(First cleanup, will be adding additional info next) Tag: n |

(added some info) Tag: n |

||

| Line 3: | Line 3: | ||

{{content from|Original:Biogas and liquid biofuels|Practical Action}} | {{content from|Original:Biogas and liquid biofuels|Practical Action}} | ||

'''Biogas''' is a an artificially produced gas created from [[manure]], [[plants|plant material]], | '''Biogas''' is a an artificially produced gas created from [[manure]], [[plants|plant material]], dead animals (ie as found in kitchen refuse, ...).<ref>[http://www.nnfcc.co.uk/publications/nnfcc-renewable-fuels-and-energy-factsheet-anaerobic-digestion "NNFCC Renewable Fuels and Energy Factsheet: Anaerobic Digestion"]</ref>. As the gas is man-made, it is differentiated from [[natural gas]]. The gas is produced trough the biological breakdown of the organic matter using microorganisms in the absence of oxygen. | ||

==Composition== | ==Composition== | ||

| Line 19: | Line 19: | ||

There are two common man-made technologies for obtaining biogas, the first (which is more widespread) is the fermentation of human and/or animal waste in specially designed [[digesters]]. The second is a more recently developed technology for capturing methane from municipal waste landfill sites. The scale of simple biogas plants can vary from a small household system to large commercial plants of several thousand cubic metres. | There are two common man-made technologies for obtaining biogas, the first (which is more widespread) is the fermentation of human and/or animal waste in specially designed [[digesters]]. The second is a more recently developed technology for capturing methane from municipal waste landfill sites. The scale of simple biogas plants can vary from a small household system to large commercial plants of several thousand cubic metres. | ||

===The source materials for making biogas=== | |||

Although, in theory work it is possible to only use vegetation, most biodigesters are operated on a mixture of manure and vegetation. This, as by including manure, there | |||

is a continuous fresh input of the microbiological organisms, which is needed for the operation of the biodigester.<ref>need to check how Hemant Thite's firm Calorees does it</ref> The microorganisms used in most biodigesters are thus the same as those found in the manure used. Besides plant material ie from gardens; grains and deoiled cakes (ie Jatropha, Pongamia, ...) are sometimes added. | |||

===Mixing the source materials=== | |||

When combining the source materials, attention must be payed that the a suitable carbon/nitrogen (C/N) ratio is attained (similar to regular composting). | |||

===Production using biodigesters=== | ===Production using biodigesters=== | ||

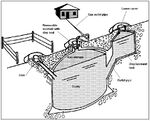

[[Image:Biodigester CFD.JPG|thumb| | [[Image:Biodigester CFD.JPG|thumb|right|150px|Figure 1. Chinese fixed dome biodigester]] | ||

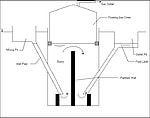

[[Image:PATB_floating_cover_digester.JPG|thumb| | [[Image:PATB_floating_cover_digester.JPG|thumb|right|150px|Figure 2. Indian floating cover biodigester]] | ||

Two popular simple designs of digester have been developed; the fixed dome biodigester (ie [[Chinese fixed dome digester]]) and the floating drum biodigester (ie [[Indian floating cover biogas digester]]). The mentioned examples are shown in figures 1 & 2. The digestion process is the same in both digesters but the gas collection method is different in each. In the floating cover type, the water sealed cover of the digester is capable of rising as gas is produced and acting as a storage chamber, whereas the fixed dome type has a lower gas storage capacity and requires good sealing if gas leakage is to be prevented. Both have been designed for use with animal waste or dung. | Two popular simple designs of digester have been developed; the fixed dome biodigester (ie [[Chinese fixed dome digester]]) and the floating drum biodigester (ie [[Indian floating cover biogas digester]]). The mentioned examples are shown in figures 1 & 2. The digestion process is the same in both digesters but the gas collection method is different in each. In the floating cover type, the water sealed cover of the digester is capable of rising as gas is produced and acting as a storage chamber, whereas the fixed dome type has a lower gas storage capacity and requires good sealing if gas leakage is to be prevented. Both have been designed for use with animal waste or dung. | ||

The waste is fed into the digester via the inlet pipe and undergoes digestion in the digestion chamber. The | The waste is fed into the digester via the inlet pipe and undergoes digestion in the digestion chamber. The product of the process is a combination of methane and carbon dioxide, typically in the ratio of 6:4. Digestion time ranges from a couple of weeks to a couple of months depending on the feedstock and the digestion temperature. The residual slurry is removed at the outlet and can be used as a [[fertilizer]]. | ||

