work with my high school's CNC router last year on the bike, and my experience on the robotics team, I decided to make my beehive entirely using the CNC router.

The natural world has always interested me, the trees, the birds, the bees, and I thought I'd try my hand as an apiarist. What seemed like a simple project to begin with, the aptly named Honey Forge took a lot more thought and time than I initially imagined. There are many different types of beehives. You have your classic Langstroth hive, WBC, CDB, Beehaus, Top-Bar, Perone, and many other types of hives. All of which have different characteristics that affect the bees kept within. I chose the Warré hive. Instead of using the typical, one may say stereotypical, super-and-frames design seen in the widely known Langstroth hives, a Warré hive uses simple top bars for the bees to more naturally build their honey combs. The Warré beehive was the simplest and cheapest to make, and will be the easiest to maintain and harvest honey from in the future. As an amateurish bee keeper, I found these traits to be quite necessary. After doing research in Warré hives themselves, I found the optimal dimensions for the individual boxes and began the design process.

Materials

Because I was going to use the CNC Router, I needed sheet material to work with. A beehive must weather years and years of, well, weather, and to ensure my hive stands the test of time I used high-density-overlay, HDO, plywood instead of regular plywood. HDO is coated with a layer of waterproof plastic to reduce the harmful effects of rain, and more importantly, snow on the wood itself. Using normal wood, such as pine or maple, the beehive boxes often become warped due to the heat of the sun and the wetness of the rain, but the HDO should stand strong and straight for years. Made specifically for outdoor signs, I am not worried about anything warping.

The smooth plastic surface is designed to adhere well to paint, so in the end I coated the exterior of the hive in three coats of an acrylic latex paint typically used on the outside of houses. Holding all the interlocking parts together are stainless steel, 1/4" lag bolts. The materials I put into the Honey Forge are meant to ensure a long life of beekeeping, and are safe for the bees to inhabit.

Te total cost of this beehive was right around $100, which is half the price of a smaller Warré hive one can find selling on the internet.

CAD Design

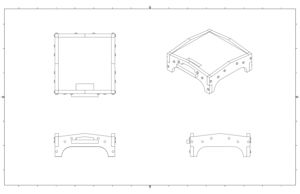

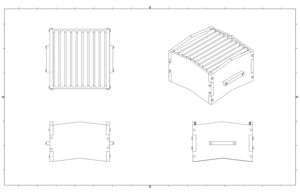

I used Autodesk Inventor to design the Honey Forge. A Warré beehive consists of boxes stacked on top of one another, a base with an entrance where the bees enter, a quilt layer that keeps the queen bee inside the hive, and a roof that protects the structure from the elements and helps regulate the hives temperature.

Usually Warré hive boxes are very standard rectangular prisms. All they need to do is stack on top of one another, and flat surfaces work rather well. The Honey Forge is a little different. Each box has fits perfectly into the next box with an original nesting design. Since both the front/back and side/side are reinforced with a slanted edge, the boxes nest more securely into each other both on the x and y axis. This decreases the chances of heavy winds, falling branches, and hungry bears from knocking over the Honey Forge. The base, quilt, and roof are all outfitted with these slants so the entire beehive is secure. Along with the separate components of the beehive fitting together nicely, each individual component fits together much like a puzzle. The corner joints of each part teeth joints reinforced with the 1/4" lag bolts.

Plans for the Future

You may need deeper level headings. Just keep adding equal signs to get that.

Costs

You may describe your costs here.

| header 1 | header 2 | header 3 |

|---|---|---|

| row 1, cell 1 | row 1, cell 2 | row 1, cell 3 |

| row 2, cell 1 | row 2, cell 2 | row 2, cell 3 |

See Help:Tables and Help:Table examples for more.

Discussion

Your discussion.

Next steps

The next steps.

Conclusions

Your conclusions.

References

Contact details

Add your contact information.