(→Screen) |

|||

| Line 329: | Line 329: | ||

===Screen=== | ===Screen=== | ||

[[File:Screen.JPG|thumb| | [[File:Screen.JPG|thumb|bottom|<b>Figure 5</b>... ]] | ||

1. Make the frame of the screen using the hammer and nails. | |||

2. Staple the screen onto the frame. | |||

3. Attach the frame onto the cold box with nails. | |||

===Box=== | ===Box=== | ||

Revision as of 03:52, 9 May 2017

Background

CCAT

The Campus Center for Appropriate Technology (CCAT) of Humboldt State University (HSU) is known as a place where students, faculty, and volunteers can collaborate, innovate, and create projects that reduces, reuses, and recycles waste. In CCAT's old location they had had a cold box that was connected to the outside in the kitchen, after CCAT moved to there new location a cold box was never put back.In this Spring 2017 project, Katelyn P. and Winessa N-S. will build a new cold box to replace where the old one once was.

Purpose

According to CCAT [1], by using Humboldt’s natural cool weather, its cold air is captured by allowing it to flow through the vents into the box, hence “cold box.” The cold air circulates in the box, dropping the temperatures of the produce and other items as well as ridding of smelly odors. For this project, we will be building a new cold box, where the old one once stood, to give more produce storage to those living in the CCAT house. The design behind the chill box is to have an insulated "box" that has one area that are connected to the outside. For our coldbox, we will use a similar design to the one that was previously in place, it will have a vent system in the back that allows cold air into the box. Then, the cold box has a tube at the top that goes through the roof of the house and ventilates the warm air out of the box and into the outdoors.

Problem statement

The objective of this project is to create a spot for produce to be stored and kept fresh by the natural Humboldt environment. By applying methods like these, we are able to reduce the use of electricity which in turn saves money as well as create something that other households may use to reduce there dependency on electricity.

Literature Review

This is a review of the available literature pertinent to refrigeration.

Refrigeration basics

Refrigeration is the science and practice of controlling temperature conditions, to slow down the growth of bacteria in food, drinks, and other items [1] What a refrigeration system typically consist of is a compressor which circulates the refrigerant and raises the pressure of the refrigerant forming vapor from. [2]. It is the art of maintaining a body of temperatures below its surroundings or alternatively as the removal of heat from a place in which it is undesirable to a place in which it is not. [3]

On the other hand, for this project, a cold box does not need a compressor. Instead, a cold box will need to consist of five characteristics. It needs to have water resistance, the ability to withstand continual use, the ability to maintain a temperature not exceeding at around 5°C for a week, affordability and simplicity. Developing countries should be able to use these “cold boxes.” The temperature of this cold box is low because it is used for vaccines. The temperatures for cold box in this project will vary depending on the season. [4]

Refrigeration concerns

In industrialized countries, people use refrigerators which has refrigerants. A refrigerant is a substance that absorbs heat by evaporating at low temperatures and pressures and gives up heat by condensing at high temperatures and pressures.” [5] Many refrigerants have been banned because these have been known to deplete the Earth’s ozone layer, which is necessary to help protect biological life from the sun’s harmful UV rays. These refrigerants are called chlorofluorocarbons or simply known as CFCs. [6]

In addition, where one part of the world uses refrigerators, another part of the world with millions of people have no refrigerators due to the lack of energy and electricity. According to the Food and Agriculture Organizations of the United Nations (FAO), more than one third of the food produced today is lost or wasted. [7] The lack of refrigeration impacts the well-being of people as well as the health of the environment. The total costs of food waste amount globally are about $2.6 trillion, which includes the environmental costs at $700 billion and the social costs at $900 billion. [8]

To help solve this problem, the implementation of refrigeration can help decrease these global costs. Sustainable methods of refrigeration can also increase the well-being of people who live in impoverished areas and protect their environments.

Types of Refrigeration

There are three methods of cooling: passive or evaporative, sorption heat driven, and mechanical compression [2]. In industrialized countries, the use of grid electricity is the main method of refrigeration. On the other hand, in developing countries, refrigeration is used without a reliable source of electricity.

