A.R.Shearer (talk | contribs) (→Design) |

A.R.Shearer (talk | contribs) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 156: | Line 156: | ||

|5| Next, drill 5-10 ¼” holes at the bottom of the dividing wall for drainage. | |5| Next, drill 5-10 ¼” holes at the bottom of the dividing wall for drainage. | ||

| Image: | | Image:roof_layer_04.jpg | perlite | ||

|6| A gutter strainer is then trimmed so that it will lay flush with the bottom of the barrel, and cover the entrance to the spigot. 100% silicone caulk is then applied to the area around the spigot, and is also used to glue the gutter strainer to the bottom of the barrel. | |6| A gutter strainer is then trimmed so that it will lay flush with the bottom of the barrel, and cover the entrance to the spigot. 100% silicone caulk is then applied to the area around the spigot, and is also used to glue the gutter strainer to the bottom of the barrel. | ||

| Line 170: | Line 170: | ||

| Image:barreloffunstep10.png | Figure 1i: The barrel is placed in the trough. (Photo by Paul Johnston) | | Image:barreloffunstep10.png | Figure 1i: The barrel is placed in the trough. (Photo by Paul Johnston) | ||

|10| The barrel is then placed in the trough. The end of the barrel opposite the spigot is elevated by placing a 2”x4” across the trough. | |10| The barrel is then placed in the trough. The end of the barrel opposite the spigot is elevated by placing a 2”x4” across the trough. | ||

}} | }} | ||

Revision as of 04:06, 18 April 2015

Abstract

Humboldt State University Engineering 305 class volunteered to construct a living roof for Bayside Park Farm a community farm in Arcata, California. The project would be the roof of an animal hutch that would simultaneously be built as this roof was being constructed. The type of living roof attempted to be created would be an extensive living roof because it would allow for the ability to low maintenance and easiest to construct. Thus far the roof seems to be serving its purpose as a roof for a housing unit.

Background

Bayside Park Farm located in Arcata California in the United States and also goes by the name Arcata Educational Farm. It is a Community Supported Agriculture (CSA) facility that also acts as an educational farm. Our (Caroline, Mayara, and Amber’s) Engineering 305 class during the North American Spring 2015 semester will be constructing a functioning living roof. This living roof must attend to the owner's specifications regarding its dimensions and purpose, which are that the living roof be made on a small animal hutch that is currently being made. The construction and development of the living roof will span from January 2015 until May 2015.

Problem statement

The objective of this project is to create a functional, sustainable and sufficient living roof at Bayside Park Farm. A living roof also known as garden roof or green roof, is a roof that provides protection to the roof base and helps reduce water runoff and allows for some temperature regulation inside the housing unit. Furthermore it can be used for improving air and water quality, promoting energy conservation, providing food, and creating an ecosystem within an urban area. If possible we plan on using affordable or recycled materials that may be donated for the roofs construction and by doing so we will cut costs down for the construction of the roof. By doing this we aim to create a feeling of community involvement and create another area of the farm that may teach the community about an alternative to roofing.

Criteria

The criteria was defined according to the farms purposes and preferences, which were very loose and only asked that the roof serve as an educational tool that could be used over time. This criteria was used as a guide for the construction of the roof. Where values were higher is where the most effort was placed in providing those demands in the construction of the project. The scale (1-10) represents the importance level of the constraint of each listed criteria.

| Criteria | Constraints | Weight (1-10) |

|---|---|---|

| Functionality | Must serve recreational and educational purposes. | |

| Maintainability | Must be low and easy maintenance. | |

| Aesthetics | Must be pleasing to the eye. | |

| Safety | Must be able to hold while put on a structure. | |

| Weight | Must be able to hold at least 20lbs per square meter. | |

| Durability/Resistance | Must be able to last for a long time and be weather resistant. |

Literature Review

Living roof basics

The basic components of green roof systems are waterproofing, soil and plants. It really is that simple. The combination of these material is easy and the success of all living roofs depends on the types of plants used and an understanding of how these combined materials will work.[1] An understanding of the type of environment the roof will be located in is also important for the success of any living roof. For example here in Humboldt County earthquakes pose a risk as well as a high precipitation level in the fall and winter months, however in the spring and summer months there is little to no rain fall. Design should account for earthquakes and the forces it will create on the building as well as any irrigation or drainage components that will function during both during the wet season and dry season. These however are design features that should be asked when building the structural support and housing unit the living roof will be placed on top of before and during construction of both the roof and the house or structures for the roof. For the purpose of our project we were only asked to concern ourselves with the construction of the roof itself because the farm would be responsible for the hutch or housing unit and the structural support. This means we focused on the weather aspect of design for the roof. Living roofs are that simple especially for small designs. Living roofs are becoming increasingly popular in North America and are starting to show themselves in large scale industrial buildings. The design and construction of those types of roofs are a little more complex and a lot more labor intensive, but the end result is worth the effort

