Available in other languages: /pt /tr

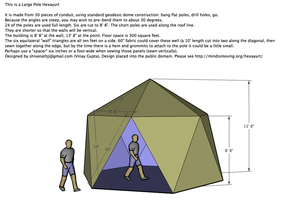

A large body of do-it-yourself hexayurt building information has been created by Vinay Gupta and average folk who made their own. Incidentally, a lot of the average folks attend the Burning Man Arts Festival, which is hosted in a windy, hot desert. Hexayurts made with rigid insulation are great in that environment. Whatever you're planning to build a hexayurt for, you can find all variety of hexayurt shapes and sizes, and instructions at Hexayurt playa. If you're interested in more about plywood hexayurts, see hexayurt.com.

Videos

Quicktime

Higher quality but we pay for the bandwidth. Please download these and save them locally if you want to view them frequently.

- http://files.howtolivewiki.com/tape_anchors.mov (7M) (How to make Tape Anchors - the tie-downs between the roof components and the guy lines on the larger hexayurts)

- http://files.howtolivewiki.com/6_foot_stretch_hexayurt assembly.web.mov (56M) (6' Stretch Hexayurt Assembly)

- http://files.howtolivewiki.com/8_foot_hexayurt_assembly_video.mov (39M) (8' Hexayurt Assembly)

Let's print a basic curriculum on each Hexayurt so that people can read useful information, relevant to their own health, comfort or survival, on the buildings we are going to send them. Furthermore, let's put the kid's material near the ground, and the more adult material further up the walls.

Sounds like a good idea?

While there is a lot of detail to be worked out, both of the materials we are considering for production units have printable surfaces, and large format printing on flat materials is a commonly solved problem. We can do this.

If we cover both the inside and the outside of the vertical walls we get the equivalent of 600 letter-sized pages on an 8' hexayurt, and 1200 pages on a 12' hexayurt. That's a lot of copy!

So what to print?

Wikipedia-type Content

We could do a lot worst than pick a few dozen of the more useful articles from Wikipedia and other open-source materials and reprint them. However, there are some severe problems with this approach:

- Wikipedia articles are long and boring

- They are not written as how-to guides

- They use a very large subset of the English language

- Some articles could be just plain wrong and misleading at the time they were taken and printed

However, as a very basic starting point, we could do worse.

Appropedia Content

The How tos from this web site would provide more targeted guides.

Repurpose Books

Another approach would be to try and get reuse rights to books like Where There Is No Doctor. However, we need a skilled team to know which books to obtain, and there may be unforeseen problems in the transition between the printed page and the printed wall. However, this approach offers the best access to high quality information in the immediate future.

One possible source of books, already scanned and ready to go, is the Appropriate Technology Library. Some of this content is already available here on Appropedia, such as that provided by CD3WD.

After reading through Where There Is No Doctor, it seems to me that wall/page space will become scarce quickly. There is a lot of information to get to the people, and printing just the basics of a topic won't get the job done, especially when it comes to medical situations with "If... then..." predicaments. This could lead to a need for lots of text on lots of walls.

We might configure the groupings of yurts in camps so that a certain number of yurts were purposed for more detailed information. In a grouping of 10 yurts, for example, 5 might be printed with medical info (ranging from very basic first aid to diagnosing and treating bacterial infections, etc), 3 might be printed with sanitation and camp/yurt maintenance recommendations, 1 might be for posting news about the camp and the after-math of the disaster, and the last 1 might be left available for people in the camps to leave messages for each other.

Of course this will also depend on the length of time a yurt camp is in use -- how much will a single family need to know about preventing heart-disease if they're in a camp for 2 months? Lots of long-term and obscure medical information could be omitted.

So how do we use camps as books? And which disaster situations require which kind of books? Is there a bank of basic educational materials in the public domain for Arabic, English, Mandarin, Hindi, French, Russian, Spanish?

Walls printed with text will effectively become "walk-through" or "live-in" books. Book/shelters. A catalog of some kind will be necessary to point people to nearby yurts with the information they need in a very quick and efficient manner.

Socio-cultural implications of this include changing conceptions of space and territory. Is a yurt the territory of the family who lives in it? How territorial will they be about the information printed on its walls? Is the potential for conflict here reason enough to develop a very basic 'curriculum' for each yurt, so that each structure is completely info-autonomous?

Custom Basic Educational Curriculum

The right approach is a basic educational curriculum targeted to each area. A BEC would provide introductory reading materials, so that those who already read English could teach others. It would have material for children and adults alike and focus on practical knowledge, explaining concepts like germ theory and crop rotation, thermodynamics in the context of drying food or making fires burn better, and so on.

As an example, consider explaining germ theory to a five year old child in a no-TV, no-Internet village.

You start from what they can see: pick an ant or another bug. Explain that we have large bodies, and the ant only has a tiny body. Explain that there are creatures which are as small compared to the ant as the ant is small compared to us. Explain that these creatures are so small we cannot see them. Explain that a person can get infested with these creatures, causing diseases. This explanation of germ theory seems like it would work more or less anywhere, for more or less anybody, and then concepts like basic sanitation practices can be taught on top of the accurate scientific model.

These basic scientific models are incredibly powerful. Consider that the Standard Days Method gives excellent birth control results with essentially no technological base. Any culture with counting could apply this technique, and there is no solid reason that a stone age culture could not have maintained the technologies to apply this method if they understood the principles giving rise to the practice.

A properly prepared knowledge packet could describe a wide range of tools and techniques, all of which can be implemented with field-available technologies, giving many of the benefits of 21st century science to people in essentially medieval living conditions. Of course, there are severe cultural problems related to magical thinking or cultural taboos which sabotage the success of some of these tools. Deep expertise and monitoring of results are required to ensure that this part of the project works.

Large Knowledgebase Distribution

There is no need to print the same material on every hexayurt. One approach would be to take a much, much larger knowledgebase and print a common set of materials on every yurt (instructions on hand washing, basic geography, whatever seems relevant) and then fill the remaining walls with parts of the larger corpus. Assuming 50% of the walls are devoted to printing parts of the larger knowledgebase, a 100,000 person camp has several million pages of text available to it. One would require a lot of replication to ensure that loss of a single building didn't make a bigger text useless - long books could span several buildings - and god alone knows how one could do indexing so you could find the building with the text you need on it... but if a sufficiently cheap and flexible printing solution can be found so we can put different material on each building, we could get enormous quantities of knowledge into the hands of those who need it most.

Language and translation issues

Most of the readily available material we have is in English. Most of the internet-connected writers who might participate in an open project speak English. So it is likely that a lot of the text will at least start in English. The BEC could be written in one of the reduced-vocabulary Englishes. One candidate is the Voice of America's Special English. This might also simplify translation and machine translation efforts.

Also, and this notion needs to be checked - my guess is that in most parts of the world, in a small camp, at least a few people will speak English well enough to teach people how to speak and read it. For short term deployment this is not going to help, but if people are going to be stuck in camps for generations, it seems like we could print as much material in the local languages as possible and the rest of the material in English and hope for the best. One approach would be to have machine-translated local language text running beside the English originals.

My guess is that a combination of these approaches could be tried at first and we could collect field data to see what was most useful.

Cultural Issues

What happens if something printed on a hexayurt is unacceptable for cultural reasons? The birth control instruction hexayurt winds up in a camp where people are angry and insulted at having improper materials sent to them.

I don't know how to avoid these issues. I don't even know where to begin to address them.

It may be that through mis-steps hexayurt camps are burned down by militant radicals that disapprove of some medical information printed on the walls. But in emergencies where the affected people have nothing left, how likely are they to react violently and destroy the only chance for their family's survival?

Cultural anthropologists should help decide what is printed and how it is printed, but even with their best guesses, some times things will fall through the cracks.

This page is for posting whatever speculations or brainstorms you have for the Hexayurt project, and asking any kind of weird question you think might help move the project along. It's a sort of sandbox. If strong ideas get generated here, refine them and post them in the appropriate wiki page (or start a new page for it).

There are further and boarder ideas on the To Do Page, which include infrastructure ideas as well as online education organization updates.

