Abstract

Background

The Campus Center for Appropriate Technology (more colloquially know as CCAT) since it’s inception in 1978, has been representative of an accessible educational and demonstrative platform; both maintained by and intended for students, CCAT encourages decentralized, innovative and organic solutions to everyday problems. Propagation and emphasis of appropriate and sustainable technology has made it one of the top authorities on campus, within the context of environmental science and environmental resource engineering. Since 1978, it’s members have grown from few to a robust and well developed community, of directors, employees and volunteers.

CCAT was originally located on the grounds where the Behavioral and Social Sciences (BSS) now stands, and was relocated in 2004 in order to accommodate. The previous location included a functioning greywater constructed wetland system, but was lost to the construction of the BSS. In 2007, plans were designed and implemented for a new marsh system, that was meant to serve as a demonstrational, self-sufficient irrigation system. This first design was implemented in 2008 (see CCAT greywater marsh (2008)), followed by a second attempt in 2009 (see CCAT greywater marsh (current)) which built on the existing system installed. However throughout its life and structural fluctuation, the design purpose of CCAT’s greywater marsh has remained consistent and intended to be multi-purpose: integration of wetland technology, sustainable greywater management strategy and educational opportunity. Both projects (2008 and 2009) encountered problems that dealt with an array of complexities, but most notably are the difficulties that arose in designing efficient and adapted components of the system. These were as follows: primary treatment for kitchen wastewater (as marsh technology is considered secondary treatment), a structurally sound surge tank, efficient baffles that divert the water in a “maze-like” fashion and finally, arguably the most challenging component, efficient conveyance that provided access to the greywater effluent pipe that rests some feet beneath the ground. The key to an efficient constructed wetland is adaption of the system to complement the local environment meant to house it; thus the success of such a system at CCAT’s current location proved to be quite an undertaking for previous projects as so many structural factors had to be accounted for. The system was always intended to be a constructed wetland meant to replicate aerobic processes via microorganisms that are sustained by the plants planted in the wetland. Both artificial and organic wetlands are used as a means of secondary water treatment, presenting a perfect design opportunity to treat greywater for the purpose of irrigation.

Problem statement

Inital

The objective of this project was to redesign and reconstruct the greywater marsh system at CCAT. Initially one of our primary goals was to update the surge tank of the old greywater marsh, which is located beneath the metal grate on the right side of the CCAT driveway (when you are facing the house.) The function of a surge tank is to temporarily store water, neutralizing pressure; it prevents against “surges” of excess water entering the system. This neutralization allows the system to treat its sized-for capacitance only. We also planned to install a more sophisticated system for straining oils and solids out of the greywater influent, that originate from kitchen sink discharge. Potential options for such a system included the implementation of a biolfilter such as a woodchip biomass filter. Other updates were to include replacement of pond liner, reconstruction of baffles in order to elongate the process of phytoremediation and the introduction of native marsh species into the system. Lastly, out team planned to revamp the testing tank, a primarily cosmetic feature of the system. The function of a testing tank is to preserve a sample of water that may be tested in order to see if the constructed wetland is functioning as it should; an untreated influent (greywater) sample is tested as well as a treated influent sample and the BOD level of each is compared in order to evaluate the effectiveness of the system.

Final

Because of structural limitations that mitigated the extent to which the old system could be reconstructed, we decided to do away with the old marsh altogether and design a completely new system. Primary challenges we faced included relative inaccessibility to the conveyance that channels greywater from the house; conveyance is approximately three feet underground, eliminating the option of a gravity-fed system. Because of this, we knew that incorporation of some form of pump mechanism would be necessary, in order to get the untreated greywater to ground level. Additionally, finding a usable treatment area that was not a waste of valuable space and that had some type of natural gradient (slope) to aid in water flow also constituted a challenge.

Our Criteria

In cohesion with our client CCAT, we came up with a set of criteria. Each criterion will have its own constraints and is ranked on a scale of 0 to 10 scale, 10 being of the greatest importance and 0 of the least.

| Criteria | Constraints | Weight (1-10) |

|---|---|---|

| Education Value | Signs must be at an 8th grade reading level. | |

| Aesthetics | Must catch the attention of atleast 50% of the people that walk by. | |

| Longevity | Must be a functional system for at least five years, with regular maintenance. | |

| Accessibility | Must be user friendly and accessible to even the layperson. | |

| Post Treatment Water Quality [1] | ||

| Capacity | Must be able to handle all of CCAT's greywater usage. | |

| Reusable Material | Must have at least 80% reusable material. | |

| Native Plants | Must include at least 75% native plants. |

Client Criteria

Education

As CCAT is designed to be a laboratory for sustainability, the greywater marsh system has undergone a series of changes and retrofits. A problem that has not been adequately addressed at any stage of upgrade is the lack of educational accessibility and opportunity. A home-tailored greywater system at CCAT has the potential to provide a visual and demonstrational platform for people to learn about greywater management in general, and perhaps even take this new information and adapt it to fit their own lifestyle and home. Our team currently considered the incorporation of truth windows in the system in order to promote greater educational accessibility. Truth windows are exactly what they sound like; they give the viewer or student a look into the function or structure of a specific component within a system. Truth windows are often employed in appropriate technology because they allow the participants and learners to see a system as a combination of interlocking components and also provide a more concise picture of the functionality of a particular component. Although the installation of a truth window never came to fruition, it would have served to compare the difference in water quality before and after treatment. For example, we would have placed one window so that the untreated greywater influent is visible as well as second window that displayed the clean and treated water flowing out of the system. This difference in quality would have demonstrated the potential constructed wetlands have to remove contaminants from greywater. It would have also proved that greywater can be managed at a household level safely and sustainably without threat to human or environmental health. [2]

Instead of a truth window, we designed as system with accessibility in mind. Our system most thoroughly serves the purpose of an educational platform rather than a full-scale treatment system, and is designed to allow for user interaction, specifically via the hand pump

Workability and Functionality

The two main problems with CCAT’s current greywater system is the described inaccessibility to the educational component of the system and the overall functionality of the system itself. Currently, the marsh does receive greywater from the house that supplies the transplanted wetland species with water, but the surface treatment area is too large for the volume of water that is being discharged into the system. The water entering the old system (the untreated greywater influent) flowed with almost no velocity; this was likely due to an oversized surge tank. Liquid that flows from a smaller cross-sectional area to a larger one will slow in velocity. Overcompensation of a surge tank cross-sectional area would result in an almost total loss of velocity; this was what was observed in the old system. Lastly in relation to functionality, the system had no end use (an essential component within the context of appropriate technology) and the treated water was left to drain into the ground table.