Living roof concerns

One concern may be the water-quality of the storm water runoff from living roofs. The water discharge from living roofs may be a new source of surface-water pollution because of the organic matter and nutrient content found in the growing medium of the roof membrane. There has been some research that shows living roofs as having increased levels of phosphorus and nitrogen leaching from the substrate.[2]

Another concern may be the types of vegetation being used. Plant communities have a huge influence on the performance of living roofs. The plants' ability to resist environmental fluctuations and recover from them and the rate at which resources can be consumed affect the performance of the roof. On living roofs, wind stress is a main factor in the low performance of living roofs mostly because of the building height, but that should not negate that on any living roof wind stress has the potential to wipe out the plant community on that roof. Using native plants may be a possible way to increase the living roof's performance because native plants are already accustomed to the local environmental conditions. However, there has been some research that shows that in extensive living roof systems the native plants do poorly because of the shallow substrate depths (the focus is on extensive living roofs because that is the ideal roof for our project). This then means that not only is wind stress the main factor in determining the types of flora being used but that the rooftop itself is challenging for the survival of plants. “Moisture stress and severe drought, extreme {usually elevated) temperatures, high light intensities, and high wind speeds increase the risk of desiccation and physical damage to vegetation and substrate.”[2]

Types of Living Roofs

Intensive

Suitable for underground garages and heavy buildings. Soil depth 15 cm. Areas is used as much as possible. Area has a high plant diversity. Conventional garden where plants tend to be maintained on an individual basis in the same way a garden ground level. High maintenance and irrigation system.[3][4][5] “Intensive green roofs are often accessible and are characterized by: deeper soil and greater weight, higher capital costs, increased plant diversity, and more maintenance requirements. The growing medium is often soil based, ranging in depth from 20–60 cm (8-24"), with a saturated weight increase of between 290 - 967.7 kg/m2 (60-200 lbs/sf). Due to the increased soil depth, the plant selection is more diverse and can include trees and shrubs, which allows for the development of a more complex ecosystem. Requirements for maintenance - especially watering - are more demanding and ongoing, and irrigation systems are usually specified.”[5] [6]

Advantages of Intensive roofs:

- Diversity of plants

- Good insulation properties

- Simulate wildlife garden

- Attractive aesthetically

- Accessable/recreation

- Longer membrane life

- Energy efficient

- Storm water retention capability

Disadvantages of Intensive roofs:

- Greater weight load on roof

- Need irrigation and drainage system

- High maintenance and cost

- More complex[5]

Extensive

Thin substrate depths 2-15cm. This means lower in extra loading. Cheaper and easy maintenance. Aesthetically looks the same as other living roofs. “The extensive solution is suitable for lightweight and low height buildings: the utilised plants are species of sedum, shrubs and bushes that need low maintenance and can be self-generative. [4][3] [6]

“Extensive green roofs are often not accessible and are characterized by: low weight, low capital cost, low plant diversity, and minimal maintenance requirements. The growing medium, typically made up of a mineral-based mixture of sand, gravel, crushed brick, leca, peat, organic matter, and some soil, varies in depth between 5-15 cm (2-6") with a weight increase of between 72.6-169.4 kg / m2 (16-35 lbs/sf) when fully saturated. Due to the shallowness of the growing medium and the extreme desert-like microclimate on many roofs, plants must be low and hardy, typically alpine, dryland, or indigenous. Typically the plants are watered and fertilized only until they are established, and after the first year, maintenance consists of two visits a year for weeding of invasive species, safety and membrane inspections.”[5]

Advantages of Extensive roofs:

- Lightweight. Generally no reinforcement.

- Suitable for large areas.

- Roof slope 0degrees-30degrees

- Long life and low maintenance

- No need for irrigation or specialized drainage system.