Flying Saucer/back rest Hexayurt. Make slight trapezoids of 4x8 wall panels of 8' Hexayurt. Trim narrow wedges from the ends of the wall pannels. Put narrow, long edge downward. Wall will then go up and out from ground, giving Hexayurt cool flying saucer appearance and also, good backrest angle to walls (though I know it's not recommended--maybe do this only with 2" thick panels or with wall reinforcement.

ABREF refugee shelters[1] at first look similar to Hexayurts. Both systems have a regular hexagonal perimeter of vertical sides. Both systems make all the roof pieces converge on a single highest point in the center. Perhaps mixing the best ideas from both systems will produce something better than either one?

Tape Eave/Drip Line Make a short eave of tape so that rain does not run down the outside of the wall. Add a 2-5" doubled over flap of tape around edge of roof panels that sticks out beyond the wall. At the very least, make tape awnings above windows and doors.

Insect-repellent panels. Organic & non-toxic. Cheap? How about a "wide spectrum" insect repellent to stave off fleas and other grim nasties too?

Kirkyan Hexayurts. This would take more money than... but if hexayurts weren't just "spimes" -- trackable in space and time, intelligent enough to push info back to the right radio signal --- but "kirkyans" --- spimes that can use environmental information to alter their form and configuration for greater efficiency and problem solving. Autopoeitic systems, environmental controls? Other uses? http://blog.rebang.com/?p=786

How do we get good Internet connection to these rural, poor camps after earthquakes? We can use the net to get very useful info quickly, and also use many apps on it as a 'virtual drive' to save info and come back to it later (like a Gmail accounts). Will the Gatr satellite sphere do this, or what else is needed?

Seed-impregnated hexacomb boards would make a ready to roll food source if the disaster were great enough that the camp would stand for 2+ months (depending on the crop). Just lay them out on the soil and use gray water. The hexacomb could come preloaded with soil. The roots would grow through the cardboard, into the topsoil.

All-season hexayurt As the structural isloation panel has two sides, one silver and one white, you could use the silver outside for hot seasons, and inside in winter. People inside would emit heat that would be reflected and saved, just as in an igloo. Also, any light used inside would reflect on the walls ; maybe it will make it possible to use very few energy for lighting : a bulb driven into a three-corner would spread much light.

http://web.archive.org/web/20160217165913/http://www.digital-librarian.com/yurts.html

Contacts

Email is the best way to contact us. Use BeautifulWorldCrew@HowToLiveWiki.Com.

Vinay's personal blog] has Hexayurt news in the "hexayurt" category.

For questions or ideas regarding the editing/updating of the Hexayurt Appropedia project, please contact User:Apepitone.

Project Discussion List

http://groups.google.com/group/hexayurt

Join the group at http://howtolivewiki.com/code/join_hexayurt_group.php

Available in other languages: /fi

When the Hexayurt is used in a hot climate it will get hot inside. The heat comes from four sources:

- Solar gains due to sunlight warming the fabric

- Fabric heat gains due to outside air being hotter than inside air

- Ventilation heat gains due to incoming air being hotter than the inside air.* Heat from people and equipment in the Hexayurt.

The Hexayurt has good insulation. It is highly reflective (when new and clean) so it reflects most of the solar energy. However it has very low thermal mass so that, with no air conditioning, it will heat up when the sun is out.

(This is theoretical. Can someone with more practical experience of using the Hexayurt please review).

Increasing the Thermal mass

If there is a significant temperature difference between day time and night time temperatures (i.e. desert areas) then increasing the thermal mass of the Hexayurt will slow down the speed with which the Hexayurt heats up during the day, reducing the temperature inside the yurt during morning and early afternoon. The simplest way to increase the thermal mass of the Hexayurt is to use the thermal mass of the ground under it. During the night maximise the exposed area of ground. Roll up any floor coverings, open all the vents. Sleep on camp beds raised off the ground so the night time cold air can circulate below the beds (or sleep outside). Wrap the floor coverings round you so they keep you warm but not the floor. Get the ground as cold as you can. As soon as the outside air temperature rises above the ground temperature (probably soon after dawn) close the vents and put back the floor coverings. In some cases the simplest way of doing this may be to move the entire Hexayurt at dawn and put it down on a nice cold bit of ground.

Controlling Ventilation heat gains

During the day limit the amount of hot outside air which comes into the Hexayurt. This will reduce the heat gains due to incoming air.

Bring the air in at low level so the cold ground can cool this incoming air so it doesn't heat the Hexayurt. This doesn't reduce the ventilation heat gains but it does improve conditions in the Hexayurt because the heat goes into the ground rather than warming the inside air and then using the ground coolth to cool the air.

The hottest air will accumulate at the highest point in the yurt so your exhaust vent should be higher up, on the downwind side of the yurt. As we have limited the ventilation to a minimum therefore we want to make sure the exhaust air takes away as much heat as possible. A Solar chimney can be used to help move the exhaust air and this will also help draw in supply air where there is no wind. (See also Cheap solar chimney)

Alternatively you can cover the ground with an insulating layer (sleeping bags, carpet etc.) to keep the ground cold during the day. You now have some nice cold ground to sit on when the Hexayurt seems hot; just pull back the floor covering and sit down. Sitting on the floor also means you are out of the bubble of hot air at the highest point in the Hexayurt. In this way the coolth stored in the ground is controlled and used for personal cooling rather than cooling the entire yurt.

Reduce the solar heat gains

Any shading which reduces the amount of sunlight hitting the Hexayurt will reduce the solar heat gains. Shading in the morning will keep out heat which would otherwise be in the Hexayurt all day. Putting the Hexayurt under trees or next to a hill can give this effect. A large banner if properly sited can cast a shadow which reduces the solar gains.

Keeping the Hexayurt shiny will mean more sunlight is reflected away and less is absorbed by the roof.

Reduce Fabric gains

Even if sunlight impinging on the Hexayurt is reduced the Hexayurt will still heat up till the outside surface is close to the temperature of the outside air and if this is hotter than the inside air then heat will leak through into the Hexayurt and heat the inside air adjacent to the walls and roof. Lining the walls and roof with drapes will keep this hot air from getting into the rest of the Hexayurt. These need to be light due to the limited load bearing capacity of the Hexayurt

Reduce equipment heat gains

As the Hexayurt is so well insulated any heat in the yurt will stay inside so be wary of operating any machinery in the Hexayurt during the day. Any heat given off will serve to heat the Hexayurt. Any computers should be laptops, not towers. Limit the amount of sunlight you let into the yurt - a lumen of light from an LED or a fluorescent lamp gives off fewer watts of heat than a lumen of sunlight. Any fridge or cooling unit should be set up so it's heat rejection (the pipe coil on the back) is to outside the yurt. If you do not do this then a fridge or cooling unit will just heat up the yurt.

SleepBreeze personal cooler

The SleepBreeze personal cooler is an intersesting device. Basically it is a small fan and which blows air into a long sock. The air leaks out of the sock creating a gentle breeze. If you put one on the bed beside you then it can create a current of air over you which may help you sleep.

Humidity

The paragraphs above consider the temperature. When considering the conditions inside the Hexayurt we also need to consider the humidity. If the Hexayurt is naturally ventilated then the moisture content of the air inside the tent (in grams of H2O per kG of air) will be pretty much the same inside and outside. If there are a lot of people or kettles boiling in the Hexayurt then moisture content will be higher inside. Moisture content is however not the same as relative humidity. When we talk of humidity we are usually talking about the relative humidity which is the moisture content as a percentage of the maximum moisture content at that temperature.

When we cool air then eventually the air gets so cold that water starts to condense out of the air as condensate or dew. That temperature is the Dew point and it is a measure of the moisture content of the air; the point at which the relative humidity is 100%. If we have air with a dew point of 10C then it's relative humidity will be 100% at 10C, 80% at 14C, 60% at 18C, 40% at 25C. The dew point of this air will still be 10C because the moisture content has not changed. The Psychrometric chart shows rH relative to temperature and dew point.