Literature Review

This is a review of the available literature pertinent to Greywater Marshes.

Defining Greywater

The EPA defines greywater as “reusable wastewater from residential, commercial and industrial bathroom sinks, bath tub shower drains, and clothes washing equipment drains.” Discharge from kitchen sinks is usually not considered greywater because of higher concentrations of organic material present in the form of cooking oils and solids. Greywater is categorically different from blackwater, in that it does not contain any fecal matter. Blackwater is defined as the the discharge from toilet outlets, and kitchen sinks in some literature. The high concentration of pollutants in blackwater create a site for bacterial growth that is potentially harmful to humans upon exposure.

Chemical Composition

The chemical composition of greywater is reflective of the households lifestyle. Any compounds used in soaps, detergents, hygiene products, etc. have the potential to be exposed to the installed greywater system and therefore have the potential to make up the composition of the subsequent greywater. Because of this the quality of greywater from any establishment is dependent on the inhabitants living standard, cultural norms, chemical usage and general lifestyle. [3]

The highest concentrated nutrients found in greywater are nitrogen and phosphorous. The majority of the nitrogen is deposited via kitchen sink discharge while the majority of phosphorous is originally contained in detergents and soaps, deposited via laundry units.

Potential Risks

When weighing the benefits and costs of implementing a household scale greywater system, many people are concerned about the potential risks that accompany the reuse of household water, to both human health as well as environmental. Risks to human health include the exposure pathogens from the digestive system and food handling pathogens, that are contained in untreated greywater. Such pathogens can cause disease through direct contact or the consumption of greywater plants and/or via contact with mosquitos. One environmental risk that accompanies the reuse of greywater is the potential for excess nutrients such as the phosphorus (contained in the untreated greywater) to enter local bodies of water, triggering eutrophication. However, upon extensive review of the available literature, it is clear that sustainable greywater reuse is possible without risking an overdose of phosphorus in the environment, but only if the system is correctly implemented. Additionally, a lot of people worry about the possible contamination of soils and aquifers from certain chemicals, oils and minerals that may change the soils characteristics. Such exposure to substances has the potential to cause salinization of soil, which reduces plant productivity. This salinization would be induced by high concentrations of salt in the greywater influent, originating from laundry detergent as well as other household cleaning agents. In order to reduce the potential for soil salinization, users should be mindful of household cleaning products they use, and what type of chemical compounds are contained in them.[4] Another environmental hazard is the potential for formation of xenobiotic organic compounds that are found in aquatic animals present in the resulting water. These compounds end up in the greywater from exposure to pharmaceutical drugs and antibiotics. To avoid this hazard, greywater system users must keep close regulation of the products being put down the drain. Last but not least are surfactants, or compounds that lower the surface tension between two liquids or between a liquid and a solid. Surfactants are used as detergents, emulsifiers, dispersants, foaming agents, etc… Although (as mentioned previously) you can use detergents that are not harmful for the environment, even the biodegradable compounds can reduce the ability of the soil to absorb water. [5]

However, if implemented properly, these risks can be minimized or completely reduced. A functioning constructed wetland mimics phytoremediation that occurs naturally in wetland settings. Rhizomes of marsh species are capable of removing the excess nutrients (phosphorous) and possible pathogens. Greywater that includes discharge from kitchen sinks usually necessitates pretreatment via a biofilter or some other filtration mechanism in order to remove any sediments, salts, or cooking oils that could be potentially decrease system efficiency. Additionally, pretreatment removes surfactants that are harmful to soil upon exposure. All of these mitigations are listed below in the <Types of Greywater Management Systems> section. Finally, all risks considered, it is important to remember: “To date, no epidemiological survey supports claims that greywater usage at a single household scale is associated with higher morbidity.” [6]

Legalities

Generally in the United States, municipalities are responsible for collection and regulation of both greywater and blackwater. However, decentralized, household scale treatment systems are becoming more and more common throughout California and many other parts of the United States. Below is a [Photo] depicting the cans and cannots of current state legislations. In CA and AZ, the current greywater law is a tiered approach that allows you to classify your utilization according to the size of your system. The first tier allows homeowners to divert their laundry water for garden irrigation without a permit. The second tier does require a permit, and provides you with regulations for a more complex system. [7]

There are many different standards for greywater reuse around the world, and the variation between these policies is great. In order to aid people living in regions with little to no regulation infrastructure, Maimon et. al. has provided a way to facilitate your own grey water risk assessment (quantitative microbial risk assessment or QMRA) of public health through Hazard identification, Exposure assessment, Dose-response characterization and risk characterization. [8] It is also critical to outline the local “governance” of your location in order to make sure that your system is up to code.

Types of Greywater Management Systems

Within in the context of prolonged drought conditions and controversial water allocation projects in California, alternative on-site greywater reuse systems have gained much momentum locally. [9] On a larger scale, these systems have been popularized in low and middle income countries where management services are inadequate or non-existent. Within these nations, if drainage infrastructure exists untreated greywater is discharged into storm drains and diverted into established aquatic systems. This compromises the health of these ecosystems, altering characteristics such as turbidity, nutrients and microbial content, chemical composition, etc. and can lead to imbalances such as eutrophication.[10] Where infrastructure is not present, untreated greywater is simply diverted into streets or open ground, presenting multiple risks to public health such as water-born diseases.