- Less technical expertise needed

- Suitable for retrofit projects

- Inexpensive

- Looks more natural

- Vegetation can grow spontaneously

Disadvantages of Extensive roofs:

- Less energy efficient

- Less storm water retention benefits

- Limited choice of plants

- Not accessible for recreation or other uses

- Unattractive usually in the winter season[5]

Semi-Extensive

Low or no-input philosophy like Extensive roofs. Deeper layers of growing medium 10-20cm like Intensive roofs allowing for a wider and diverse range of plants.[3]

Living roof design

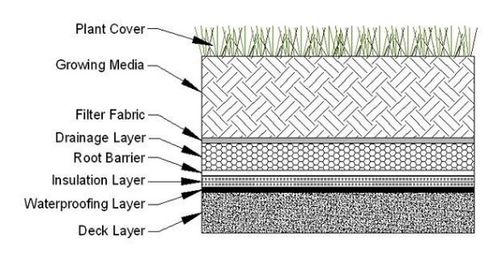

The basic components of green roof systems are waterproofing, soil and plants. However, although the combination of these components seems easy, the success of green roofs systems depends on the understanding the interaction among the parts and its complexity. [1] A green roof is composed of different layers which are described below:

Layers

- Deck Layer: is the foundation of a green roof and may be of concrete, wood, metal, plastic or a composite material.[7]

- Leak Detection System (optional). Leak detection systems are often installed above the deck layer to identify leaks, minimize leak damage through timely detection, and locate leak locations. [7]

- Waterproofing Layer: very important to prevent water damage through the deck layer. This layer must be entirely waterproof and long lasting. Several waterproofing materials can be used, like thermoplastic membranes, elastomeric membranes, modified bitumen polyvinyl chloride (PVC), applied rubberized asphalt, built up bitumen and others. The waterproofing material may be loose laid or bonded, which is more recommended. [7]

- Insulation Layer (optional): usually located above, but sometimes below, the waterproofing layer. Its function is to increase the energy efficiency. Recommended for metal roofs.[7]

- Root Barrier: used to protect the waterproofing membrane from root penetration.[7]

- Drainage Layer: placed between the root barrier and the growing media to remove excess water from the vegetation root zone. Must consist of synthetic or inorganic materials. The thickness of the drainage layer type is an important design decision. For extensive green roof systems, the depth of the drainage layer usually varies from 0.25 to 1.5 inches thick and increases for intensive designs. [7]

- Filter Sheet: consists in a “semi-permeable needled polypropylene filter fabric placed between the drainage layer and the growing media” in order to prevent the drainage layer to clog by the migration of some particles from the media into it. The filter sheet must allow the water migration into the drainage layer. [7]

- Growing Media: usually 3 to 6 inches deep and composed of approximately 70 to 80 percent lightweight inorganic materials like clays, pumice, scoria or other similar materials. The remaining media must not exceed 30 percent organic matter because it can transport nutrients into the runoff from the roof and clog the permeable filter sheet. [7]

- Plant Cover: it is the top layer and consists of plants that are non-native, slow-growing, shallow-rooted and perennial. The selected plants must be able to withstand harsh conditions at the roof surface. For drought periods it is recommended the installation of a watering system. [7]

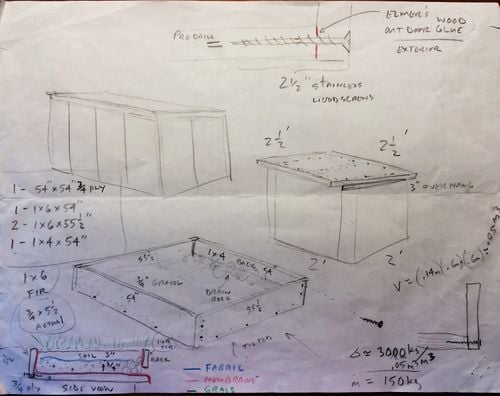

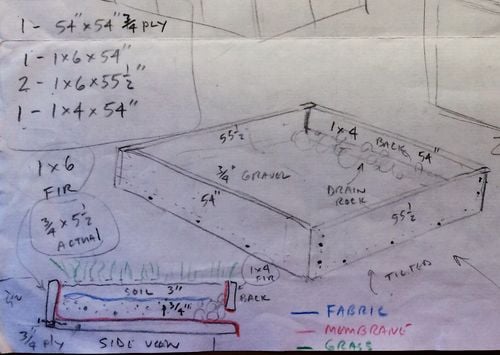

Design

blah lbah blakjnhdkwjfj lkjhkfjs fkfhkdjfhk jhbsdsafskjfhdjkghr kgjkfdnfdsfnsdmnfkjdb k ;Sdfhekhergtknrknkbnf slfjSpofk WlDSKJGLFgj lkfgjdflkgj dkfvxkkdfhkjdrhfrkeh righerigheiarhfgewihfer;ituhqe 'WOEIJF'O 'OIEFOEIWJFKEJSFK KDFJHLKJH RKJJEKJG OWEFJK 'EWOFJ.

Construction

Very complete description of how final project is made. This large section should have lots of pictures.