Cooling air will not affect the moisture content but it will increase the relative humidity. The only way to reduce the moisture content is to cool the air to below the dew point and make the moisture condense out. Then keep this drier air from mixing with the more humid outside air.

Evaporative cooling

See the article on Evaporative Cooling

If the humidity of the air is less than 100% then water will evaporate. It takes heat to turn liquid water into vapour so the remaining water will cool as it gives up heat to the vapour. In principal this will continue until the water temperature has dropped to the dew point of the air. This is how our bodies regulate their heat - by sweating and then, as the sweat evaporates, it takes this heat away, helping the body stay cool. This is why standing in a breeze feels so cooling - evaporation works much better if there is a constant stream of dry air on our skin. If the air is still we get a thin boundary layer of air which as been saturated in our evaporated sweat and this layer can't absorb any more moisture.

If, instead of a bucket of water we were to spray the water into the air then the water will evaporate in the air. As the water evaporates it cools until all of the spray droplets have evaporated and the air has cooled and the moisture content of the air has increased. This is known as Adiabatic cooling. Energy in the form of heat in the air is converted into energy in the form of water vapour in the air but the total enthalpy of the air doesn't change. The drier the air is the more effective evaporative cooling will be. From the psychrometric chart we can see that air with a dew point of 15C and a temperature of 30C (i.e. rH = 40%) can theoretically be cooled to 20C if we increase the rH to 100%. If we increase the rH to 70% then this will can cool the air to 24C.

In a Hexayurt possibilities include:

- Spraying the water into the air

- Spraying the water onto peoples skin or clothes so the cooling effect is directly applied to the body

- Put a net curtain in front of the incoming air stream with the bottom of the curtain in a trough of water so the water wicks up into the curtain as it evaporates off.

Note that the effect of any of these options will be to increase the relative humidity and the moisture content of the air.

See also Burning Man Evaporative Cooler

A hexayurt-like design pattern made from metal conduit.

Fully Funded Project Plan (pdf)

We estimate that it would take about $110,000 to get the Hexayurt project done to the point where it could be tested in the field with people's lives depending on it. That budget would fund a team of two full timers building units, living in them, coordinating both hired consultants and volunteers, to produce a completely tested, finished, documented hexayurt and infrastructure package.

All intellectual property we create or control would be released under an open license, most likely fully public domain, and available for any commercial entity to produce or for organizations like non-profits to source for themselves. Some of our vendors may also choose to open their designs, but if they do not, those products will be recommended and we will do our best to link to information about open alternatives where they exist. Not everything can be provided on an open IP basis, however (for example, LEDs still have many patents, as do NIMH batteries).

However, even $10-20,000 gets us a lot of forward progress - a long term (3-6 month) test of one or two units in one or two climates. A lot more investment would be required before we were ready to use hexayurts in a disaster or refugee situation, but it would at least prove several key concepts.

If you are interested in supporting further development of this project, please contact us. Small, non-institutional donations (yes, your $50 can help!) are welcome as well.

Available in other languages: /fi

Gas will be used for cooking and heating applications.

Substitute for natural gas infrastructure (pipes and plants, trucked in propane) with:

Wood gasification stoves use sophisticated combustion engineering realized in the form of cheap sheet metal forced air stoves. Two AA cells power ten hours of cooking, with a peak heat output of 3KW from finger-sized twigs. Wood gasification stoves are low emissions because the fuel is burned either as gas (volatiles boiled out of the fuel) in super-abundant oxygen blown in by the fan, or as charcoal similarly burned in abundant oxygen.

Wood gasification stoves are rated as ten times more efficient than open fires, and three times more efficient than high-efficiency clay stoves.

Financial model:

- $20 or less per stove, one per household

Fuel costs are low, perhaps $1 per household per week or less. In a small and well insulated shelter or home, even this relatively modest heating device should provide most or all of the heat required -- even through the winter -- in most climates.

This page is about making the hexayurts information rich at several levels.

The basic strategy is to use a variety of media and formats to make information about the hexayurts and about survival and recovery available to affected people.

I. Print useful text on the panels.

II. When possible and desirable, print the panels with 2D bar codes or embedded RFID tags.

III. Arrangement of hexayurts into patterns readable from a distance or from an aerial view.

Issues arising from this strategy

I.

- In what language or dialect to you print the panel text?

- Should there be standing "books" waiting in warehouses, ready for shipment? If so, what is the most useful text to put on the most generic panel?

- First aid. Hygiene.

- Use pictographs to illustrate assembly process.

II.

- Expense is not major issue for RFIDs compared to other material costs. Under 1 USD per tag for passive tags.

- Security is even more important. RFIDs are hackable, and they can be used as a platform for spreading viruses or malware to other systems and databases (citation needed). Could pirates exploit this by using the info on the RFIDs for ill purposes? Yes. Is this worth worrying about, or is it worth preventing RFID use? Probably not. Benefits outweigh risks.

- Passive RFID is just relaying an identifier number. This could be used to flag source material.

III.

- Think Semacode (link) or Kaywa's QR Code (link). Not human-eye readable, but from a distance ketai cams can discern massive amounts of information by the configuration of black and white pixels. What could physical camp configs tell relief workers?

- physical camp configuration would require that the entire camp layout be managed by planners able to arrange the camp in particular order adding needless complication to getting shelter assembled on the ground.

- Think "eye in the sky". If other communication channels fail, the arrangement of yurts in the camp could communicate information to aerial cams as 2-D barcodes. This is a built-in level of security. Only 2 guys know that if the water-pump pup hexayurt is moved adjacent to the 6th wall of the med supplies yurt it generates a message to equipped cams that reads: "Taliban is moving poppies thru this camp."

- integration of covert communication would only serve to encourage hostile parties to destroy the infrastructure, and again require the movement of individual units in a carefully planed fashion in order to communicate.

Gallery

-

Aerial view of camp works like QR code.

-

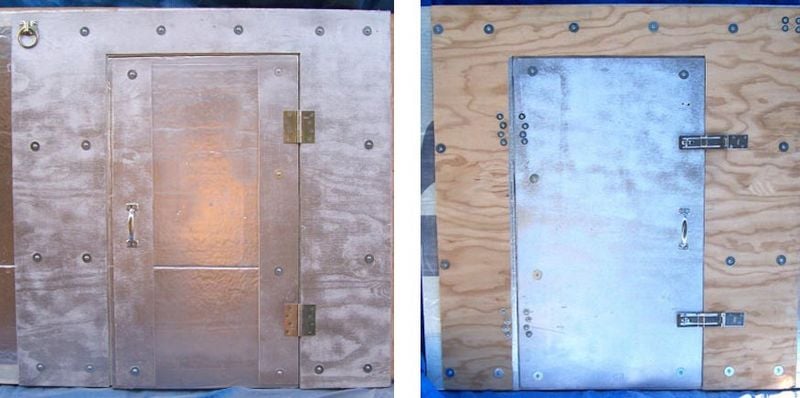

This is a standard printed panel. It incorporates at least 2 points from the strategy: eye readable; machine readable through barcodes and RFID.

-

Sketch of kirkyan concept for hexayurt camps. Kirkyan hexayurts are virtual/real and changes in one environment causes the kirkyan to respond by changing itself as needed in the other.

-

RFIDs can link database information to uniquely identified objects. Efficient way to track medicines and supplies, and to then deliver the medicines to the proper patient.

-

People and hexayurts (with attached property, infrastructure, medicines, etc.) are linked with RFID and QR tags. This is a real aid in managing thousands of people after a disaster.

Hexayurt Object Database

Hexayurt panels, wherever possible, have a 2D barcode or RFID tag attached to each one. The same thing should be done, wherever possible, with stoves and other items.

The goal is that items can be found in the field, their GUID extracted from the barcode or tag, and then that information checked against the database to show the history of this particular object.

This allows for long term lateral studies of several kinds.

The first is object endurance: which items, from which manufacturers, lasted? Which ones are commonly used, vs. being left in the scrap heap. What *worked.*

It's important that tags are per object, and not per class. While 50 stoves may appear to be identical, and were purchased at the same time, lo! the supplier changed sheet metal suppliers half way through the run, and the ones from Batch B rust to uselessness in 4 years, but the others last for 25.