Water scarcity, lack of adequate infrastructure and various other catalysts have lead to decentralized greywater reuse efforts both in rural and urban communities. These systems are usually self-implemented and designed for on-site reuse. Treated greywater can be recycled to serve a couple different domestic purposes but the system must be designed specifically to fit source/type of greywater and need. A number of approaches are used to treat water but the most common uses for the final product are irrigation (outdoor) and direct water reuse via sinks and flushing (indoor). Indoor usage requires more intensive water treatment techniques than that of outdoor. Here are descriptions of the general design plan for the most popular systems:

Laundry Drum

Greywater treatment systems span a wide range of complexity. A system can be as simple as diverting used water from your washer to a drum that holds excess[11]; this is referred to as a “surge tank” (See definition in mechanisms.)A hose attached to the drum can then further divert the water to your crops directly or be hooked to an irrigation system. Because of the nature of the chemical composition of washing machine greywater, treatment is not as necessarily intensive so diverted water can be used directly to water crops (see chemical composition of greywater in introduction).[12]

Benefits

The benefits of this system are threefold: first is the duality of the washing machine’s built in pump as a mode of washing clothes and a pump source for the greywater system itself; this system is not reliant on gravity. The second benefit is that because of the nature of the greywater source (washing machine) the water does not have to be treated and can be used directly for gardening. Lastly, the plumbing for most washing machine units is exposed providing easy access for diversion if you are a home renter.

Considerations

The largest complication to this sort of greywater system is the dependence of irrigation on the frequency of laundry days.

Laundry-to-Land

Land to laundry (L2L) systems embed the same purpose of the laundry drum (the source/type of greywater and need are the same) and was first designed by Art Ludwig, a greywater activist. Similarly to laundry drums, L2Ls divert used water from washing machine units via a three-way valve connected to the unit. The three-way valve allows for easy diversion of greywater to outside or to the main sewer line, to be used if your garden is becoming overwatered or bleach was added to the laundry load. This feature of the L2L differentiates the system from the laundry drum model. Additionally, the L2L model recommends installation of an anti-siphoning vent on the garden-side of the valve to ensure water is not taken up from the machine while it is filled. (See siphon definition in mechanisms)[13].

The biggest disparity between the two systems is the L2Ls application of mulch basins as a natural surge tank (see surge tank definition in mechanisms) to release water for irrigation gradually. Mulch is an organic material more commonly referred to as bark, compost or a combination of these that aid in soil insulation and mitigate erosion. Water is diverted via the valve and then directed through a series of underground pipes to these basin, filtering water through and allowing for gradual release of moisture to root systems. The diversion of water to underneath the landscape is another fundamental component of L2Ls. This is preventative of over-saturation that can lead to overwatering and mosquitoes breeding. Piping is usually buried underneath the ground and fed into the mulch basins.

Construction of the mulch basins is simple. It can either consist of a singular large trench or series of trenches that are dug around the vegetation, typically about 12 inches deep and filled with “coarse” mulch (i.e. woodchips).[14]. The dimensions of the basins should be designed with consideration to the volumetric load they will hold, or the amount of water that will “surge” into the basins. Additional components can be added to aid in treatment processes such as a an outlet chamber. Outlet chambers can be constructed by burying a overturned 5-gallon pot with holes drilled into the sides.[15] The chamber allows for solids to flow into the basin for biodegradation without clogging over time. This consideration is meant to treat greywater sources that contain solids, or otherwise sources that are not originating from washing machine units (see branched drain in Types.)

Benefits

Mulch basins simulate natural water filtration by serving as an organic surge tank. The suggested three-way valve is a feature that is not included in the laundry drum model and gives the user more control over irrigation frequency. Like the laundry drum model, the intended greywater source is washing machine discharge which does not require intensive treatment but the model can be tailored to fit other sources.

Considerations

Regular maintenance of the mulch basins is required. Designer Ludwig suggests re-digging basins every year or two to counteract erosion.[16] Additionally, adequate design in regards to mulch basin dimensions are essential to ensure water is effectively filtered to plants.

Branched Drain

This model was also innovated by Art Ludwig, and incorporates the same mulch basin component as an organic surge tank. However, this system is gravity-fed rather than dependent on the internal washing machine pump also allowing for the greywater source not to be limited to this unit. The defining characteristic of branched drain is somewhat self-explanatory; a series of pipes descending in circumference “branch” out from the system’s water source input, allocating an initially large flow of water to smaller outlets. It is recommended that like the L2L model the piping is hidden beneath the landscape, though Ludwig’s design allows for above ground piping system if the user so desires. Subsurface systems are categorically more sanitary and up to code.

Ludwig suggests three methods for “splitting” the flow from the source of greywater. The first mechanism involves the installation of “double ell” attachments which split pipes outlets in two, allowing water to be diverted into different pipes. A branched network can be created with these attachments so that smaller amounts of water are delivered to the necessary places. The second mechanism suggests leaving the water sources separated initially; that is creating separate piping systems for each source input, i.e. kitchen sinks, washing machine, bathroom sink and shower. The third mechanism simply suggests manually moving outlets so that no area becomes too over watered. A combination of all three of these can be constructed in order to fit the specific needs of your system.[17]

Benefits

Branched drain systems are primarily suited for property that is situated on some type of grade. The larger the degradation the more easy the installation process. This can either be beneficial or an impediment, depending on the nature of the property. This system is open to design interpretation and specialization because the amount of irrigation outlets should be based on the volume of greywater discharged. It can therefore be tailored to fit the needs of any specific property. This also alleviates over-watering because large surges of water can be distributed via branched diversion, delivering smaller amounts to the desired areas.

Considerations

Because this system is gravity fed it must be constructed so that the water is diverted downhill. This system cannot accommodate to uphill irrigation, without the supplementation of a pump. At least a 2% grade (¼” per foot) must exist in order for proper water flow and the pipes must be sloped to exact tolerance. That is, pipes must be installed so that they create a continuous, downhill conduit or else the system may not function correctly.[18] Additionally, all the considerations pertaining to mulch basin maintenance (see considerations for Land-to-Laundry systems) apply to this system as well as these are an essential component to filtration.

Constructed Wetlands

A constructed wetland (CW) or artificial wetland is a system inspired by the natural biological processes that are occur in wetland ecosystems. CWs can be categorically broken down into three different basic designs: subsurface, surface and floating treatment wetlands.

Subsurface wetlands simply imply diversion of greywater below surface level, limiting exposure to air. Subsurface wetlands can be further broken down based on diversion pathway: horizontal subsurface CWs allow effluent to pass parallel to the surface, propelled by gravity while vertical subsurface CWs allow for the release of water vertically. [19]In vertical systems, the water is technically discharged on surface, first watering the strategically chosen wetland plants. It then penetrates the soil to be filtered through the roots and lastly through the chosen substrate (sand, gravel, etc.) Vertical systems require less area as compared to horizontal systems but effluent must be discharged in intervals to avoid flooding, necessitating the implementation of a surge tank. While horizontal systems require more area, they have a larger capacity for discharge. The wetland systems themselves are comprised of the same basic components: a top layer of soil containing wetland species (preferably native to the area) and a medium of filtration. This medium is typically sand or gravel and serves as a platform for microbial growth and aids in filtration and absorption of greywater.[20] The bottom is either line with a waterproof synthetic material (such as pond liner or tarp) or organic insulating material such as clay in order to mitigate groundwater contamination.

