The earthen oven at the Blue Ox Millworks in Eureka, California was constructed in 2004 by Appropriate Technology (Engr305) students at Humboldt State University. The project took four, three-hour work sessions to complete over a total of four weeks. As of 2007 it is still standing, is in immaculate condition and retains nearly the same heating efficiency as when it was first constructed. This page includes information on the construction of the Blue Ox earthen oven and information and updates on its current condition.

Overview of Earthen Ovens

Earthen Ovens have been used for thousands of years by cultures all over the world and they are still built today by people all over. Earthen ovens are made up of just that, EARTH! Sand, clay and straw are used in building these versatile ovens.

An earthen oven can be used to cook the same things cooked in a normal household oven, so long as you can fit it through the door! Often Earthen Ovens are somewhat unique from other ovens in that they don’t have a fire burning continuously to cook with. The oven is heated before any cooking is going to take place. Generally Earthen Ovens are fired for a few hours and the hot coals are then scraped out of the interior. Once the coals are scraped out, the oven is ready to cook in.

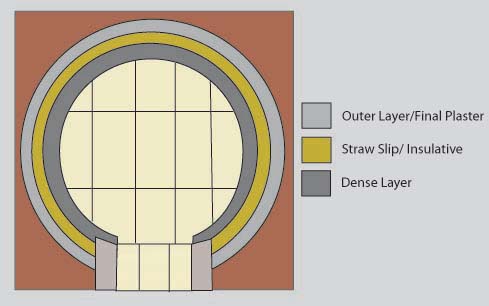

Earthen ovens are generally made up of three different layers, which are as follows:

- The Dense, Thermal mass, Layer

- The Insulative Layer

- The Earthen Layer/Outer Layer

Heating up the mass of the oven requires a large amount of fuel, so the better use you make of the slowly declining heat, the less waste there is. Efficiency in masonry ovens (whether made of brick or earth) depends on how you use them, as well as by how well insulated they are. (The new (2007) edition of Kiko Denzer's Build Your Own Earth Oven includes a more thorough review of both insulation and efficiency issues, as well as other designs that may be more efficient.)

Layer One: The Dense Layer

The first layer, which is the inner wall of the cooking area, is known as the dense layer, this is perhaps the most important layer to the oven. This layer is the "thermal mass", meaning it absorbs the heat of the fire and slowly radiates it. This radiated heat is what cooks the food in the oven. The dense layer is made up mostly of sand with some clay added.

Layer Two: The Insulative Layer

The second layer of the oven aids the dense layer by keeping the heat from the fire within the oven instead of letting it radiate outwards. This second layer is known as the insulative layer. It is composed of straw, with some clay slip added.

Layer Three: The Earthen Layer

The third layer is another earthen layer that is made up of sand and clay, however this layer has straw added to provide the structure with tensile strength and overall stability. The outer layer provides strength to the oven and can be used to make the oven more aesthetically pleasing by using it as a sculpting medium.

Earthen Oven Expenses

Earthen ovens can be built by anybody and can be done quite inexpensively depending on the resources that you have available. Our oven was built for only $40, but we had clay, straw, and bricks at our disposal. A more realistic figure for cost would be around $200, depending what your foundation is made up of. Ours was made up of old bricks that were on site, but basically anything stackable and solid could work (i.e. broken chunks of concrete, often called urbanite, works well). The $200 price figure will change depending on the size of the oven and the price of materials in your geographic location. The cost of the oven also depends on how much time you are willing to spend building it. As with the cost, the time invested is dependent upon the size of your oven. A good way to have more fun and spend less time in actually building is to invite all your friends over or have a class help out.

Earthen Oven Construction

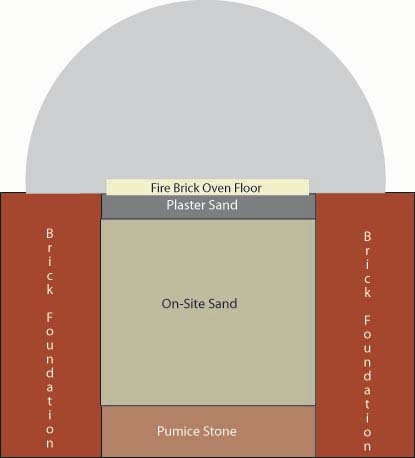

Foundation

In order to build a good earthen oven a solid foundation is needed. The foundation for your oven serves two main purposes. The first purpose is to raise the oven up to a working level. This working level is important, as the oven is unlikely to be used if people must stoop to access it. The second purpose that the foundation serves is as a capillary break. In other words this means it keeps the oven from soaking up water from the ground. Water can be detrimental to earthen ovens and other earthen structures, so it is also a good idea to cover it.