Henry Ford allegedly had staff crawl around in junk yards to see what pieces of the Ford never failed, and were in good useful condition after the rest of the car had died. Those pieces where then allegedly manufactured to lower specifications to save money without impacting vehicle life.

We need a similar approach: understand exactly what got made where, and how it performed in the field.

Additionally, lateral tracking of object movement becomes very important: the stoves dropped in a camp in the Sudan show up in Tanzania, and the locals love them much more than their regular stoves because the Sudanese stoves handle fuel a little differently, for instance. Well, knowing which items are being traded and how they circulate tells us about local preferences, and also about appropriate technology transfer routes.

For this to work, we need a "Stamper" service like https://www.thinglink.org/ - a service which issues GUID numbers for arts and crafts projects.

Vinay

Available in other languages: /tr

Take your house. Cut off the water, the electrical power, the natural gas, and the sewage lines. That's what a hexayurt is like without the infrastructure systems which need to be shipped with it as an integral part of the housing system.

It helps to think of your own house as you go through this: replace each system in your mind with the one from the outline below. Remember that the systems are huge: the electrical system isn't the wires in your house, or strung along the poles outside. It's the power station, the huge transformers, the high voltage long distance lines, and the aspects of the government which regulate the grid, as well as the banking infrastructure to keep all that stuff paid for.

To provide services in the traditional way in the developing world is extremely difficult. Even though some of these line items look expensive, it's important to remember that they are very, very cheap compared to their first world equivalent service infrastructures!

Development Status

Together these systems appear to combine to provide the majority of the services provided by the pipe-and-wire infrastructure harness of a first world household for a cost in the neighbourhood of $200 per household for a relatively plush system, and a minimalist installation could be under $100 per household or less with more resource sharing.

The vast majority of the products required to put together this package are common, off-the-shelf items. However, very few if any of them have gone through the rigours of deployment in the field conditions we are talking about. The CCFL flashlights are an excellent example: available in stores for around $10, with an excellent battery life and 10,000 hour or better tubes, they appear perfect. But the are not waterproof, only water resistant.

What would the failure rate be if we deployed them in a refugee camp? Would the manufacturer - either Eveready, or the plant which makes them in China, be willing to make small design changes or product a special edition, or would we hit dead ends unless we were willing to have a custom model produced from scratch (a whole different line of business.)

My hope is that we can rely on the open source approach to solve many of these problems - that as long as all of our intellectual property is open, then domain experts can help us find answers to all the questions that come up, without feeling like they are helping a for-profit or partisan group. Free IP means freedom to participate for many people. We can give the companies who produce the products we want tweaked or improved the ideas on how to do it, and they can use them or not as they please.

My estimate is that it will take 10 to 15 years for this approach to be fully vested - tried in the field, failures identified and rectified, and technologies matured to the point where it becomes obvious to all parties that we have a scalable solution. Whole systems design is hard, and takes time, and a lot of lives are at stake.

But if we don't start now, we aren't going to have that fully finished solution 10 or 15 years down the line.

This is not to say that we could not push much harder and much faster - deploy units in the field and just see what happens, and learn by doing.

PS: the $200 number is padded for a more expensive toilet, and for a share of village-scale utilities like the one-per-village 2 kilowatt central power utility.

PPS: http://web.archive.org/web/20120820091728/http://www.rmi.org:80/sitepages/pid560.php (the Sustainable Settlements Charette, where a lot of the definition of scope happened)

http://web.archive.org/web/20150128031953/http://worldchanging.com:80/archives/002202.html (some older writing I did on infrastructure which might help fill in some details in my unusual perspective on this stuff.)

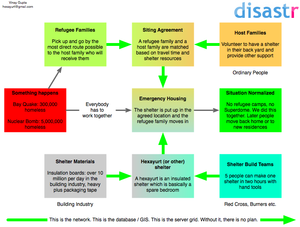

Disastr / Networked Domestic Disaster Response

A Note On This Plan

disastr.org is the current public homepage of this project.

A novel approach to handling mass refugee situations in the United State.pdf - the original proposal. Please note that there is new material on this Appropedia page which is not in the original proposal.

I presented this outline to two of the Directors of the American Red Cross in Washington, DC earlier this year. Their response was extremely favorable, calling the plan "incredibly innovative; as good as anything we have seen."

I talked with FEMA at the end of August 2007 and they are also extremely interested in the plan, and I believe that American Red Cross is discussing it with the Californian branch of FEMA also. This is a real and credible proposal, not just something you found on the internet. I'm publishing it widely because it is a community-led disaster response plan rather than something driven from centralized resources like those of government agencies.

This is about you.

The technology parts of this plan: a GIS, perhaps some online training tools, and a database application are well below the level of complexity of many services offered by, for instance, Yahoo or Google. An organization like that could build and host this service (except the financial infrastructure) as a way of helping ordinary Americans protect themselves in the event of a natural disaster or terrorism.

To do the supply chains for the building materials would require assistance from building supply companies like Home Depot or Lowes, and the tape is going to need to be stockpiled - call 3M. But with these pieces assembled, plus perhaps some of the additional infrastructure components outlined in the presentation PDF, there is no reason why an extremely high level of resilience could not be achieved without requiring complex government planning.

You can build a hexayurt yourself.

You can build a disaster response capability based on the hexayurt by working with your community and some companies.

A novel approach to handling mass refugee situations in the United States

- Vinay Gupta

- Hexayurt@gmail.com

Introduction

This document outlines a low cost ICT/training approach to handling millions or tens of millions of domestic refugees in the event of a natural disaster, epidemic, industrial accident, WMD or other event. The basic building block of this response is a low cost building called the Hexayurt which can be rapidly manufactured and assembled using common materials by semi-skilled teams. We then proceed to show how these simple, high quality shelters can be distributed and sited in a way which enables the non-displaced population to seamlessly absorb the displaced people at minimal cost.

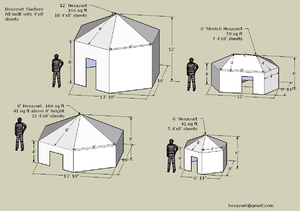

Hexayurt Properties

A hexayurt is a 166 square foot "microbuilding" assembled from one to two dozen 4' x 8' panels. These panels are typically off-the-shelf polyisocyanurate building insulation boards, as commonly found at Home Depot and other building supply outlets for around $15 ea. Harsher climates and longer term use requirements can be met by custom runs of this material. The building geometry is extremely simple: the roof is made from half-panels, and the walls are made from full panels - an entire building requires only six straight cross-panel diagonal cuts. There are no framing timbers or other structural components. The pieces are then joined using an off-the-shelf 6" wide 600lb breaking strain industrial box closure tape or a custom adhesive. The entire process - from panels in a truck to a finished building - takes about two hours the first time and more like one hour with an experienced team of five or six. The design is in the public domain so can be used by anybody.

Shelter for One Million Families

One hexayurt can house a family group of up to five people. Building and siting one million units in three days is achievable at a cost ballpark cost of under $700,000,000 ($120 per head) given preparation, training and supply chain management. The notion is to use these buildings as "guest quarters" for refugees, to be added to existing family homes that provide hospitality and infrastructure.

Manufacturing the Hexayurts

The materials cost for each hexayurt is around $200 for very basic temporary units, through to about $600 for long-term high durability units. Cutting a factory-quality hexayurt takes about two hours with a single table saw, or about 30 minutes with garage space, two saws, timber jigs and a small team to cut, move stock and finished panels. Pre- assembling the walls and roof into a folding unit takes about another 30 minutes for a second team of three to five people. A unit built this way can be assembled on site in about an hour by a team of three. Each shop requires well under $1000 of equipment and can produce around 50 units (housing for up to 250 people) per day assuming three shifts. Note that the manufacturing capacity costs are around the same as two units.