Type 1

Passive and evaporative refrigeration is a system that utilizes temperatures at 10 to 25°C. [9] In this type, traditional methods are used with wet sack coverings or porous jars in which the heat is evaporated from the water into a dry atmosphere. The best utilization of this refrigeration method is during the night or in the shade. The only disadvantage is that this method cannot be used in wet weathers. [10].

Type 2

Sorption heat driven coolers is a type of refrigeration that utilizes both liquid absorption and solid adsorption. [2]. This method has several advantages. It does not need any moving parts, therefore, there would be less need for replacing components and skilled maintenance personnel. The next advantage that these are simple to manufacture. It will only need local maintenance. The third advantage is that these adapt to locally available fuels like solar energy and biomass. The last advantage is that this method does not need the use of CFCs. [2].

Type 3

Mechanical compression refrigeration is a system that utilizes power. It ranges from the use of the grid electricity, solar photovoltaic systems, and to water turbine driven coolers. The advantage of having this type of method is having food and other items cool for a long period of time; however, to maintain these types of mechanical compression refrigeration and to replace its parts will be costly. [2].

Vacuum Basics

A vacuum, the "space in which there is no matter or in which the pressure is so low that any particles in the space do not affect any processes being carried on there. It is a condition well below normal atmospheric pressure and is measured in units of pressure (the pascal). A vacuum can be created by removing air from a space using a vacuum pump or by reducing the pressure using a fast flow of fluid, as in Bernoulli’s principle." [11]. In modern particle physics, the vacuum state is considered the ground state of matter. [12]. For this project the idea that 'The warm wet air is forced up and over the cold air. When the warm air is forced up, it causes surface air pressure to drop, sort of like having a small vacuum develop'. [13] In our chill box the cold air flowing in will create a change of pressure in the box sucking the hot air, that has risen to the top, out the window and these will create the cool temperature in the box allowing for food storage.

Designing interpretive materials

According to the FAO, the most realistic method of refrigeration used in developing countries is evaporative cooling. It typically consists of an outer pot and an inner pot. [14]Between the two pots consists of an evaporative medium like sand. The food is placed into the inner pot. To create the cooling effect, water is added into the sand, and it draws heat from the inner chamber pot. This cause and effect cools the food and other items down to 20°C. [15]

Project Evaluation Criteria

| Criteria | Constraints | Weight (1-10) |

|---|---|---|

| Cost | Cannot exceed budget | |

| Maintainability | Must be easy to clean (vents) and cheap to maintain | |

| Aesthetics | Must be pleasing to the eye | |

| Educational Aspect | Must explain to the public and educate students and community members | |

| Safety | Must not interfere with doorways and exits | |

| Reproducibility | Easy to reproduce so others can make there own | |

| Feasibility | Possible to do | |

| Functionality | Must meet requirements of client | |

| Sustanability | Made out of recycled materials | |

| Convenience | Easy for client to use and made so they use it instead of an alternative | |

| Correct Measurements | To meet the client’s needs | |

| Accessability | Access to water (rainwater) and cold air | |

| Mobility | Easy for client to move to new locations if necessary | |

| Placement | Should be on stand to not be in way of shelves | |

| Usability | Must be able to cool food and other products | |

| Temperature | Must have a certain temperature to cool food and other products |

Timeline

| Due Date | Action | Description | Date Met (Y/N) | |

|---|---|---|---|---|

| 2/03/17 Fri | Research | Work on the Project Evaluation Criteria | ||

| 2/10/17 Fri | Research | Work on Tentative Timeline | ||

| 2/14/17 Tue | Research | Look at other examples and pick a few to prototype. | ||

| 2/20/17 Mon | Make prototype | Start with tape and cardboard. | ||

| 2/26/17 Sun | Make a budget | Make a budget on the approximate estimates of the materials for CCAT approval. | ||

| 2/27/17 Mon | Finalize design | Pick favorite of prototypes and design it with CCAT approval. | ||