Surface CWs (also called free-surface CWs) are structurally similar to subsurface systems but differ in that they allow for pooling of effluent. Once the effluent is discharged it slowly flows through a basin, allowing suspended sediment to settle. The water then moves downward and is filtered through the rhizomal network established by the planted wetland species. These networks are supportive of microorganisms which feed on the nitrogen and phosphorous contained in the effluent.[21] Pathogens are broken via natural decay, predation and exposure to UV radiation. [22]This exposure is an important disparity when compared to subsurface mechanisms. However, this exposure also creates a breeding ground for less desirable organisms such as mosquitoes. Suitable vegetation for surface CWs include emergent, submerged and subsurface plants.

Free-floating systems differ in structure drastically when compared to surface and subsurface wetlands. The design mimics some components of hydroponic growth, as organisms are planted on a floating mat or substrate in a pond. The stems of the plants are exposed to air, while the roots intake nutrients directly from the water column. The function of the established rhizomal system itself is the same as in a subsurface or a surface CW, except the network may be more extensive in the absence of a soil medium. The network also forms a microbial biofilm, a thin layer of cells. In this system the roots execute both biological and physical processes of treatment. That is they physically filter and trap particulates while also converting nitrogen and phosphorous via biochemical processes in the biofilm.[23]

Benefits and Considerations

Constructed wetlands are by far the most complex of the described management systems, with the most room for customization. They are also wide ranging and a number of hybrid systems that incorporate aspects from different designs are used to accommodate specific criteria. The biggest benefit of these systems is their self-sufficiency if installed correctly while perhaps the biggest drawback is the rigorous and involved process of design specialization and implementation.

Summary

The systems described are not representative of the entirety of greywater management approaches but are a summarized list of the most popular, decentralized, “low-tech” systems. Of course more exotic systems have been created such as rotating biological contactors which treat water via UV exposure and sequencing batch reactors which utilize activated sludge technology.[24] However these systems are not applicable to the layperson and thus not available for self-installation. For this reason they have been excluded from the scope of this review.

Previous CCAT Greywater System

As far as we know the most recent update for this project is the 2009 edition. Per Connor Kennedy, the CCAT grounds keeper (2017), this system has been redesigned many times since then.

Design

The current system is a simple design to filter CCAT’s grey water. It starts by coming out of the house and flows to a first settling tank that is located underground next to the bike rack. This settling tank takes out particulates by slowing the flow of the water, giving the particulates time to settle on the bottom. From here the water is transpoted underneath the drive way and to a second settling tank right before the greywater marsh. This settling tank acts as an oil trap. From the here the water is directly poured into the marsh where it moves through a baffled filter system. Since there is no direct place for the water to go after it has been fully treated, it ends up just being run off.

Problems

The known problems with the system include level ground, and too much surface area per volume of greywater. To begin, the ground where the pipe is laid has too even of a slope. This inhibits the water's ability to reach the actual location of the marsh. Finally, the built marsh has too much area to be effective. This current system was not designed with the small amount of water use of CCAT in mind.

Settling tank

The settling tank is a very simple design, but effective. The settling tanks acts like a sedimentation tank.[25] A sedimentation tank works by slowing the flow of water, allowing the suspended particles to settle onto the bottom. This collection of waste is called primary sludge[26], and must be removed manually. The way that this settling tank is designed incorporates an oil filter into it. It is a series of two buckets, the second bucket is smaller than the first so that it can be suspended inside the first bucket. The water comes from a pipe that is attached to the roof of the system and pours through the oil filter and rises back up to the top where it flows through another pipe that leads to the marsh. This allows for the flow of water to stop, giving the suspended solids the ability to sink to the bottom and effectively be filtered out of the water.

Oil filter

The primary objective of an oil filter is to remove any oils that may be in the water. The reason for this is so that the marsh system does not become clogged. The oil filter is a part of the sediment tank design. This is simply a wire mesh sheet attached to the first bucket described above. This essentially acts as a screen[27] that traps and captures the oil. The oil is further filtered through the sedimentation trap part of the settling tank and settles to the bottom becoming primary sludge.

Baffled system

The baffled filtering system includes a series of up – flow chambers.[28] The water initially enters the first section. Then, as the water level goes up it overflows into a second section where it penetrates through the soil, filling up the area, and overflows into the next. It repeats this process until the water is fully filtered. This system is not effective with weakly polluted water, but is hard to clog.[29]

Surge Tank

A surge tank is a storage reservoir that is on the downstream end of a water source that mitigates sudden bursts in water flow.[30] Surge tanks are very helpful in systems where the grey water is being treated. This initial tank stores water and allows for an even flow of water to the next stage in the process. This stops flooding to certain parts of the system that takes longer, like filters and pumps.[31]

Siphon

A siphon is a tube or pipe that is used to transfer water from one reservoir to another, on a lower level, without the use of a pump. Siphons contain steady flow using suction or immersion. An example of this would be a dosing siphon, where it uses suction, gained from breaking a vacuum, to obtain a constant flow.[32]

Pumping

While many systems will be gravity fed, there is still the case where one would need to pump the water. This may be the case in a situation with the filtration system being uphill from the initial output. This can be done with a general water pump, and is the easiest method for such scenarios. Unfortunately, this does not mean it is the most efficient.

Construction

Designing a new greywater system for CCAT is crucial because students and community members read and hear about CCAT's greywater treatment system and they often come by with questions. This new and improved greywater system will provide an approachable and informative demonstration of just one the innumerable ways to install greywater treatment systems. Our design is unique because it relies on a hand-cranked drum pump to convey greywater from CCAT's subterranean settling tank to the demonstration tub on the surface. Pumping greywater presents a risk and challenge because the wide variety of waste present can clog and degrade pumps. We felt we had to pump the greywater because the previous underground pipe is dysfunctional and inaccessible. If the water is allowed to sit for too long in the settling it will become black water which poises health risks to all CCAT visitors. The pumped greywater system will allow CCAT to convey greywater into the treatment tub at its convenience instead of the greywater remaining stagnant and turning into black water. Gravity fed greywater systems are simpler and more reliable but in this instance we were forced to incorporate a pump into our system.