Given these figures, manufacturing one million units in two days requires 10000 shops. Equipped from scratch, this is $10,000,000 of capital investment. However most of the required equipment is already in widespread use - table saws and 2x4 - so most of these shops would not have to be set up from scratch. Indeed, in a real disaster situation, the goal would be to press all available capacity into service.

The materials themselves, at over-the-counter prices, would cost $600,000,000. Polyisocyanurate boards are in common use all over the country in the building industry. 4 billion board feet (approximately 500,000,000 4'x8' panels) are used every year, which gives a daily supply volume sufficient to shelter around 600,000 people. Latency for further manufacture on an emergency basis has not yet been researched. It is likely that the various manufacturers of these products could stockpile the liquid chemicals required and step up production in a crisis. Another issue is tape - 6" wide bidirectional filament tape is widely available but not widely used. It may make sense to simply stockpile the required tape all over the country. Shelters can be constructed with standard 3" tape, which is extremely widely available, but requires more skill and can be a hit-and-miss process.

Staffing the Manufacturing Operation

The Red Cross training courses all over the country. Adding an "emergency shelter" training course, where volunteers are trained and certified to manufacture, site and assemble hexayurts and similar building systems, seems like a reasonable way to build local capacity. People with the certification could additionally register as having a shop with a "crew" – a staff like a volunteer fire department – who could manufacture units at a given capacity if materials were available.

To have 10,000 shops ready in the area around a disaster seems unrealistic at first. However, with the exception of the Mid West, cities cluster. A multi-year program to build local capacity could easily find 5,000 shops in most major cities. In a crisis, capacity close to the disaster is activated first. The trained staff of each shop would be augmented by other, unskilled volunteers who would pick up basic skills on the job.

Alternative Manufacturing Approach

Over the past year, it has become apparent that a basic, but functional, hexayurt can be cut in the field without power tools. This approach gives an hour to hour and a half end-to-end construction time for the shelter. Heavy duty insulation boards cannot be cut using this approach, but they comprise only a few percent of the total board volume. Standard boards as found in the supply chain can be cut as effectively with a snap-blade knife as with a table saw, which makes field manufacture eminently feasible.

Siting the Buildings

Buildings should be put up in the back yards of ordinary American families. The infrastructure requirements of one million families cannot be effectively met by large, centralized facilities. However, existing oversupply is so large that, for many Americans, providing a place to cook, shower and watch TV for a guest family in an emergency would not only be no hardship, but a welcome opportunity to participate. However, it is unrealistic to expect this kind of meeting of overcapacity and need to happen 'on the fly' when considering mass evacuation.

Therefore a national register of families willing to site American refugees in their back yards would be created: a centralized GIS database showing locations where hexayurts could be sited would be created and, in the crisis, individual evacuation maps would be prepared.

The first step is that the GIS marks off the areas which are effected in the disaster, and a first estimate of the refugee population is made. Secondly, information about local transport conditions is added: if major highways are out, they would be taken off the map. Finally, the system begins to identify the "closest" sites for hexayurt placement based on a transport- driven distance metric, rather than simply distance. These homes are contacted by an autodialer or SMS message and an automated system asks if they will be there to help receive an incoming family.

This "readiness roster" is then passed to a second system which communicates with the manufacturing shops; shops in each area are married to a set of sites and, as units come off the local production lines they are transported by pickup truck (one truck can take 5 units) to the home sites, where neighbors assemble them and wait for the refugees to arrive. I would foresee an additional "transport corps" which would help take refugees from centralized pickup points to their interim homes.

The requirement for databases with cell phone access to manage this entire process cannot be overstated. Although clearly a backup system based on paper is possible – maps printed off at a centralized location and then flown into the disaster zone and handed out to refugees – the challenges in keeping basic communications available and building robust interfaces to the planning databases are likely a lesser challenge.

Special Considerations in the Nuclear Scenario

In the nuclear scenario there are four special considerations.

- a large number of extremely severely injured people

- radiological contamination of individuals clothes and personal effects

- radiological contamination of individuals themselves

- massive national shock

Four measures may help.

Firstly, the ability to rapidly establish field hospitals, using military equipment for treatment facilities, and hexayurts and other temporary shelters for wards may address the need for segregated hospital facilities for victims.

Secondly, "wash and change" stations must be established at the perimeter, where people who show low levels of contamination can shower, abandon their contaminated clothing, and step into new outfits. These items can be provided by the large retail stores - simply transporting the stock wholesale is probably the best immediate approach. Shower greywater should probably be routed into settlement pits (which can be dug rapidly with backhoes) so that radioactive particles are not flushed directly into drains.

In practice, these "wash and change" stations also act as a filter - after washing and changing, people who still show significant levels of radioactive exposure may need to be quarantined, and can be expected to become very sick in the immediate future, where as those who show levels closer to background exposure may be safely resettled into the general population.

People who have taken extremely high levels of contamination may require seclusion while the short half-life isotopes degrade. Rather than siting shelters for these people in areas with existing infrastructure (homes) it may be wiser to site buildings for them in a green field area, with some separation from the general population until their condition stabilizes.

Finally, the overwhelming desire to Do Something can be channeled into shelter construction and housing the homeless after a nuclear event. There is a lot that people can do to help.

Managing the Supply Chains

In order to smooth this process, every American should be issued with a debit card akin to the FEMA cards or prepaid debit cards as commonly used. These crisis cards should ship in the "deactivated" condition. When a crisis happens, the cards should be enabled either nationally (in the event of a huge crisis) or locally – for example, turning on all the cards for a given set of zip codes. All the cards for people on the rosters as either manufacturing hexayurts, hosting refugee families, or otherwise providing services should also be enabled, with balances reflecting the expected expenses incurred by each group. For example, a manufacturing shop could easily go through $30,000 of building materials in two days and should have credit available to this task. This "pay as you go" approach to managing the supply chains has multiple benefits including empowering individual Americans to help themselves, and working smoothly with existing supply chain systems in place in building supply stores.

Because these cards are issued in peace time to individuals, and have strong identity information attached to each one, it should be possible to track fraud and abuse. It should also be possible to call an automated service and requisition additional card capacity so that, for example, an individual traveling in the disaster area can call in, activate their own card, and get out of trouble.

The Hard Case

This entire approach involves using overcapacity in the national system to cover Americans affected by disaster. However, in a bigger disaster, the national communications and electrical infrastructure may simply be unavailable. What then?

In these scenarios, local stockpiles of tools, material and information provide the only hope of effective local grass roots response. For example, schools could be nationally understood as being gathering points for planning groups, and school buses could drive their normal routes at all hours of the day and night to provide transport to these aid hubs. The Hexayurt infrastructure package (pdf) for the developing world includes heating, electrical lighting and various other essential services and an upgraded version of this package could be manufactured and stockpiled for use in crisis conditions in the United States.

Available in other languages: /fr /ja /ru /tr

Note: This page is very much related to Hexayurt Thermal Analysis.

Walls and Roof

- Hunter XCI 286 - Much like Tuff-R but *VASTLY SUPERIOR IN EVERY WAY* - much stronger, more fireproof, will last for years. This is The Way. -vg

- Tuff R/Super Tuff R - Quick-and-dirty units constructed directly from materials purchased at Home Depot or Lowes. That's what we did at Strong Angel.

- OSB Board - with precision cutting of angles for tighter assembly. That means a table saw. Ideally we'd find a local wood shop and have them cut for us because: I'm, er, not the guy to be doing that work, and keeping my fingers!

- Dow Thermax HD - Higher spec materials which may need some wrangling to obtain. Two or three inches thick, better foil facing, generally much more like what you'd use in disaster relief situations.

- Hexacomb cardboard - (http://hexacomb.com/) which can be manufactured on site from flat pack core materials, so the 1"x4'x8' board is made from a core about two inches by six feet by one inch, and a couple of rolls of foil. Hard to explain, see the "Rapid Deployment Concept" page on http://howtolivewiki.com/hexayurt/

- Waterproofed Triplewall Cardboard - Weyerhauser has a really good waterproofed triplewall cardboard, as used in the Global Village Shelters. We're trying to source some but having problems, but of all the materials, it's probably the one closest to spec for developing world use if somebody wanted to start making units ASAP.

