Abstract

This page represents "Team Biopod," the solar dehydration group for Flock House. This group has been brought together through the Humboldt State University class, Engineering 215 - Introduction to Design, taught by Lonny Grafman.

Background

The client is Flock House, which is founded by a New York City based artist named Mary Mattingly. The Flock House is a living system that is designed to be sustainable and mobile while providing a way to teach and inspire people. The Flock House will be traveling throughout New York City during the summer of 2012. For more information on Flock House go to: http://www.flockhouse.org/

Objective and Criteria

Team Biopod was given the task of constructing two solar dehydrators; a small educational unit and a larger main unit each with its own objective. A table of the criteria and their descriptions are given for each unit. Weights, from 1 - 10 ten being high, were given to each criteria based on how important that criteria was with respect to the individual design.

Main unit

Objective

The objective of the main unit is to provide enough dehydrated food to significantly contribute to the sustenance of the two individuals who will be living in the pod during the summer of 2012.

Criteria

| Criteria | Weight | Descriptions |

|---|---|---|

| Portability | 8 | The dehydrator must be lightweight such that it does not to exceed 50lbs. |

| Cost | 4 | The final cost of both the main dehydrator and the educational dehydrator must be under 375 dollars. |

| Durability | 8 | The dehydrator must be able to withstand continuous outside exposure and daily use for the summer months in New York City. |

| Aesthetics | 8 | The dehydrator must fit into the artistic design of the Flock House. |

| Functionality | 10 | The dehydrator needs to be able to effectively dry enough food for two people whose diet depends mainly on dehydrated food. The dry time is within 2-4 days (depending on weather conditions). |

| Ease of Use | 6 | Trained Flock House occupants can use and operate the dehydrator. |

| Educational Value | 3 | The dehydrator should serve as an easy to see and understand example of solar drying to visitors to the Flock House. |

| Safety | 9 | The dehydrator cannot pose a threat to the trained users of the dehydrator. |

| Reproducibility | 4 | The dehydrator should be able to be reproduced by a skilled worker. |

Educational Unit

Objective

The objective of the educational unit is to design a fun, innovative and hands on way to teach communities about solar dehydration.

Criteria

| Criteria | Weight | Description |

|---|---|---|

| Portability | 10 | The dehydrator must be lightweight and capable of being carried by a child of approximately five years old. |

| Cost | 4 | The final cost of the dehydrator must be under $375 when combined with cost of the main unit. |

| Durability | 8 | The dehydrator must be able to withstand continuous handling, and must be able to withstand regular use by children with adult supervision. |

| Aesthetics | 8 | The dehydrator must be put together nicely and must contribute to the fun aspect of the unit. The dehydrator must fit into the artistic design of the Flock House. |

| Functionality | 5 | The dehydrator needs to be able to dry small amounts food effectively in 2-4 days (depending on weather conditions). |

| Ease of Use | 9 | Children with adult supervision should be able to use the dehydrator. |

| Educational Value | 10 | The dehydrator is able to teach users the process of solar food dehydration. The dehydrator should raise awareness of solar dehydration and sustainable living practices. |

| Safety | 10 | The dehydrator cannot pose a threat to the people and children using it. |

| Reproducibility | 4 | The dehydrator should be able to be reproduced easily by a skilled worker. |

| Level of Entertainment | 10 | The dehydrator must have a high level of entertainment value that is able to gain the interest of visitors. |

Description of Final Design

Main Unit

The main solar dehydrating unit is made from a pine box with dimensions of 12"X49"X24" with a wall depth of 0.5". There is an acrylic plexiglass face with a bottom opening door. There are 2 dehydrating screens for the food to dehydrate on. There are also two vents on opposite sides, with one vent on the bottom near the door and the other vent near the top of the plexiglass window.

Educational Unit

The educational unit is made from the frame of an old baby carrier. The front of the backpack unit is covered with a clear polypropylene plastic for sun collection. Inside the backpack unit is a tray made of mesh that acts as the food shelf, the tray is angled within the unit so it collects more of the sun’s energy.

Costs

The following tables show the cost in materials broken down into the main solar dehydration unit "Window Shopper" and the educational unit "Back Me Up."

Main Unit

The table below breaks down the cost of each material used to build the Window Shopper Solar dehydrating unit.