Changes to old System

After careful consideration of the design to the new system, the old greywater marsh had been deemed ineffective and was thrown out as an idea for the new system. We decided, along with our client CCAT, that the best bet for this old system was to get rid of it. The pit was decided to be made into a Huegelkultur type site because just filling the old grey water marsh was not cost effective, and there were better resources that could be used. Huegelkultur is a German word meaning "hill culture", and is the practice of composting large woody material in a raised bed. CCAT fortunatley enough had an abundance of this large woody materials that could be used in turning the old greywater marsh into a Huegelkultur site. This turned out to be a benefit to us because it was cost effective for our budget, and was a benefit to CCAT because it eliminated a safety hazard.

The filling of the pit is as follows. (Bottom to Top)

- -clay bed

- ->large wooden stumps

- ->larger sticks to cut branches

- ->smaller sticks

- ->mulch

- ->top soil

- Filling the Old Greywater Marsh

-

The tedious task of taking out the old constructed greywater marsh.

-

Inflow pipe for overflow.

-

Close up to inflow pipe for overflow.

-

Protective barricade for inflow pipe

-

Filled pit.

Sizing

Typical methodology for sizing constructed wetlands is based on finding the total surface area of the treatment area. Because our team was working with a fixed area (the bathtub) we decided to size for flow rate or treatment capacity of our system; that is, how many gallons of water per day can the system treat while still meeting desired BOD5 threshold for the effluent.

To back up a step and define some key terminology, BOD5 is a quantification of how much dissolved oxygen is used by microorganisms during the oxidation of organic material, contained in some effluent [33] In other words, it is the amount of biodegradable organic material in a substrate. The ‘5’ implies that the test to measure this parameter was conducted over a five-day period. Bod is always measured in parts per million or mg/L. Influent describes the initial, untreated water flowing into the system while the effluent describes the treated water that flows out of the system.

The goal of system treatment is BOD5 reduction, based on influent and effluent comparison. Reported greywater BOD5 concentration ranges from a specific site are 45-330 mg/L [34] , while other estimations report an average of 65 mg/L.[35]. Typical treated effluent (or water exiting the system) from natural systems ranges from 2-7 mg/L.[36]

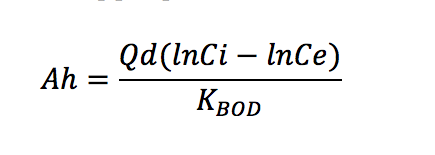

The chosen methodology for sizing our system was initially found in literature[37] and a is also the suggested approach on appropedia (see Subsurface flow constructed wetland for greywater).

Where:

- Ah= Surface Area of bed (m2)

- Qd = Average daily flow rate (m3/day)

- Ci = Influent BOD5 (mg/L)

- Ce = Effluent BOD5 (mg/L)

- KBOD = Rate Constant

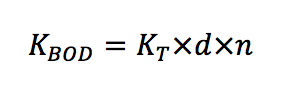

KBOD describes the rate at which BOD is removed (which is essentially the goal of treatment) and is temperature specific.

Where:

- KBOD = Rate constant at 20°C

- KT=K20 (1.06)T-20 (day-1)

- T = Average lowest monthly temperature (°C)

- d = Depth of water column (m)

- n = porosity of substrate medium (% expressed as a decimal)

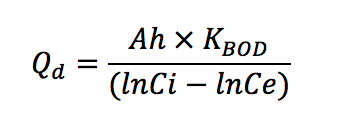

Because our team sized for flow, we rearranged the equation:

Where:

- Ah= 0.8 m2 based on fixed dimensions of bathtub

- K20= A value of 1.1 day-1 was assigned based on research for wetland systems

- T = 10°C based on reported monthly temperatures and the evapotranspiration zone Arcata falls in

- d = 0.41 m based on the fixed depth of the bathtub

- n = 0.38 based on the chosen filtration medium of pea gravel

- Ci = 75 mg/L based on BOD loading estimation

- Ce = 5 mg/L based on desired results

With these values, our sized flow rate was equal to 7.47 gal per day or 52.3 gal per week, accounting for 23.2% of CCAT's total greywater discharge.

Pump

Our team decided early on that we would not be able to rely on existing conveyance infrastructure, and since the settling take is surrounded on three sides by impermeable surfaces we determined that most viable direction for our greywater to go was up. We initially planned to build a hand pump using PVC pipe, wooden gates, and recycled valves from soda bottles. After weeks of prototyping, it became clear that our team did not possess the skills to make a reliable hand pump on our own. A few months into the planning of the projected we decided to purchase a pump. This posed a new question, do we look for a hand pump or do we look for something mechanical? Greywater is home to microorganism, food scraps, fats, and all sorts of other pieces of effluent that make it difficult to pump cheaply and simply. Of course there are large submersible trash pumps that can handle the job, however these pumps were cost prohibitive and CCAT was worried about them being forgotten and left to deteriorate. Because of these possible issues with mechanical pumps, we decided to install a rotary drum pump like the ones used to remove oil from barrels. We decided on a cast iron rotary drum pump because it was simple, cheap, and seems reliable. One concern is that this pump was designed to pump oil so there is concern that using it to repeatedly pump water could cause rust that could make speed up the deterioration process. There is a possibility that the fats and oils from the kitchen could help keep the rotary drum lubricated, but only time will tell. Our pump has the capacity to provide 10 GPM to our marsh demonstration.

Treatment Area (Bathtub)

As mentioned above, the component of constructed wetlands that is typically sized for is treatment area. Treatment area describes the ground surface area that is generally the only visible part of a subsurface constructed wetland. Depth is not sized for because it is based on selected plant species ability to develop rhizomal networks, and so values based on plant rooting depths are used instead. However, because our system favors accessibility over capacity, we decided to work with a fixed, above ground treatment area: the bathtub.

The decision to utilize a bathtub was in alignment with a number of our criteria, although it is rather unconventional within the scope of constructed wetland implementation. The tub was recovered from a local scrap yard, fitting the requirement for recycled materials. The subterranean greywater effluent pipe from the house necessitated a pumping component if the treatment system was to be above ground; the bathtub represented the potential for not only an above ground, but also interactive treatment area. Finally the aesthetical value of the bathtub was consistent with the criteria as well.