- Honeycomb Polypropylene - usually sold as a flexible mesh which will need to be glued to two facers to form a sandwich panel, but karton dot it has a material called exalite which has this done already, and looks like a good choice for hexayurts - but untested!

Plywood / OSB

https://web.archive.org/web/20100712052444/http://opensourceecology.org/weblog/?p=340 - $132 plus paint for 166 square feet. Unbeatable. and there's a ton of unedited video and pictures here:

http://www.files.howtolivewiki.com/open_source_ecology_plywood_hexayurt_build/

I think there's scope for an approach here where there is no flashing used, but (for example) the roof triangles over-lap a few inches at the center of each triangle and screws hold the boards together, and at the roof edges, the roof goes over the lower of the two boards comprising the roof triangle, and is screwed directly into place.

Could be hell to waterproof, could have structural problems, but my intuition is that there's an approach here which does plywood with no fasteners beside screws/nails which might be very useful for some circumstances.

Plastic-Hinged Hexayurt

Andrewed says: Here is a prototype of an OSB hexayurt made with permanent plastic hinges. Worked really nicely.

4 roof panels and 2 wall panels, all with miter-cut edges, are joined permanently, Danger Hinge-style. Then these sub-assemblies get assembled into a complete building with the "opening" hinges. See each picture for detailed caption.

-

Roof before raising

-

Opening hinge

-

Completed Hexayurt

-

Hinge demo

The plastic hinge is made from propaflex. See:

propagroup.com > impact and handling problems > propaflex

It comes in rolls with the thin creases running perpendicular to the length of the roll. I just cut it at every second crease to make the hinges.

It is cheaper than standard plastic hinging and it works. It is a little weaker, so I worked out a trick to prevent tearing at the ends. Just trim the end of each piece so the thin, bending part in the middle sticks out beyond the thick flaps, like this:

___ ______/ | \_____ | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |_______ | ______| \_|_/

Corrugated Plastic

This is generally not a recommended approach because for most applications, polyisocyanurate boards with aluminum facing are a better bet for long life and insulation properties. However, should you wish, here's how to do it.

I had a little think about coroplast again, and spotted two things I have missed the first time we looked at coroplast.

We can now offer a pre-fab or field-fab hexayurt which folds up very much like the existing folding units. The mechanism might change just a little on the roof.

As a bonus, the coroplast hexayurts can be fastened with pop-rivets rather than tape, which cuts the price even more. Pop rivets are five cents each, and we'd use one about every six inches. They go in with a cheap manual tool or a power tool.

The trick for strength is that for the roof, where two panels come together, you take about four inches of each panel and make a crease. The panels are put side by side, with the 4" strip bent up at 90 degrees to each panel, forming a fin.

Those fins then re-enforce the roof from wind loads.

That fin - that vertical ridge - is then folded over in half, forming a 2" fin - and pop-riveted in that position. This connects the two panels, and and produces a structural reinforcing fin which is also watertight because there is no route for water to enter the building's roof, except by going up the fin, through the tight folds, and into the building.

A similar approach can be taken at the roof edge, incidentally producing a Rainwater harvesting gutter if done right.

Taking down the hexayurt would be a matter of using bolt cutters on the rivet (light ones, maybe even tin snips) or just ripping the rivets through the material - note the holes would only be in the fins.

With a little additional work, I'm also pretty sure we could make this entire assembly fold. There might be some fiddly little cuts or creases in the coroplast to make it work, but nothing you couldn't do with a craft knife or a hack saw. We could also spec an 8' roof pole to go into the center of the space, which removes all and any structural issues about the coroplast permanetly by putting it in tension, and it will simply never tear in that configuration (*very* strong in tension). I should have thought of that before.

Or consider the IcosaPod direction, and use ?triangular? box girders on the structure. They could, for example, be fabbed on the edge of each panel, or possibly done as separate items. Might be a good way of getting the roof pole also.

Tape

- Some great providers of Bidirectional tape are:

- Tape Providers -> Bidirectional filament tape, 6", Aluminum foil tape 4" and also they had created a Bundle with both tapes at a discount. Tape Providers also, sell this on Amazon but the price is better on their website

- T.R.U -> Bidirectional filament tape, 6" wide. Available from DistributorTape (ABT TRADING GROUP, Inc.), or by phone at 1-786-565-9858. Also available at Amazon: T.R.U. FIL-835B/D.

- Ideally we need a one-stop tape; a duct style waterproof, bidirectional filament tape with a foil face.

- People are adding some reflective tape to their Hexayurts and it looks awesome

Tent Pegs

Roof

Leather can be used on top of the OSB roof panels see the 2008 Hexayurt at Open Source Ecology.

Floor

Raised & Leveled Sand/Earth + Sheet Plastic or Tarp + Insulating Board + Plywood or Board (+ Carpeting or Mats) (Toczko Floor1)

The idea is create a level, dry, insulated floor that will support the weight of furniture legs and appliances, etc.

- First, to keep water out, prepare a level raised sand or earth surface, surrounded by rocks, cinder blocks or other material to keep it from spreading out. A ring of cinder blocks or rot-resistant wood staked in place with pieces of rebar would work. This is where the walls of the structure will sit, and where water will run off away from the structure, so we want the edge of the wall to be at the outer edge of the raised surface. Place the outer edge level. Fill the cinder blocks with sand or earth, if we are using blocks, and then fill the center area with sand or earth and level it with a long straight piece of wood, or scrape the high areas with the edge of a sheet of plywood until the floor is as level as we want it. (If you think that later on we will wish that we'd spent more time leveling the floor, then do that now :)

- The next layer is a one-piece sheet of plastic to keep moisture out of the structure. It doesn't need to be strong thick plastic because its not going to be exposed to wear and tear if we use the insulating board and plywood layers. if the plastic is going to be the top layer then yes, we do want the strongest plastic sheeting or tarp we can get. The plastic should extend out over the edge of the floor, and over the edge, to let water run off and away. (I'm assuming a tropical rain forest in a typhoon, or a winter flooding rain storm that goes on for a week. The sort of conditions that warrant building emergency shelters.)

- The next layer is insulating board, if we are in a cold environment. In a warm climate we probably don't need this.

- Plywood or board layer. This can be cheap thin sub-flooring, or scrap 2x4, or any flat material strong enough to support a furniture leg pressing on it. This could also be optional if we aren't going to be using that kind of furniture, or if there isn't any insulating board layer.

- Comfort layer: Carpeting, mats, blankets, etc. Whatever we have on hand, or whatever we want to use and can plan for.

If we make this floor with all the layers we have a surface that feels and acts like a standard Western floor: Carpeted, warm and dry, that we can sit a chair on and rock back and not poke holes in the insulated floor.

1 First described to me by my friend Greg Toczko as a geodesic dome floor.

Available in other languages: /fi /ja /tr

Why is the military interested in Hexayurts?

The short answer is that the military is always looking for new ways to solve problems.

The long answer is more complicated.

The Long Answer

The role of the military changes over time. Things are changing at the Pentagon. In 2005, Gordon England signed 3000.05 which says that the military has to develop really advanced capabilities in fixing things up, and that they should get about as good at fixing things as they currently are at breaking them. To be more precise, it says:

Stability operations are a core U.S. military mission that the Department of Defense shall be prepared to conduct and support. [Stability operations] shall be given priority comparable to combat operations and be explicitly addressed and integrated across all DoD activities including doctrine, organizations, training, education, exercises, materiel, leadership, personnel, facilities, and planning.

Stability operations are conducted to help establish order that advances U.S. interests and values. The immediate goal often is to provide the local populace with security, restore essential services, and meet humanitarian needs. The long-term goal is to help develop indigenous capacity for securing essential services, a viable market economy, rule of law, democratic institutions, and a robust civil society. (emphasis added)

This is a mandate for military-funded development of appropriate technology resources. Nothing else is even close to fulfilling this requirement.

I believe what's going to come out of this directive in the long run is high quality solutions for shelter, for housing in general, for power, for water, for lighting, for cooking, and for every needful thing.

