Bold text

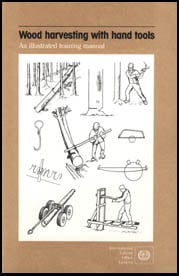

Wood Handling and Transport[edit | edit source]

HANDLING BILLETS AND LOGS[edit | edit source]

Loading and stacking of billets and moving of logs is easier if simple helping tools are used.

In the absence of such helping tools, the worker has to bend down and pick up the wood from the ground, which may be muddy (1a).

A timber pick makes it much easier to pick up and handle small pieces of wood (1b).

Different types of handling tools are available, such as metal hooks (2), timber picks with a short wooden handle, fitting the hand of the worker (3) and small timber tongs (4). The latter tool is particularly handy but the former ones can be locally made more easily.

The sappie is used for lifting or for short-distance skidding of logs (5). A model for heavier logs has a handle 190 cm long and a hook 42 cm long. A lighter model has a handle 110 cm long and a hook 28 cm long.

Sappies are typically used for pulling logs (6) and for turning them (7). In the Alpine countries they were widely used for gravity skidding of logs and continue to be indispensable in handling logs during tree felling and transport.

Figure

Figure

Figure

Figure

Figure

Figure

Figure

MANUAL TRANSPORT OF SMALLER-SIZED WOOD[edit | edit source]

Carrying wood manually should be avoided as much as possible. It is a heavy and inefficient job which is only permissible over short distances of just a few metres (1).

Small logs can be pulled more easily to the stacking or loading place using skidding tongs (2). The tong should be attached close to the end of the log to achieve a lifting effect and thus facilitate pulling.

If the terrain and ground cover permit, the wheelbarrow is an excellent means of assembling loads of short pieces of wood for transport over short distances, e.g. for taking wood to a site for a charcoal kiln (3).

Figure

Figure

Figure

USE OF SKIDDING SULKIES[edit | edit source]

The skidding sulky (1) is used for short-distance transport of small-sized logs, especially downhill on moderate slopes. Loads can consist of single logs or bundles and may have a weight of up to 200 kg. On flat terrain, loads are attached at the centre of gravity. On increasing slopes, the load is shifted more towards the back to serve as a brake. Skidding sulkies can be built with 2 wheels (1a) or with 4 wheels fixed to bogie axles (1b). The latter type is more sophisticated but permits the handling of larger loads and negotiating rougher surface conditions.

Two sulkies can also be connected to skid bigger logs (2). In this case, the load is guided by one handle in the front and one in the rear. On slopes, the rear part of the log should hang close to the ground to facilitate rapid braking when required.

On steep terrain, two sulkies may be operated together (3). They can be connected by a cable which is guided by two pulleys attached to trees (3a). The loaded sulky (3b) can thus be used to pull up the empty one (3c), together with the worker, who guides it by the handle.

Figure

Figure

Figure

SLIDING WOOD DOWNHILL[edit | edit source]

Timber chutes are used for sliding small logs or short pieces of wood downhill on slopes with a gradient of 25% or more (1).

Plastic chutes are commercially available in sections of 5 m and with a diameter of 35-50 cm. At a diameter of 40 cm, the chutes can take logs up to a length of 5 m and short pieces to a diameter of 30 cm.

Chutes may be used over distances of up to 150 m. Under favourable conditions, 2 m stacked may be transported per hour over that distance.

Commercially-available chutes are easily assembled thanks to different connecting systems. Chutes may be made locally from plastic tubes cut lengthwise or from other materials, e.g. wooden boards, although these are heavier and more difficult to handle.

In clearfelling areas on moderate slopes, logs may be rolled down to the roadside across trees which have been felled up the slope (2). They can subsequently be cut into shorter assortments, if necessary, at the foot of the slope. This technique, if applied properly, can save considerable expense in skidding.

Figure

Figure