| 3/24/17 Mon | Change of Project | Current cold box works. We will need to build a different one. | ||

| 3/27/17 Mon | Create new prototype | New prototype to reflect new project. | ||

| 4/06/17 Thurs | Get materials | Built frame and staple screen. | ||

| 4/10/17 Mon | Cut materials | Attach sides and bottom to the frame with the screen. | ||

| 4/12/17 Weds | Cut materials | Cut the wood for the door and top, and attach the door with hinges. | ||

| 4/17/17 Mon | Stain box | Stain whole box. | ||

| 4/23/17 Mon | Measure hole for pipe | Go to CCAT and measure diameter and placement of the hole on the top of the cold box for the vent. | ||

| 4/26/17 Mon | Cut materials | Insulate the box and attach shelve leaves. | ||

| 5/1/17 Tues | Screw top on | Attach top onto the box, insert pipe, and add insulation to the top. | ||

| 5/6/17 Sat | Install | Installation halted because there was a leak in the pipe of the ceiling. |

Budget

Introduction for the budget: The materials used for the cold box will be donated by CCAT, materials used from a friend, gathered from our environment (beachgrass), or bought from ArcataSCRAP, Scrapyard in Arcata and Ace. We have thought on refurbishing the existing cold box at CCAT, but it was too bulky for the current residents; therefore, we will use materials to accommodate their needs. The following table is a draft of our budget, approximating estimates of purchasing materials.

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 1 | Box Nails | Ace | 3.83 | 3.83 |

| 2 | 4'x8' | Ace | 36.00 | 72.00 |

| 1 | 2'x4'x8 | Ace | 9.00 | 9.00 |

| 1 | Handle | Ace | 5.00 | 5.00 |

| 1 | Hinges | Ace | 4.00 | 4.00 |

| 1 | Screen | Ace | 5.00 | 5.00 |

| 1 | Nail gun nails | Ace | 4.00 | 4.00 |

| 1 | Pipe | Ace | 5.00 | 5.00 |

| 1 | All screws | Ace | 6.00 | 6.00 |

| 1 | Insulation | Ace | 16.00 | 16.00 |

| 2 | Shelve leaves | Ace | 3.00 | 6.00 |

| 1 | Sealant | Ace | 6.00 | 6.00 |

| Total Cost | 195.83 | |||

Construction

We were told by CCAT on March 24th that the current cold box at CCAT works and that it did not need to be fixed, we were told instead that there used to be a cold box at the old CCAT and that there was still a hole in the wall where it had been mounted. During the meeting, we created a new design with the CCAT Co-Directors to create something that they liked and wanted and that would fit in the specific spot. We decided to make it look similar to the old one that had once been there which looked like a cabinet with insulation. When we went on May 7 the Co-Directors told us that the pipe where the hot air would leave the cold box from has a leak and that it would need to be fixed before the cold box could be mounted therefore we can not mount it until this problem is solved.

Measurements

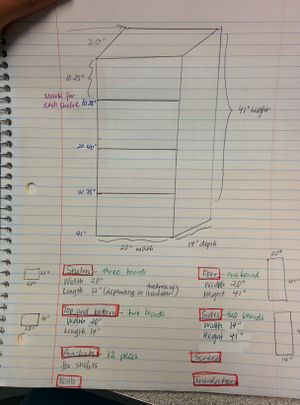

These are the measurements that were used for the construction of the cold box.

| Component | Measurements (inches) |

|---|---|

| Shelves | |

| Door | |

| Top and Bottom | |

| Sides | |

| Screen | |

| Frame |

Design

Prototype

Screen

1. Make the frame of the screen using the hammer and nails.

2. Staple the screen onto the frame.

3. Attach the frame onto the cold box with nails.

Box

Insulation

Stain

Conclusion

Results

We were able to create our cold box that is insulated but will not be able to test it until it is mounted on the wall in front of the vent to the outside. The cabinet looks like the old one though; however, when we shown the cold box to the CCAT Co-Directors, they were pleased with the results and excited to put it in place. After building the box we decided to only do two shelves instead of three because there would not have been space to store taller objects with three, and the clients agreed. Furthermore, the shelves are also not screwed onto their leaves because CCAT wanted to be able to take them out to wash and clean them if necessary. All together Winessa and I are pleased with the outcome, even though neither of us had ever built anything like this. We were excited that it finally came together in the end, and the clients were happy. We hope to have CCAT contact us when the leak is fixed so that we can go there and mount it to see the final product in place. Also, we can then test it to make sure that it works as it should.