I built Hexayurts at the Strong Angel III demonstration in San Diego, CA, and Combined Endeavor 2007 in Germany. I also presented on them to a group of senior logistics officers at the Pentagon, and work with the "Expedient Infrastructure for Transitory Populations" project. Buckminster Fuller worked extensively with the Department of Defense for many, many years, and I hope that I am helping keep his ideas alive for the current generation of the military.

- -Vinay Gupta 08:40, 2 August 2007 (PDT)

Available in other languages: /ar /de /es /fi /fr /ja /pt /ru

The Hexayurt Project won the Participate! Treehugger > Current.TV > Burning Man prize for eco-nifty Burning Man stuff. Never let it be said that weirdos can't get things done!

Scroll down to see why hexayurts are so fabulous, which one is best for you, and how to build one without standing around in the sun too long.

What is a Hexayurt

A hexayurt is a shelter designed for refugees and other people with a small housing budget. It's also for "recreational refugees" like Black Rock City residents, if built with rigid insulation.

Vinay Gupta invented the basic shape for classic hexayurts and a number of variations, and placed it in the Public Domain. This allows others to develop the original idea further. This wiki page, and associated pages, are the repository for hexayurt do-it-yourself building data, and primarily reference building techniques for the dusty desert environment of the Burning Man Arts Festival. If you're looking for plywood hexayurt information, see hexayurt.com. Other developments are here, also in the Public Domain.

The Hexayurt can be made from about $300 of materials from Home Depot, plus about $100-150 of mail-ordered tape (or a new method using vinyl, discussed later. Depending on the construction technique, it takes about 8 hours to prepare at home and 0.5-4 hours of assembly at your destination.

The Hexayurt is design is completely free, public domain. It's great for Burning Man. Anybody can use it, improvements are welcomed! This means you.

Become aware of hexayurts for refugees and disaster relief: Hexayurt Pentagon Presentation PDF - all about refugee use, including solar use, wood stoves, & water filters. The Hexayurt Mass Evacuation Plan - hexayurt use for evacuating cities in an American context.

Above: Hexayurts at Burning Man 2010: two 8' hexayurts and a 6' hexayurt (back left). Notice they are very thoroughly staked down using tape-anchors, and sport a sturdy rounded door.

Why is this a good idea?

Millions and millions of people do not have proper housing. Designing like you give a damn can help.

Oh, you meant why for the Playa? That's simple. Hexayurts really enhance the Burning Man experience. You can sleep in during the morning heat. You have a warm place to party at 4AM. In short, it rocks. At 9AM a tent is an uninhabitable solar cooker, a hexayurt is blissfully cool and dark. The tape seals it from dust. And you did it yourself, without lugging an RV with air conditioning to the Playa. You built your own shelter with your own two hands. It's creative and very participatory. By building a hexayurt you're joining a community of engineers and creators who are helping to transform the planet.

Hexayurts aren't just for the playa, they're for the world.

Why is the Hexayurt cool and dust-free?

The Hexayurt is dust-free because, once it is securely staked down and taped to a tarp, it is basically air-tight.

The outside is silver, so it reflects away sunlight. You may want to bring some paint or other material to Burning Man to mat the surface if you are located in a position where the reflected light and heat is causing somebody a problem and you can't move. On top of that, the material itself is an insulator. Thermax has an R-value (insulation value) of 6.5 per inch, which is about the same as fiberglass. Between this and the reflective surface, very little heat enters a closed Hexayurt.

The ground is always at around 58F at a depth of six or more feet. If you shade an area for a day or two, the surface of the earth settles towards that temperature. So the floor of the Hexayurt gets cool, and stays cool, and tends to suck the heat out of the air inside making you feel cool. For maximum cooling, in the daytime, keep the floor of the Hexayurt free from insulating materials like blankets and cushions. For maximum warmth, at night, cover the floor of the Hexayurt with blankets.

Finally, the greatest trick on the playa is to take a little spray bottle (or, better still, a pump-up five-gallon garden sprayer!), close all the doors and windows, and spray high into the air in your yurt. The evaporation of the water rapidly cools the air of the Hexayurt. If you spray for a minute or two you can get shivering cold in the middle of the day. Also the air gets very humid, which is very nice. Then the air begins to warm up again as heat re-enters the space. So instead of being dry and hot, you are now damp and hot. This is worse. So you open a door or a window, and let out the warm, moist air, let in the warm, dry air, and then close the window and spray again. Usually, you have to do this every fifteen minutes or half an hour, and it takes about half a cup per cycle.

I've spent entire days sitting in the hexayurt doing this with friends, having people come in, sit down, drink some water, take their shoes off, cool down for a while and then go about their day. It's a really fun way of making a space to get to know people on the playa, and offering them something they need and enjoy.

A hexayurt at Burning Man is really good with a solar powered swamp cooler (it's been said it's better than an RV). See further down this page for details.

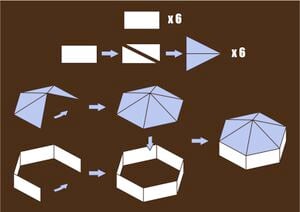

Classic Construction: This involves prepping panels at home (cutting some of the panels in half diagonally, and sealing all the raw edges of the panels with tape.) Then you cart the components to Burning Man and assemble them. Most of the Classic instructions and video include assembly in 3D by holding the pieces in midair to get them to their desired shape (this takes 4 people). There's a new way of assembling the pieces in 2D that will require 2 people for most of the process.

Semi-Folding Construction: Semi-folding hexayurts are perhaps the ideal design for Burning Man or any environment, because most of the prep is done at home. They are much easier to re-use because they are pre-fabricated in 4 pieces that accordion fold open. Initially they require the same amount of tape as in classic construction, but when you re-use your hexayurt, you'll need much less tape. You can make a semi-folding hexayurt two ways: with fancy tools and dust handling to miter the edges of the panels, or using Camp Danger Hinges. Mitering panel edges is messy and time consuming, but you get slightly better insulation.

Fully Folding Hexayurt: You can also build the hexayurt as a fully Folding Hexayurt. Few people choose this design. The Folding Hexayurt needs a table saw and precise angle cutting on the edges of boards, and is a large object to transport (8' x 12', six inches thick.) If you can swing that, you get a Hexayurt that goes up in 20 seconds plus the time it takes to stake it down. It's so fun to see it open and close, you might never live in it, but keep popping it open and closed as an art project. Just letting you know.

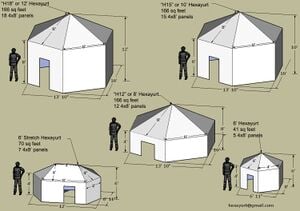

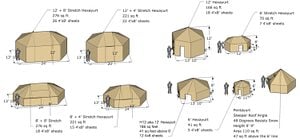

The 8 Foot Hexayurt aka 'H12': This is currently the most popular hexayurt (shown above, lower left.) The 8' Hexayurt has been ideal for Burning Man because it's a good size to transport, has 166 square feet inside, is short and not too vulnerable to high winds, and very easy to build. It has decent square footage that you can stand upright in, but the height of the entryway is 4'. Not bad compared to the average tent, but it's a limitation that has been improved upon in the taller hexayurts below. It is probably the simplest design, after the 6' hexayurt. There are very detailed instructions for building the 8' using the classic construction or as a semi-folding hexayurt. From the 8' Hexayurt instructions, you can probably learn to make any other hexayurt design shown on the side.

The Pentayurt aka H10: Previously a design considered for snow because of its steep roof. These gained some popularity at Burning Man 2011 because of the increased standing room and the smaller footprint in cramped camps with concerns about having enough space. More data to follow, here's an image (see bottom, right). Hexayurt project/Semifolding Pentayurt

The 6 Foot Hexayurts: The smaller Hexayurts have their niches, but they've lost popularity. The 6' Hexayurt is comparable to a small tent: good for one person, very cramped for two. The 6' Stretch Hexayurt is cozy for two, but provides little storage or room for people to socialize in your cool, dust-free place. These are easy to construct. They can also be made semi-folding, and plans are almost complete, see this great video for one person construction. The 6' stretch feels really big if you pop up the walls by an extra 2 feet, so you can stand in the whole yurt and have a full height door. A great solution for a camp that's cramped for space on the playa.