We built a perimeter wall box out of stacked up reclaimed bricks and then infilled it. To fill it we used a layer of pumice stone, on-site sand, and the plaster sand that was free of organic material on top. Our oven’s foundation was made up of old brick pieces that were reclaimed from berry vines and stacked up in a perimeter wall fashion. The brick perimeter was then filled with a layer of pumice stone and then with a layer of sand that was on site. It was finally topped off with a layer of sand that had no organic material in it so as to prevent the baking surface from burning and becoming less level through shifting. Once the final layer of sand was applied it was smoothed out so the firebrick oven floor would lay flat. For our oven floor we used 23 firebricks that were in good condition (free of major dents, cracks and chips). We laid them on the plaster sand that was smoothed out on top of the foundation filler. They were set down six wide and three deep with two in front perpendicular to the main body of the bricks. Out from the two perpendicular firebricks we set three more in the same direction as the main body of firebricks, to have a sort of tongue out of the front of the oven. This layout of bricks allowed us to be able to have a 27-inch inside diameter for our oven.

-

Here is our brick oven foundation with the firebrick laid

-

Building with earth doesn't take experts, or even adults. Building earthen ovens can be enjoyed by kids of all ages. Who doesn't enjoy playing in the mud?

Dense Layer

Once the foundation is built and the firebricks are laid, you are ready for the first step of building the oven. Some questions might arise for the potential earthen oven builder such as, how do I create a cooking space if the oven is dome shaped? This is taken care of by first crafting a dome using sand. You use moist sand to build a mound that will be the desired height of your oven; this process is much like building a sand castle. To make a sand mold we used the plaster sand that we bought to use in the mixes for the oven. This sand was already moist, so it was easy to pile up and make a stable mold, but water may need to be added if it is dry. The height of your oven is dependent upon the diameter. You want the oven to be no higher than 2/3 the diameter. Our oven was 27 inches in diameter, so we needed to have a mold that was 14-18 inches tall. Our mold wound up being 16 and 1/4 inches tall. The sides of this mold should be fairly steep and as wide as the firebrick oven floor. Once we completed the sand mold we covered it with a plastic trash bag (don't worry, it gets removed!).

Now that the sand mold is finished and covered you are ready to construct the first layer (the dense layer). This layer is called the dense layer because a good portion of it is made up of sand. For our dense layer we used approximately a 2:1 sand/clay ratio, but we had to add a little more sand until the right consistency was found. The reason we had to add more sand was because the clay we were using was extremely wet (we got it out of a trough filled with water and clay). The makeup of this layer is important because it is the sand in this layer that acts as the thermal mass. When building with earth it is important that ocean beach sand is not used because the shape of the beach sand tends to be more rounded. When round grains are used the clay doesn't hold them together as well. A better type of sand would be river, plaster, or masonry sand as they have less rounded grains. To mix the dense layer we used 5-gallon buckets for measuring. We found that 1 bucket of sand worked pretty well with a 1/2 bucket of clay. A good rule when mixing your dense layer is that you want it to feel gritty and kind of "crunchy" sounding when squeezed in your hand. A good way to test your dense layer is to ball it up in your hand, toss it about a foot in the air, and let it fall back to your hand. If it crumbles apart, it has too much sand. To remedy this add a little clay. If it deforms and flattens out, it needs more sand. The ideal consistency would be for it to hold its ball shape and not crumble apart. To apply this layer all you need to do is to begin adding the material around the perimeter of your sand mold and work your way up. A good width for this layer is about hand-width, which means roughly about 3-4 inches.

-

Applying the dense layer

-

Here is our finished sand mold, ready for the plastic bag to cover it

Making the Doorway

After the dense layer is completed the next thing to do is to cut the door out of the dense layer material. This is an important step because the height of the door is important to the thermal characteristics of the oven. The door height should be close to 63% of the interior height of the oven. For example, the interior height of our oven was 16 and 1/4 inches, so our door height was roughly 10 and 1/4 inches tall. The door should be cut while the layer is still soft and it can be cut with any type of knife-like object that is fairly strong. Once the door is cut, the sand mold gets pulled out. After the door was cut and the sand mold was removed we used cob loaves that were a 1:1:1 clay/sand/straw ratio. These loaves were then corbelled to form the entryway to the oven.