The bathtub is curved around the sides, and tapers downward so average dimensions were taken based on top and bottom measurements. Our team found a total surface area of 0.8 m 2 (8.6 ft 2). The bathtub depth was found to be approximately 0.45 m (1.6 ft). A depth of 0.4 m was used with the assumption that the roots of the selected plant species would eventually colonize the entirety of the subsurface volume. Two baffles sets were installed, constructed of recycled wood and pond liner. Each set is 0.34 m (1.1 ft) from their respective ends of the bathtub. One set constitutes a first 0.27 m baffle that is secured at the base of the tub and a second baffle that is suspended by approximately 92 mm (3.63 in), (or the width of a standard brick) and a height of 0.36 m (1.2ft) (excluding the height of the brick). Each baffle within a set is spaced 0.13 m (0.43 ft) away from each other, and the two sets have a distance 0.34 m (1.1 ft) between them ( from the last baffle of the first set and first baffle of the second set.)

The influent pipe was placed 0.25 m (0.82 ft) from the bottom of the tub, and the effluent pipe was secured 0.2 m (0.67 ft) from the bottom of the tub on the exiting side, resulting in about 5 cm (2 in) of head. This difference in pipe elevation was necessary for the employment of gravity as the driving mechanism for water flow through the wetland system; without head the water would sit stagnant. Additionally the tub was place on an existing natural gradient, which our team was unable to report. The filtration medium of pea gravel (with a porosity of approximately 38%) was filled to a height ranging from 5-7 cm (2-2.7in) below the lip of the tub.

Marsh Plants

Constructing a system of plants for our greywater marsh will help us reach the goal of lowering excess nutrients, nitrogen and phosphorous, that can allow for growth of unwanted bacteria. As well as lowering the Biological Oxygen Demand (BOD) of the water. The reason we focus on the BOD is because it is an indirect measure of the organic material in the water. BOD represents the amount of oxygen needed by anaerobic biological organisms to break down organic material. We can then use this information to decide how many plants we need for our system.

Once we knew how many plants will be needed for a safe BOD, we chose the plants best for our climate and very small ecosystem. Here in Arcata, we have a large scale constructed wetland that processes all of the water from the city[38]. The plants originally planted at the Arcata marsh for filtration purposes are Hardstem bulrush, Sago pondweed and Hydrocotyl[39]. Each of these plants has rhizomes, an underground root system or modified stem that increases anaerobic degradation of organic matter and nitrification[40]. As well as microorganisms living in their roots that reduce the BOD and breakdown settled algae. Leading to a reduction of excess nutrients, and healthier water.

Our team recycled bullrush from the decommissioned greywater marsh at CCAT, as these plants were doing their job and were not the problem with the system, as well as added. In order to find which emergent plants are best for your greywater system, check out the Appropedia page Emergent plants for constructed wetlands.

Timeline

| Item | Description | Date | Date met? | |

|---|---|---|---|---|

| Start prototyping | We will begin the process of designing our pump system and obtain bathtubs. | Week 2/06/17 | YES! | |

| Prototyping | We will begin soil testing and anything left over from the previous week | Week 2/13/17 | YES | |

| Survey aesthetics and meet with the Arcata Marsh | We will begin watching how many people interact with the system to get a feel if people are attracted to it based off of how it looks. As well as meet with the Arcata Marsh to ask about their systems. Also, still continuing the prototyping process. | Week 2/20/17 | YES | |

| Plant implementation/Prototyping/BOD testing | We will be finalizing various plants, as well as the bath tub configuration. | Week 2/27/17-3/06/17 | YES | |

| Full client agreement/Start building project | We will finalize the client agreement as well as begin the construction of the finished project. | Week 3/20/17 | YES | |

| Prototyping/Building | We will work on building the project and begin designing/prototyping different pumps. | Week 3/27/17 | YES | |

| Construction and Design Updates | We will work on constructing the project by prepping the area for installation. As well as work on design updates and creating the design for the garden (end use). | Week 4/3/17 | YES | |

| Acquiring Materials | We will begin purchasing needed materials such as piping, plants and the bathtub. | Week 4/10/17 | YES | |

| Deconstruction of Old Site | The team will tackle the old marsh site. Doing so by digging up the greywater marsh and filling the hole with other materials so that the space can be used in the future. | Week 4/17/17 | YES | |

| Finishing Up Construction | Building and installation the wildflower planter box. Placement tub in new location and leveling out of the tub. Installed baffles. | Week 4/24/17 | YES | |

| Finish Construction/Surveying | We will finish building the system by installing the gravel and marsh plants. As well as start working on educational signs and begin surveying people's usage of the finished system. | Week 5/1/17 | YES |

Costs

This project is entirely endorsed and funded by CCAT for the two-part purpose of greywater management and a demonstrative platform for educational opportunity. In alignment with our client criteria, we plan to construct our proposed system using 80% reused material, much of which will be supplied by CCAT itself. Other sources of reused material we plan to utilize are Arcata Scrap Yard, SCRAP Humboldt and the Arcata Marsh.

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 1 | Bathtub | Arcata Scrap Yard | 20.00 | 20.00 |