| Material | Quantity | Cost Per Item ($) | Total ($) |

|---|---|---|---|

| Fiberglass Food Tray | 2 | 17.00 | 36.47 |

| Spray Varnish | 1 | 10.99 | 10.99 |

| All Purpose Glue | 1 | 4.79 | 4.79 |

| White Caulk | 1 | 2.51 | 2.51 |

| Acrylic 24"X48" | 1 | 24.29 | 24.29 |

| Plywood Pine 1/2"X2'X4' | 1 | 26.99 | 26.99 |

| Plywood Solid 1/4"X2'X4' | 1 | 14.39 | 14.39 |

| Wood Glue | 1 | 3.14 | 3.14 |

| Screen Fiber | 1 | 5.99 | 5.99 |

| Molding Square | 5 | 5.99 | 29.95 |

| Wood Screws | 15 | 0.15 | 2.25 |

| Insulation | 1 | 0.00 | 0.00 |

| Spray Varnish | 1 | 9.89 | 9.89 |

| Chrome Duct Tape | 1 | 5.99 | 5.99 |

| Corner Brace | 1 | 3.99 | 3.99 |

| Undereave Vent | 4 | 2.49 | 9.96 |

| Hinge Broad | 2 | 7.49 | 14.98 |

| Panel Nail 1" | 1 | 3.79 | 3.79 |

| Screws | 20 | 0.12 | 2.40 |

| Galvanized Staples | 1 | 1.49 | 1.49 |

| White Thermometer | 1 | 3.14 | 3.14 |

| Chest Hinge | 1 | 6.74 | 6.74 |

| Screw | 20 | 0.10 | 2.00 |

| Rope Loop | 2 | 1.16 | 2.32 |

| Bolt Eye | 2 | 0.75 | 1.50 |

| Screen Fiber | 2 | 5.39 | 10.78 |

| Turn Buckle | 2 | 2.24 | 4.48 |

| Subtotal | $261.92 | ||

Educational Unit

The table below breaks down the cost of each material used to build the Back Me Up Solar dehydrating unit.

| Material | Quantity | Cost per Item ($) | Total ($) |

|---|---|---|---|

| Flat Slotted Steel | 1 | 7.99 | 7.99 |

| Canvas Fabric | 2 (yd) | 6.21 | 6.21 |

| Velcro | 1 | 5.97 | 5.79 |

| Molding Square | 2 | 5.99 | 11.98 |

| Bug Mesh | 0.5 (yd) | 10.90 | 5.45 |

| Thread | 1 | 0.0 | 0.0 |

| Screws | 10 | 0.09 | 0.90 |

| Chrome duct tape | 1 | 5.99 | 5.99 |

| Metal Backpack Frame | 1 | 3.00 | 3.00 |

| Insulate Reflect (16"X25') | 1 | 18.99 | 18.99 |

| Subtotal | 78.01 | ||

| Total for Main and Educational Unit | $339.93 | ||

Design Costs

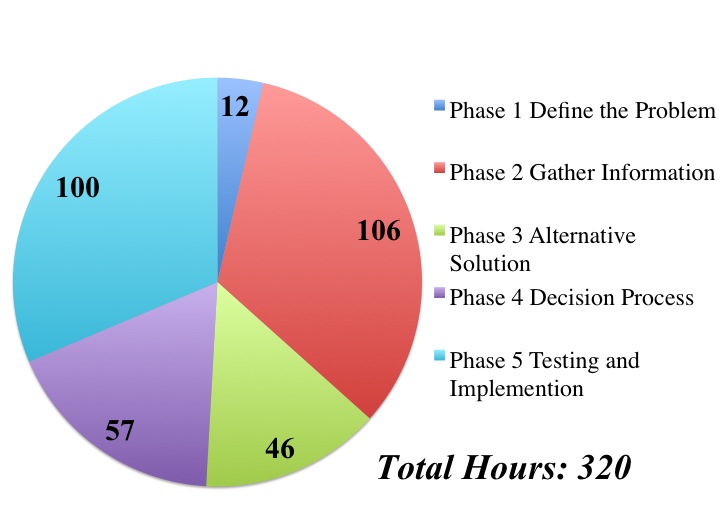

Design cost is measured in hours. The total hours spent on the creation of the dehydrating units for the Flock House are 320 with the total being broken into respective segments as shown in the Figure.

Testing Results

Testing is in progress.

Main Unit

Educational Unit

Maintenance

Main Unit

The Window Shopper will be shipped to New York so that Flock House will be able to begin the integration into the Flock Houses pod.

The table below breaks down the maintenance of the Window Shopper Solar dehydrating unit.

| Task | Time(min) | Frequency |

|---|---|---|

| Clean screens where food is placed | 15 | After every use |

| Wipe down Plexiglas face | 15 | After every use |

| Wipe down reflective insulation | 10 | Twice a month |

| Total Monthly Maintenance | 2.3 hours | |

Educational Unit

The Back Me Up portable solar dehydrating unit will be shipped to New York so that Flock House will be able to use this unit to help teach communities about solar dehydration.

| Task | Time(min) | Frequency |

|---|---|---|

| Clean screens where food is placed | 10 | After every use |

| Wipe down plastic face of the backpack | 10 | After every use |

| Wipe down reflective insulation | 5 | Twice a month |

| Total Monthly Maintenance | 1.5 hours | |

How to build

The following steps shows how we built our 2 units.

Main Unit

Tools required for the construction of The Window Shopper unit:

- Power Drill

- Circular Saw Attachment

- Wood Saw

- Wood Glue

Materials needed:

- Pine Wood

- Weather sealing

- Reflective Insulating Material

- Acrylic Plexiglas

- L-brackets

- Hinges

- Screws

- Reflective Duct Tape

- Prefabricated Screens

- Aluminum Screening

- Wooden Dowels

Note: All materials must be non-toxic and produced no toxic off gassing at temperatures up to 140 degrees Fahrenheit.

Educational Unit

Tools required for the construction of the Back Me Up unit:

- Scissors

- Screw Driver

- Sewing Needle

- Sewing Pins

- Sewing Machine (Needle can be used in lieu of a machine)

Note: The instructions assume the use of a sewing machine.

Materials needed:

- Waterproof Canvas

- Netting/Screening Material

- Pre-drilling Screws

- Reflective Insulating Material

- Thread

- Sticky ¾” Velcro

- Clear Plastic

Note: All materials must be non-toxic and produced no toxic off-gassing at temperatures of up to 140 degrees Fahrenheit.

Authors

Josh O'Rourke | Jonathan Roldan | Sarah Morton | Leabeth Mae Peterson |