Lessons Learned

We should prepare earlier and have better communication with the Co-Directors as well as Lonny. We could have saved ourselves a lot of time and stress if there had been more communication and if we had known earlier that the current cold box works. If there had been one initial meeting between all the parties it would have made this project less stressful and more fun. We did learn though how to use different types of power tools and how to construct a cold box which we can then teach to others. We also learned how vacuums and air circulation work in relation with one another.

Team

Acknowledgements

- ↑ 1. Arora, Ramesh Chandra. Refrigeration and Air Conditioning. PHI Learning Private, Ltd., 2010. Print. 31 Jan. 2017.

- ↑ 2.0 2.1 2.2 2.3 2.4 "Refrigeration in Developing Countries." Practical Action. The Schumacher Centre, n.d. Web. 31 Jan. 2017. <http://practicalaction.org/media/preview/10539>.

- ↑ Granet, Irving. Elementary applied thermodynamics. New York: J. Wiley, 1965.

- ↑ Lundbeck, H., B. Hakansson, J.S. Lloyd, S.K. Litvinov, & F. Assaad. "A Cold Box for the Transport and Storage of Vaccines." Bulletin of the World Health Organization, 56(3):427-432 (1978). Web. 31 Jan. 2017. <https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2395592/pdf/bullwho00440-0097.pdf>.

- ↑ Walker, Rusty. "Refrigeration 101.” Energy & Store Development Conference. Web. 31 Jan. 2017. <https://www.epa.gov/sites/production/files/documents/Refrigeration_101.pdf>.

- ↑ Walker, Rusty. "Refrigeration 101.” Energy & Store Development Conference. Web. 31 Jan. 2017. <https://www.epa.gov/sites/production/files/documents/Refrigeration_101.pdf>.

- ↑ "Food Wastage Footprint." Sustainability Pathways: Food Loss and Waste. Food and Agriculture Organizations of the United Nations, 2017. Web. 31 Jan. 2017. <http://www.fao.org/nr/sustainability/food-loss-and-waste/en/>.

- ↑ "Food Wastage Footprint." Sustainability Pathways: Food Loss and Waste. Food and Agriculture Organizations of the United Nations, 2017. Web. 31 Jan. 2017. <http://www.fao.org/nr/sustainability/food-loss-and-waste/en/>.

- ↑ "Refrigeration in Developing Countries." Practical Action. The Schumacher Centre, n.d. Web. 31 Jan. 2017. <http://practicalaction.org/media/preview/10539>.

- ↑ "Evaporative Cooling." Practical Action. The Schumacher Centre, n.d. Web. 31 Jan. 2017. < http://www.fao.org/climatechange/17850-0c63507f250b5a65147b7364492c4144d.pdf>.

- ↑ The Editors of Encyclopædia Britannica. "Vacuum." Encyclopædia Britannica. November 06, 2016. Accessed February 01, 2017. https://www.britannica.com/science/vacuum-physics.

- ↑ "Vacuum." Wikipedia. Accessed February 01, 2017. https://en.wikipedia.org/wiki/Vacuum.

- ↑ "Weather Basics (Stormsurf)." Weather Basics (Stormsurf). Accessed February 01, 2017. http://www.stormsurf.com/page2/tutorials/weatherbasics.shtml.

- ↑ "The Science." Evaptainers. Web. 31 January 2017. <http://www.evaptainers.com/the-technology>

- ↑ "The Science."Evaptainers. Web. 31 January 2017. < http://www.evaptainers.com/the-technology>