| 2 | PVC Pipe | Arcata Scrap Yard | 5.00 | 10.00 |

| 1 | Wood Chips | Wes Green Landscaping | 35.00 | 35.00 |

| 1 | Yard Soil (Pete moss/bark) | Wes Green Landscaping | 35.00 | 35.00 |

| 1 | Yard of #3 rock | Wes Green Landscaping | 35.00 | 35.00 |

| 4 | Scraps of wood for baffles | CCAT | Reuse | - |

| 1 | Yard of sand | CCAT | Reuse | - |

| 1 | Pond Liner | CCAT | Reuse | - |

| 1 | 10 GPM Action Pump | Amazon | 64.11 | 64.11 |

| 1 | Post-Pump Filter Screen | CCAT | Reuse | - |

| N/A | Marsh Plants | Arcata Marsh | Donation | - |

| 3 | Large Wooden Stumps | CCAT | Reuse | - |

| N/A | Cut Tree Branches | CCAT | Reuse | - |

| N/A | Mulch and Top Soil | CCAT | Reuse | - |

| 1 | PVC Primer and Glue | Ace Hardware | 6.99 | 6.99 |

| 1 | Thread Seal Tape | Ace Hardware | 1.29 | 1.29 |

| N/A | Couple | Ace Hardware | 1.29 | 1.29 |

| N/A | 2 inch Galvanized Floor Flange | Ace Hardware | 15.99 | 15.99 |

| N/A | Screws | Ace Hardware | 0.76 | 0.76 |

| N/A | Whiskey Barrel | Craigslist | 70.00 | 70.00 |

| 3 | metal clamps | Ace Hardware | 5.00 | 5.00 |

| N/A | 1.5 inch rubber couple | Ace Hardware | 4.00 | 4.00 |

| N/A | 2 inch threaded nipple | Ace Hardware | 2.00 | 2.00 |

| N/A | 4 ft of PVC | Ace Hardware | 5.00 | 5.00 |

| N/A | 1.5 inch PVC couple | Ace Hardware | 3.00 | 3.00 |

| Total Cost | $309.43 | |||

Operation

This is how to operate and maintain the 2017 greywater system at CCAT. It is very important that the system is maintained and cleaned per this schedule. If not, the system will fail to treat the greywater and it will become a health hazard to have this system on [[CCAT] grounds.

Maintenance

The greywater marsh has been designed to be as easy to maintain as possible. Most necessary tasks are to be done once every month and only take a few minutes.

Schedule

- Weekly

- Pump greywater into the system once a week.

- Monthly

- Clean oil trap

- Yearly

- Clean settling tank

Instructions

These are the step-by-step instructions on how to maintain this greywater marsh.

Conclusion

Testing results

BOD5: unable to final results until root system established

Pump: conveys greywater through system after fixing leaking pipe junctions

Discussion

This project is relatively hard to test in our time frame considering that there is not enough time to establish a full root system. The root system is the most important aspect of our project, it filters the greywater making it pure enough to water the wildflower garden. This will be tested in the future with BOD5 testing, resulting in weather or not the system sufficiently filters the greywater. Our initial pump test yielded unsuccessful results because we couldn't get greywater to come out through our pump. Through troubleshooting we identified the junction between our metal pipe and the PVC as the most likely place where we were losing suction. After retaping all pipe junctions with thread tape we were able to get the pump to work. We'll see how long it goes.

There is a possibility that the pump may malfunction because it was designed to transport oil instead of water and is made of cast iron. One of our biggest fears is that the water will cause the rotary drum part of the pump to get stuck and eventually stop working. We are also aware that our treatment area may not succeed in getting the greywater clean enough for use on edible plants (which is why it is being used on wildflowers), but this serves our purpose of just being a demonstration piece. Because all of the components are accessible maintenance will be more straight forward that it was for the previous system. Problems will also be easier to deal with because they're accessible and easy to identify.

Lessons learned

While implementing this project our team learned a few things through trial and error. For starters, although we learned a lot form the process of building our own hand pump. Something that is going to be used to convey greywater should be very heavy duty. Our handmade pump just didn't seem to suffice as it could not stand up to the thickness of the greywater. Hand pumps such as the one we built would be much better used on a system that is just conveying clean water. In addition, we would suggest doing more BOD5 testing. The lab results that we received were sort of inconsistent and could have benefited from a larger sample size. We would also suggest finding a better way to secure the baffles. Our resulting baffle display has the baffles secured in a fashion that isn't as aesthetically pleasing as it could be. We would also suggest finding a way to locate your greywater at a higher elevation so that there was a larger end use. The location of our project hindered this for the team.

Next steps

Possible expansions for the project into the future could include and expansion of the end use. The current 2017 system's end use ends up in a small wildflower garden. It would help the system if there were more planter boxes built and an expansion of the irrigation. In addition, the movement of the barrel could be made a little more efficient for the cleaning of the pump. Currently the movement of the barrel requires two or more people. If one were to install a hinge so that the barrel could be moved safely by a single person this could make the cleaning of the pump easier and more efficient. Making it much more likely to get done in the future. If a future CCAT engineer feels the need to really update the system, they could install a solar pump. This would remove the problem of they greywater possibly turning into blackwater by employees forgetting to pump the system when necessary. The main future issues that this system may face are user errors.

Troubleshooting

This is only how to troubleshoot basic operation. For complex issues, the solution might just say contact ________. It should be a table in this format:

| Problem | Suggestion |

|---|---|

| Pump isn't pumping | Check on all pipe section connectors. Possibly retape the connectors with thread tape to provide suction |

| Water is't flowing | Clean the screens that the greywater flows through. Please read above maintenance section. |

| Suggestion for large CCAT events | Switch the effluent pipe over to the sewer instead of flowing into the greywater system. This can be done by using the greywater "key" located at CCAT. One has to open the grate near the system, close they greywater pipe and open the pipe to the sewer. This is suggested to be done at large events because the pipe leaving the house has a very small flow. Sized for the people thrivign at CCAT on a regular day. |

Team

CCAT greywater team 2017:

References

- ↑ https://nepis.epa.gov/Adobe/PDF/P100FS7K.pdf

- ↑ Maimon, Adi, Alon Tal, Eran Friedler, and Amit Gross. 2010. Safe On-Site Reuse of Greywater for Irrigation - a Critical Review of Current Guidelines. Environmental Science & Technology. 44, no. 9: 3213.

- ↑ Turner, Ryan D.R, Ryan D.R Turner, Geoffrey D Will, Les A Dawes, Edward A Gardner, and David J Lyons. 2013. Phosphorus as a Limiting Factor on Sustainable Greywater Irrigation. The Science of the Total Environment. 456 457: 287.

- ↑ Allen, L. (2015). Water Wise Home, Storey Publishing, Massachusetts. 46-139.

- ↑ Turner, Ryan D.R, Ryan D.R Turner, Geoffrey D Will, Les A Dawes, Edward A Gardner, and David J Lyons. 2013. Phosphorus as a Limiting Factor on Sustainable Greywater Irrigation. The Science of the Total Environment. 456 457: 287.

- ↑ Maimon, Adi, Alon Tal, Eran Friedler, and Amit Gross. 2010. Safe On-Site Reuse of Greywater for Irrigation - a Critical Review of Current Guidelines. Environmental Science & Technology. 44, no. 9: 3213.