===Insulation=== | |||

The temperature of the biogas production process is quite critical. [[Methane]] producing bacteria operate most efficiently at temperatures between 95°F and 100°F (or about 35°C). In colder climates heat may have to be added to the chamber to encourage the bacteria to carry out their function. In places where the temperature drops below 5°C (40°F) in winter, about 20% of the gas generated will be needed for heating the digestor and maintaining the digesting material. As such, proper insulation is needed. | |||

==Uses== | ==Uses== | ||

Revision as of 09:52, 6 August 2012

Template:Content from Biogas is a an artificially produced gas created from manure, plant material, dead animals (ie as found in kitchen refuse, ...).[1]. As the gas is man-made, it is differentiated from natural gas. The gas is produced trough the biological breakdown of the organic matter using microorganisms in the absence of oxygen.

Composition

The gas is composed of

- methane: 54 – 70%

- carbon dioxide: 27 – 45%

- nitrogen: 0.5 – 3%

- hydrogen: 1 – 10%

- carbon monoxide: 0.1%

- oxygen: 0.1%

- hydrogen sulfide: traces[2]

Production

Biogas is produced by means of a process known as anaerobic digestion. It is a process whereby organic matter is broken down by microbiological activity and, as the name suggests, it is a process which takes place in the absence of air. It is a phenomenon that occurs naturally at the bottom of ponds and marshes and gives rise to marsh gas or methane, which is a combustible gas.

There are two common man-made technologies for obtaining biogas, the first (which is more widespread) is the fermentation of human and/or animal waste in specially designed digesters. The second is a more recently developed technology for capturing methane from municipal waste landfill sites. The scale of simple biogas plants can vary from a small household system to large commercial plants of several thousand cubic metres.

The source materials for making biogas

Although, in theory work it is possible to only use vegetation, most biodigesters are operated on a mixture of manure and vegetation. This, as by including manure, there is a continuous fresh input of the microbiological organisms, which is needed for the operation of the biodigester.[3] The microorganisms used in most biodigesters are thus the same as those found in the manure used. Besides plant material ie from gardens; grains and deoiled cakes (ie Jatropha, Pongamia, ...) are sometimes added.

Mixing the source materials

When combining the source materials, attention must be payed that the a suitable carbon/nitrogen (C/N) ratio is attained (similar to regular composting).

Production using biodigesters

Two popular simple designs of digester have been developed; the fixed dome biodigester (ie Chinese fixed dome digester) and the floating drum biodigester (ie Indian floating cover biogas digester). The mentioned examples are shown in figures 1 & 2. The digestion process is the same in both digesters but the gas collection method is different in each. In the floating cover type, the water sealed cover of the digester is capable of rising as gas is produced and acting as a storage chamber, whereas the fixed dome type has a lower gas storage capacity and requires good sealing if gas leakage is to be prevented. Both have been designed for use with animal waste or dung.

The waste is fed into the digester via the inlet pipe and undergoes digestion in the digestion chamber. The product of the process is a combination of methane and carbon dioxide, typically in the ratio of 6:4. Digestion time ranges from a couple of weeks to a couple of months depending on the feedstock and the digestion temperature. The residual slurry is removed at the outlet and can be used as a fertilizer.

Insulation

The temperature of the biogas production process is quite critical. Methane producing bacteria operate most efficiently at temperatures between 95°F and 100°F (or about 35°C). In colder climates heat may have to be added to the chamber to encourage the bacteria to carry out their function. In places where the temperature drops below 5°C (40°F) in winter, about 20% of the gas generated will be needed for heating the digestor and maintaining the digesting material. As such, proper insulation is needed.

Uses

The digestion of animal and human waste to biogas has several uses:

- the production of biogas or pure methane for use as a fuel.

- the waste is reduced to slurry which has a high nutrient content which makes an ideal fertiliser; in some cases this fertiliser is the main product from the digester and the biogas is merely a by-product.

- during the digestion process bacteria in the manure are killed, which is a great benefit to environmental health.

Biogas is a well-established fuel for cooking and lighting in a number of countries, whilst a major motivating factor in the development of liquid biofuels has been the drive to replace petroleum fuels.