The H2 Pup-yurt aka Siestayurt: New as of 2012, the tiniest, simplest yurt. 2 panels form a pup-tent that's big enough for 1 person to sleep in. Ideal for efficient cooling and playa-naps.

The Square-a-Yurt aka H8: A few 4-sided yurts were seen at Burning Man 2011. Sometimes this was because there were not enough panels to make each household in a camp a separate hexayurt, so this solution was improvised. Photos and stories to follow.

H13 Hexayurt: A brilliant new variation of the 8' hexayurt is Hexayurt project/Hexayurt H13. This yurt design uses 13 panels instead of 12 (hence the name: H13), and raises one side of the hexayurt to 8 feet, allowing increased headroom and a good place for a door. It's a bit trickier than the standard 8' hexayurt because it is asymmetrical on one axis. This hexayurt is expected to be moderately stable in high winds, but it's second structural weakness is that a full height door cuts into the 'tape ring'. Be sure that you make a model of this hexayurt before you construct full-scale, and be sure that you have exceptional skills at tying down a structure. This can also be a semi-folding hexayurt using tape-hinges. here's a great picture. (H13 is a new design as of fall 2010).

H15 aka 10 Foot Hexayurt: Want a taller yurt? The 12' yurt (shown) is perhaps too tall for playa winds. The H13 is almost a perfect answer by just adding 1 more panel, but it's a trickier design. The simpler 8' hexayurt, or any other shapes, can have the wall height increased by 2 feet without waste of materials. This has taller walls, so thicker panels are recommended for stability in playa winds. You can also make this semi-folding.

H15 (10' tall hexayurt) versus H13? There's some debate about the practicality of the above "taller" hexayurts (H13 versus H15), mostly because they're new designs that haven't been tested multiple times in playa conditions. None were reported to blow down in 2011, but the winds were very mild. The 10' might have more stability than expected because it is symmetrical, doesn't have the protruding, high face of the H13, and is more reliable to tie down (especially with a rope halo, because the loads on the rope halo or tape anchors will be equal. Structures like H13, which are not symmetrical on all axes, are unpredictable. In general, the 10' is a conceptually simpler design to build. Structural engineers have been known to side with the 10' hexayurt over the H13. The H13 also lures one into building a human-sized door on the high 8' wall, however a door that size will cut into the tape tension ring that also creates stability in the hexayurt. At the end of the day, the common 8' hexayurt is still amazing because of its symmetry, low air drag (due to low height) and simple assembly.

12 Foot Hexayurt aka 'H18': The 12' Hexayurt is pushing the envelope on 1" Tuff-R rather further than is advisable for Playa use, the increased height is just not as aerodynamic in playa-force winds. Increased height requires thicker panels, and you'd better stake it down well. [2]

The Octayurt: This design created at GLAMCOCKS camp in 2012 can be built with only six 4'x8' panels, and comfortably sleeps two or three people.

Domes: Just to complicate matters, there's new 'Nearodesic Domes', in the hexayurt family. They are based on the 8'x4' standard building material size. These are challenging to build, uncertain in major playa winds, but apparently were made successfully at Burningman 2011. If you're building these, you should overbuild them, miter them, and tie them down very securely. Know what you're doing. Having one of these blow across your neighbors' camps would be BAD. Click for photos of the quaddome and tridome.

Octatipi: here's [another thought: http://www.youtube.com/watch?v=yYwHToAC3iY&feature=related]

(You can download Google SketchUp models of the basic Hexayurts.)

Building Basics

The basic 'classic' instructions for hexayurts are super simple. They vary depending on which shape and size of hexayurt you choose.

- Buy 4 (or better, 5) rolls of six-inch-wide bidirectional filament tape, like T.R.U. FIL-835BD. More on tape here. Total cost: ~$150 shipped. (Or ~$180 for 5 rolls.)

- Buy 12 sheets of a suitable 4' x 8' building material, like Thermax, from your local building supply store. More on panels here. Total cost: $200 - $400, depending on the thickness of the panels.

- Using a craft knife, cut six of those sheets in half along the diagonal, three from right to left, three from left to right. Total labor: an hour.

- Tape the edges of each board to protect you and the playa from the raw material. Total labor: two or three hours, or far less with three people and practice.

- Tape the building together by forming the roof from the triangles, and the walls from the six boards you did not cut. Total labor: two or three people for about an hour, barring difficulties.

Hexayurt project/Camp danger Hexayurt hinge technique has full instructions for building the 8' hexayurt as a semi-folding yurt, plus shopping info and video. Also ideas for the H13 and the 10' yurt as semi-folding, hinged hexayurts.

Hexayurt project/Hexayurt playa checklist has detailed instructions for building an 8' hexayurt the "classic" way (without making the hexayurt semi-folding), a shopping list, and video clips of the process.

Look at the picture and go through the steps in your mind again. You get the boards and you get the tape. Then you cut some of the boards into triangles, and tape them together to make the roof, and then you tape the roof to the walls and you are done. You just built a Hexayurt. This is easy. You can do this. If we were working with index cards and sticky tape, you could make one right now on your desk. You know how this works now. You can do this. There are details you will get have to get right to make sure the building stands on the Playa but all playa projects have details, and we cover the details in detail on this page and in the videos.

How Long, How Many People?

How Long does Construction Take? Basically, it depends. Like the estimated amount of tape, assume that 'your mileage may vary.' Save a day for at-home construction, after you acquire most of your supplies. On-playa, timing depends on your chosen construction technique: semi-folding hexayurts need a day of work at home, but are easy to assemble on playa, probably an hour plus the time to stake it to the ground, or less. Classically constructed hexayurts just need a little prep at home, but the assembly process is difficult, requires 4-5 people, and has numerous pitfalls that can increase time spent. Ultimately it would help if you share your experience on our discussion page. Tell us the following:

- Which hexayurt you chose to make.

- Which construction technique: classic, semi-folding, fully folding.

- Your skills, use of power tools or hand tools, # of people to help.

How many people? At home, all the prep of the panels (no matter what technique you use) is best with pairs of people: 2, 4, or 6, because the panels are large and the tape sticks to everything. An 8' hexayurt can be prepared at home with just one person, but this is difficult and not recommended. On playa, you'll need two people for most of the work, but then it depends on your construction technique: "classic construction using the 3D strategy" requires 5+ people for about 45 minutes. "Classic construction using the 2D strategy" only uses two people for 45 minutes, and then about 5 people to lift the roof cone up. Semi-folding needs two people for about 30 minutes and 5+ people for the roof cone lift.

Transport: You'll need the ability to transport a stack of 4 foot by 8-foot panels from the hardware store to your home, and then to Burning Man.

Watch the videos

The step by step instructions for the classic construction and the semi-folding construction have videos linked in at various steps, which is probably the less confusing way to view.

We don't yet have a perfect start-to-finish video resource. We probably have the footage from which a pretty decent guide could be made, but I have no significant video skills. For example, here's the raw footage from Hexayurt showing us constructing a roof cone.

This is all in the public domain, so perhaps there will be a tutorial video cut from there. I may even take a crack at it myself. In the mean time, I'm going to refer you to the raw footage.

Start with the Roof Cone construction video above (recall that this is for the "classic construction" of a hexayurt, the semi folding yurts don't require this step). It's also better to download and watch full screen than in the little flash video window. It's really complete and very easy to understand. You'll have the principle down in the first five minutes. Unfortunately the camera person had to leave before we put the roof cone on the walls, but that's the easy part.

The rest of the videos are in the Additional Resources section at the end of this page.

Make a model

You can build a paper model really easily. Try 1' to 1" - cut 12 pieces of paper or card, 4" by 8". Cut six of them in half with scissors, three left to right, three right to left. Now tape together a roof cone that looks like the one in the pictures, and tape the walls under it. Surprisingly sturdy, isn't it?