After the door is cut a cob section needs to be formed at the front of the oven. Our mix was made up of a 1:1:1 sand/clay/straw ratio. This cob material can be seen in the above photo sitting on the bricks. It should have more clay to sand than the dense layer. The basic technique to do this is similar to corbelling, which is a technique that is used to form arches out of cob material in building. Semi-rectangular loaves are made and stacked on each side of the door, with each one just a little to the inside of the other. They are stacked in this fashion until they meet in the middle, at the apex of the door.

-

Figure 3: This figure shows the door height to the interior height

-

Cutting the door

Insulative Layer

Once the doorway is finished, the next step is to add the straw-slip insulative layer. It is mixed with one flake of straw at a time. To make the slip add water to clay, mix until there are no chunks and the slip webs up and breaks between your fingers when you dunk them and split them apart. The prepared slip is then fluffed into the straw. The way to tell when your straw-slip layer is ready to be applied is when a handful can be compacted and it holds together well when pinched in the middle and lightly shaken without falling apart. We then applied this layer about 6 inches thick all the way around the oven. We used this step as a stopping point for the day when we built our oven, so it was necessary to add more clay slip to the slip-straw layer before applying the outer layer.

-

This is the oven with the insulative layer applied. It is dry in this photo because we applied it and then decide to use that a stopping point. We added more clay slip to the insulative layer before applying the next layer

-

The prepared straw-slip layer waiting to be applied

Outer Layer

Once this layer was applied we began to do the final sculpting for our ox. With the insulative layer finished, the next step is to begin the outer layers, which are made up of clay, straw, and sand. Our mix for this layer was made up of a 1:1:1 clay/sand/straw ratio. For the initial covering of the insulative layer, the straw in this layer needs to be chopped into pieces that are no more than 3 inches long. This is done to make it smooth over the straw-slip/insulative layer better. To get the straw into small enough pieces we utilized a weed-whacker to chop it up. This first outer layer is applied by kind of pushing it onto the straw-slip layer. To apply this layer we pushed it onto the insulative layer in a thin fashion. Once this initial covering of the straw-slip layer is complete you can begin sculpting the form or adding any artistic contours you like. For us the sculpting was done using the same material but just making it thicker in certain spots to add the contour and shape. Just remember that it is difficult to get any sculpting to rise off of the oven (notice the horns of our ox are laying down), so whatever your design it cannot extend out from the surface too much or it will fail.

-

Covering the insulative layer with the first of the outer layers

-

Rough sculpting begins after the first of the final layers is applied. Our ox begins to take shape!

Final Plaster

The preparations for the final plaster material is fairly labor intensive because you need finer materials to work with. The straw for this layer must be in fine pieces no more than 1/2 inch long. To get the straw to the correct consistency we chopped it and grated it over a screen. We also had to sift the sand to isolate smaller grain sizes for a more fine finish. For our final plaster layer, as an experiment, we decided to add redwood sawdust that had been soaked in water and lime. This was done to try to lighten the weight of the final plaster coat. The lime was added as a preservative to ward off rotting problems with the organic material. The ratio for the plaster mix really depends upon your materials. For our oven we tested four different mixes. We tested 1:2:1, 1:2:2 clay/sand/straw mixes and 1:2:1:1, 1:1:1:1 clay/sand/straw/hydrated lime sawdust mixes. For our oven, we decided on the 1:2:1:1 mix. To test your materials simply make up a few different mixes and lay them out flat on a piece of plywood or whatever flat surface is available that will not get rained on. For your final layer use the mix that cracks the least and seems most sturdy. To apply the plaster mix, just smooth it on over the last layer you put on. The plaster layer should be no more than 1/2 inch thick. Once applied, it can be run over with a wooden board to smooth it out.

-

Testing our mixes. The mix we used is at the bottom left

-

Our earthen ox oven completed!

Drying the oven

Once finished with the oven it must be given sufficient dry time. Starting small fires inside the oven to provide warmth and to facilitate evaporation of moisture can quicken drying the oven. It is a good idea to use several of these small fires over a couple of days in the oven to help dry it out, especially if you live in a moist climate. We built three small fires in our oven to help get the moisture out before firing it to cook with. Our oven did experience some cracking in the dense layer however. The fix for cracks is to patch it up with material that is the same mix as whichever layer cracked. So, for our oven we used a 2:1 sand/clay ratio mix to patch it up, and it has lasted well through at least two hot firings. After these small drying fires it is time to begin cooking. With the oven itself completed, a door will need to be constructed to help keep the heat in while baking. The door is basically just a wooden plug that is fit to slide into the doorway of the oven. It can be covered with foil to keep it from burning, but some people find that when cooking it helps to drape a wet cloth over the door to let more moisture into the baking chamber.