How to Build

Proposed timeline

| Weeks | Tasks | Observation |

|---|---|---|

| 16-Fev | Prototype budget and get the materials | |

| 23-Fev | Build the prototype | |

| 2-Mar | Build the prototype | |

| 9-Mar | Find donation, materials, weekly checks | Wait until the plants grow |

| 16-Mar | Find donation, materials, weekly checks | Wait until the plants grow |

| 23-Mar | Find donation, materials, weekly checks | Wait until the plants grow |

| 30-Mar | Analyse if everything is ok, recalculate | |

| 6-Apr | Build the real one | |

| 13-Apr | Build the real one | |

| 20-Apr | Build the real one | |

| 27-Apr | Verify functionality | |

| 4-May | Verify functionality | |

| 11-May | Verify functionality |

Costs

This is a proposed budget. We are hoping these items will be donated.

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 1 | Pond liner-10ft x 12ft | Donated by Pierson Building Center | 00.00 | 00.00 |

| 1 | Landscaping fabric-3' x 25' | Donated by Pierson Building Center | 0.00 | 0.00 |

| 1 | Soil-28L | Donated By Farm | 00.00 | 00.00 |

| 1 | Growing medium-6qt | Donated by Pierson Building Center | 0.00 | 0.00 |

| 1 | Wood Glue-18oz | Donated byPierson Building Center | 0.00 | 0.00 |

| 36 | Stainless Steel Wood Screws | Donated by Pierson Building Center | 0.00 | 00.00 |

| 1 | Wood Preserver Paint-32 oz | Donated by Pierson Building Center | 00.00 | 00.00 |

| 1 | Rubber membrane-5' x 6 ' | Donated by Pierson Building Center | 00.00 | 00.00 |

| 1 | Shower Pan Liner Adhesive-16oz | Donated by Pierson Building Center | 0.00 | 0.00 |

| 5 | Wood | Donated By Farm | 00.00 | 00.00 |

| 8 | Plants | Donated By Farm | 00.00 | 00.00 |

| 1/4 | Landscape Rocks | Donated by Miller Farms Nursery | 00.00 | 00.00 |

| 1 | Drop cloth 9'x12' | Ace Hardware | 03.99 | 03.99 |

| 1 | Paintbrush 3" poly | Ace Hardware | 02.99 | 02.99 |

| 1 | Paintbrush 2-1/2" poly | Ace Hardware | 02.79 | 02.79 |

| Total Cost | $010.58 | |||

Operation

The roof should be very low maintenance with weeding being done once a year if desired.

Maintenance

Introduce this maintenance section.

Schedule

This is when to maintain what.

- Daily

- A daily task

- A daily task

- Weekly

- a weekly task

- a weekly task

- Monthly

- a monthly task

- a monthly task

- Yearly

- a yearly task

- a yearly task

- Every __ years

- task

- task

References

- ↑ 1.0 1.1 Weiler, S.K. and Scholz-Barth. 2011. "Green rood system: A Guide to the Planning, Design, and Construction of Landscapes over Structure".

- ↑ 2.0 2.1 Oberndorfer, Erica, Jeremy Lundholm, Brad Bass, Reid R. Coffman, Hitesh Doshi, Nigel Dunnett, Stuart Gaffin, Manfred Köhler, Karen K. Y. Liu, and Bradley Rowe. 2007. “Green Roofs as Urban Ecosystems: Ecological Structures, Functions, and Services. (Cover Story).” BioScience 57 (10): 823–33.

- ↑ 3.0 3.1 3.2 Dunnett, Nigel, and Noel Kingsbury. Planting Green Roofs and Living Walls. Portland: Timber Press, 2008.

- ↑ 4.0 4.1 Lazzarin, Renato M., Francesco Castellotti, and Filippo Busato. 2005. “Experimental Measurements and Numerical Modelling of a Green Roof.” Energy and Buildings 37 (12): 1260–67.

- ↑ 5.0 5.1 5.2 5.3 5.4 Peck, S. and M. Kuhn. 2003. Design Guidelines for Green Roofs (PDF) (22 pp, 551K). Canada Mortgage and Housing Corporation and the Ontario Association of Architects

- ↑ 6.0 6.1 "Green Roof Systems: Intensive, Semi-Intensive, and Extensive.".Architect's Technical Reference. Accessed February 8, 2015. http://www.archtoolbox.com/materials-systems/site-landscape/green-roofs.html..

- ↑ 7.0 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 "Hoffmann, G., Stack, R.C. and Wye, B.V. 2012. “Stormwater Management Guidebook”.