- ↑ California Plumbing Code. 2013. Alternate Water Sources for Non-Potable Applications. California Uniform Building Code. 16a.

- ↑ Maimon, Adi, Alon Tal, Eran Friedler, and Amit Gross. 2010. Safe On-Site Reuse of Greywater for Irrigation - a Critical Review of Current Guidelines. Environmental Science & Technology. 44, no. 9: 3213.

- ↑ Press, Ellen Knickmeyer The Associated. "California drought spurring ‘grey water’ recycling at home." California drought spurring ‘grey water’ recycling at home. June 05, 2015. Accessed January 28, 2017. http://www.dailynews.com/environment-and-nature/20150605/california-drought-spurring-grey-water-recycling-at-home. .

- ↑ Morel, Antoine, and Stefan Diener. "Greywater management in low and middle-income countries." Review of Different Treatment Systems for Households or Neighborhoods (2006). .

- ↑ About Greywater Reuse. Greywater Action for Sustainable Water Culture. http://greywateraction.org/contentabout-greywater-reuse/.

- ↑ ÜSTÜN, Gökhan, and Ayşenur TIRPANCI. "Gray Water Treatment and Reuse." (2015): 119-139..

- ↑ Sturgis, Michael. "Laundry to Landscape, a How-To." Permaculture Magazine. June 03, 2016. Accessed January 27, 2017. https://permaculturemag.org/2016/06/laundry-to-landscape-a-how-to/..

- ↑ Sturgis, Michael. "Laundry to Landscape, a How-To." Permaculture Magazine. June 03, 2016. Accessed January 27, 2017. https://permaculturemag.org/2016/06/laundry-to-landscape-a-how-to/..

- ↑ Ludwig, Art. Create an oasis with greywater: choosing, building, and using greywater systems, includes branched drains. Santa Barbara, CA: Oasis Design, 2006..

- ↑ "Greywater Mulch Basins." The Walden Effect . August 16, 2012. Accessed January 31, 2017. http://www.waldeneffect.org/blog/Greywater_mulch_basins/..

- ↑ Ludwig, Art. Create an oasis with greywater: choosing, building, and using greywater systems, includes branched drains. Santa Barbara, CA: Oasis Design, 2006..

- ↑ Ludwig, Art. Create an oasis with greywater: choosing, building, and using greywater systems, includes branched drains. Santa Barbara, CA: Oasis Design, 2006..

- ↑ "Constructed Wetlands for Wastewater Treatment." FH Wetland Systems Ltd. - Constructed Wetlands. Accessed January 31, 2017. http://www.wetlandsystems.ie/constructedwetland.html..

- ↑ "Constructed Wetlands for Wastewater Treatment." FH Wetland Systems Ltd. - Constructed Wetlands. Accessed January 31, 2017. http://www.wetlandsystems.ie/constructedwetland.html..

- ↑ Tilley, E., et al. "Compendium of Sanitation Systems and Technologies-. Swiss Federal Institute of Aquatic Science and Technology (Eawag), Duebendorf, Switzerland." (2008): 10..

- ↑ Hoffmann, Heike, C. Platzer, M. Winker, and E. Von Muench. "Technology review of constructed wetlands Subsurface flow constructed wetlands for greywater and domestic wastewater treatment." Deutsche Gesellschaft für, Internationale Zusammenarbeit (GIZ) GmbH, Sustainable sanitation-ecosan program, Postfach 5180 (2011): 65726..

- ↑ Headley, T. R., and C. C. Tanner. "Constructed wetlands with floating emergent macrophytes: an innovative stormwater treatment technology." Critical Reviews in Environmental Science and Technology 42, no. 21 (2012): 2261-2310..

- ↑ ÜSTÜN, Gökhan, and Ayşenur TIRPANCI. "Gray Water Treatment and Reuse." (2015): 119-139.s.

- ↑ United States. Environmental Protection Agency. Wastewater managment . Primer for municipal wastewater treatment systems. Washington, D.C., California: U.S. Environmental Protection Agency, Office of Water, Office of Wastewater Management, 2004.

- ↑ United States. Environmental Protection Agency. Wastewater managment . Primer for municipal wastewater treatment systems. Washington, D.C., California: U.S. Environmental Protection Agency, Office of Water, Office of Wastewater Management, 2004.

- ↑ United States. Environmental Protection Agency. Wastewater management . Primer for municipal wastewater treatment systems. Washington, D.C., California: U.S. Environmental Protection Agency, Office of Water, Office of Wastewater Management, 2004.

- ↑ Imhof, Barbara, and Joelle Muhlemann. "Greywater treatment on household level in developing countries ." February 2005.

- ↑ Imhof, Barbara, and Joelle Muhlemann. "Greywater treatment on household level in developing countries ." February 2005.

- ↑ Merriam-Webster. Accessed January 31, 2017. https://www.merriam-webster.com/dictionary/surge%20tank.

- ↑ Ludwig, Art. Create an oasis with greywater: choosing, building, and using greywater systems, includes branched drains. Santa Barbara, CA: Oasis Design, 2006.

- ↑ "How Siphons WorkOperation of Single Automatic Siphons." How Dosing Siphons Work | Fluid Dynamic Siphons, Inc. Accessed January 31, 2017. http://www.siphons.com/how-siphons-work.html.

- ↑ http://drinc.ucdavis.edu/dairyp/dairyp9_new.htm.

- ↑ http://www.sswm.info/sites/default/files/reference_attachments/WAFLER%202008%20Small%20scale%20Constructed%20Wetlands.pdf

- ↑ Casanova, L.M., V.Little, R.J.Frye, and C.P.Gerba 2001. A survey of the microbial quality of recycled household graywater. Journal of the American Water Resources Association (JAWRA) 37(5)

- ↑ Crites, Ronald, and Techobanoglous, George, 1998, "Small and Decentralized Wastewater Management Systems", Water Resources and Environmental Engineering.

- ↑ N-HABITAT, Constructed Wetlands Manual. "Water for Asian Cities Programme Nepal." (2008).

- ↑ https://www2.humboldt.edu/arcatamarsh/overview.html

- ↑ http://www.ecotippingpoints.org/our-stories/indepth/usa-california-arcata-constructed-wetland-wastewater.html

- ↑ http://wst.iwaponline.com/content/35/5/117