Cooking in Earthen Ovens

Cooking in earthen ovens generally takes some experimentation in order to get it right, since each oven is unique. Once the experimentation begins you will begin to find out about your oven's personality and the nuances of cooking in it. Once you learn your oven's personality you can become a master baker in your backyard. To get the oven hot, a large fire is built inside and burnt down to coals. The time to heat up your oven is dependent upon its size. A handy tool to have when firing your oven is an oven thermometer as it will give you a ballpark idea of how hot your oven is. Our oven took three hours to heat up to 500 oF, then within an hour dropped down to the 425-375 oF range, where it then held a steady temperature of 350 oF for approximately three hours, and it was still over 200 oF the next day! To get the most out of the fire you should try to cook as many things as possible that utilize the entire heat range of your oven from the highest to the lowest temperatures. This is done by cooking things that need a high temperature first while the oven is still hot and then as the temperature falls you can cook items that need less heat.

-

Heating up the oven

-

Solomon the baker with a fresh loaf of bread

Project Update: February 2007 - Three Years Later

As of February 2007 the earthen oven at the Blue Ox Mill is in immaculate condition. The following things were observed or researched during the update:

- A tin roof shelter was built for the oven shortly after the oven was constructed in 2004 (see fig. a). This roof shelter is also covered on two sides and helps protect the oven from the elements, particularly the rain. The owner Eric reports that the roof had a small leak which was causing some minor deterioration, but the leak has been fixed.

- The oven is reportedly used on a monthly basis, particularly by Blue Ox High School students, to bake anything from pizza bread to biscuits

- There are no reports of leaks or heating inefficiencies. The oven is reported to be working at max efficiency. Eric at the Blue Ox Mill reports that the oven can get up to 400 oF and that has in the past maintained a temperature at or above 250 oF for a 24 hour period after a single heating.

- Maintenance performed consists of heating a fire in the oven once a month to dry it out. I am unsure if this fire is created any differently than the standard cooking fire.

- There does not appear to be any cracking in the outside or inside layer of the oven nor does there appear to be any foundation damage.

- At this time the owner Eric's only complaint about the oven is that there is no vent for the smoke, otherwise he is highly satisfied with the oven.

The Blue Ox earthen oven appears to be a case example of a well-constructed and maintained natural building structure that is holding up very well in a rainy environment. The addition of the tin roof to protect against the rain appears to be the number one factor preventing massive damage to the oven by rainfall.

-

Figure A: The Blue Ox Earthen Oven with Roof

-

Figure B: The Blue Ox Earthen Oven with Roof 2

-

Figure C: The Earthen Oven in 2007

Project Update: October 2013

Two years ago there was an Earthquake in January that threatened the entire foundation of the Blue Ox Earthen Oven. Issues:

- Cracks in back of oven

- Inside of the lip is falling

- Foundation is shifting causing bricks to shift and crack

The last time the Blue Ox Oven was used was during the annual Craftsman Day Fair in Humboldt County. Students from the Blue Ox Pathway High School cooked pizzas in the oven during this even. The fire during these events would be started at 8:30 am by taking just a small amount of firewood, about the size of football. By 10:00 am the oven would already be at 375 degrees. Eric Hollenbeck, the owner of Blue Ox Mill Worked, said he was impressed that the oven can get up to 400 degrees and maintain a 250 degrees for a 24 hour period after a single heating. The only maintenencece that Eric continues to do on the oven is a fire once a month to dry it out. Eric says that there are a few improvments that could be done on the Blue Ox Oven

- improve the filler (rubble) because it is not compact enough for a strong foundation

- the mouth of the oven could be bigger to fit larger unbaked goods

- the mixture used by students has been very durable, however he does think that concrete would have kept a stable foundation even with the earthquake.

<gallery> Image:Eric-blueox.png|Eric Hollenbeck: Owner of Blue Ox Millworks Image:A.jpg| Oven Image:ShiftingBricks.jpg| Shifting Bricks Image:lip.jpg| Lip Image:OvenRoof.jpg| Roof Image:CrackLip.JPG|Crack