Small-scale biogas digesters usually provide fuel for domestic lighting and cooking. It can be used as a fuel for running heat engines as well, however it is a lot less potent than comparable gases (ie pure methane), it is generally only used with stationary heat engines.[4] Vehicle engines typically better use (compressed) methane, or yet another type of fuel.

| Application | 1 m3 biogas equivalent |

| Lighting | equal to 60 -100 watt bulb for 6 hours |

| Cooking | can cook 3 meals for a family of 5 - 6 |

| Fuel replacement | 0.7 kg of petrol |

| Shaft power | can run a one horse power motor for 2 hours |

| Electricity generation | can generate 1.25 kilowatt hours of electricity |

Table 1: some biogas equivalents (Source: adapted from Kristoferson, 1991.)

Adoption in developing countries

Some countries have initiated large-scale biogas programmes, Tanzania being an example. The Tanzanian model is based on integrated resource recovery from municipal and industrial waste for grid-based electricity and fertiliser production.

Small-scale biogas production in rural areas is now a well-established technology, particularly in countries such as China and India. At the end of 1993, about five and a quarter million farmer households had biogas digesters, with an annual production of approximately 1.2 billion cubic metres of methane, as well as 3500 kW installed capacity of biogas fueled electricity plant.

Kenya relies on imported petroleum to meet 75% of its commercial energy needs. In 1980, in an effort to reduce this high level of dependence on an externally controlled fuel source, the Kenyan government set up the Special Energy Programme (SEP). One aspect of the programme was the introduction and dissemination of biogas plant technology. After a poor start working with educational institutions, the programme turned to local artisans and commercial outlets working in the private sector. Hands-on training was given to masons and plumbers and private traders were encouraged to manufacture and stock appliances such as cookers and lights. By 1995, the number of plants installed in Kenya was estimated to be 880.

Scrubbing out unwanted gases

Carbon dioxide

Carbon dioxide (CO2) is present in biogas. This reduces its performance as a fuel.[5]

The ways of dealing with this are:

- Accept the lower performance - it will still do the job, and you'll save a lot of hassle. This may be the best option for very small applications.

- Scrub the CO2 with sulfur - e.g. see Biogas CO2 scrubbing project

- In future, separation technologies such as a plastic molecular sponge may become available.[6]

Hydrogen sulfide

Hydrogen sulfideW (H2S, also called "rotten egg gas") is a common product of anaerobic digestion. It causes an unpleasant odor, and in high enough concentrations can be highly poisonous. (Note that it numbs the sense of smell long before it becomes fatal - so if you can smell it, it's not deadly yet.)

Hydrogen sulfide is corrosive and renders some steels brittle, meaning that if there is any significant quantity, it is important to remove it before the gas passes through any equipment, especially iron or steel equipment. (What about other materials? It's only very weakly acidic, so it's seems to not be the acidity that causes the problem with steel.

Biomass gasification

Biomass gasification is a distinctly different process. See Biomass gasification.

References and resources

- Anonymous (Office of the Leading Group for the Propagation of Marshgas), A Chinese Biogas Manual, 1981. A classic work on biogas production in China, showing construction of small-scale, underground digesters.

- Gunnerson C. G. and Stuckey D. C., Anaerobic Digestion - Principles and Practices for Biogas Systems. World Bank Technical Paper No 49, The World Bank, 1986. A good overview.

- Gitonga, Stephen, Biogas Promotion in Kenya. Intermediate Technology Kenya, 1997.

- Fulford, David, Running a Biogas Programme: A Handbook, Practical Action Publications, 1988 (being updated). Offering good information about the management of regional or country-wide biogas programs, and good technical information about the design of burners for biogas.

- House, David, The Complete Biogas Handbook, revised 2007. A very extensive work. There are several chapters available for download.

See also

- Biodigester designs

External links

- Wikipedia:Biogas

- http://www.rebelwolf.com/essn/ESSN-Oct2005.pdf

- Al Rutan's Bio-digester manual

- Biogashelpline; directed by Hemant Thite, sells some books on the issue

- Video: Low cost biodigester installation on the Altiplano. Bolivia

- Video: Industrial Two-Stage Biogas Plant. Germany

- Bio Latrines in Kenyan Slums.

- Biofuel library

- Biogas F.A.Q.

- Brief overview of biogas projects, mainly in India, China, Nepal and Africa

- Village Earth: Energy: Biogas

- ↑ "NNFCC Renewable Fuels and Energy Factsheet: Anaerobic Digestion"

- ↑ EESN October 2005

- ↑ need to check how Hemant Thite's firm Calorees does it

- ↑ Even methane gas only being used with stationary heat engines

- ↑ Is that the reason scrubbing is desirable?[expansion needed] That's just my best guess. --Chriswaterguy

- ↑ Plastic 'Sponge' Could Help Biofuels Scrub CO2 From the Environment